Photovoltaic bracket for double-T plate plant roof

A technology for photovoltaic supports and workshops, which is applied to the support structure of photovoltaic modules, roofs, and roofs using tiles/slate tiles, etc., which can solve the problem of restricting the design and installation of photovoltaic support structures, weak wind load overturning force, and failure to report To reduce the risk of load-bearing, strong overturning resistance under wind load, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

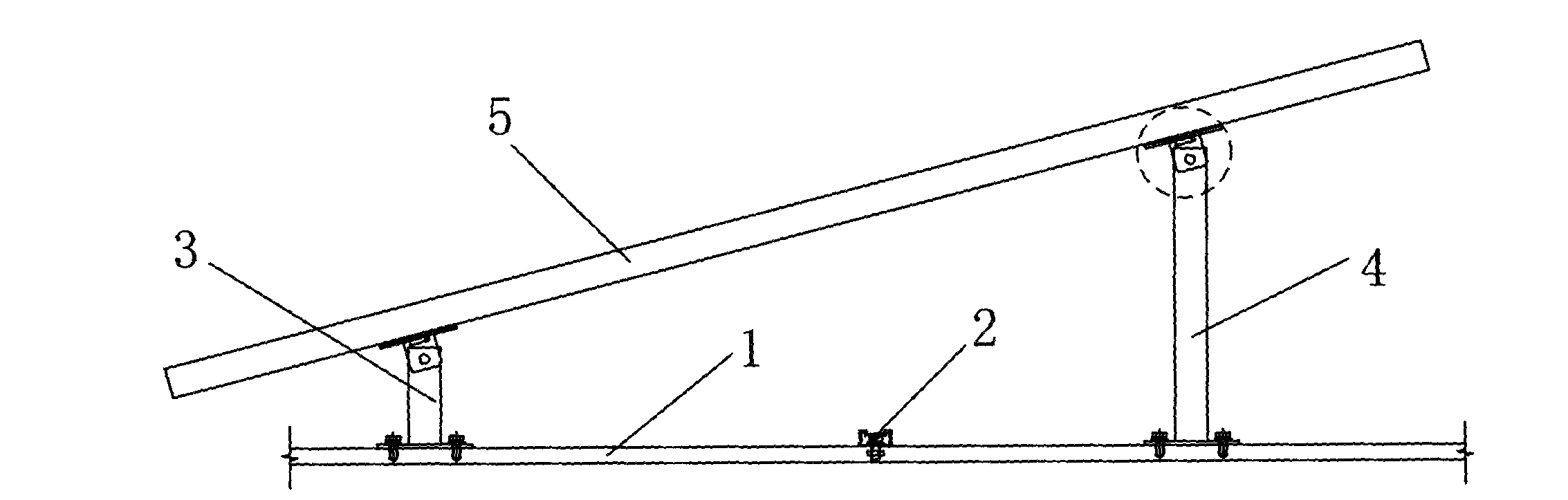

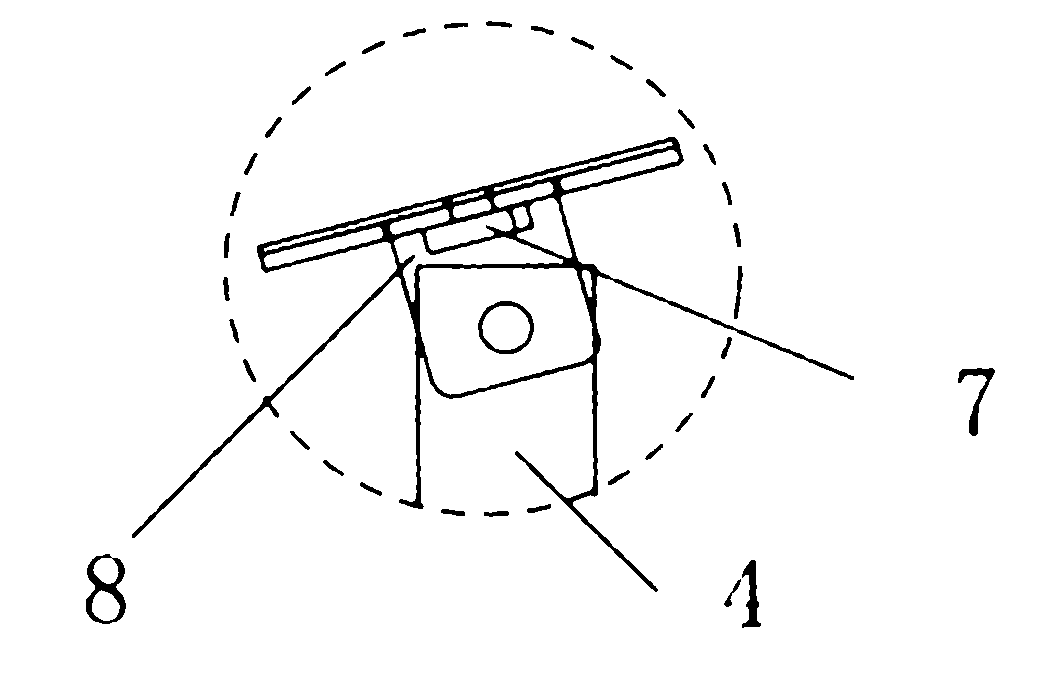

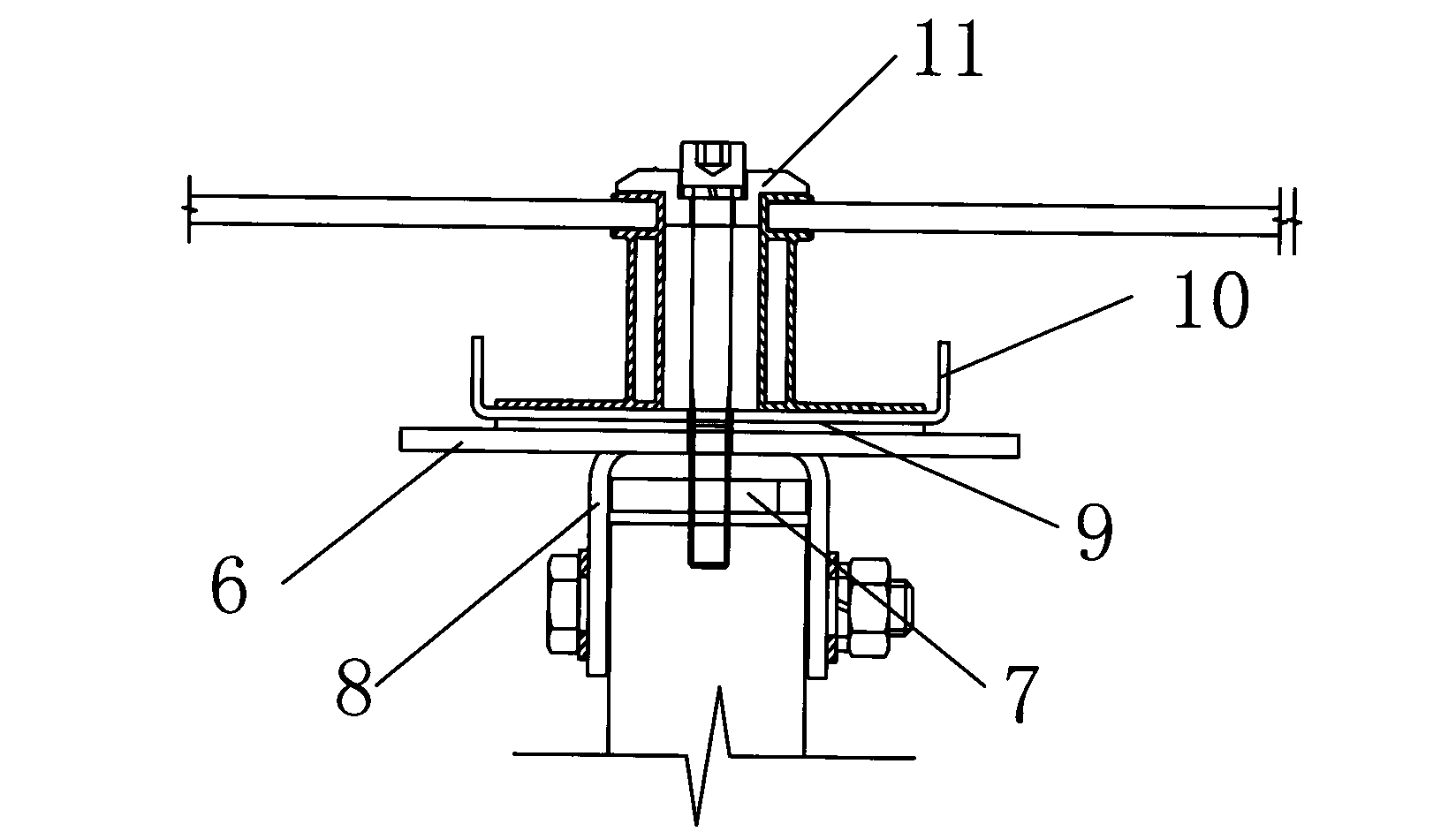

[0023] Such as Figure 1-3 The photovoltaic support on the roof of a double T-plate factory building includes a vertical ground grid 1, and a horizontal ground grid 2 is distributed across the vertical ground grid 1. The difference is that: on one side of the vertical ground grid 1 The front support 3 is distributed, and the rear support 4 is distributed on the other side of the vertical ground net 1. The front support 3, the rear support 4 and the horizontal ground net 2 intersect to form a "well" network, and the positioning is stable. At the same time, in order to connect the corresponding external components, a pressing block component 11 is arranged on the top of the front support 3 and the rear support 4 . An inclined bearing plate 5 is connected to the pressing block assembly 11 by screws. Specifically, the front support 3 can raise the inclined bearing plate 5 to form an inclination angle with the rear support 4 , and the rear support 4 can also raise the inclined bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com