Binder for casting core mould

A binder and casting mold technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of scarring rejection rate, low thermal strength, sand washing and sand inclusion, etc. The effect of reducing the rate and improving the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

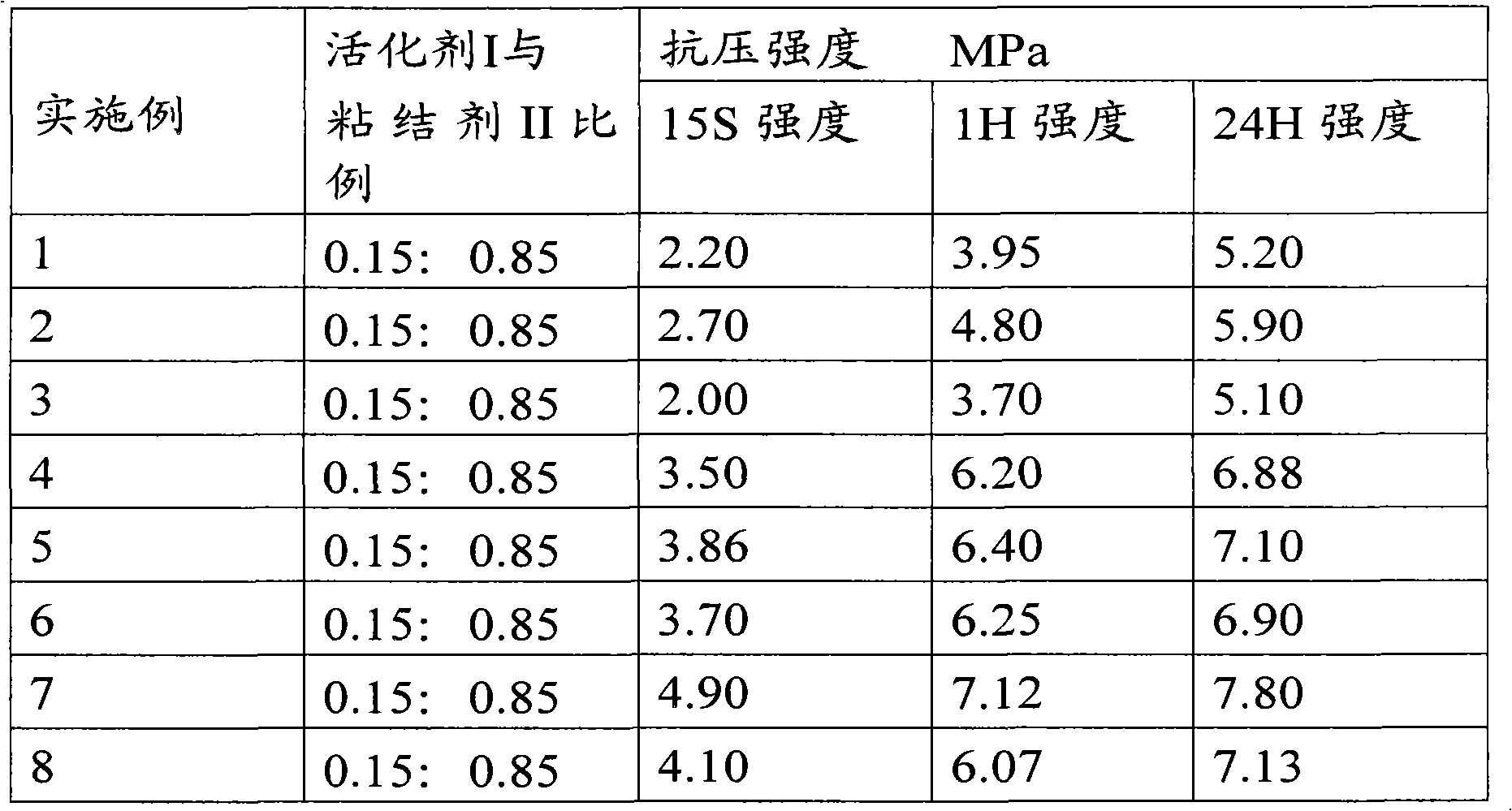

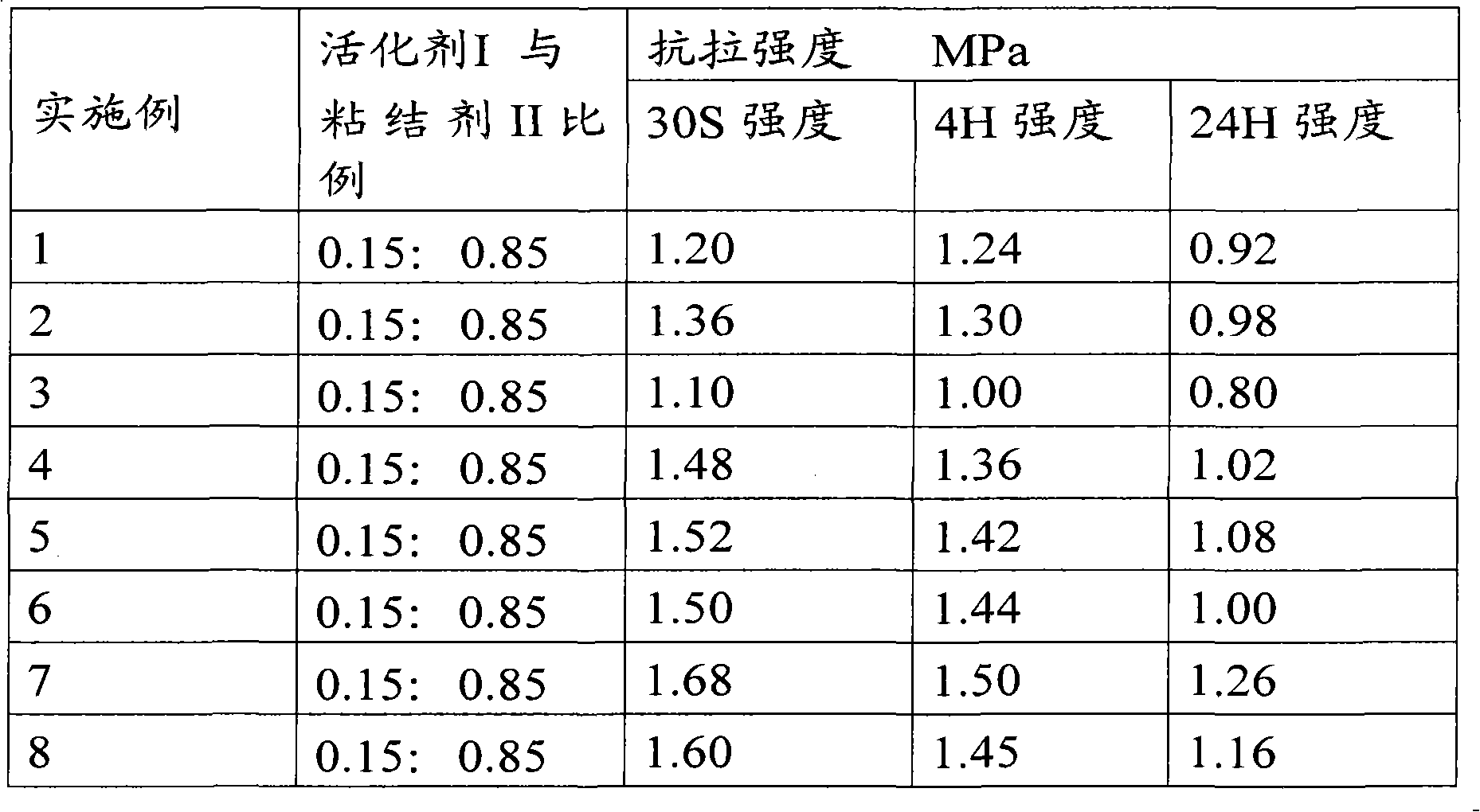

Examples

Embodiment 1-8

[0045] According to the ratio of raw materials listed in Table 1, according to the following method to prepare the cold box binder for sulfur dioxide blow hardening according to the present invention.

[0046] Put the melted benzyl ether phenolic resin into the reaction kettle, heat and stir, and dehydrate under vacuum (vacuum degree is 15mm Hg), until the temperature reaches 120°C and there are no bubbles. Cool down to 60°C, add polyisocyanate;

[0047] Adjust the condenser of the reaction kettle to the reflux state, heat up with steam under stirring, raise the temperature to 70°C within 30 minutes, and keep the reaction at 70-90°C for 180 minutes;

[0048] After the heat preservation is over, cool the material down to 60°C, add epoxy resin, raise the temperature in the kettle to 110°C within 60 minutes, and keep the temperature at 110-150°C for 180 minutes;

[0049] Cool down to 60°C, add acrylate, high-boiling point ester, and hydrocarbon diluent into the mixing kettle, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com