Surfacing welding flux-cored wire

A technology of welding wire and flux, applied in the field of surfacing welding flux-cored welding wire, which can solve the problems of low hardness and poor wear resistance of weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

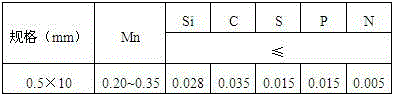

[0060] The steel sheath of the flux-cored wire is made of low-carbon steel strip, and its chemical composition is shown in Table 1.

[0061] Table 1 Chemical composition of steel strip (wt%)

[0062]

[0063] The chemical composition and raw material composition of the drug core powder are shown in Table 2, and the particle size is 40 mesh. Since there are many specifications of some raw materials, only one of them is selected here as a representative for illustration. FeSi45 is used for ferrosilicon, FeNb50 for ferroniobium, FeV50 for ferrovanadium, and yttrium oxide or cerium oxide for rare earth oxide.

[0064] Powder Composition Content (wt%) rutile 1.0~4.5 Feldspar 0.20~0.50 NaF and Fluorite 2.0~4.5 Magnesium powder 0.3~1.5 graphite 0.5~4.0 Ferrosilicon (FeSi45) 1.0~4.5 Medium carbon ferromanganese 6.0~10.0 High carbon ferrochrome 23.0~35.0 Tungsten carbide 40.0~60.0 Ferroniobium (FeNb50) 1.0~3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com