Low-temperature self-heating method for lithium ion battery

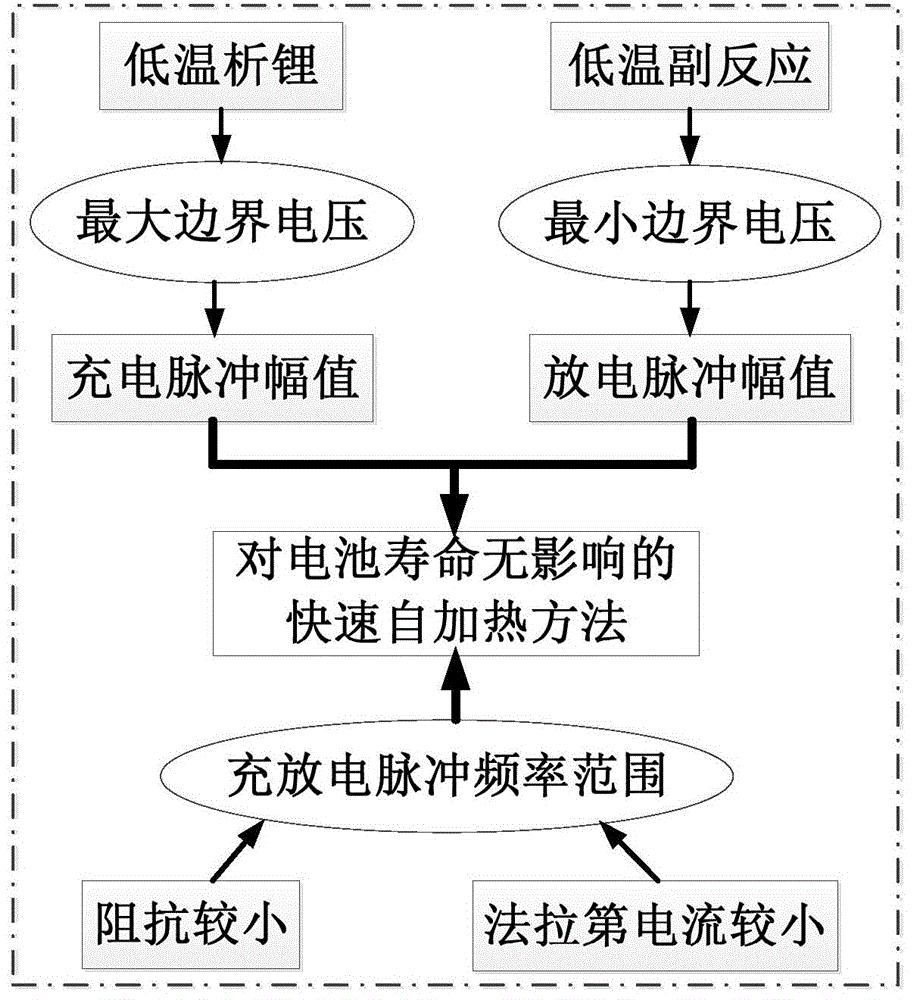

A lithium-ion battery and heating method technology, applied in battery temperature control, secondary batteries, circuits, etc., can solve the problems of large impact on battery service life, low efficiency of external heating methods, high low temperature performance cost, and achieve improved charging performance, Reduced impact, fast self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with a set of embodiments and accompanying drawings.

[0038] The battery in this embodiment may be a lithium manganese oxide power battery, a lithium iron phosphate power battery, a ternary material power battery, etc. used in electric vehicles. Take lithium manganate-ternary hybrid material power battery as an example for illustration.

