Wear-resistant roll and manufacture method thereof

A roll and preparation process technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of uneven distribution of eutectic carbides, poor fatigue performance of carbides, and reduced service life of rolls. Good abrasion resistance and improved fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

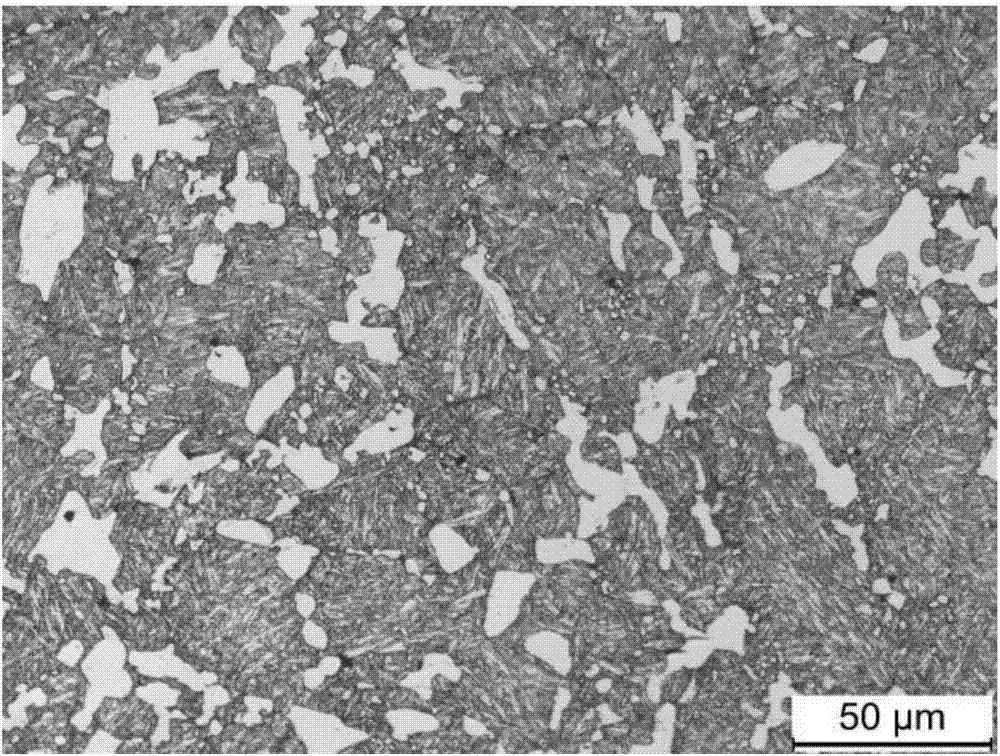

Image

Examples

Embodiment 1

[0025] A wear-resistant roll and a preparation method thereof, characterized in that it is smelted in a 3-ton power-frequency induction furnace, and the specific preparation process steps are:

[0026] ① Use scrap steel, pig iron, ferrochrome, nickel plate, ferrotungsten, ferro-niobium, ferrosilicon, ferromanganese and metal aluminum as ingredients, firstly mix ferro-tungsten, ferro-niobium, scrap steel, pig iron and nickel plate in the furnace and heat and melt them. After all the materials are melted, add ferrochrome. After the ferrochrome is melted, raise the temperature of the molten iron to 1532°C, then add ferrosilicon, ferromanganese and metal aluminum in sequence, and remove slag from the molten iron at 1563°C and test its composition. Its mass fraction is 3.28%C, 2.44%Cr, 0.064%Nb, 3.95%Ni, 2.19%W, 0.88%Al, 0.72%Si, 0.51%Mn, 0.031%S, 0.034%P, the balance Fe and unavoidable When there are impurities, the molten iron is taken out of the furnace to the ladle, and the cop...

Embodiment 2

[0029] A wear-resistant roll and a preparation method thereof, characterized in that it is smelted in a 1.5-ton medium-frequency induction furnace, and the specific preparation process steps are:

[0030] ① Use scrap steel, pig iron, ferrochrome, nickel plate, ferrotungsten, ferro-niobium, ferrosilicon, ferromanganese and metal aluminum as ingredients, firstly mix ferro-tungsten, ferro-niobium, scrap steel, pig iron and nickel plate in the furnace and heat and melt them. After all the materials are melted, add ferrochrome. After the ferrochrome is melted, heat the molten iron to 1555°C, then add ferrosilicon, ferromanganese and metallic aluminum in sequence, and remove the slag at 1587°C and test the composition. Its mass fraction is 3.63%C, 2.15%Cr, 0.095%Nb, 4.38%Ni, 2.56%W, 0.69%Al, 0.99%Si, 0.25%Mn, 0.028%S, 0.037%P, the balance Fe and unavoidable When there are impurities, the molten iron is taken out of the furnace to the ladle, and the copper-magnesium alloy (the chemic...

Embodiment 3

[0033] A wear-resistant roll and a preparation method thereof, characterized in that it is smelted in a 1000 kg medium-frequency induction furnace, and the specific preparation process steps are:

[0034] ① Use scrap steel, pig iron, ferrochrome, nickel plate, ferrotungsten, ferro-niobium, ferrosilicon, ferromanganese and metal aluminum as ingredients, firstly mix ferro-tungsten, ferro-niobium, scrap steel, pig iron and nickel plate in the furnace and heat and melt them. After all the materials are melted, add ferrochrome. After the ferrochrome is melted, heat the molten iron to 1547°C, then add ferrosilicon, ferromanganese and metal aluminum in sequence, and remove the slag at 1574°C and test the composition. Its mass fraction is 3.47%C, 2.36%Cr, 0.088%Nb, 4.20%Ni, 2.32%W, 0.75%Al, 0.79%Si, 0.46%Mn, 0.033%S, 0.029%P, the balance Fe and unavoidable When there are impurities, the molten iron is taken out of the furnace to the ladle, and the copper-magnesium alloy (the chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com