Welding method and welding structure of accelerometer movement

A technology of accelerometer and welding method, which is applied in the direction of measuring acceleration, speed/acceleration/impact measurement, welding equipment, etc., which can solve the problems of uneven distribution of the circumference, increased welding stress, and increased number of welding repairs, etc., to improve welding The effect of quality, low-stress welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

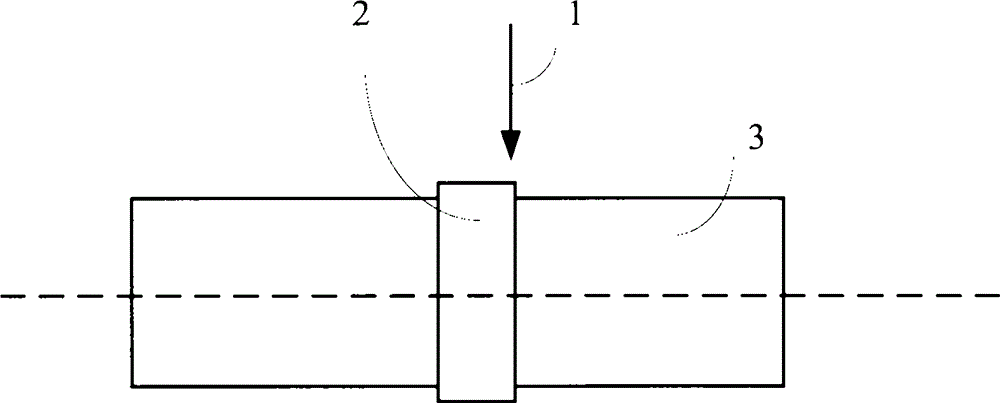

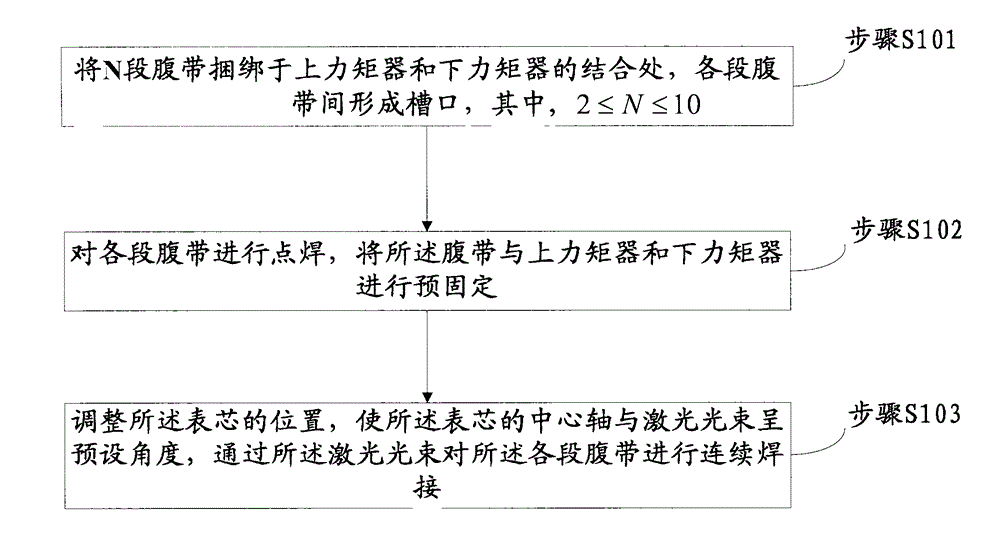

[0021] refer to figure 2 , the present embodiment provides a welding method for an accelerometer watch core, the watch core includes an upper torque device, a lower torque device and N sections of abdominal belt, and the method includes:

[0022] Step S101, binding N sections of abdominal belts to the junction of the upper torque device and the lower torque device, forming notches between each section of abdominal belt, wherein, 2≤N≤10;

[0023] Step S102, performing spot welding on each section of the abdominal belt, and pre-fixing the abdominal belt with the upper torque device and the lower torque device;

[0024] Step S103 , adjusting the position of the watch movement so that the central axis of the watch movement is at a preset angle with the laser beam, and continuously welding each section of the abdominal belt through the laser beam.

[0025] In the welding method and welding structure of the accelerometer watch core provided in this embodiment, the notch between th...

Embodiment 2

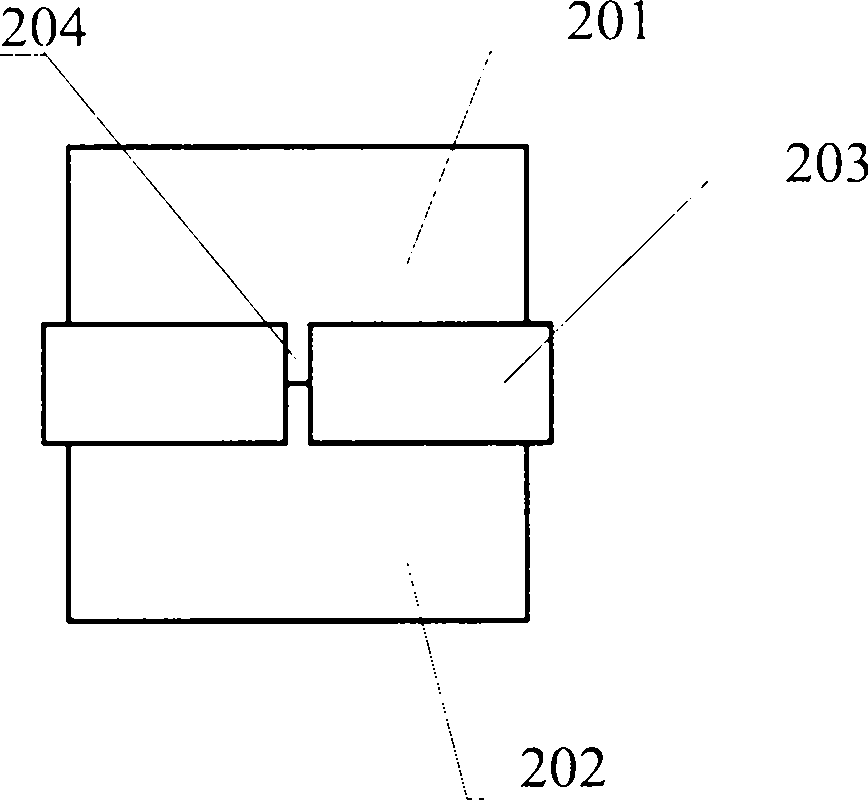

[0039] refer to image 3 , the present embodiment provides a welding structure of an accelerometer watch core, including an upper torque device 201, a lower torque device 202) and an N-section abdominal belt 203, and the N-section abdominal belt 203 is fixed on the upper torque device 201 and the lower torque device by welding At the joint of 202, notch 204 is formed between each section of abdominal belt 203, wherein, 2≤N≤10.

[0040] Wherein, the radians of the N sections of abdominal belt 203 can be the same or different, and can be set according to actual conditions.

[0041] As a preferred embodiment, refer to Figure 5 , Figure 5 The top view of an embodiment of the welded structure of the accelerometer watch core provided in this embodiment, the welded structure includes 7 sections of abdominal belt, and the 7 sections of abdominal belt are arranged symmetrically with respect to the longitudinal axis.

[0042] Such as Figure 5 As shown, the 7-section abdominal bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com