SA738GrB steel plate for nuclear power plant containment and manufacturing method thereof

A nuclear power plant containment and steel plate technology, applied in the field of iron and steel smelting, can solve the problem of no data on the width, achieve good safety, improve overall performance, and reduce production resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

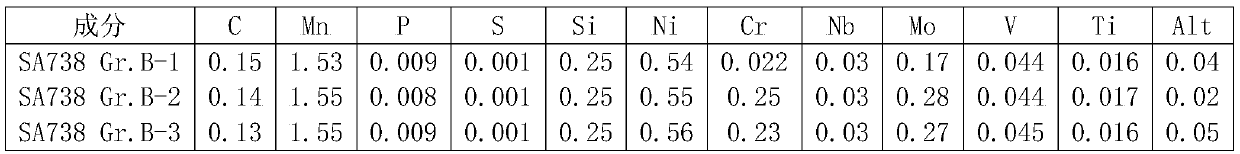

[0025] A SA738GrB steel plate for nuclear power plant containment, the thickness specification is 101mm, the width specification is 4650mm, its chemical composition and mass percentage are as follows: C≤0.2%, Si: 0.13%~0.6%, Mn: 0.9%~1.6%, Ni≤ 0.6%, Cr≤0.3%, Nb≤0.05%, Mo≤0.35%, V≤0.08%, Ti≤0.03%, the balance is Fe and unavoidable impurities.

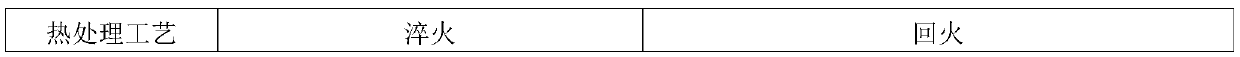

[0026]The manufacturing method of the above-mentioned steel plate includes the following steps: molten steel pretreatment-converter smelting-refining-continuous casting-heating-rolling-heat treatment,

[0027] Hot metal desulfurization pretreatment: start temperature 1330~1370℃, end temperature 1320~1350℃, spray magnesium powder 0.3~1.0kg / ton, lime powder 2.5~4.0kg / ton, end S≤0.005%;

[0028] The molten steel is smelted and refined for continuous casting, the superheat of molten steel is 5-25°C, the casting speed is 0.55-0.75m / min, the secondary cooling electromagnetic stirring for continuous casting: current 200-450A, frequency 5-7Hz, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com