Pallet structure

a pallet and structure technology, applied in the field of pallets, can solve the problems of reducing the weight and volume of freight, reducing the economic and environmental impact, and only able to manufacture six conventional pallets, so as to facilitate loading and unloading operation, reduce the total weight, and enhance the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

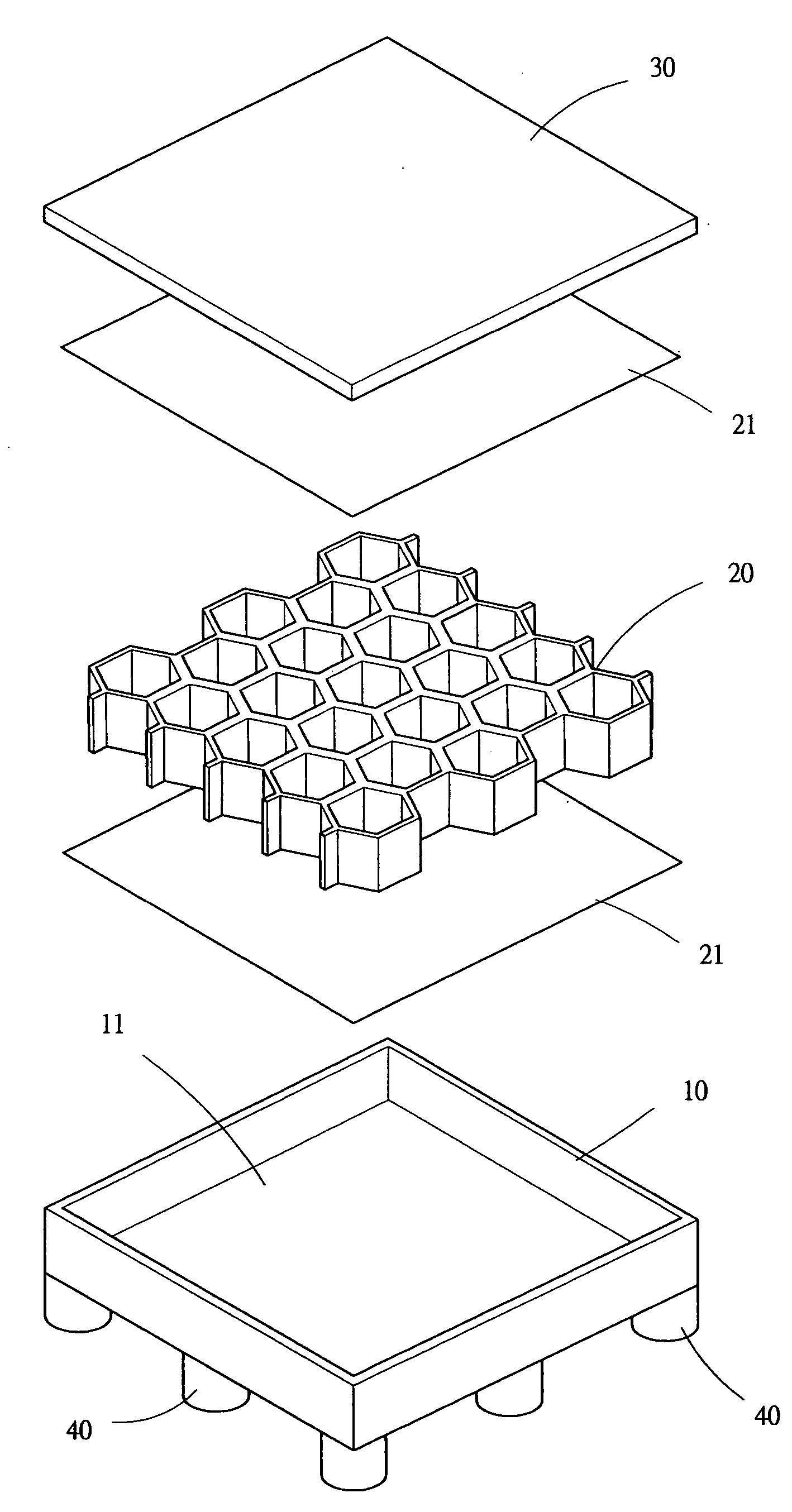

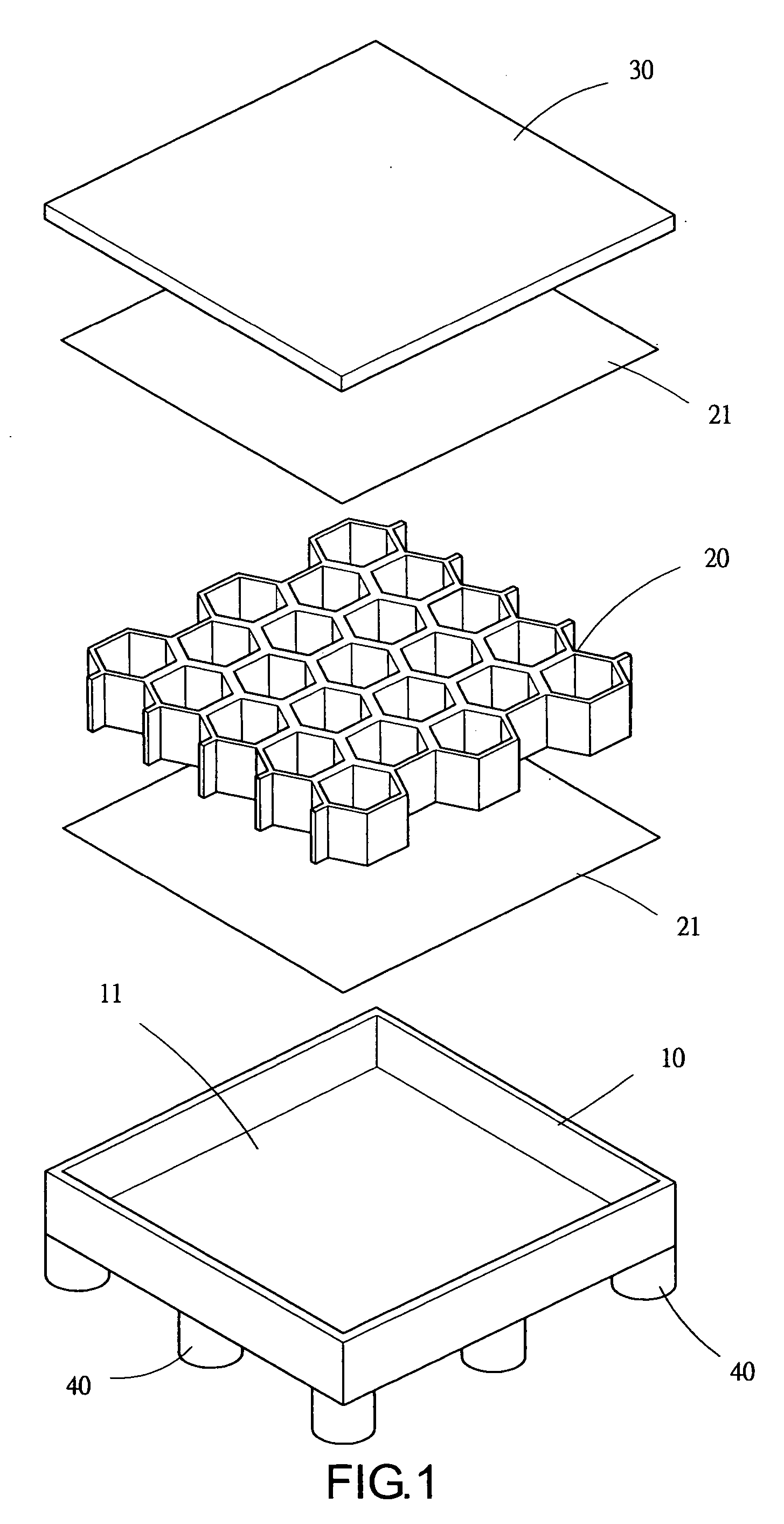

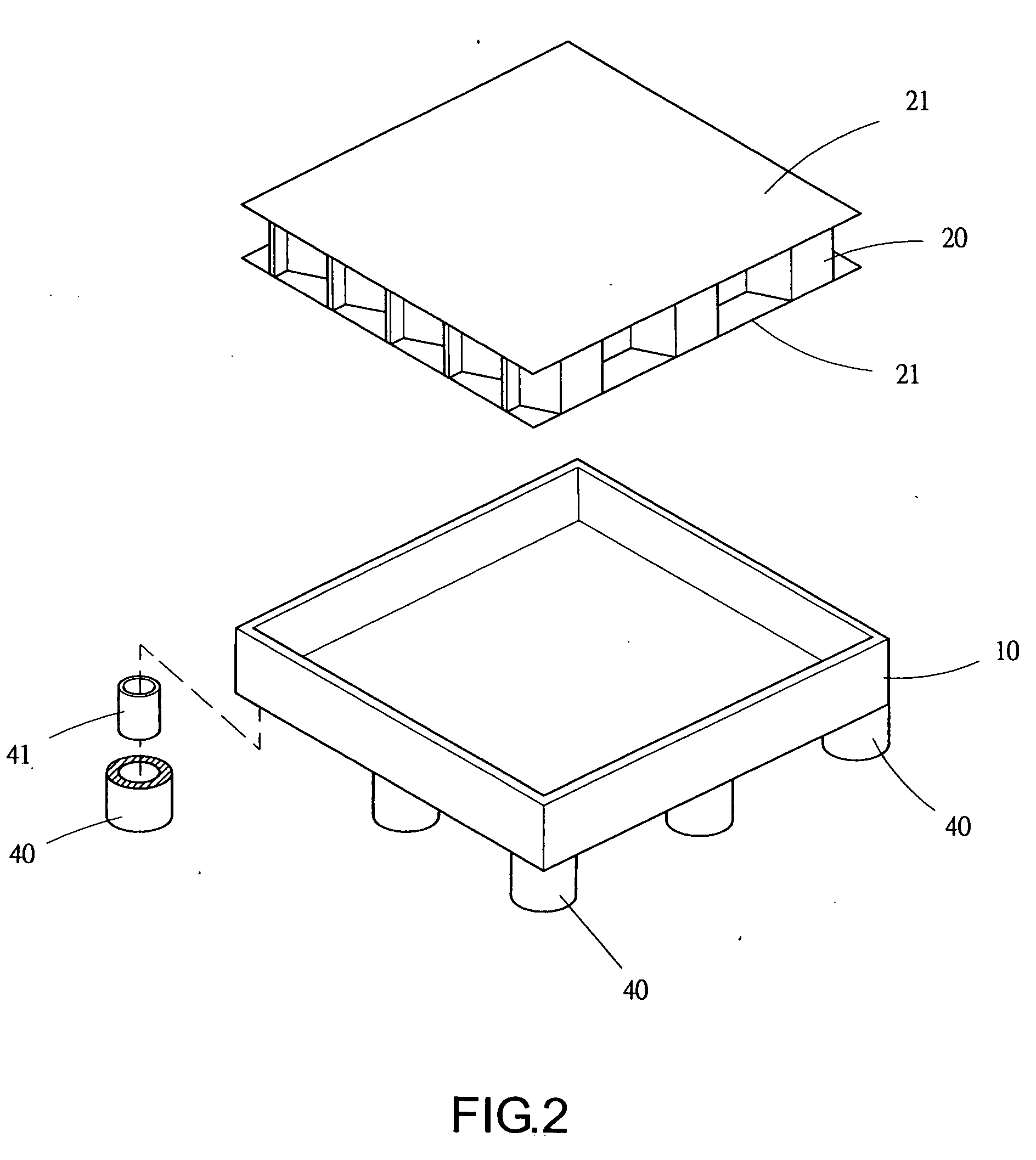

[0017] Referring to FIGS. 1 to 3. The present invention relates to an improvement to a pallet including a base 10, a paper cellular structure 20, and a lid 30, wherein the base 10, being made of plastic, wood, plastic-wood, or plastic-stone, including a tray-like structure 11 with feet 40 formed underneath, the paper cellular structure 20 having krafts 21 adhere to the top and the bottom to fix its shape and being fastened in the tray-like structure 11, and the lid 30 being made of the same material as that in the base 10 and fixed on the base 10.

[0018] Referring to FIGS. 2 and 4. Each foot 40 is a hollow cylinder with a light-weight 1 cm thick paper cylinder 41 inserted to enhance strength. With the feet 40, the pallet is easy to be stacked up and is much more convenient when operating with a fork lift or a crane.

[0019] Referring to FIG. 5. The lid 30 fixes on the base 10 to form a light-weight, heavy-duty, low cost, and also environmental friendly pallet.

[0020] In summary, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com