Efficient nickel base welding rod special for ultralow temperature steel welding of LNG (liquefied natural gas) ship

A technology for nickel-based welding rods and LNG ships, which is applied in the direction of welding/welding/cutting items, welding media, welding equipment, etc., can solve the problems that limit the development of 9Ni steel welding technology, and achieve thermal stress avoidance, good slag removal, and arc stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

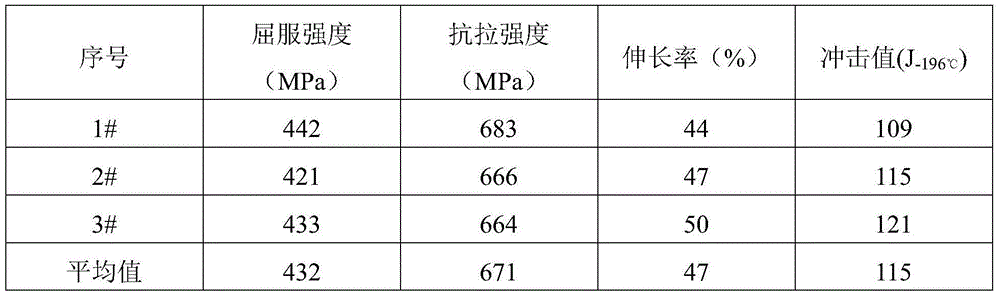

Examples

Embodiment Construction

[0025] The following examples of the present invention are described in detail. The following examples provide detailed implementation and specific operation process on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following examples.

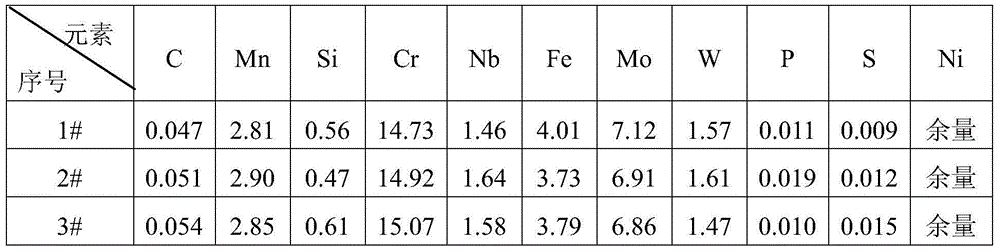

[0026] The invention provides a high-efficiency nickel-based electrode specially used for welding ultra-low temperature steel of LNG ships, which includes a welding core and a coating covering the surface of the welding core. The welding core uses a nickel alloy welding core, the chemical composition and weight percentage of the welding core are: C≤0.03%, S≤0.01%, P≤0.01%, Mn: 0.5-1.5%, Mo: 4-9%, Nb: 1.5-2.5%, Si≤0.25%, Fe≤1.0%, Cr: 12-18%, the balance is Ni, and the total amount of each component is 100%.

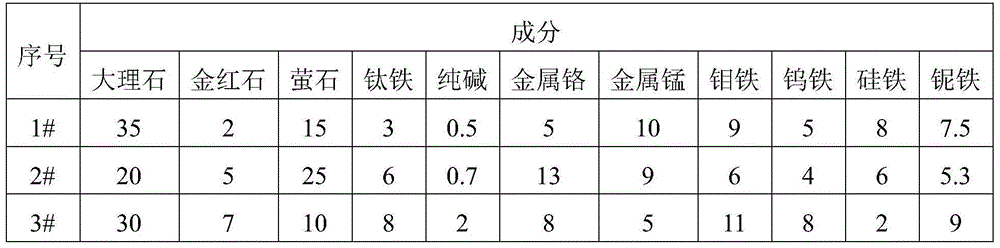

[0027] The composition and weight percentage of the powder in the coating are: 20-35% of marble, 2-7% of rutile, 10-25% of fluorite, 5-13% of metal ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com