Magnet yoke for electric induction furnace

An induction furnace and yoke technology, applied in the field of yokes, can solve the problems of long time consumption, many processes, and long welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

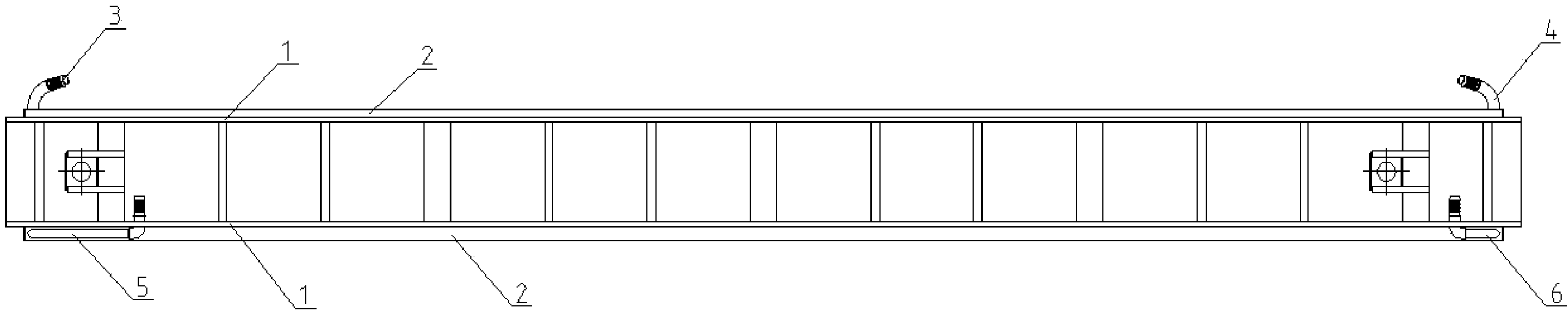

[0034] Figure 4 It is the front view of the induction furnace yoke of the first embodiment.

