Application of zinc impregnation technology in rail suspension steel spring

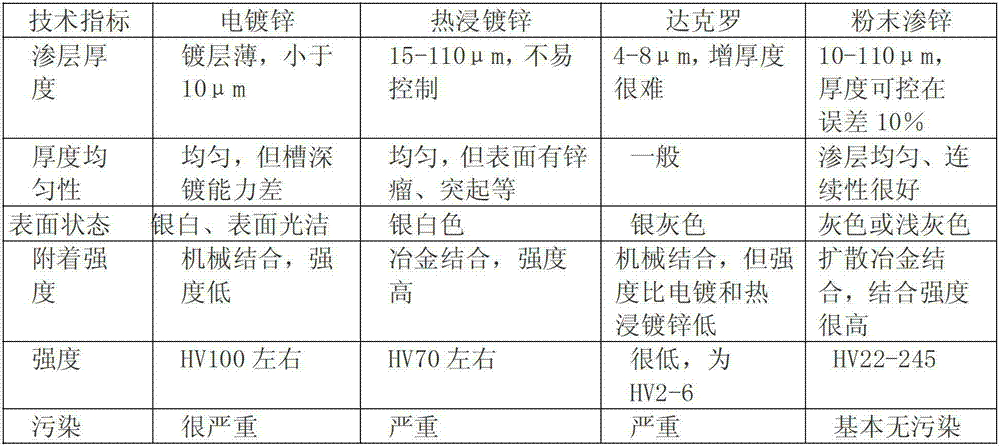

A technology of suspension steel and galvanizing, which is applied in the direction of low internal friction spring, spring/shock absorber, coating, etc., can solve the problems of suspension steel spring corrosion, etc., and achieve strong corrosion resistance, good corrosion resistance, The effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A kind of sherardizing technology applied to railway suspension steel springs, characterized in that: the application of sherardizing technology to railway suspension steel springs, strict control in the spring manufacturing process: strictly control the coverage rate of shot blasting surface treatment to 100% %, in the control of spring tempering temperature and sherardizing temperature: the upper limit of sherardizing temperature < the lower limit of tempering temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com