Self-heating container

a self-heating container and container technology, applied in the field of containers, can solve the problems of affecting the quality of the seal, requiring many parts to be sealed, and complex assembly, and achieve the effect of cost-effective manufacturing and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

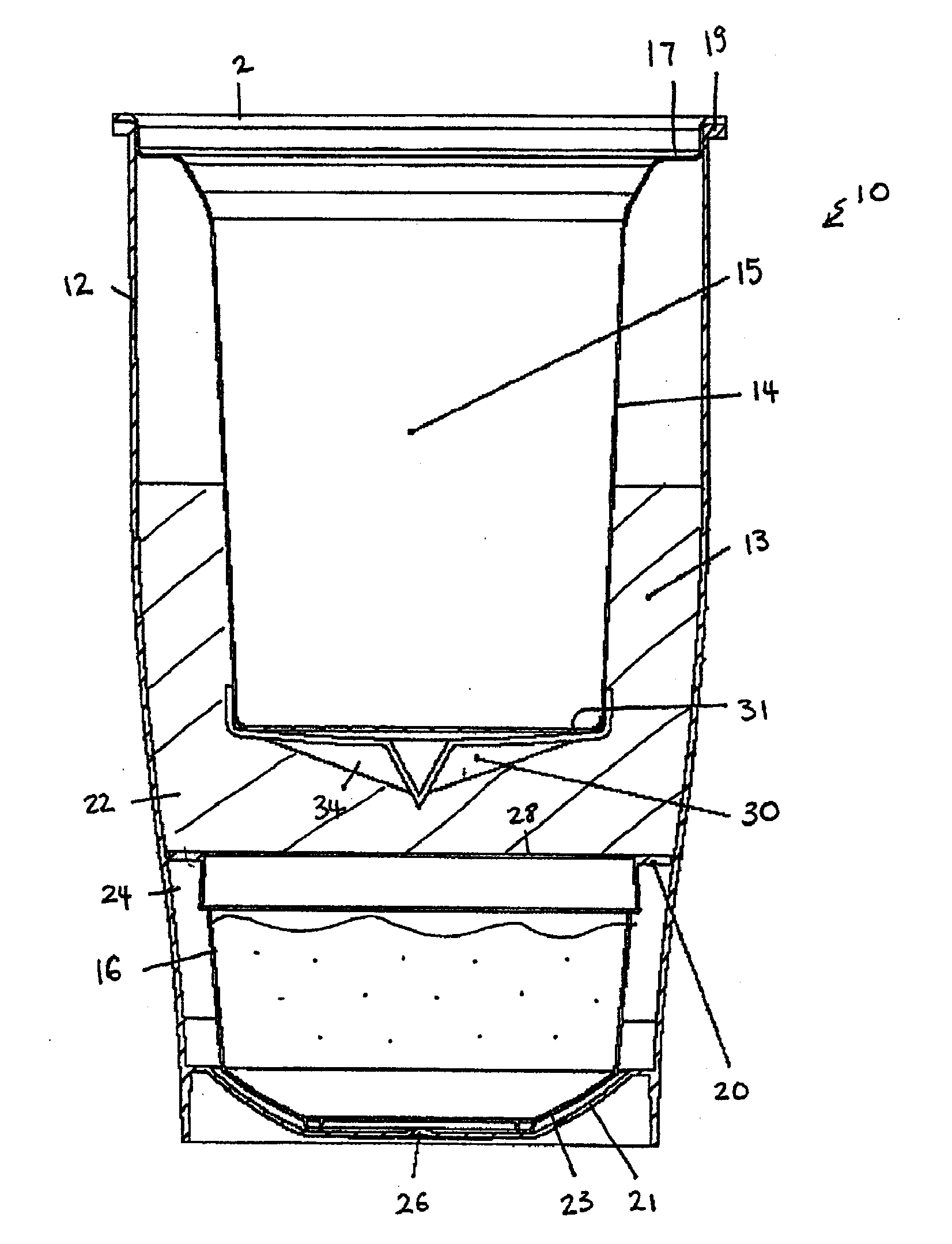

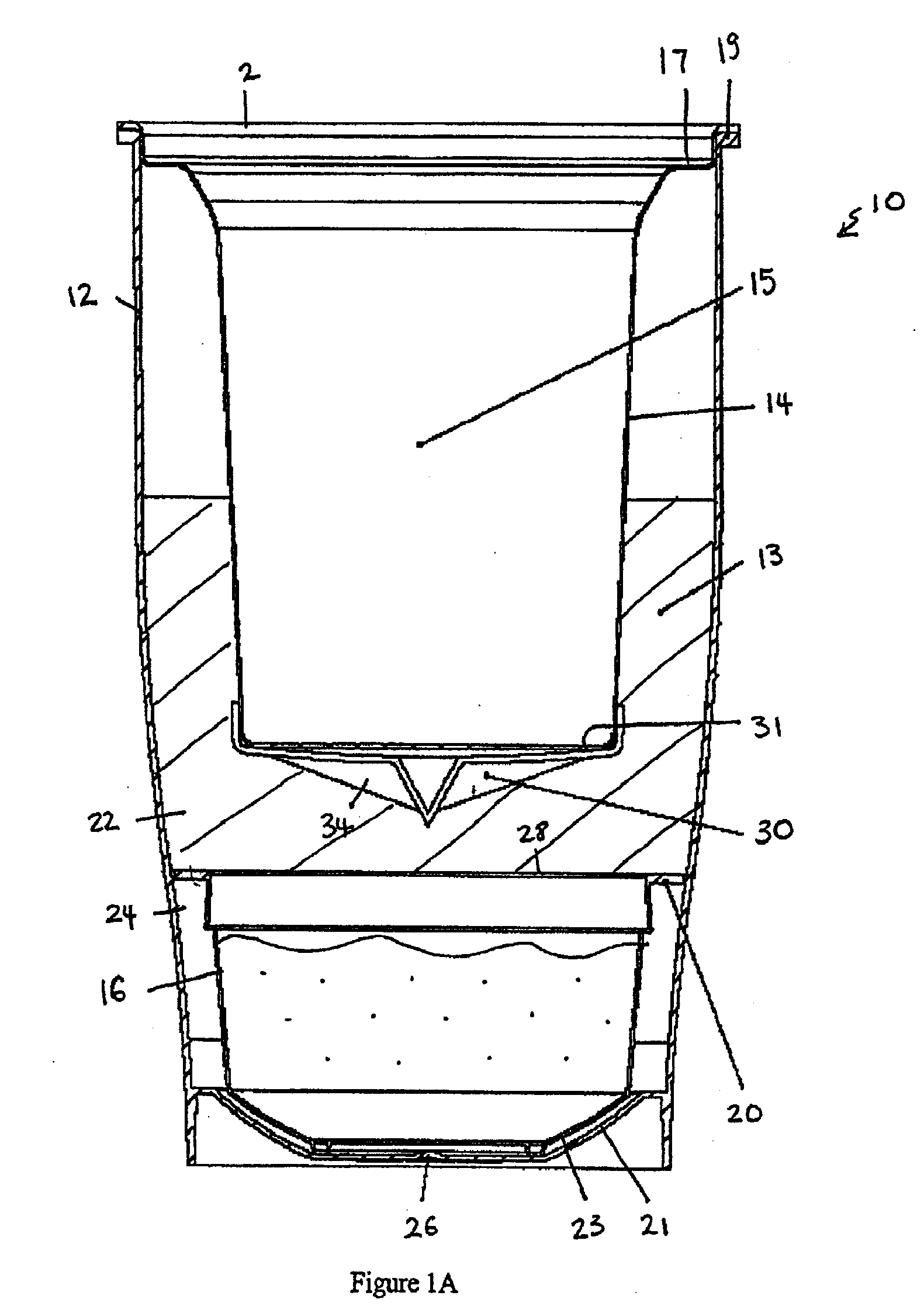

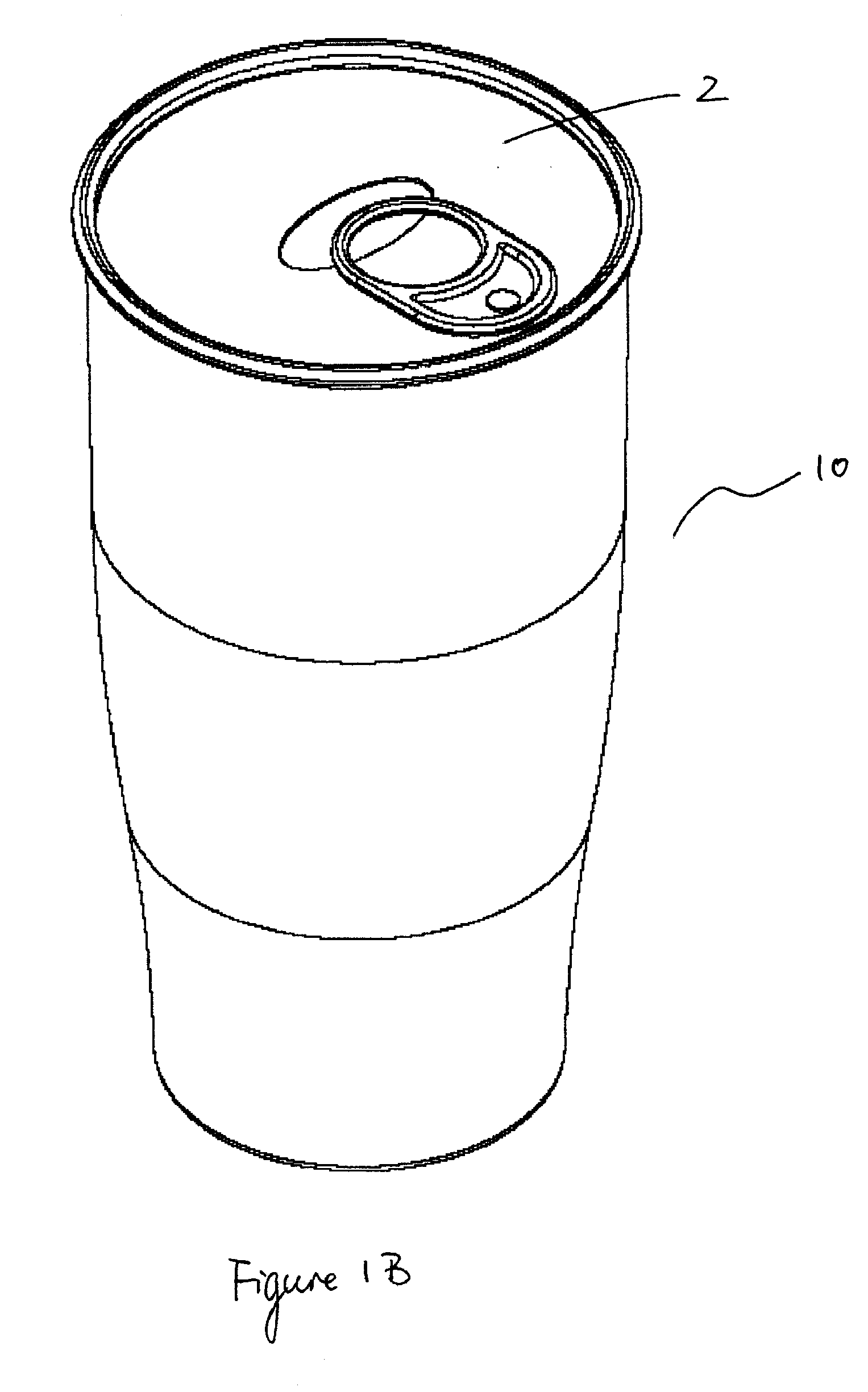

[0050] Referring to FIG. 1A, in one embodiment of the present invention, a container 10 includes an outer container body 12 defining a first chamber 13, an inner container body 14 defining a second chamber 15 disposed within the outer container body 12, and a reactant vessel 16 disposed within the first chamber 13. The inner container body 14 holds the beverage, food item, or other substance to be heated. A lid 2 covering the inner container body 14 maintains the substance inside the second chamber 15. It would be desirable to construct the inner container body 14 with a material having high thermal conductivity. For example, the inner container body 14 can be constructed of a metallic material such as aluminum or certain polymeric material such as polyolefin. In a preferred embodiment, the inner container body 14 defines a second chamber 15 which is able to hold liquid capacity of greater than 100 mL and in a more preferred embodiment, liquid capacity of greater than 200 mL of liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com