Production process for Biluochun black tea

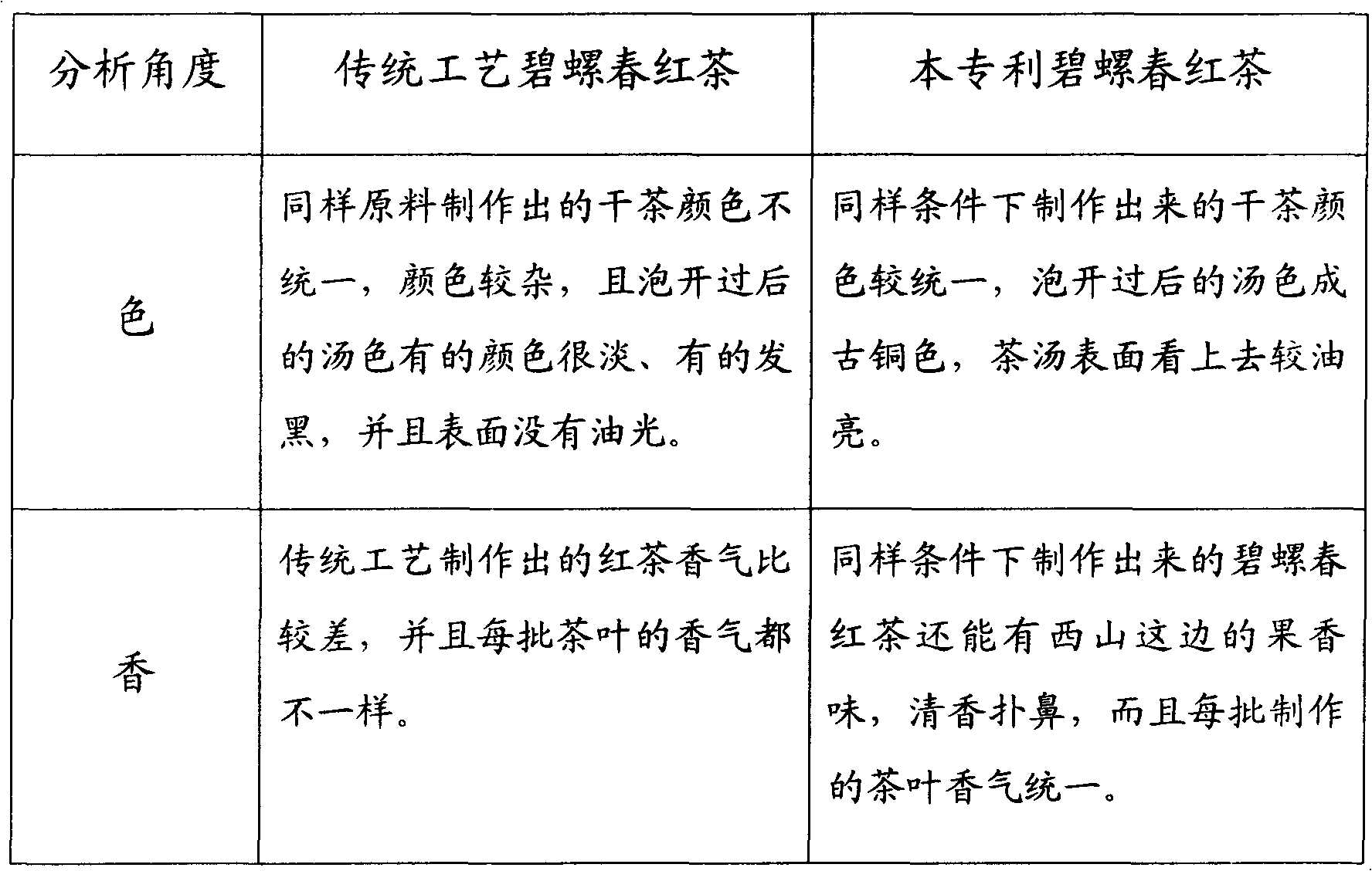

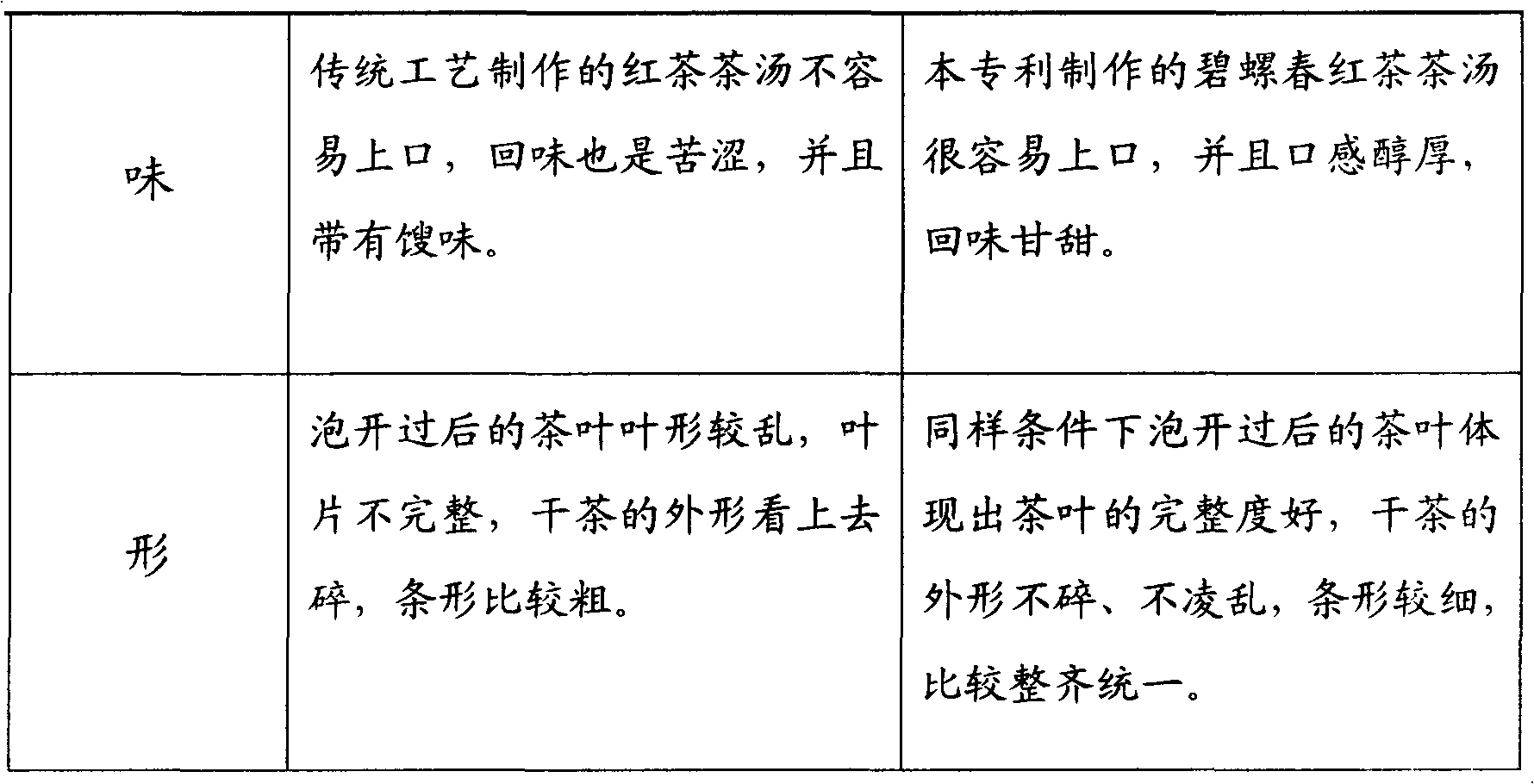

A production process, black tea technology, applied in the production process field of Biluochun black tea, can solve the problems of uncontrollable time, temperature and humidity, easy to spoil, and unguaranteed taste and quality of Biluochun black tea, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The manufacture technology operation of this patent Biluochun black tea is as follows:

[0025] 1. Withering: Pick 5 kg of small-leaf tea greens from the Biluochun group and spread them evenly on the shelf in the temperature-controlled room, with an air gap underneath, so as to promote the even distribution of water in the tea greens. The temperature in the temperature-controlled room is controlled at 20°C, and the air humidity is at 65%, the thickness of the spread is 20cm, and the total time of withering is 24 hours, wherein the first 12 hours are withered and spread on the shelf to stand still, and the second half of withering will be turned once every 2-3 hours.

[0026] 2. Kneading: put into a kneading machine and knead the withered green tea at room temperature with a speed of 80 rpm, and the kneading time is guaranteed to be 30 minutes.

[0027] 3. Fermentation: Put the green tea after rolling into an indoor fermenter, the indoor temperature is controlled at 20°C...

Embodiment 2

[0032] The manufacture technology operation of this patent Biluochun black tea is as follows:

