Carbon element crystal heating plate and preparation method thereof

A technology of carbon crystals and heating plates, applied in chemical instruments and methods, electric heating devices, heating element materials, etc., can solve the problems of unimproved far-infrared radiation performance, environmental pollution, etc., and achieve high conversion efficiency of electric heat radiation, durable Strong acid and alkali corrosion ability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of carbon crystal heating powder: first soak the chopped bamboo carbon fiber with a length of 1-2mm in tetrachlorethylene solvent for 2 hours, then dry it at 150°C, and then grind it to 2-3um powder, and finally bamboo carbon fiber powder, ceramic crystals with a particle size of 1-2um and Nb 2 o 5 : Y 2 o 3 The rare earth oxide modifier composed of 4:1 was mixed in a vacuum mixer for 5 hours according to the ratio of 1:2:0.01 to obtain carbon crystal powder;

[0021] (2) Preparation of epoxy resin tape:

[0022] Use flame-retardant epoxy resin (EX-48) and non-alkali glass fiber cloth (electronic grade), and make flame-retardant and insulating epoxy resin tape on the dipping machine;

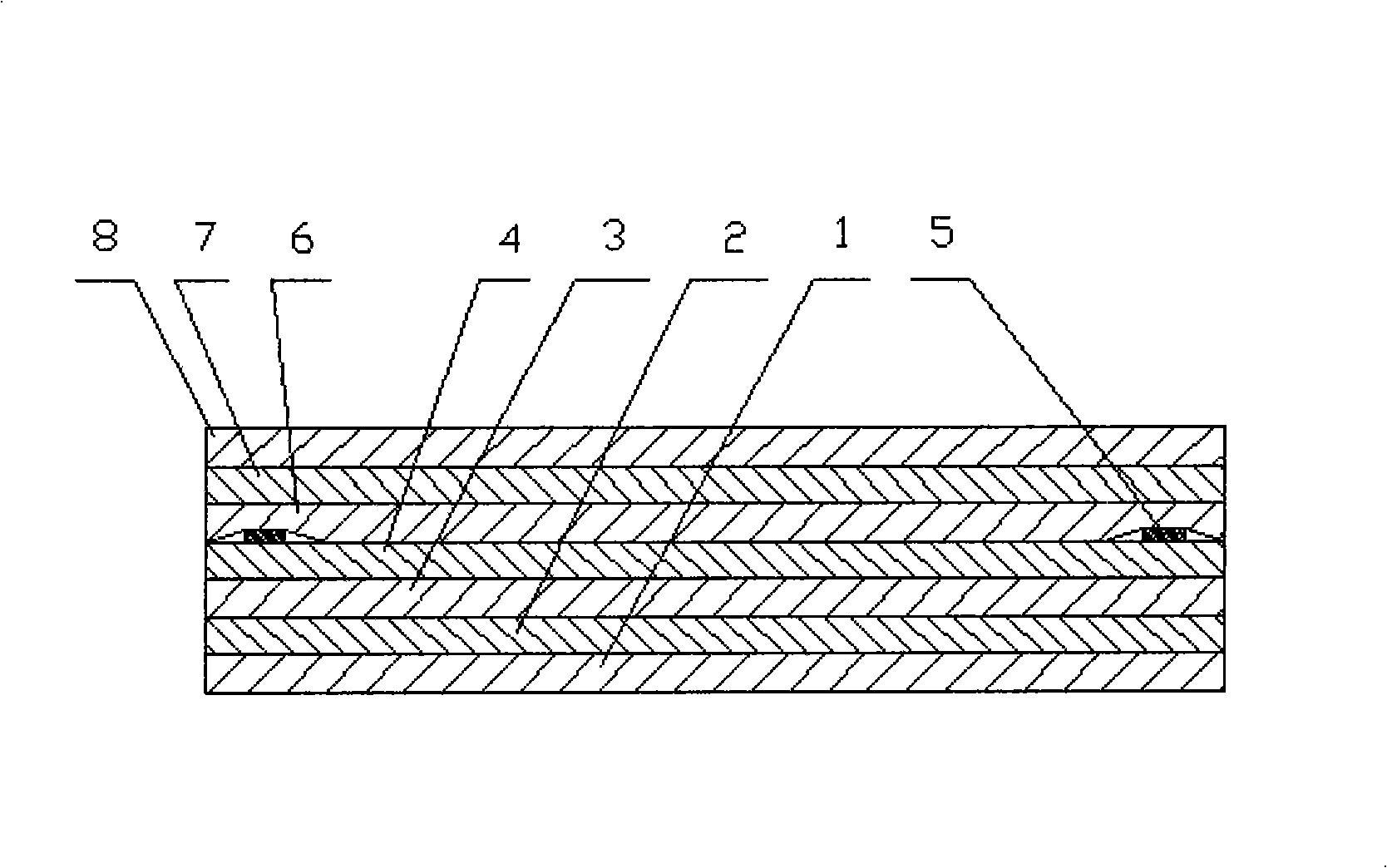

[0023] (3) Preparation of carbon crystal heating plate:

[0024] ① Put a layer of aluminum foil on the lower metal mold plate as a metal reflective film;

[0025] ②Lay 3 layers of epoxy resin tape on the metal reflective film as the bottom layer of the epoxy resin ta...

Embodiment 2

[0031] (1) Preparation of carbon crystal heating powder: first soak the chopped bamboo carbon fiber with a length of 3-5mm in tetrachlorethylene solvent for 3 hours, then dry it at 200°C, and grind it to 4-5um powder, and finally bamboo carbon fiber powder, ceramic crystals with a particle size of 2-3um and Nb 2 o 5 : Y 2 o 3 The rare earth oxide modifier composed of 4:1 was placed in a vacuum mixer and mixed for 10 hours according to the ratio of 1:5:0.05 to obtain carbon crystal powder;

[0032] (2) Preparation of epoxy resin tape:

[0033] With embodiment 1;

[0034] (3) Preparation of carbon crystal heating plate:

[0035] ① Put a layer of aluminum foil on the lower metal mold plate as a metal reflective film;

[0036] ② Spread 6 layers of epoxy resin tape on the metal reflective film as the bottom layer of epoxy resin tape, then brush a layer of epoxy resin adhesive, and then spread a thin layer of kraft paper as the kraft paper layer;

[0037] ③ Spray a layer of 0...

Embodiment 3

[0042](1) Preparation of carbon crystal heating powder: first soak the chopped bamboo carbon fiber with a length of 2-4mm in tetrachlorethylene solvent for 2.5 hours, then dry it at 180°C, and then grind it to 2-4um powder, and finally bamboo carbon fiber powder, ceramic crystals with a particle size of 2-3um and Nb 2 o 5 : Y 2 o 3 The rare earth oxide modifier composed of 4:1 is placed in a vacuum mixer for 7 hours according to the ratio of 1:3:0.03, and the carbon crystal powder is obtained;

[0043] (2) Preparation of epoxy resin tape:

[0044] With embodiment 1;

[0045] (3) Preparation of carbon crystal heating plate:

[0046] ① Put a layer of aluminum foil on the lower metal mold plate as a metal reflective film;

[0047] ②Lay 5 layers of epoxy resin tape on the metal reflective film as the bottom layer of epoxy resin tape, then brush a layer of epoxy resin adhesive, and then spread a thin layer of kraft paper as the kraft paper layer;

[0048] ③ Spray a layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com