Method for manufacturing wood skin decorative high-pressure laminates sheets based on thermosetting resins

A technology of resin impregnation and manufacturing method, which is applied in the direction of wood layered products, fire protection, decorative art, etc., can solve the problems that cannot meet people's requirements for being close to nature and multifunctional requirements, and achieve good decorative effects, enhanced feeling, and enhanced smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

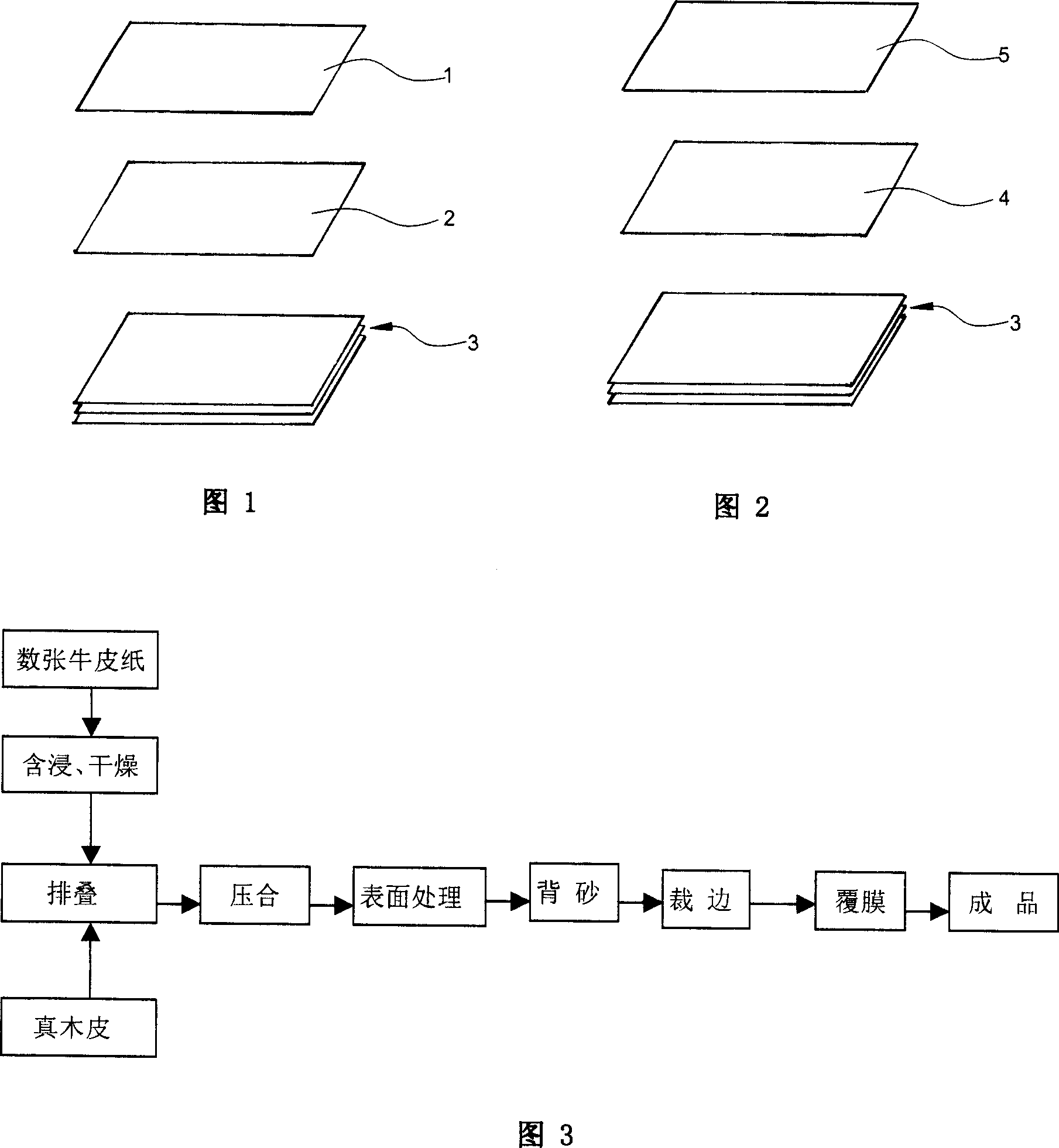

[0033] The real wood veneer is made of sliced thin bamboo with a moisture content of 10%, a format size of 2540mm (length) × 1330mm (width), and a thickness of 0.6mm; the thickness of 3 sheets produced by International Paper Company is 0.83±0.015mm, and the density is about 0.53g / cm 3 kraft paper.

[0034] (1) impregnating and drying the above-mentioned kraft paper in modified melamine formaldehyde resin, the solid content of modified melamine formaldehyde resin in the resin is 45~55%, and the weight percent content (RC) of making resin is 20~40% resin Impregnated paper, its volatile content (VC) is 4-10%.

[0035] (2) Stack the above-mentioned dried resin-impregnated papers to obtain stacked paper, then cover the real wood veneer on the resin-impregnated paper, and stack them into blanks, and add mirror panels and BOPP high-temperature resistant panels between multiple blanks The quantity of film and kraft paper reaches 5-6 sheets of real wood veneer decorative fireproof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com