Vacuum discharge sauce production line

A production line and vacuum technology, applied in applications, food preparation, food science, etc., can solve the problems of easy pollution of sauce, complicated operation, and affecting the quality of sauce, so as to avoid easy blockage of pipelines, avoid oxidative deterioration, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

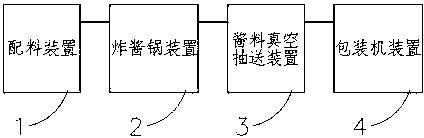

[0012] as attached figure 1 As shown, the vacuum discharge sauce production line of the present invention comprises a batching device 1, a frying sauce pot device 2, a vacuum pumping device 3 and a packaging machine device 4, and is characterized in that: the batching device 1, the frying sauce pot device 2, the vacuum pumping device The device 3 and the packaging machine device 4 are connected by a fully enclosed pipeline in turn; the frying sauce pot device 2 has an upper discharge suction port, and discharges from the upper discharge suction port; the vacuum pumping device 3 has a stirring storage tank and a vacuum device, through The vacuum negative pressure of the stirring storage tank draws the sauce material from the upper discharge suction port of the frying sauce pot device 2 into the stirring storage tank for vacuum storage.

[0013] The upper discharge suction port is located at the position above the middle of the bottom of the frying sauce pot device 2 .

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com