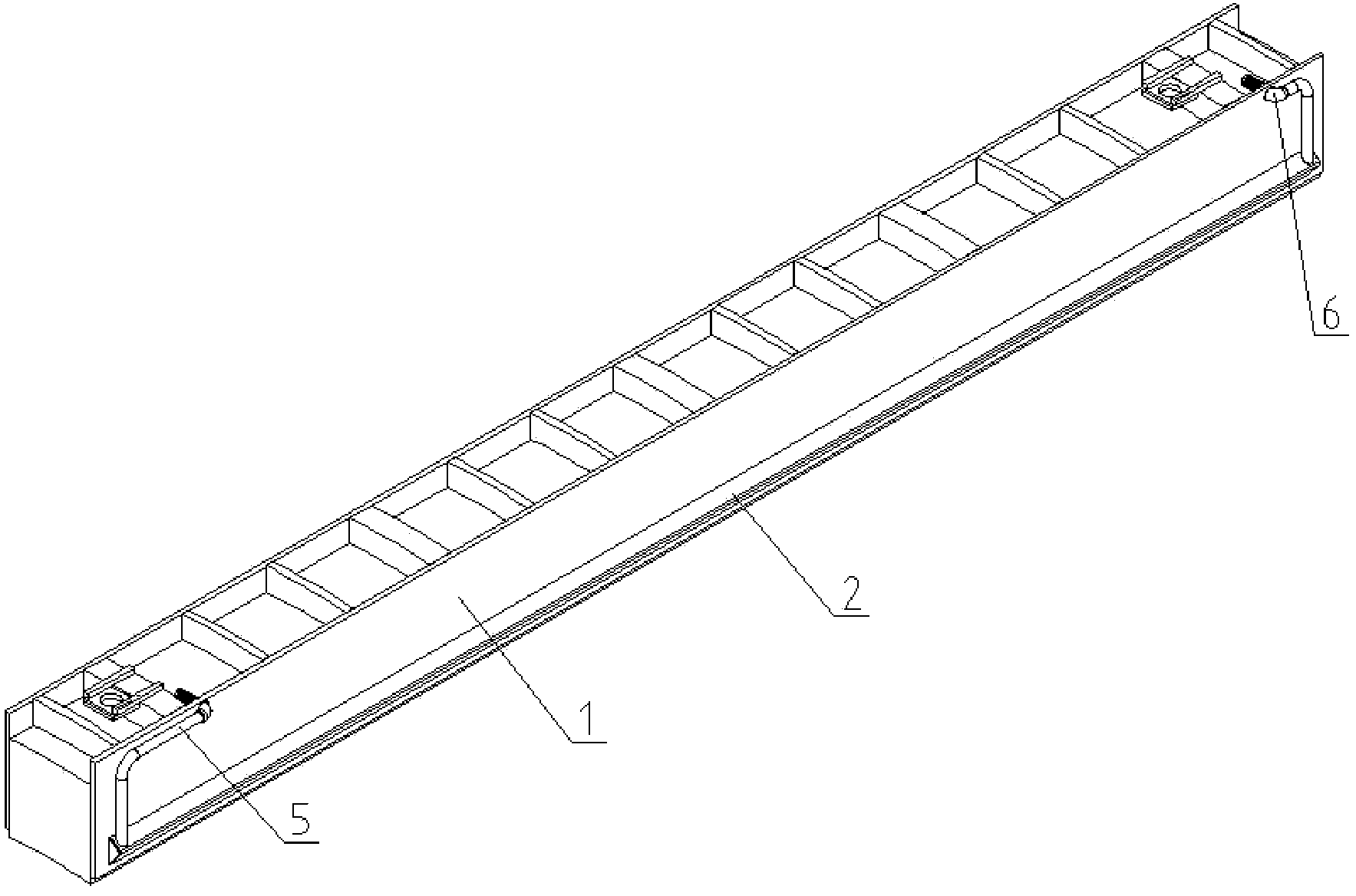

[0035] Figure 5 It is a three-dimensional view of the induction furnace yoke of the first embodiment.

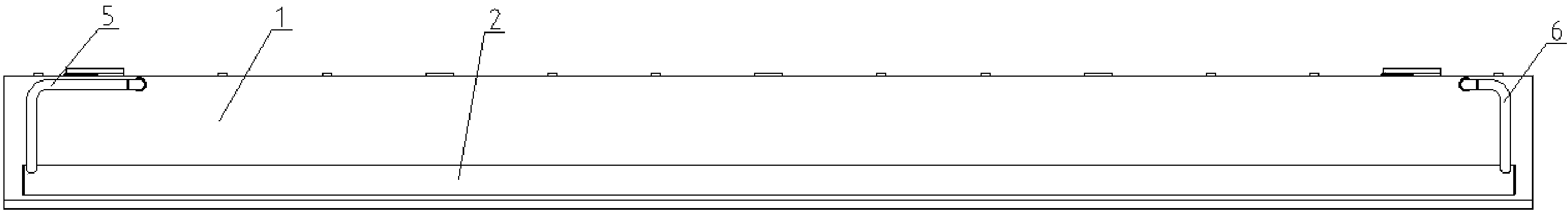

[0036] Image 6 for Figure 4 A-A cutaway view.

[0037] like Figure 4 , Figure 5 and Image 6 As shown, the induction furnace yoke includes: a stacked silicon steel sheet group 50, a back plate 40, two side plates 10, several fixed plates 20, several support plates 30, several fixed installation components 21, water outlets 11, 13 And water inlet 12,14.

[0038] The silicon steel sheet group 50 is formed by stacking multiple silicon steel sheets, and is sandwiched between two side plates 10 .

[0039] The backboard 40 is fixedly connected to the sideboards 10 , and the sideboards 10 are symmetrically fixed on both sides of the backboard 40 . The fixing method can be welded.

[0040] The two side plates 10 are hollow plate structures, providing fluid channels for cool...

Embodiment 2

[0047] Figure 7 It is the front view of the induction furnace yoke of the second embodiment.

[0048] Figure 8 It is a three-dimensional view of the induction furnace yoke of the second embodiment.

[0049] Figure 9 for Figure 7 The B-B section view.

[0050] like Figure 7 , Figure 8 and Figure 9 As shown, the induction furnace yoke includes: a stacked silicon steel sheet group 50, a back plate 40, two side plates 10, several fixed plates 20, several support plates 30, several fixed installation components 21, two communicating pipes 61 , 62, water outlet 15 and water inlet 16.

[0051] The structures and functions of the silicon steel sheet group 50 , the back plate 40 , two side plates 10 , several fixing plates 20 , several support plates 30 , and several fixed installation assemblies 21 in this embodiment are the same as those in the first embodiment.

[0052] Two hollow communication pipes 61, 62 are arranged between the two side plates 10, and at the two ...

Embodiment 3

[0057] Figure 10 It is the front view of the induction furnace yoke of the third embodiment.

[0058] Figure 11 It is a three-dimensional view of the induction furnace yoke of the third embodiment.

[0059] Figure 12 for Figure 10 C-C section view.

[0060] like Figure 10 , Figure 11 and Figure 12As shown, the induction furnace yoke includes: a stacked silicon steel sheet group 50, a back plate 40, two side plates 10, several fixed plates 20, several support plates 30, several fixed installation components 21, two communicating pipes 61 , 62, the intermediate connecting pipe 63, the water outlet 18 and the water inlet 17.

[0061] The structures and functions of the silicon steel sheet group 50 , the back plate 40 , two side plates 10 , several fixing plates 20 , several support plates 30 , and several fixed installation assemblies 21 in this embodiment are the same as those in the first embodiment.

[0062] The hollow communication pipes 61 , 62 and the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com