Automatic open-type double-alkali-method desulphurized gypsum oxidation system and control method thereof

A technology of desulfurization gypsum and oxidation system, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc. It can solve the problems of reducing the utilization rate of oxidation pools, it is difficult to control the degree of oxidation, and the oxidation efficiency of gypsum can only be reached. effect, the effect of improving oxidation efficiency and increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0034] Example.

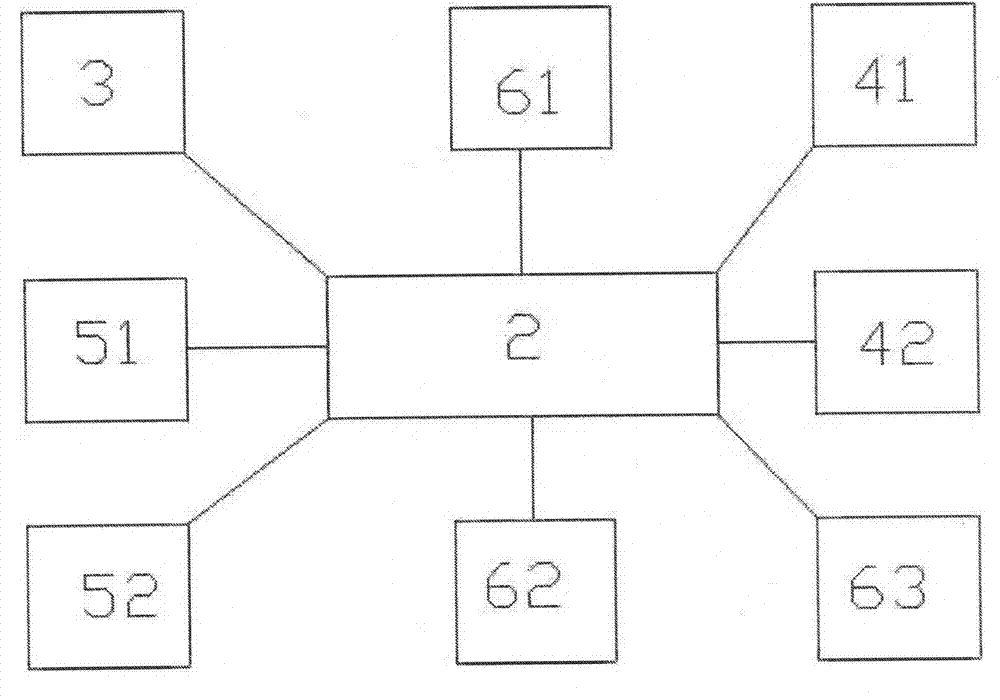

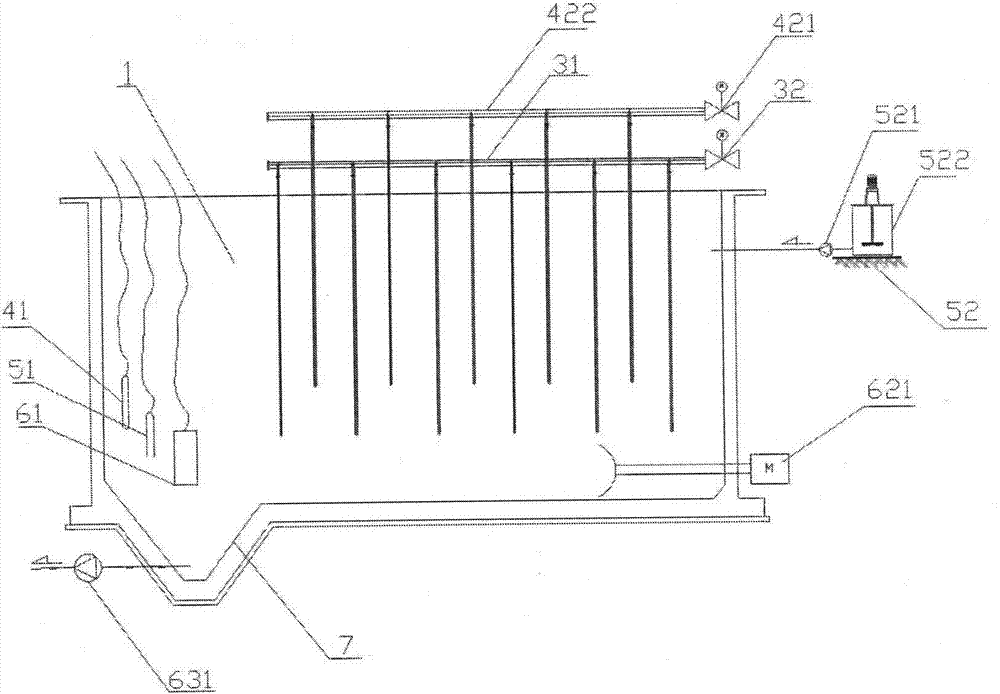

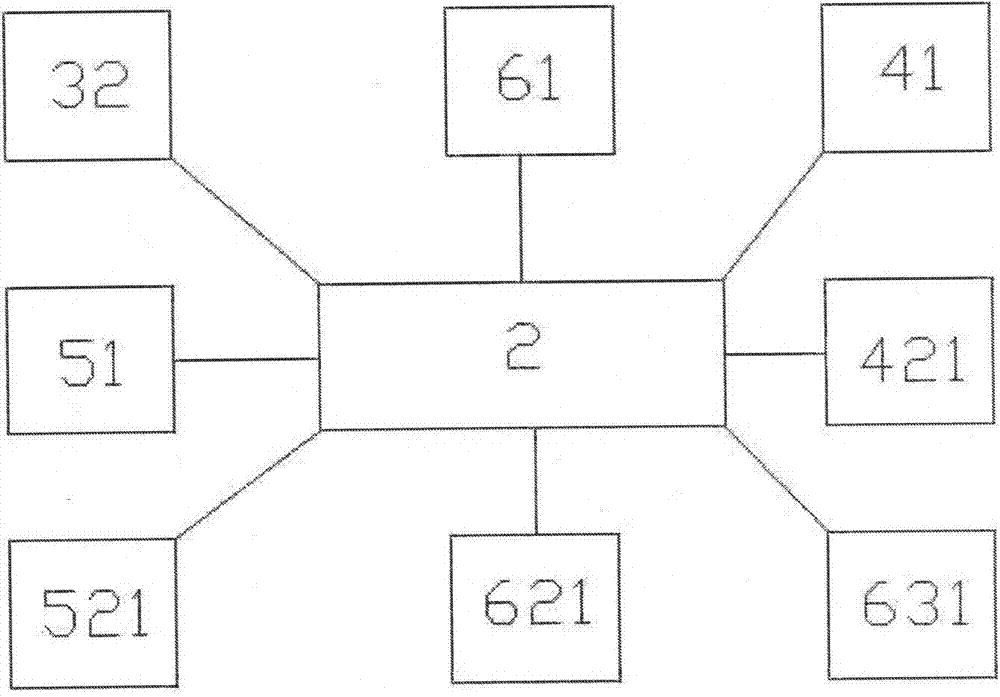

[0035] In this embodiment, the open double-alkali desulfurization gypsum automatic oxidation system includes an oxidation tank 1, a PLC control system 2, an air delivery system 3, a temperature control system, a pH control system, and a slag discharge system. The air delivery system 3 includes air Delivery pipeline 31 and air delivery electric valve 32, temperature control system includes temperature sensor 41 and steam equipment 42, steam equipment 42 includes steam electric valve 421 and steam pipeline 422, PH control system PH sensor 51 and feeding system 52, feeding system 52 includes a feeding pump 521 and a feeding tank 522. The slag discharge system includes a density meter sensor 61, a slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com