High-scrap-ratio KR molten iron desulfurization method

A technology of hot metal desulfurization and scrap steel ratio, applied in the direction of improving process efficiency, etc., can solve the problems of reducing slag removal time, difficulty in removing slag from front slag, reducing slag viscosity, etc., to reduce slag removal time, reduce desulfurizer consumption, reduce Effect of Slag Viscosity

Pending Publication Date: 2022-05-31

ANHUI UNIVERSITY OF TECHNOLOGY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to overcome the defects and shortcomings of the prior art, and the purpose is to provide a method for desulfurizing hot metal with a large scrap steel ratio KR. The method can significantly reduce the viscosity of slag, reduce iron loss, and reduce scraping by adding the pre-slag treatment mixture before slag removal. slag time and reduce the temperature drop of molten iron, thereby solving the technical problems such as difficulty in removing slag, large iron loss and low desulfurization efficiency in the pretreatment process of molten iron under the condition of large scrap steel ratio of 25% to 30%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0046]

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

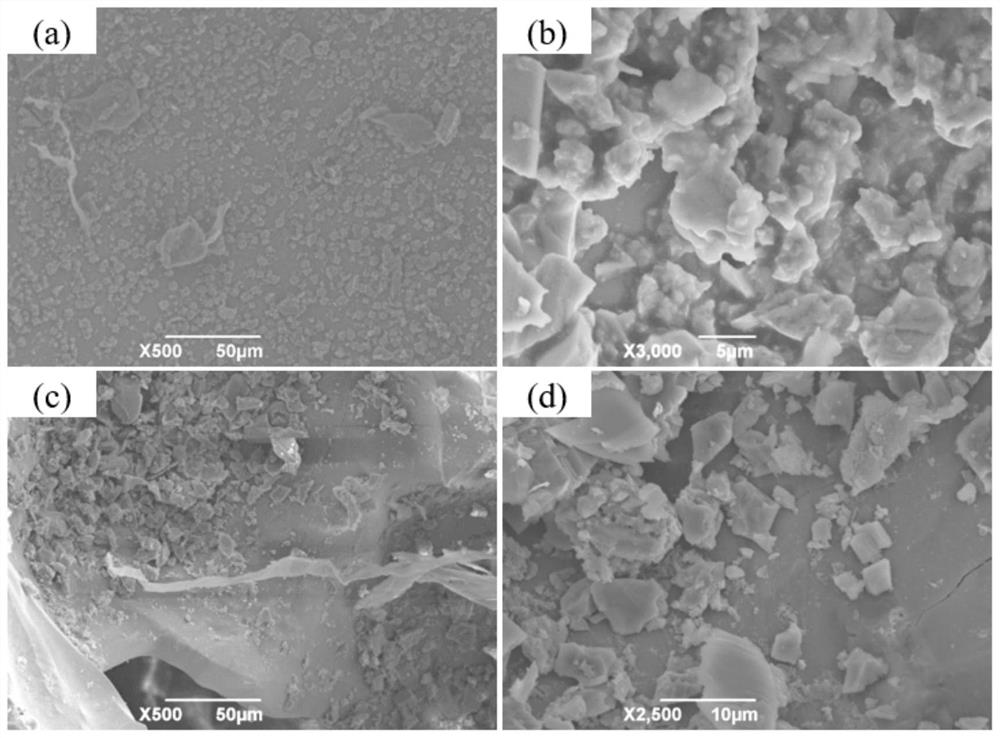

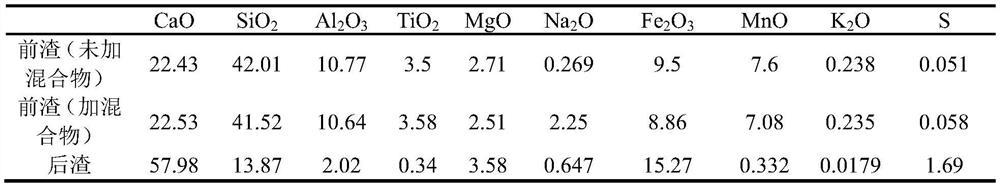

The invention discloses a KR molten iron desulfurization method with a large scrap ratio, and belongs to the technical field of molten iron desulfurization. The method comprises the following steps that before KR molten iron desulfurization treatment, a pre-slag treatment mixture is added into the center of a ladle, the pre-slag treatment mixture is spread on the surface of slag, and the pre-slag treatment mixture comprises 60 wt%-70 wt% of soda ash, 10 wt%-14 wt% of titanium dioxide and 20 wt%-26 wt% of fluorite powder; a slagging-off plate is used for slagging off the slag added with the pre-slag treatment mixture for 20-30 s, and then the ladle is inclined; and after slagging-off is finished, the ladle is shaken to be normal, and complete slagging-off is carried out after the desulfurization reaction. According to the KR molten iron desulfurization method with the large scrap steel ratio, the slag viscosity can be obviously reduced by adding the pre-slag treatment mixture before slagging-off, the iron loss is reduced, the slagging-off time is shortened, and the temperature drop of molten iron is reduced; therefore, the technical problems of difficult slagging-off of front slag, large slagging-off iron loss, low desulfurization efficiency and the like in the molten iron pretreatment process under the condition that the large scrap steel ratio is 25%-30% are solved.

Description

A kind of large scrap ratio KR molten iron desulfurization method technical field The present invention relates to molten iron desulfurization technical field, more specifically, relate to a kind of large scrap ratio KR molten iron desulfurization method. Background technique The development of iron and steel industry directly affects the national economy, and while it contributes to the national economy, it also consumes It has a large amount of natural resources and brings great pressure to the environment. Unlike the limited natural resources of iron ore, scrap steel can be Recycled green resources. The use of scrap steel not only promotes the recycling of resources and the sustainable development of production, but also Reduce carbon emissions and NO x It has good economic and environmental benefits. The addition of scrap to the ladle is An important means for iron and steel enterprises to develop circular economy is the current development trend of China'...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C1/02C21C7/064

CPCC21C1/02C21C7/064C21C7/0645C21C1/025Y02P10/20

Inventor 李明晖彭家云齐江华劳栋李赛赛李灿华黄贞益周剑丰

Owner ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com