[0033] 1. Withering: Pick 10 kg of small-leaf tea greens from the Biluochun group and spread them evenly on the shelf in the temperature-controlled room, with an air gap underneath, so as to promote the even distribution of water in the tea greens. The temperature in the temperature-controlled room is controlled at 26°C, and the air humidity is 70%, the thickness of spreading is 20cm, and the total time of withering is 20-28 hours, wherein the first 12 hours are withered and spread on the shelf to stand still, and the second half of withering will be turned once every 2-3 hours.

[0034] 2. Kneading: put into a kneading machine and knead the withered green tea at room temperature at a speed of 90 rpm, and the kneading time is guaranteed to be 30 minutes.

[0035] 3. Fermentation: Put the green tea after rolling into an indoor fermenter. The indoor temperature is controlled at 20°C ±...

Embodiment 3

[0040] The manufacture technology operation of this patent Biluochun black tea is as follows:

[0041] 1. Withering: Pick 10 kg of small-leaf tea greens from the Biluochun group and spread them evenly on the shelf in the temperature-controlled room, with an air gap underneath, so as to promote the even distribution of water in the tea greens. The temperature in the temperature-controlled room is controlled at 20°C±3, and Humidity is 65% ± 5, the thickness of spreading is 20cm, and the total time of withering is 20-28 hours. The first 12 hours of withering are laid flat on the shelf and left standing, and the second half of withering needs to be turned every 2-3 hours.

[0042] 2. Kneading: put into a kneading machine and knead the withered green tea at room temperature at a speed of 100 rpm, and the kneading time is guaranteed to be 30 minutes.

[0043] 3. Fermentation: put the green tea after rolling into an indoor fermenter, the indoor temperature is controlled at 17°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com