Oxidation type catalyst-assisting regeneration system for diesel particulate filter (DPF)

A technology of oxidation catalytic converter and particle filter, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of poor fuel economy, affecting engine life, and high cost of technical use, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

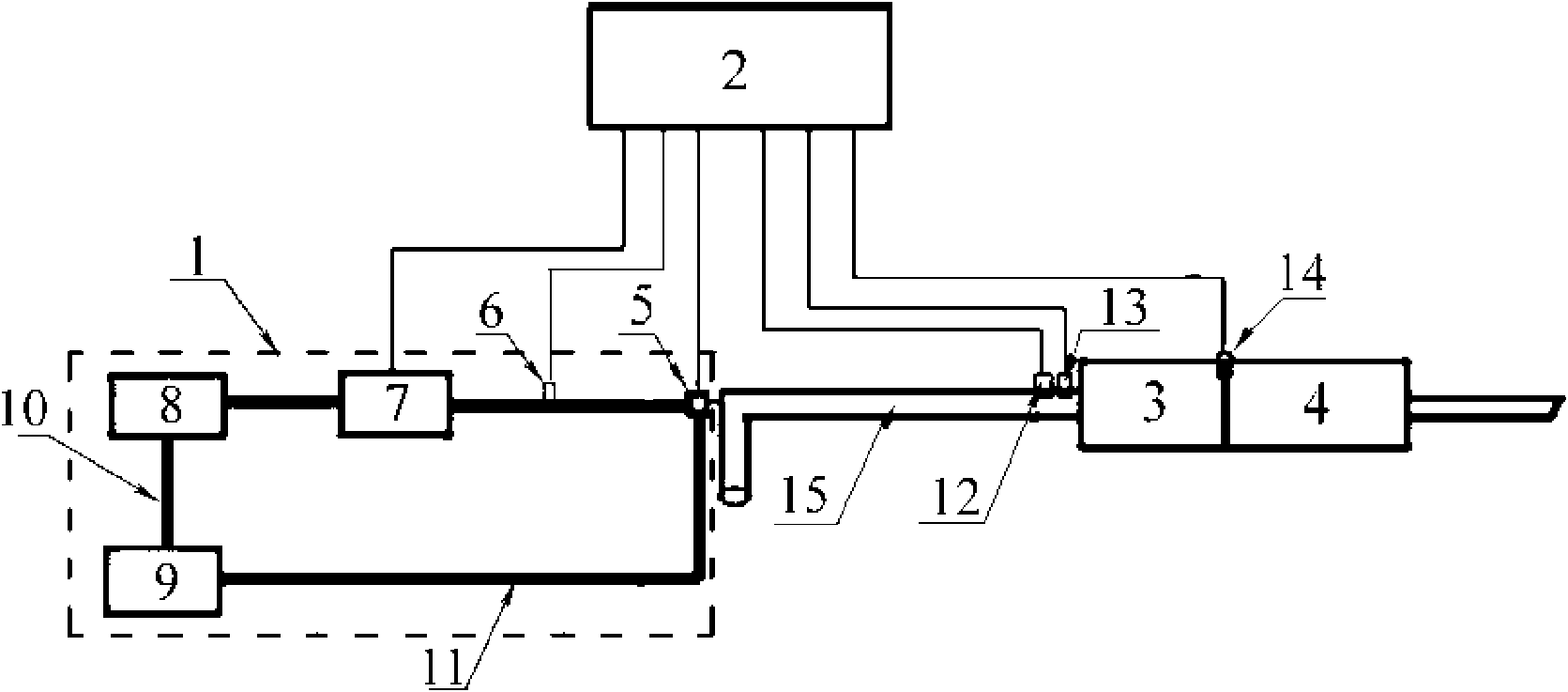

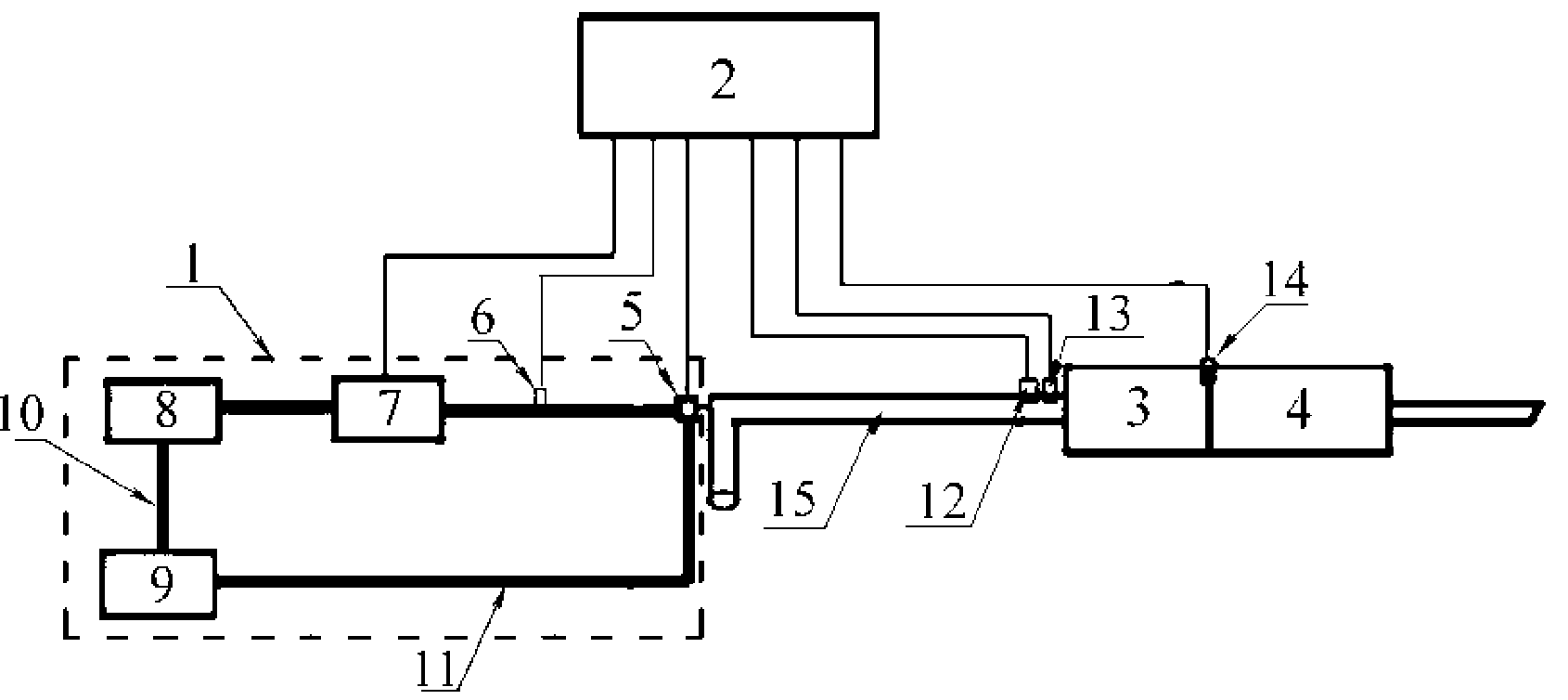

[0012] The diesel particulate matter filter regeneration system of the present invention is as figure 1 As shown, the whole system is composed of fuel injection system 1, control system 2, DOC3 (oxidation catalyst), DPF4, exhaust back pressure sensor 12 and exhaust temperature sensors 13,14. The fuel injection system 1 includes: a nozzle 5, an oil pressure sensor 6, a filter 7, an oil pump 8, a fuel tank 9, an oil inlet pipe 10 and an oil return pipe 11.

[0013] When the DPF4 is in the non-regenerating condition, the oil pump 8 generates a small circulating pressure (300kPa) for cooling the nozzle 5 . When DPF4 needs to be regenerated, the control system 2 judges the regeneration timing and the fuel injection timing according to the exhaust back pressure and the exhaust gas temperature before D0C3. Large cycle pressure (500kPa), nozzle 5 injects diesel oil in DOC3 upstream exhaust pipe 15, and the injected diesel oil and engine exhaust fully mix mist in straight pipe section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com