Integrated cylinder valve suitable for 70 MPa high-pressure hydrogen

A high-pressure hydrogen, 70MPa technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as imperfect functions, high structural design requirements, and inability to meet the needs of 70MPa fuel cell vehicles, so as to reduce leakage points, The effect of reducing the cost of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The purpose of the present invention is to provide a 70MPa high-pressure hydrogen integrated cylinder valve for installation on the hydrogen storage cylinder of a fuel cell vehicle. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

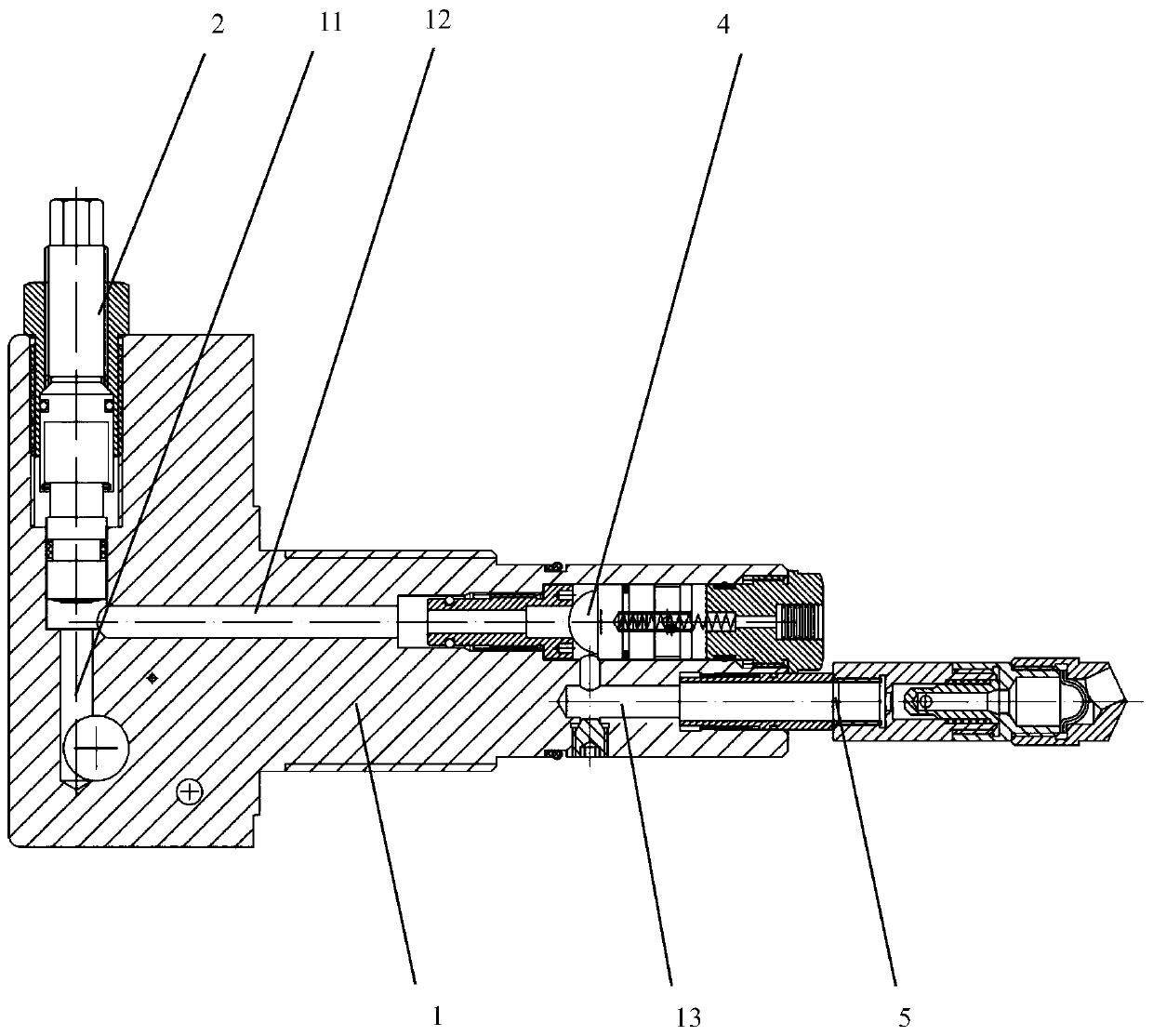

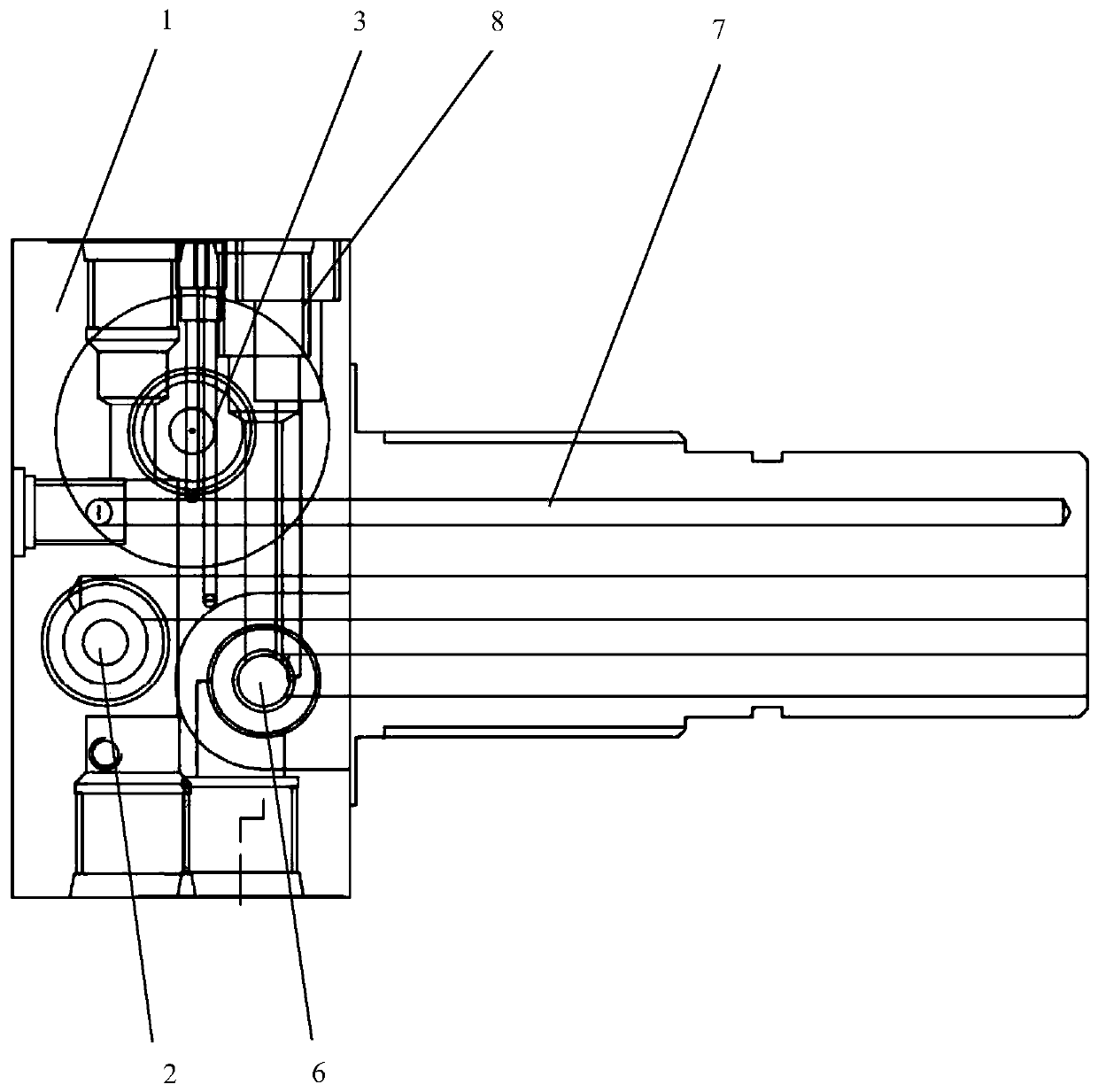

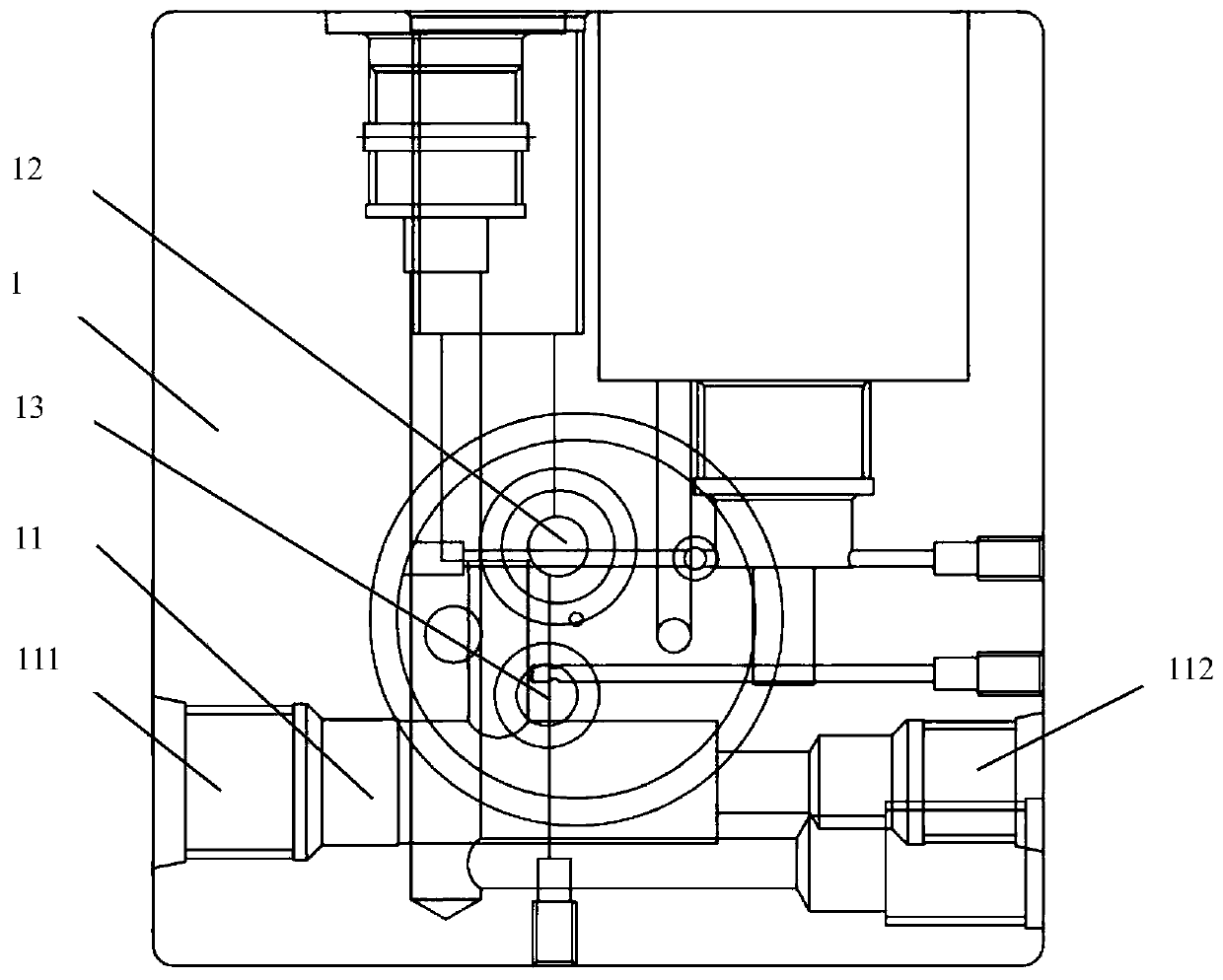

[0031] See figure 1 , figure 2 and image 3 As shown, it shows the first preferred integrated bottle valve for 70MPa high-pressure hydrogen gas, including a bottle valve body 1, a manual shut-off valve 2 and a pilot solenoid valve 3 respectively installed on the top of the bottle valve body 1, respectively installed on The solenoid valve main valve 4 and the filter overflow valve 5 at the bottom of the bottle valve body 1, the manual stop valve 2, the solenoid valve main valve 4, and the filter overflow valve 5 are sequentially connected in the bottle valve body 1, wherein the bottle valve body 1 There are main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com