Self-heat-insulating concrete building block

A self-insulating block and concrete technology, which is applied in the field of building wall materials, can solve problems such as difficulty in achieving energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

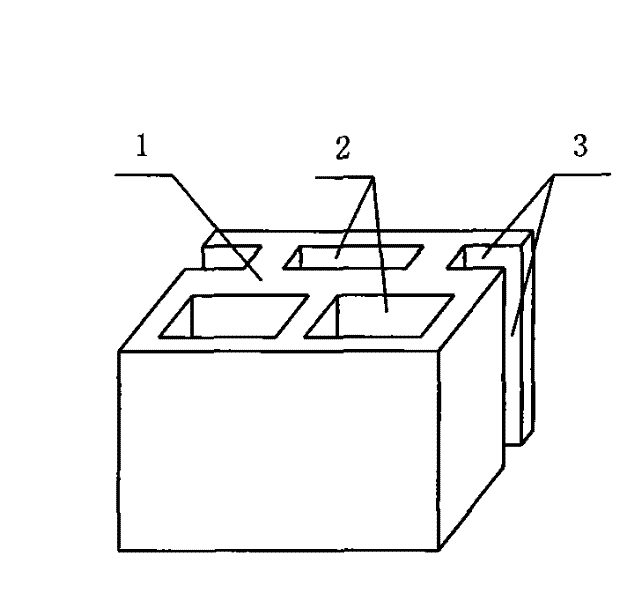

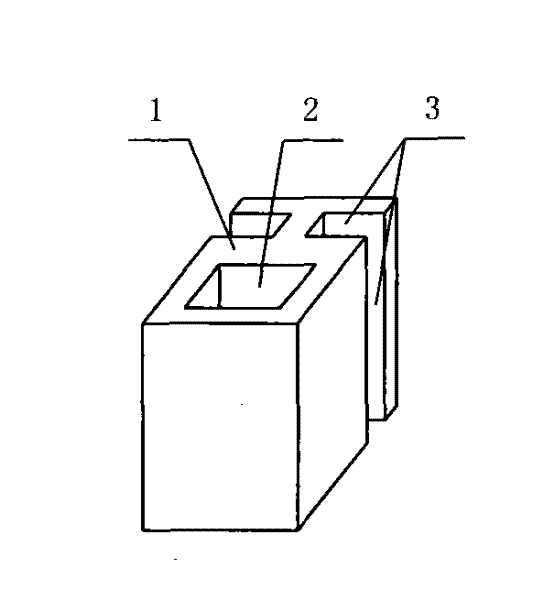

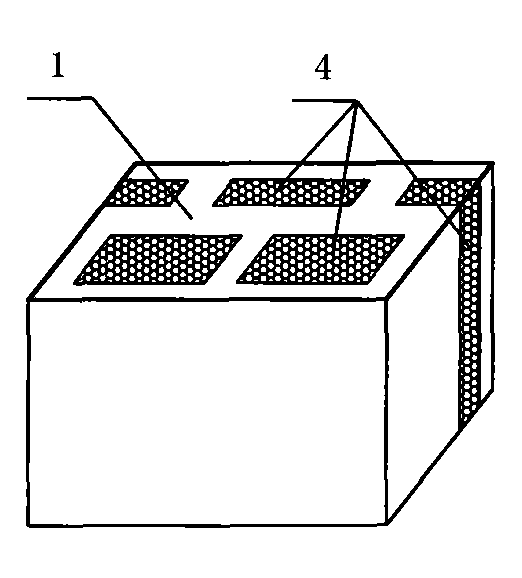

[0014] according to figure 1 and figure 2 As shown, the fine stone concrete is used, poured into the mold, and after curing, the main specification concrete hollow block and the auxiliary specification concrete hollow block, that is, the semi-finished product. Then, insert foam plastic blocks in the heat insulation through holes and heat insulation grooves of the semi-finished product, and the finished product is a concrete self-insulation block main specification block (such as image 3 shown) and a concrete self-insulating block auxiliary specification block (such as Figure 4 shown). It does not have cold bridges, and its wall masonry plan is as follows Figure 5 As shown, the elevation of the wall masonry is shown in Image 6 As shown, the energy-saving effect of the thermal insulation wall is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com