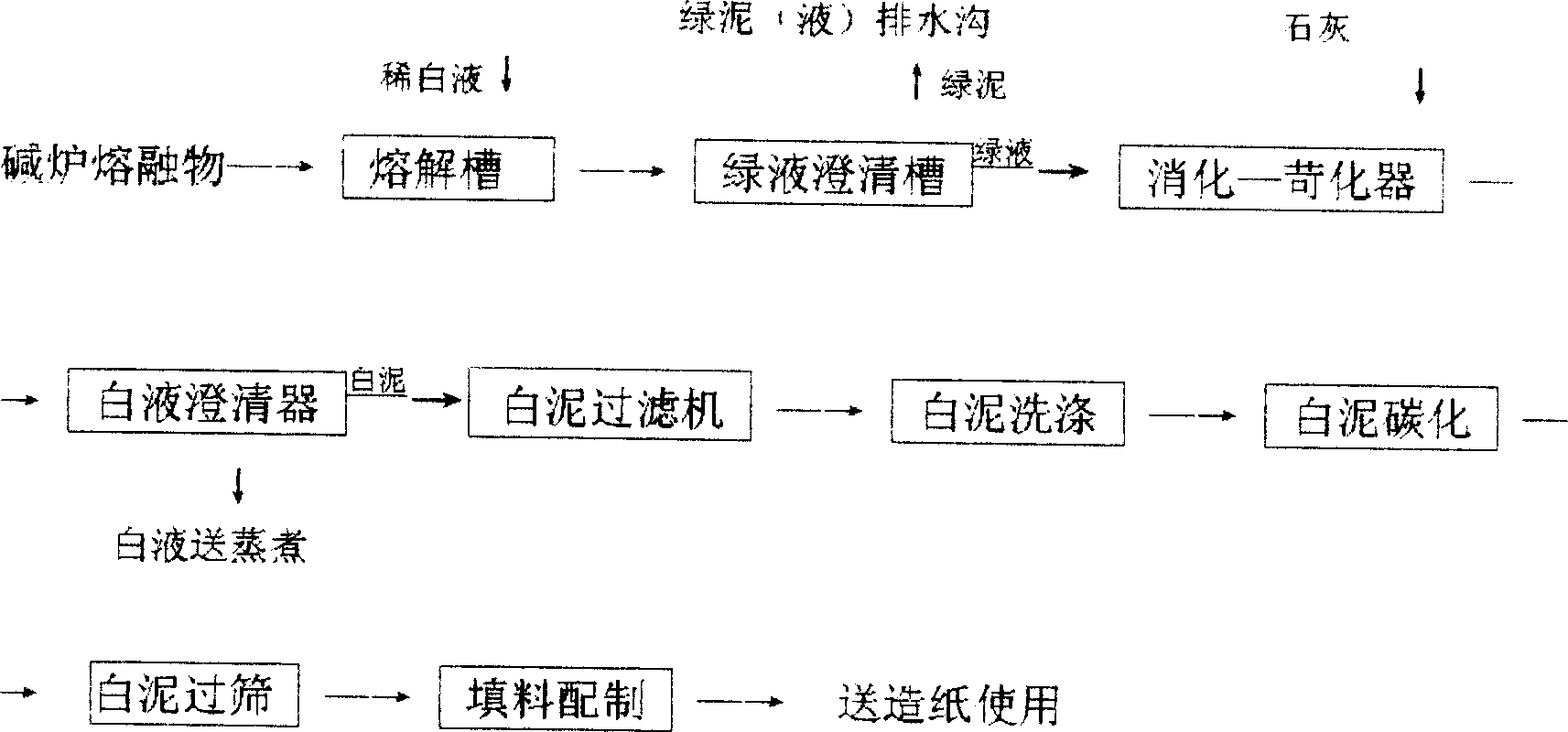

Technological process of recovering white clay to produce stuffing calcium carbonate

A calcium carbonate, a new process technology, applied in the field of regeneration of pulping liquid, can solve the problems of difficult utilization, poor uniformity, and difficult sedimentation of impurities, so as to reduce the loss of sodium salt, reduce production costs, and improve alkali recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

