A kind of hydrophobic anti-corrosion coating and preparation method thereof

An anti-corrosion coating and hydrophobic technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor anti-corrosion effects, improve self-cleaning and corrosion resistance, improve hydrophobicity, and improve Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

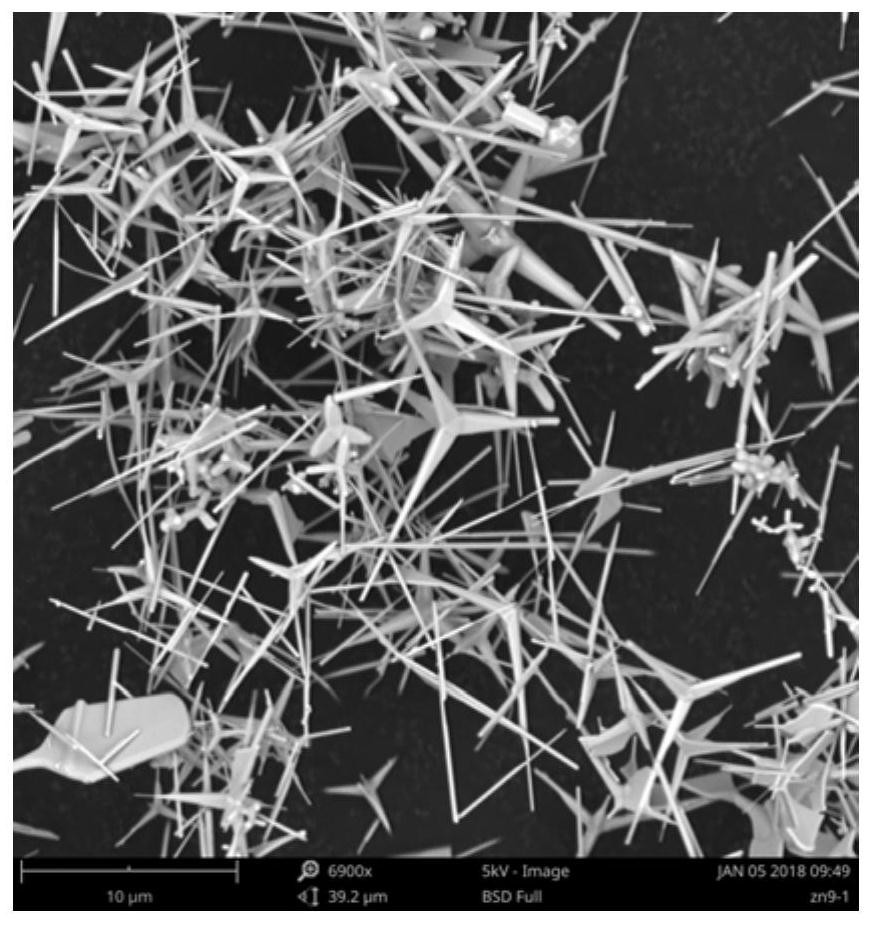

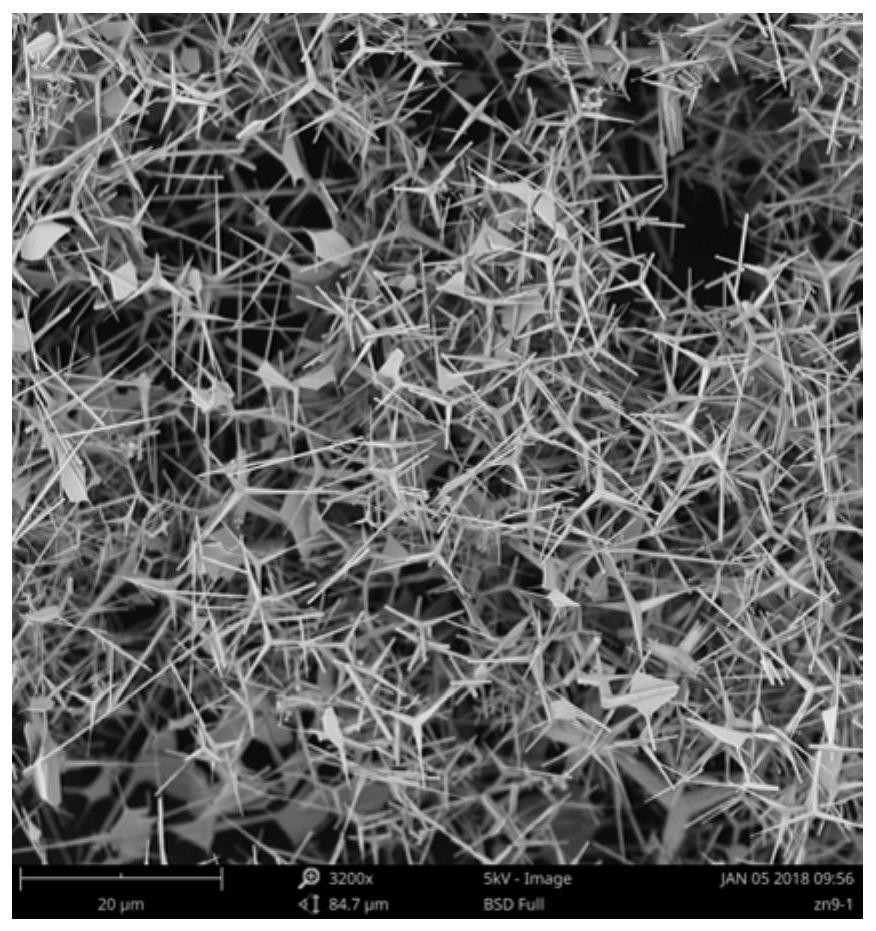

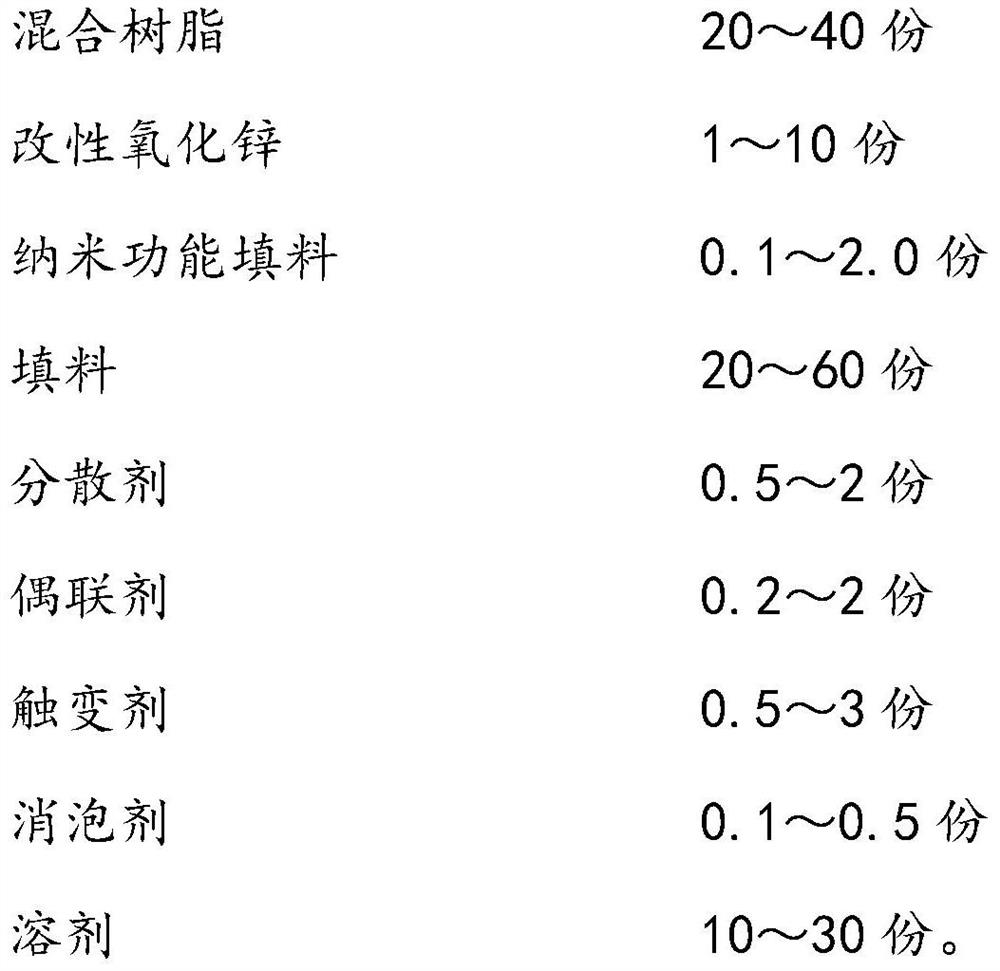

Image

Examples

Embodiment 1

[0042]The mixed resin is composed of bisphenol A epoxy resin and epoxy-modified silicone resin, the mass ratio of the bisphenol A epoxy resin to epoxy-modified silicone resin is 2:1, and the nano-functional The filler is nano silica, the thixotropic agent is bentonite, the dispersant is BYK110, the defoamer is BYK141, the coupling agent is KH560, the solvent is xylene, and the curing agent is Modified cycloaliphatic amine curing agent.

[0043] And prepare as follows:

[0044] The preparation method of described A component is:

[0045] Step 1. Add the mixed resin into the reaction vessel and mix and stir evenly. The stirring speed is 500rpm, and add it into the mixer to stir and achieve uniformity;

