Snow pushing device

A snow pusher and support device technology, which is applied to snow surface cleaning, construction, cleaning methods, etc., can solve the problems of easy damage of the blade or snow pusher, low reliability, poor adaptability to unevenness, etc., and achieve maintenance Convenience, high structural reliability, and the effect of improving snow removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

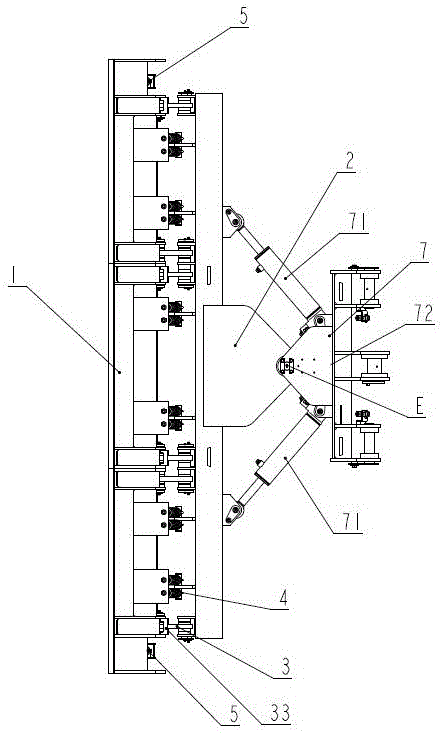

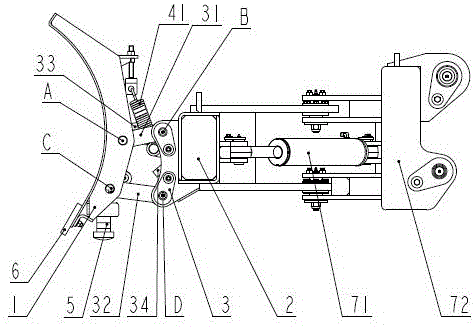

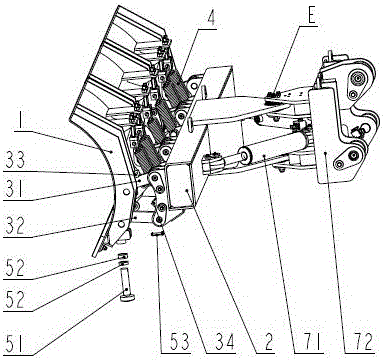

[0018] Such as figure 1 , figure 2 , image 3 As shown, a snow pusher includes a snow pusher 1, a support device 2 and a linkage mechanism 3, the snow pusher 1 is connected to the support device 2, and the other end of the support device 2 is hinged to the main machine; The snow pusher 1 is connected with the support device 2 through a link mechanism 3, and the link mechanism 3 includes an upper link 31, a lower link 32, an upper limit 33 and a lower limit 34; one end of the upper link 31 is connected to The snow pusher 1 is hinged at point A, and the other end is hinged with the support device 2 at point B; one end of the lower link 32 is hinged with the snow pusher 1 at point C, and the other end is hinged with the support device 2 2. Hinged at point D; the points A and B are above points C and D; the upper limit 33 is set on the back of the snow pusher 1 and is located within the movement range of the upper link 31. The range of motion of the upper link 31 prevents the ...

Embodiment 2

[0020] Such as figure 1 , figure 2 , image 3 As shown, a snow pusher includes a snow pusher 1, a support device 2, a link mechanism 3 and a reset device 4, the snow pusher 1 is connected to the support device 2, and the other end of the support device 2 is connected to the host The snow pusher 1 is connected to the supporting device 2 through a link mechanism 3, and the link mechanism 3 includes an upper link 31, a lower link 32, an upper limit 33 and a lower limit 34; the upper link One end of the rod 31 is hinged to the snow pusher 1 at point A, and the other end is hinged to the support device 2 at point B; one end of the lower link 32 is hinged to the snow pusher 1 at point C, and the other end is hinged to the The support device 2 is hinged at point D; the points A and B are above points C and D; the upper limit 33 is set on the back of the snow pusher 1 and is located within the range of movement of the upper link 31 , which prevents the snow pusher 1 from turning b...

Embodiment 3

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a snow pusher includes a snow pusher 1, a support device 2, a link mechanism 3, an adjustment device 5, a movable blade 6 and a swing device 7, and the snow pusher 1 is connected to the support device 2, The other end of the support device 2 is hinged to the main engine; the snow pusher 1 and the support device 2 are connected through a link mechanism 3, and the link mechanism 3 includes an upper link 31, a lower link 32, and an upper limit 33 and the lower limit 34; one end of the upper link 31 is hinged with the snow pusher 1 at point A, and the other end is hinged with the support device 2 at point B; one end of the lower link 32 is hinged with the snow pusher 1 is hinged at point C, and the other end is hinged with the support device 2 at point D; the points A and B are above points C and D; the upper limit 33 is set on the back of the snow pusher 1 and is located at the Within the range of motion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com