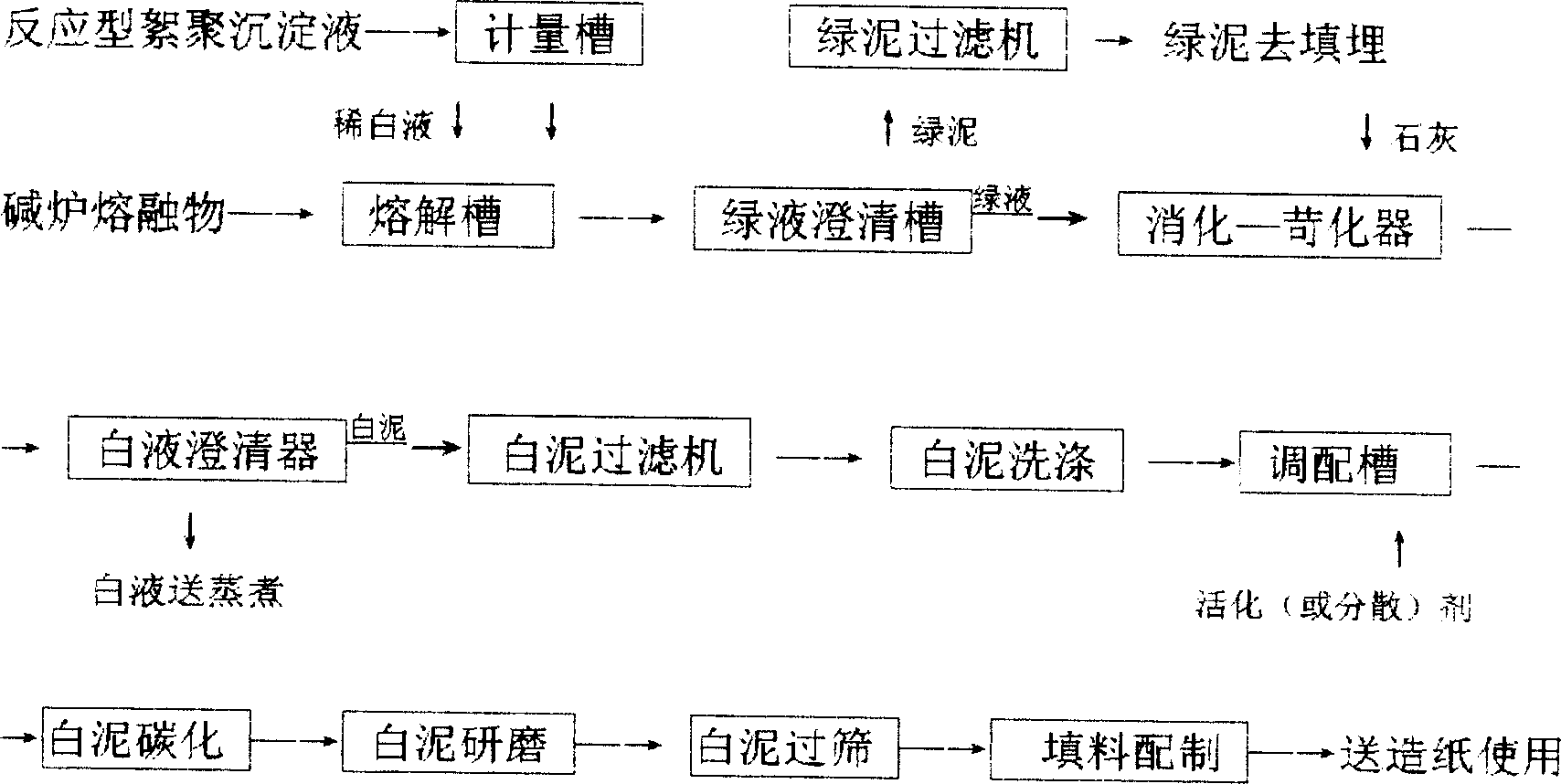

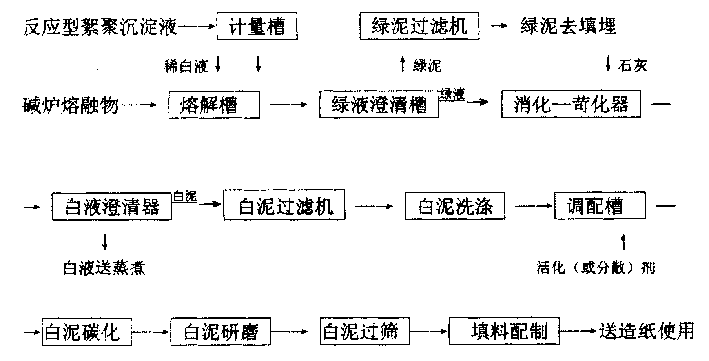

[0020] Such as figure 2 As shown, the white mud recovery and filling process includes melting tank, green liquor clarification, causticization, white liquor clarification, white mud refining, thin white liquor and alkali furnace melt are added to the melting tank, and the green liquor is treated in the melting tank. Carry out purification treatment, that is, add reactive flocculation and sedimentation aids in the melting tank; in the white mud refining process, increase the grinding process, that is, after the white mud is carbonized, grind it with a grinder.

[0021] The reaction-type flocculation-precipitation aid is lime emulsion, and its dosage is 2% (total sodium salt content, calculated as 100% CaO), the temperature of the green liquor is controlled at 85° C., and the reaction clarification time is 8 hours.

[0022] The vacuum degree is controlled to 0.0533MPa in the green slime filtration after the green liquor is clarified.

[0023] Due to the flocculation characteri...

Embodiment 2

[0025] The reaction-type flocculation-precipitation aid is lime emulsion, and its consumption is 4% (to the total sodium salt amount, calculated as 100% CaO), the temperature of the green liquor is controlled at 95° C., and the reaction clarification time is 8 hours. The rest are the same as embodiment 1.

Embodiment 3

[0027] The reaction-type flocculation-precipitation aid is lime emulsion, and its consumption is 3% (total sodium salt content, calculated as 100% CaO), the temperature of the green liquor is controlled at 90° C., and the reaction clarification time is 8 hours. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com