Assembled type fixed electrode capacitive pressure sensor

An electrode and capacitor technology, applied in the field of capacitive pressure sensors, can solve problems such as the mismatch between the deformation of the moving electrode and the surface shape of the fixed electrode, the easy adhesion of gas in the ceramic insulator, and the many accessories of the capacitive pressure sensor, so as to improve the stability and measurement accuracy. , Simple structure, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

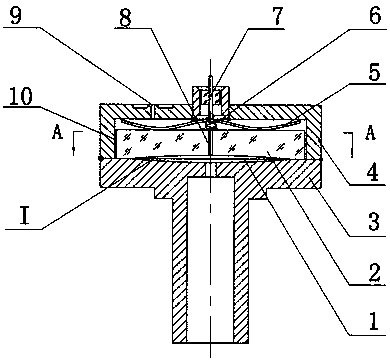

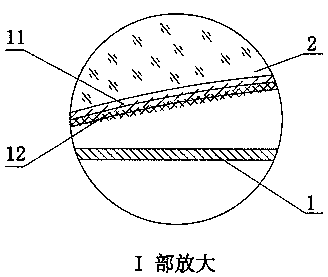

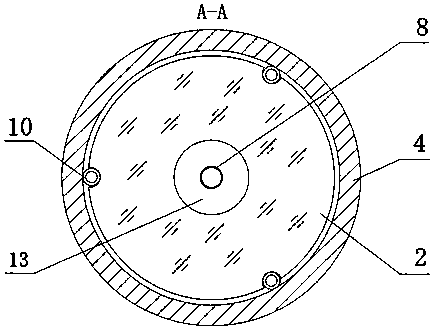

[0020] according to Figure 1~5 The specific structure of the present invention will be described in detail. The assembled capacitive pressure sensor with fixed electrodes includes a casing, a support 3 with a pressure port, a fixed electrode insulator 2 , a sealing electrode 7 and a moving electrode assembled in the casing. The housing adopts a clamping pressure ring 4 with a cover, and the moving electrode adopts a thin-film moving electrode 1 made of constant elastic metal with double-sided plating of precious metal layers. The thin-film moving electrode 1 coated with precious metal layers on both sides can be double-sided gold-plated, ruthenium-plated or iridium-plated thin-film moving electrode according to actual needs. A ring-shaped ohmic contact conductive layer 13 is provided around the metallized guide hole 8 on the top of the fixed electrode insulator 2 made of sapphire single crystal. The outer periphery of the parabolic concave surface at the bottom of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com