Heat insulation and decoration integrated curtain wall plate

A technology of curtain wall panels and thermal insulation cotton, which is applied to walls, building components, coverings/linings, etc., can solve problems such as waste of resources, poor fire resistance, and poor aging resistance, and achieve tight, reliable and firm connections, and excellent thermal insulation performance , the effect of strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

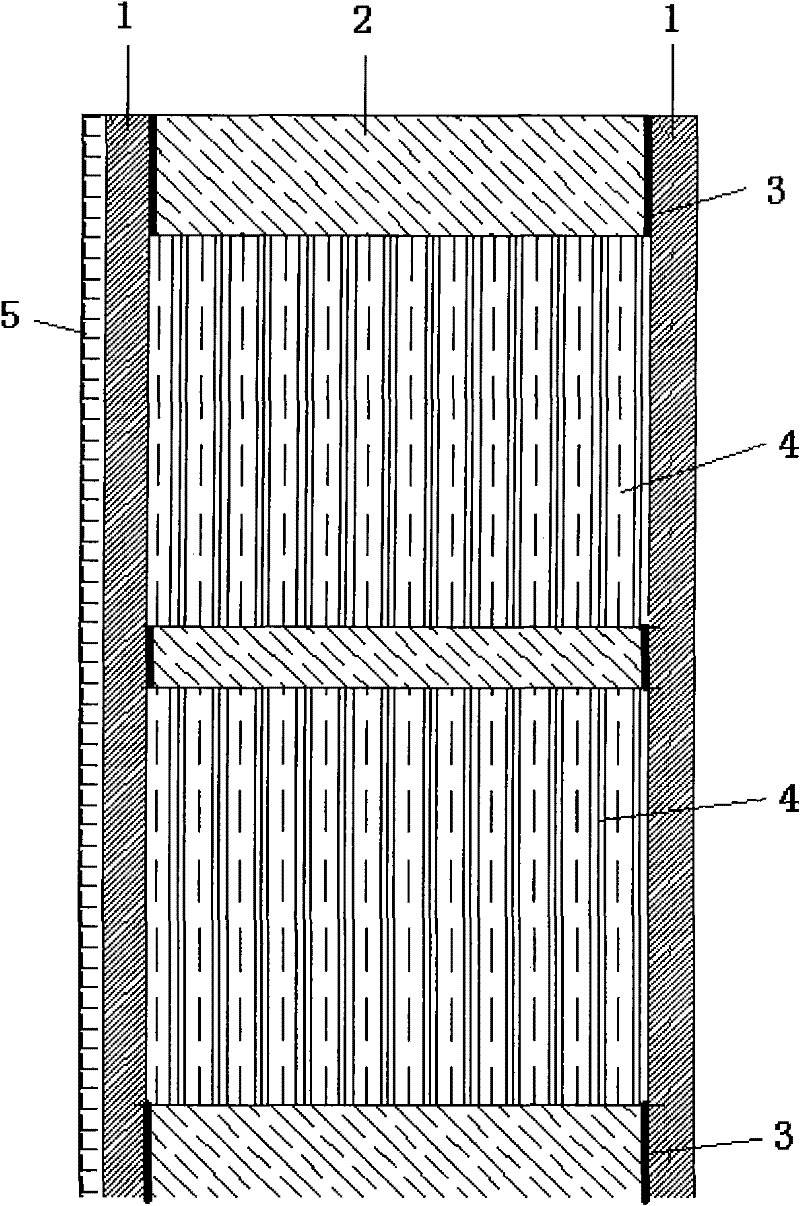

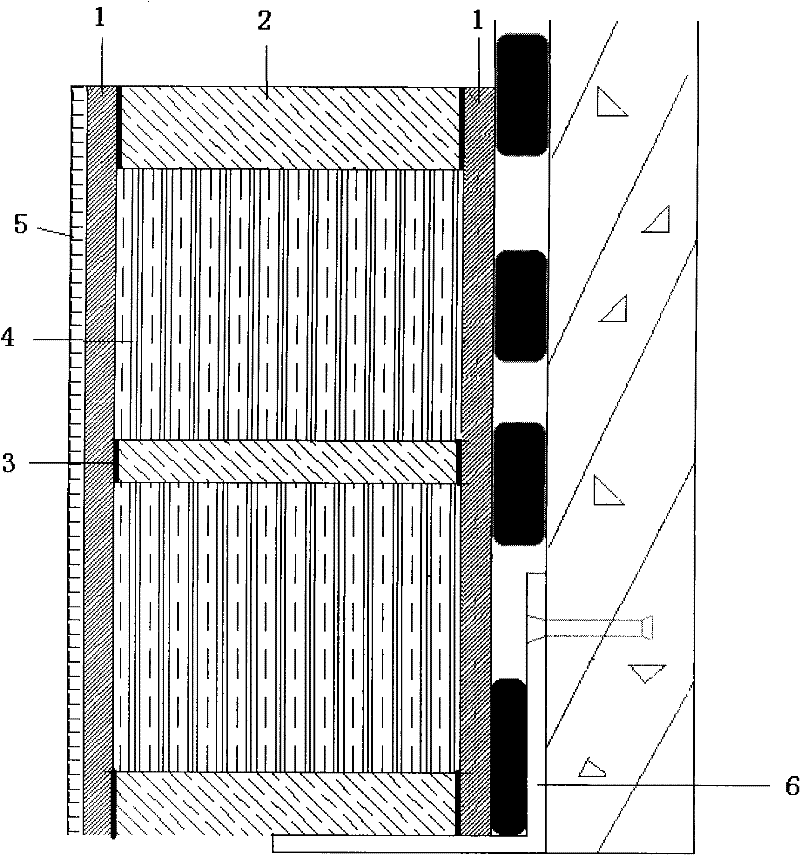

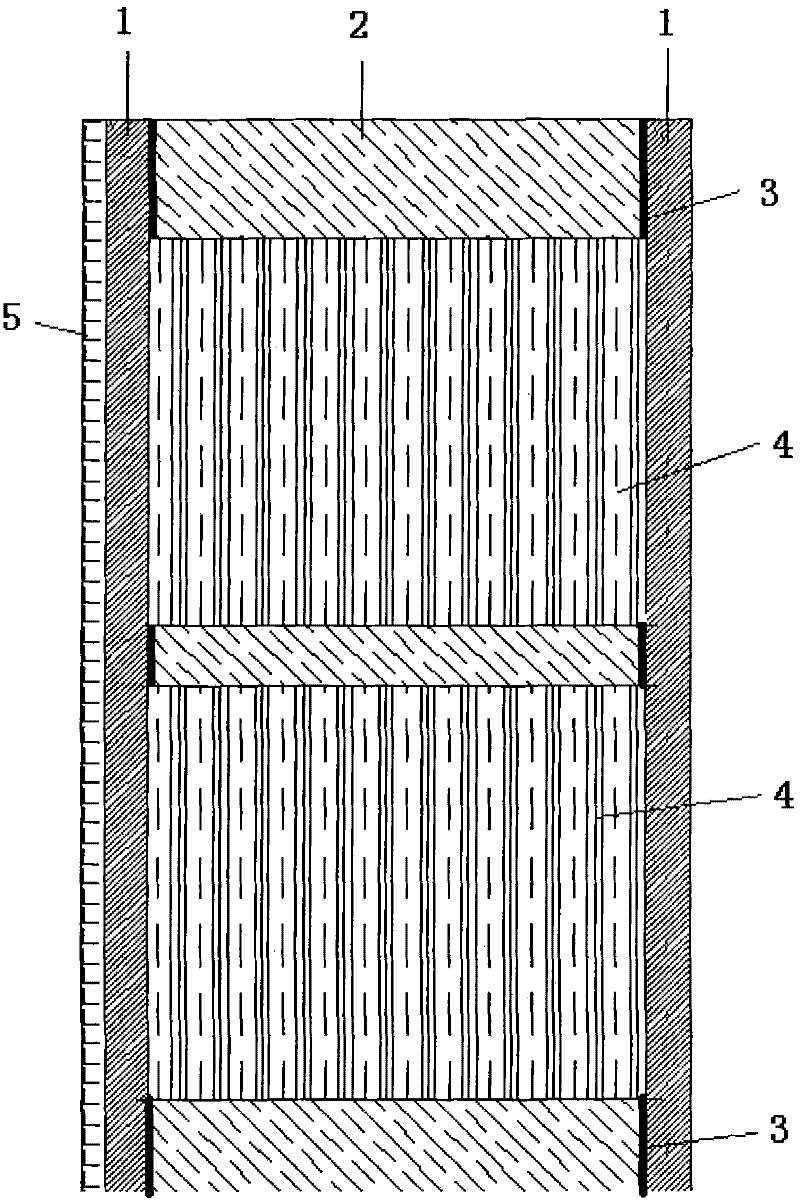

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation.

[0014] The present invention aims to use non-combustible material as insulation layer, while using non-combustible material as protective layer. Therefore, the present invention selects a high-strength and weather-resistant A1 grade non-combustible material—cement fiber board 1 as the protective layer of the curtain wall board. The base layer of the surface layer. There is a certain gap between the two layers of cement fiber boards 1, and adiabatic foamed glass 2 is arranged in the gap. The heat-insulating foam glass 2 is used as the connecting material between the upper and lower layers of cement fiber boards. First, because it and the cement fiber boards are both inorganic materials, they are bonded with polymer cement mortar 3 to ensure a tight and stable connection. It has reliable connection performance; secondly, due to the high compressive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com