Arched side plate of container, manufacturing method for arched side plate and container with arched side plate

A manufacturing method and container technology, applied in the field of containers, can solve the problems of high manufacturing cost and insufficient strength of side panels, and achieve the effects of saving materials, improving strength, and shortening line lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

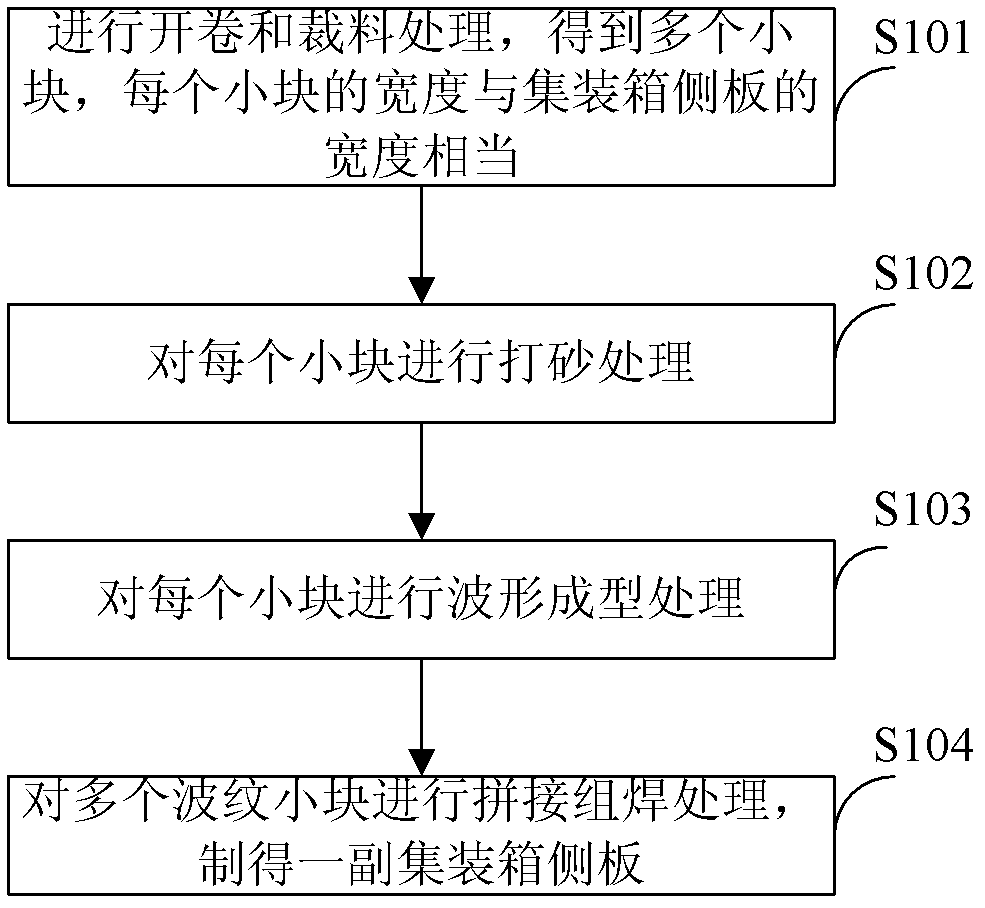

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

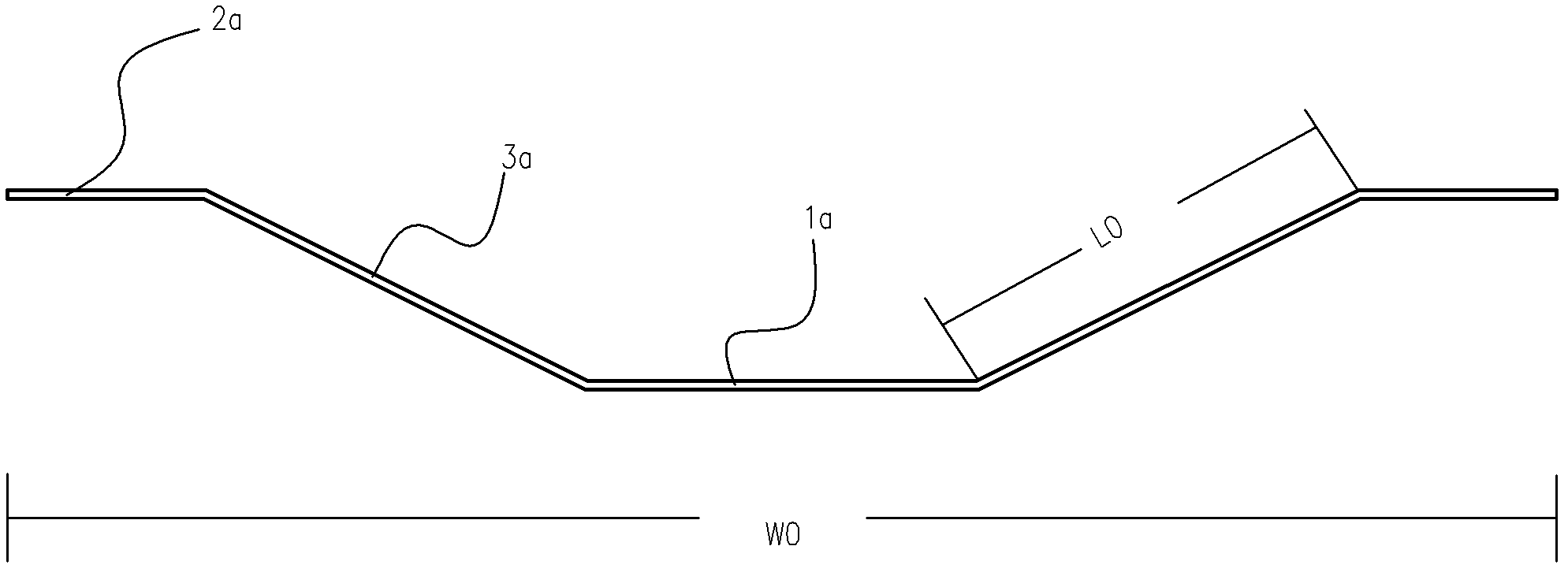

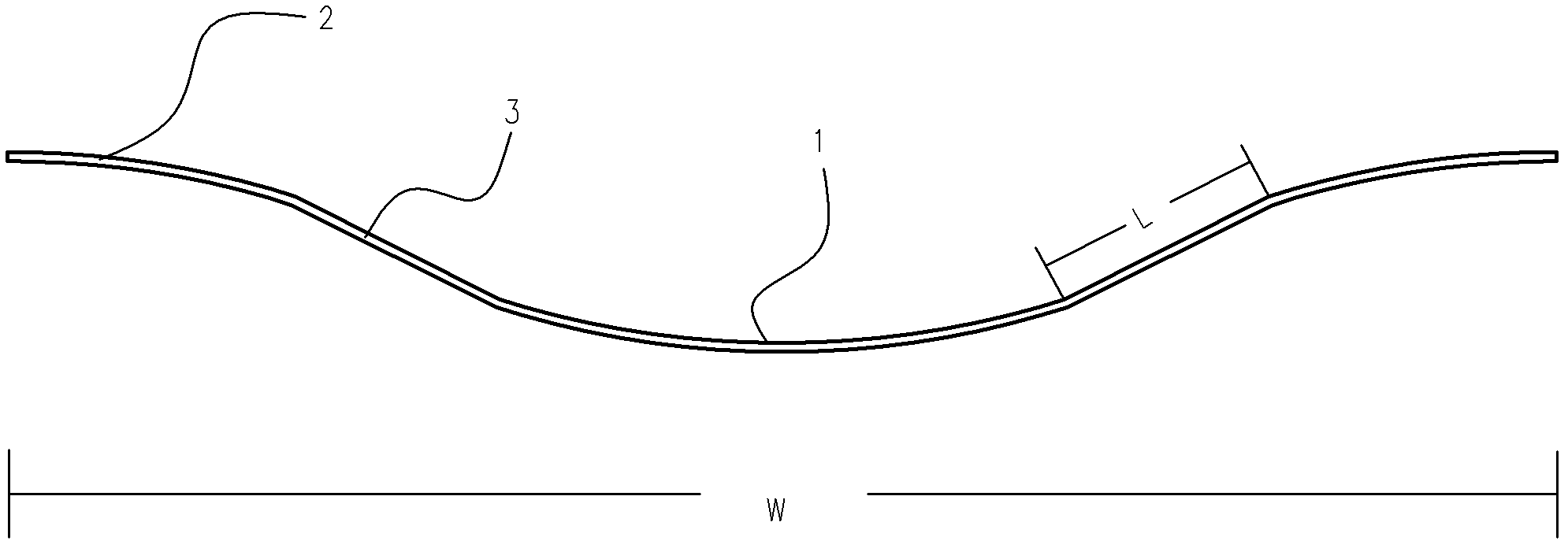

[0020] see figure 2 Shown is the cross-sectional structure of a preferred embodiment of the arched side plate of the container of the present invention, each wave structure of the arched side plate includes a crest 1, a trough 2 and a wave structure connected between the crest 1 and the trough 2 between a slope portion 3, wherein, the crest portion 1 and the valley portion 2 are arched, and the slope portion 3 is a straight line. The length W is 279 mm, the length of the slope part 3 is 41.37 mm, and the distance between the crest part 1 and the trough part 2 is 36 mm. Preferably, the arches of the crests 1 and the troughs 2 are arc segments.

[0021] Verified by finite element analysis software, compared with the corrugated plate structure of 1.6 mm thick flat-bottomed trapezoidal wave in the prior art, when the thickness of the steel plate used for the arched sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com