Method for enriching niobium from titanium-containing ferrocolumbium concentrate through dressing-metallurgy combination

A combination of dressing and smelting, iron ore concentrate technology, applied in the fields of mining, metallurgy and resource comprehensive utilization, can solve the problems of low niobium ferroniobium content, reduced yield, increased energy consumption per unit of product, etc., to achieve high production efficiency, reaction Fast, easy-to-automate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

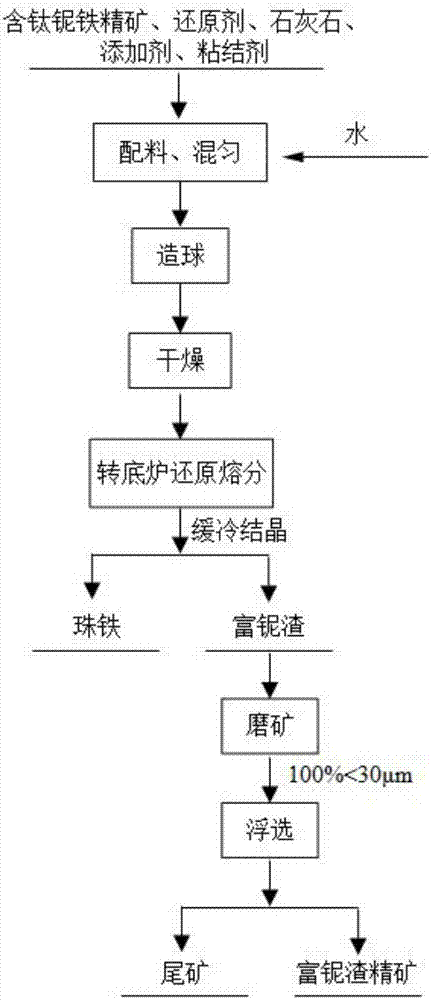

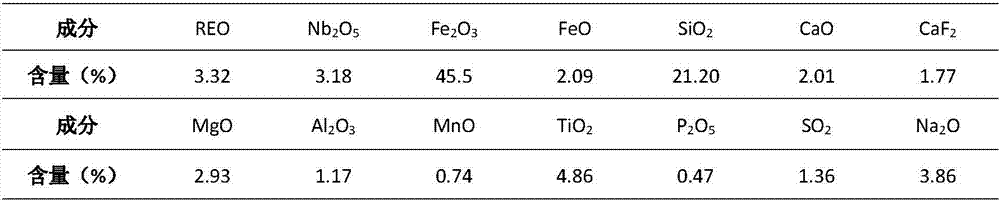

[0024] according to figure 1 process flow shown, will contain Nb 2 o 5 3.18% low-niobium niobium ferro-niobium concentrate ore powder, coal powder with a weight of 12% of the niobium-iron concentrate weight, CaCO with a weight of 30% of the niobium-iron concentrate weight 3 , industrial pure Na with a weight of 1% by weight of ferroniobium concentrate 2 CO 3 , the binder whose weight is 2% of the ferroniobium concentrate weight is conveyed to the mixer through a belt for mixing, and the moisture content of the mixed material is adjusted to 7%. The mixed material is conveyed to the double-roller ball pressing machine through the belt to make carbon-containing pellets, the pressure is 15MPa, and the size of the pellets is 40×30×20mm pillow-shaped ellipsoid. The raw balls are dried and spread on the carbonaceous refractory material of the rotary hearth furnace in a single layer, and a layer of 10-20mm thick carbonaceous powder is laid on the carbonaceous refractory material i...

Embodiment 2

[0028] according to figure 1 process flow shown, will contain Nb 2 o 5 6.40% titanium-containing ferro-niobium concentrate ore powder with higher niobium content, coal powder with a weight of 12% by weight of ferro-niobium concentrate, CaCO with a weight of 30% by weight of ferro-niobium concentrate 3 , industrial pure Na with a weight of 1% by weight of ferroniobium concentrate 2 CO 3 , the binder whose weight is 2% of the ferroniobium concentrate weight is conveyed to the mixer through a belt for mixing, and the moisture content of the mixed material is adjusted to 7%. The mixed material is conveyed to the double-roller ball pressing machine through the belt to make carbon-containing pellets, the pressure is 15MPa, and the size of the pellets is 40×30×20mm pillow-shaped ellipsoid. The raw balls are dried and spread on the carbonaceous refractory material of the rotary hearth furnace in a single layer, and a layer of 10-20mm thick carbonaceous powder is laid on the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com