Continuous casting machine for stainless steel seamless composite hollow pipe blank

A technology of stainless steel and hollow tubes, applied in the field of stainless steel seamless composite hollow billet continuous casting machines, can solve the problems of low production efficiency, interrupted production process, high cost, etc., and achieve the goals of reducing equipment investment, convenient and flexible adjustment, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

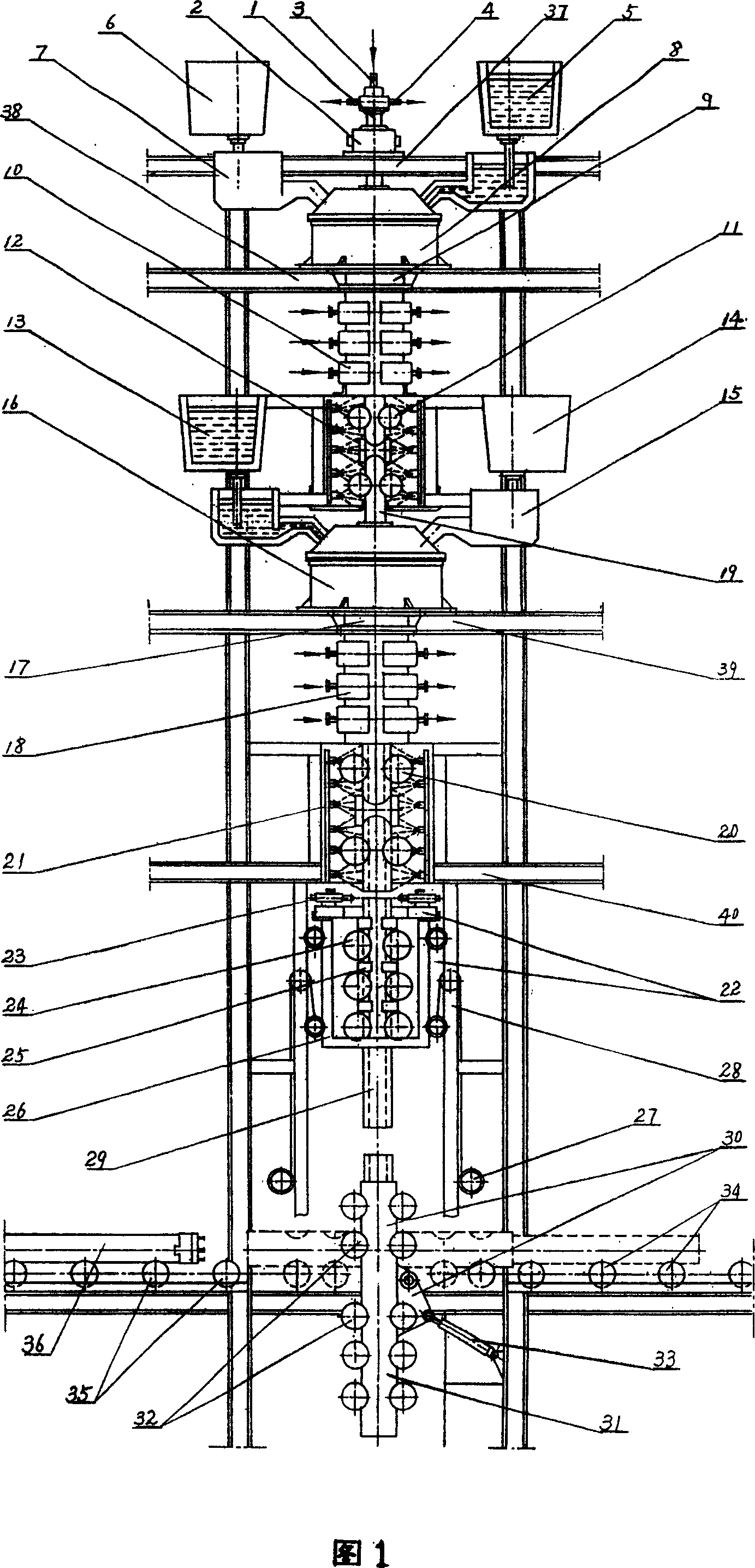

[0032] 1. (see Fig. 1), taking the production of stainless steel inner composite tube billet as an example, when starting to cast billets, first send the dummy bar 36 into the upper crystallizer 10, and simultaneously put the dummy ring on the dummy bar into the lower After the crystallizer is sealed, the stainless steel water 5 is poured into the upper mold 10 through the upper ladle 6 and the upper casting trough 7, and the stainless steel water immediately forms a billet shell under the quenching of the inner and outer molds, and at the same time moves along with the dummy bar. Moving down, when it moves to the outlet of the upper crystallizer, all the molten steel crystallizes into a tube blank, and the tube blank continues to move down and enters the upper traction roller 11. At this time, the spray device 12 sprays steam and water evenly on the tube blank, so that it is subjected to secondary cooling The tube blank continues to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com