Coater scraper apparatus

A scraper device and coating machine technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of poor applicability, inability to correspond, unfavorable glue thickness control, etc., to ensure the glue thickness and flatness , improve the quality of gluing, and adjust the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

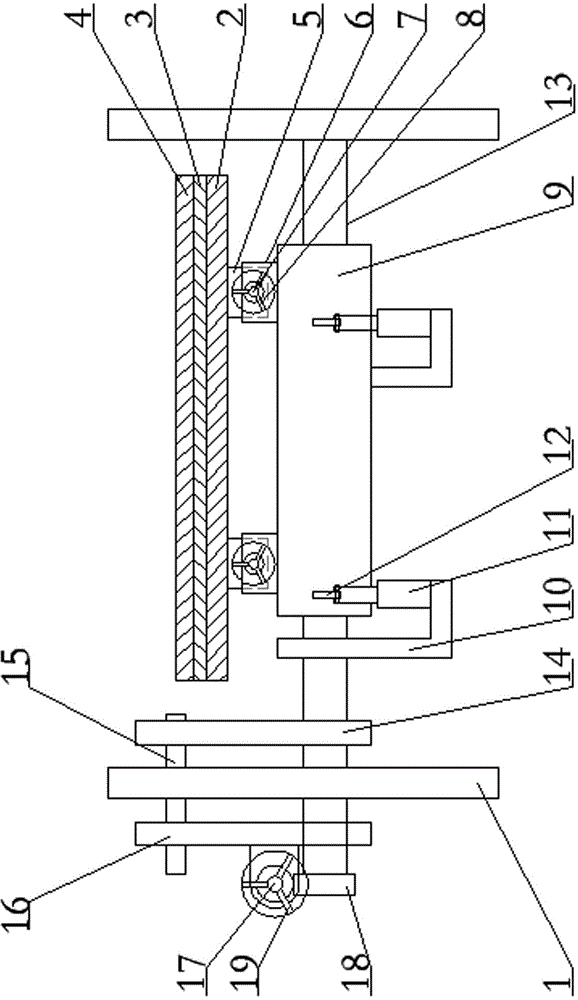

[0018] figure 1 As shown, a coating machine scraper device includes a coating machine frame 1, a scraper pallet 2, a scraper 3, a pressure plate 4, a slider 5, a scraper adjustment seat 6, an adjustment screw 7, an adjustment hand wheel 8, and a scraper frame 9 , cylinder connecting rod 10, fine-tuning cylinder 11, fine-tuning push-pull rod 12, scraper frame adjustment shaft 13, support handle 14, support shaft 15, mounting plate 16, adjustment worm 17, adjustment worm wheel 18 and handwheel 19. A scraper frame adjustment shaft 13 is movable on the coating machine frame 1, and the scraper frame adjustment shaft 13 is fixedly connected with more than one scraper frame 9, and the scraper adjustment seat 6 is connected to the scraper frame 9, and the scraper adjustment seat 6 is provided with To adjust the track, the slider 5 is arranged on the adjustment track, and an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com