Flux-cored wire for titanium- or niobium-contained austenitic stainless steel welding

A technology of niobium austenite and stainless steel, which is applied in the welding field of material processing engineering, can solve the problems of reducing the strength and corrosion resistance of welded joints, stress concentration of weld seams, and failure of stainless steel components, so as to achieve excellent welding process performance and reduce oxidation Good effect on burning loss and weld seam forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

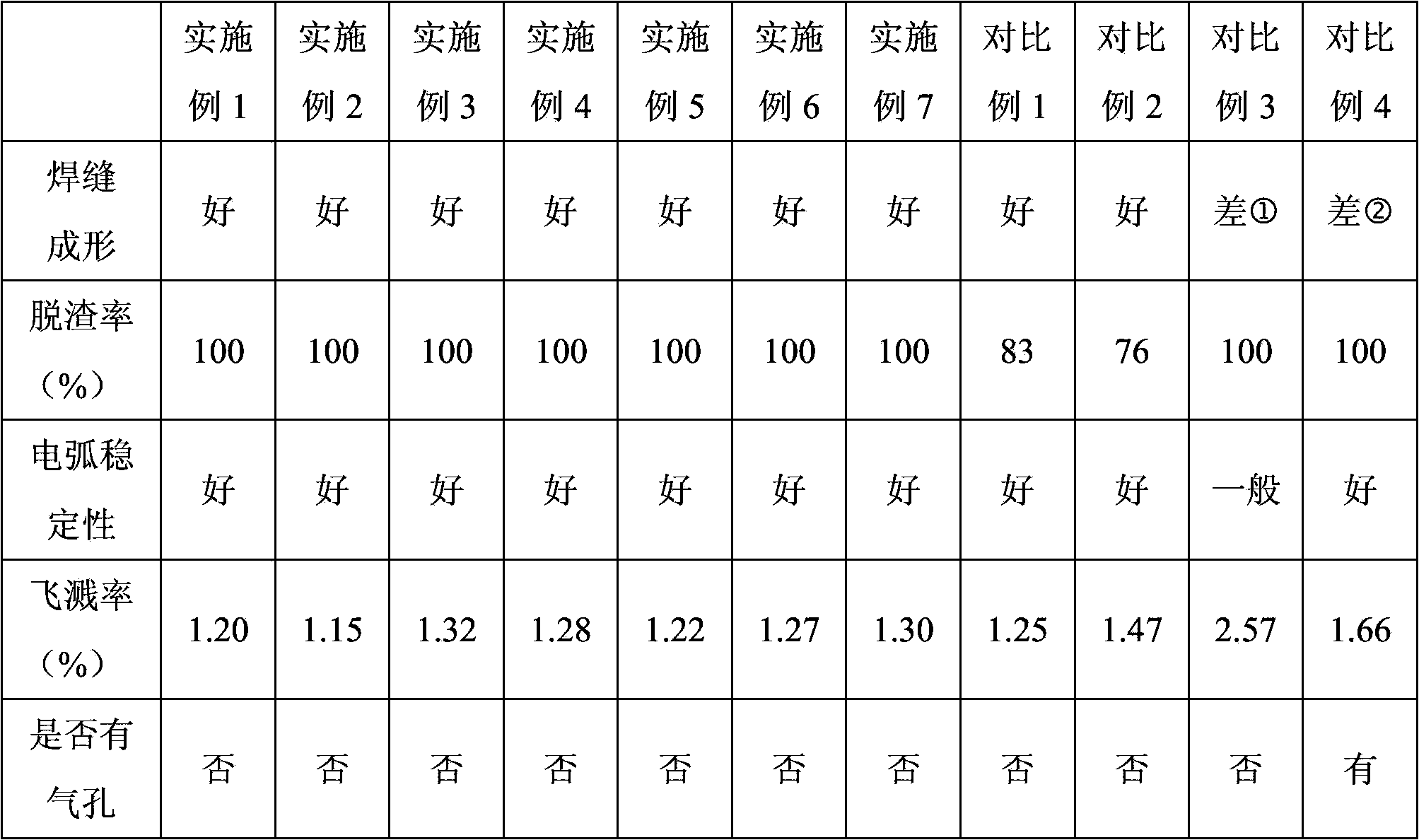

Examples

Embodiment 1

[0043] Select thickness 0.4mm, width 10mm, the austenitic stainless steel strip 304L that weight is 3762g, it is rolled into U shape, with 150g chromium powder, 95g nickel powder, 40g ferroniobium, 40g electrolytic manganese, 15g silicon-calcium alloy powder (calcium content is 58%, silicon content is 34%), 100g rutile, 35g quartz, 150g zircon sand, 60g feldspar, 15g cryolite, 5g lithium carbonate, 5g bismuth oxide, 290g iron powder, totally 1000g medicine powder, after mixing evenly Put it into the U-shaped groove, the filling rate is 21%. After the joint is closed, it is rolled and reduced, bright annealed, and drawn and reduced. The final diameter of the finished welding wire is 0.9mm.

Embodiment 2

[0045] Select thickness 0.4mm, width 10mm, the austenitic stainless steel strip 304L that weight is 3762g, it is rolled into U shape, with 180g chromium powder, 110g nickel powder, 50g niobium iron, 60g electrolytic manganese, 30g silicon-calcium alloy powder (calcium content is 56%, silicon content is 32%), 150g rutile, 50g quartz, 200g zircon sand, 110g feldspar, 25g cryolite, 10g lithium carbonate, 8g bismuth oxide, 17g iron powder, altogether 1000g medicine powder, after mixing evenly Add it into the U-shaped groove with a filling rate of 21%. After the joint is closed, it is rolled and reduced, bright annealed, and drawn and reduced. The final diameter of the finished welding wire is 1.2mm.

Embodiment 3

[0047] Select thickness 0.4mm, width 10mm, the austenitic stainless steel strip 304L that weight is 3762g, it is rolled into U shape, with 180g chromium powder, 110g nickel powder, 50g niobium iron, 60g electrolytic manganese, 30g silicon-calcium alloy powder (calcium content is 58%, silicon content is 35%), 150g rutile, 50g quartz, 200g zircon sand, 60g feldspar, 25g cryolite, 10g lithium carbonate, 8g bismuth oxide, 67g iron powder, altogether 1000g medicine powder, after mixing evenly Put it into the U-shaped groove, the filling rate is 21%. After the joint is closed, it is rolled and reduced, bright annealed, and drawn and reduced. The final diameter of the finished welding wire is 0.9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com