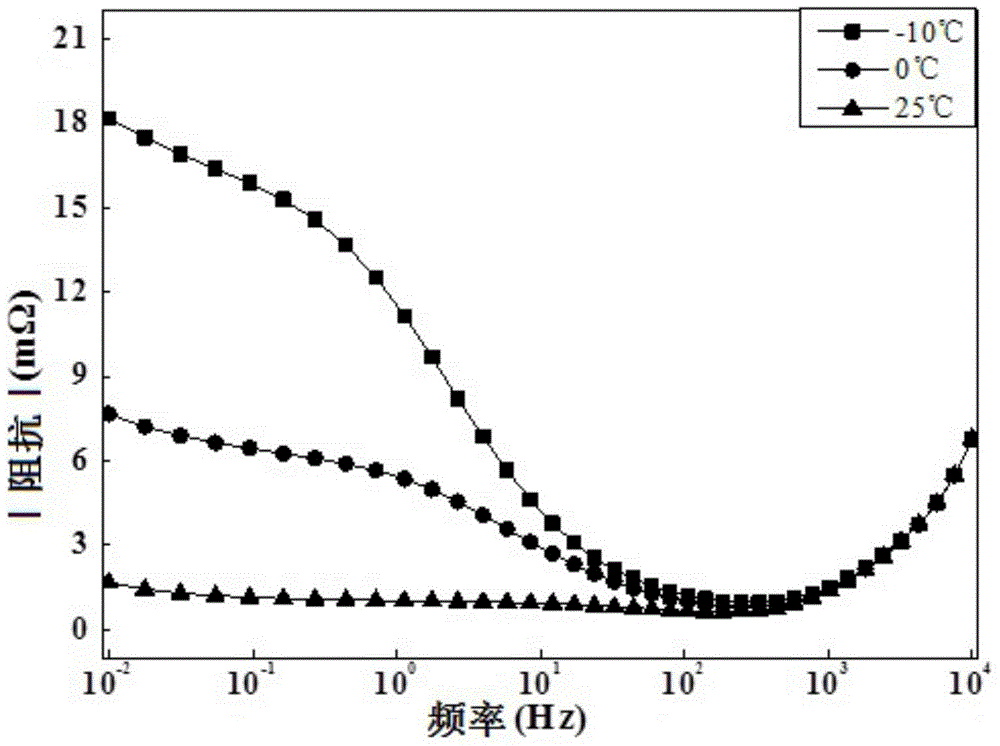

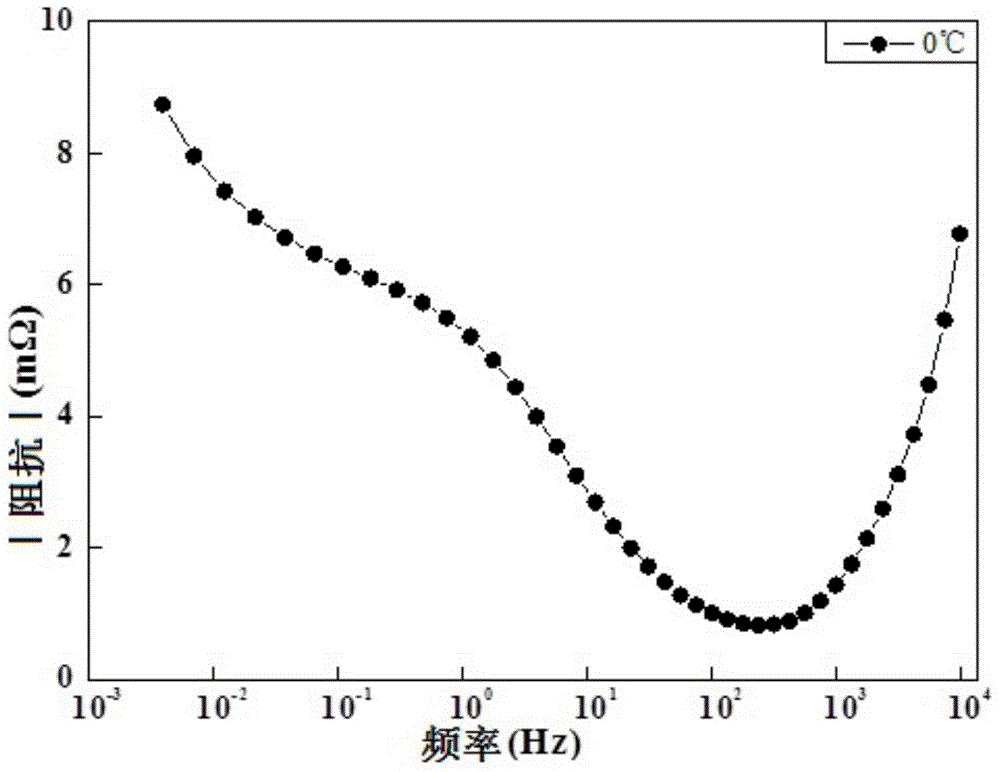

[0039] When the SOC of the lithium-ion battery is 50%, several representative temperature points are selected for impedance spectroscopy test. In this embodiment, the electrochemical workstation is used to test the performance of the lithium-ion battery at -10°C, 0°C, and 25°C. Electrochemical Impedance Spectroscopy, the curve of impedance changing with frequency is obtained as figure 2 As shown, the results show that: at each temperature, with the increase of the frequency, the impedance of the lithium-ion battery first decreases and then increases, so it can be b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com