Car gear shifter with shock absorber

A technology of shock absorbing device and automobile gear shifting, which is applied to components with teeth, transmission device control, belt/chain/gear, etc. It can solve the problem that the rebound sound of the reverse gear lock can not be eliminated and interfere with the shifting noise and other issues to achieve the effect of reducing the cost of modeling and processing and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

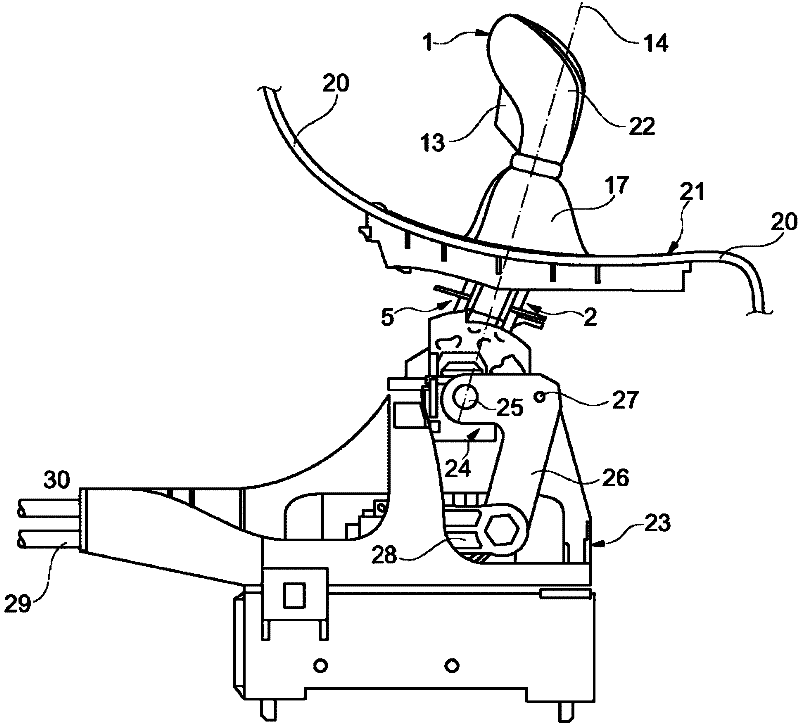

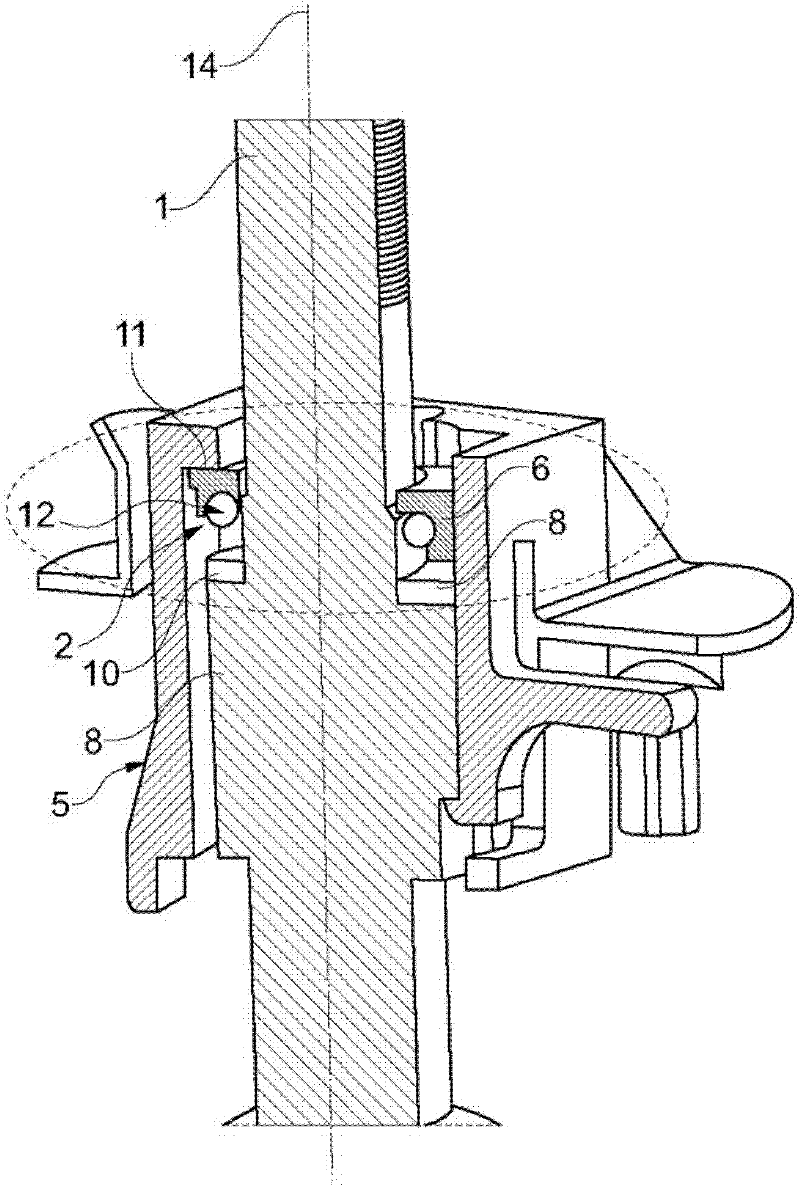

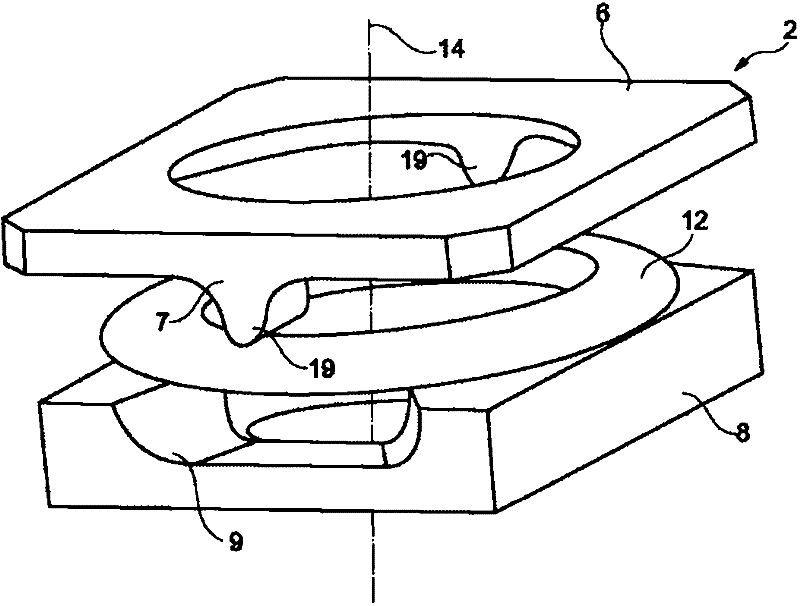

[0029] figure 1 A side view of the automobile shift lever 1 is schematically shown, and its knob 22 protrudes from an opening 21 of the shift bracket 20 . The opening 21 of the shift bracket 20 is covered with a cup 17 so that the actual shift box 23 and the driver's shift mechanism 24 are covered. The shift lever 1 has a shift lever axis 14, which can pass through the supporting ball socket of the shift mechanism 24, from the neutral slot of the shift gate plate into the plane of the drawing or out of the plane of the drawing, and for the inside of the shift gate plate As far as the selector gate or shift gate is concerned, it can be turned in the direction of the left edge of the shift gate and in the direction of the right edge of the selector gate.

[0030] For the neutral slot, a shift toggle pin 25 protruding from the plane of the drawing on the ball joint of the shift lever 1 is hinged with the rocker arm 26, wherein the rocker arm 26 winds around a fixed shaft pin 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com