[0046] Step 2, adding defoamer, dispersant, coupling agent and solvent into the reaction vessel while stirring, the stirring speed is 500rpm, and stirring the reactants in the reaction vessel until they are uniformly dispersed;

[0047] Step 3, adding the thixotropic agent int...

Embodiment 2

[0052] The mixed resin is composed of bisphenol A epoxy resin and epoxy-modified silicone resin, the mass ratio of the bisphenol A epoxy resin to epoxy-modified silicone resin is 2:1, and the nano-functional The filler is nano silica, the thixotropic agent is bentonite, the dispersant is BYK110, the defoamer is BYK141, the coupling agent is KH560, the solvent is xylene, and the curing agent is Modified cycloaliphatic amine curing agent.

[0053] And prepare as follows:

[0054] The preparation method of described A component is:

[0055] Step 1. Add the mixed resin into the reaction vessel and mix and stir evenly. The stirring speed is 500rpm, and add it into the mixer to stir and achieve uniformity;

[0056] Step 2, adding defoamer, dispersant, coupling agent and solvent into the reaction vessel while stirring, the stirring speed is 500rpm, and stirring the reactants in the reaction vessel until they are uniformly dispersed;

[0057] Step 3, adding the thixotropic agent in...

Embodiment 3

[0062] The mixed resin is composed of bisphenol A epoxy resin and epoxy-modified silicone resin, the mass ratio of the bisphenol A epoxy resin to epoxy-modified silicone resin is 2:1, and the nano-functional The filler is nano silica, the thixotropic agent is bentonite, the dispersant is BYK110, the defoamer is BYK141, the coupling agent is KH560, the solvent is xylene, and the curing agent is Modified cycloaliphatic amine curing agent.

[0063] And prepare as follows:

[0064] The preparation method of described A component is:

[0065] Step 1. Add the mixed resin into the reaction vessel and mix and stir evenly. The stirring speed is 500rpm, and add it into the mixer to stir and achieve uniformity;

[0066] Step 2, adding defoamer, dispersant, coupling agent and solvent into the reaction vessel while stirring, the stirring speed is 500rpm, and stirring the reactants in the reaction vessel until they are uniformly dispersed;

[0067] Step 3, adding the thixotropic agent in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com