Fuel cell system using hydrogen supply manifold

A fuel cell system and manifold technology, applied in fuel cells, fuel cell additives, power system fuel cells, etc., can solve the problems of difficult to manage assembly torque, decreased productivity, increased costs, etc., and achieves a compact overall structure and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

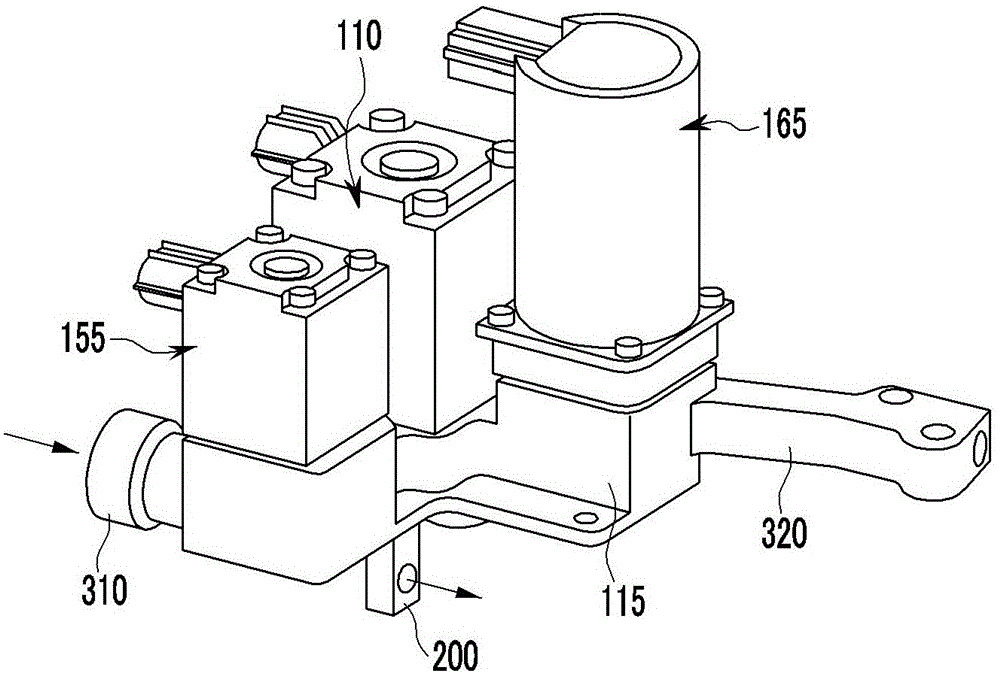

[0052] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

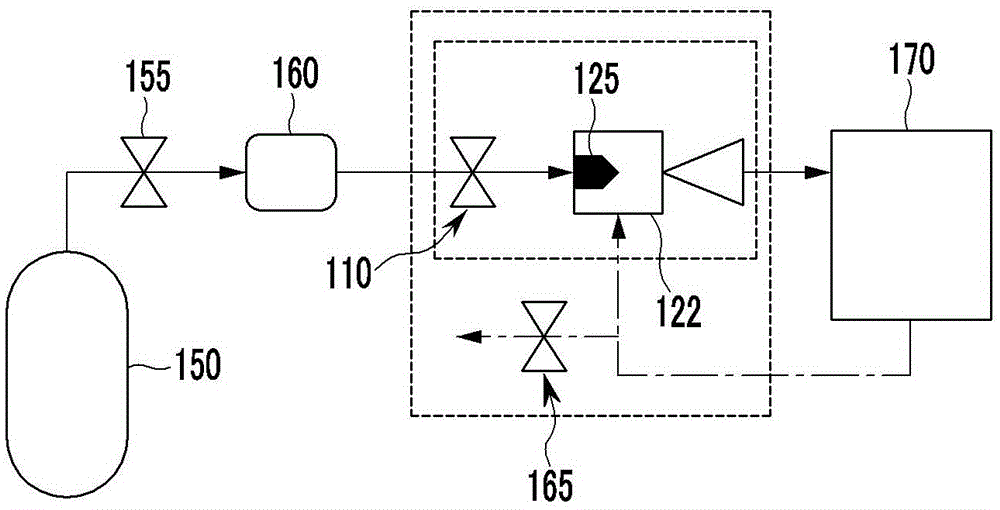

[0053] figure 1 is a schematic diagram of a fuel cell system according to an exemplary embodiment of the present invention.

[0054] refer to figure 1 , the fuel cell system includes: a hydrogen tank 150 , a shut-off valve 155 , a high pressure regulator 160 , a control valve 110 , a nozzle 125 , an injector 122 , a purge valve 165 and a battery stack 170 .

[0055] Hydrogen as fuel is stored in the hydrogen tank 150 under high pressure, and the shutoff valve 155 can completely close the hydrogen supply line. The high pressure regulator 160 reduces the high pressure hydrogen to a predetermined pressure, and the control valve 110 controls the hydrogen supplied to the nozzle 125 .

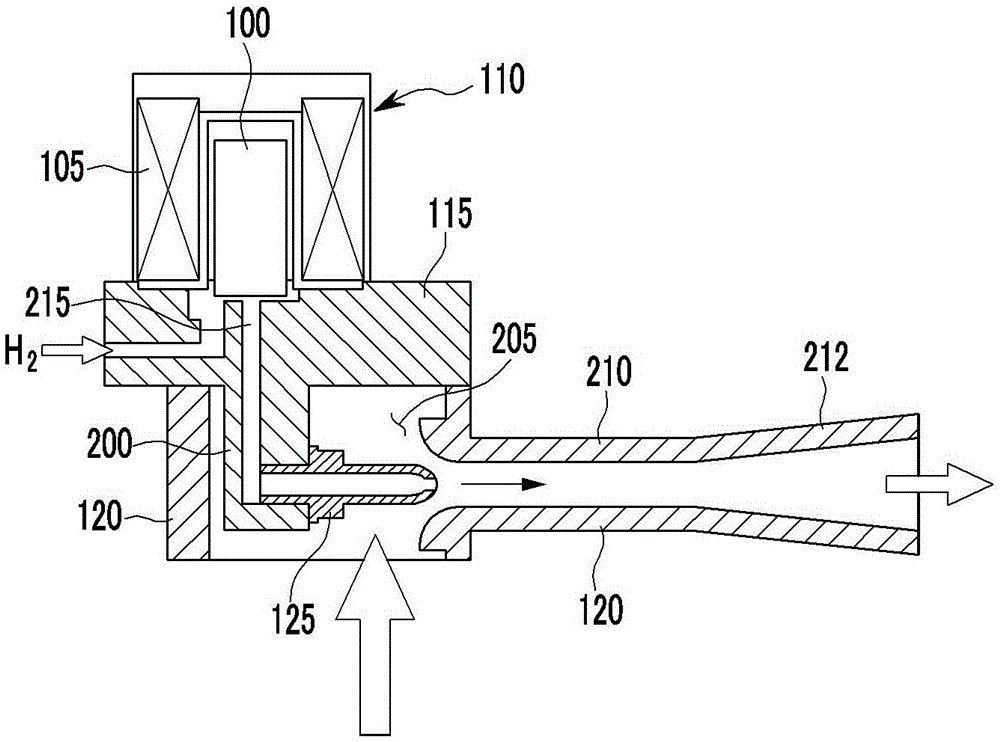

[0056] The injector 122 mixes hydrogen injected from the nozzle 125 with recycled fuel gas, which passes through the venturi 210 and the diffuser 212, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com