Production method of high-quality insoluble sulfur

A production method and high-quality technology, applied in the preparation/purification of sulfur, etc., can solve the problems of poor thermal stability, prolong production cycle, need manpower and equipment, etc., achieve high thermal stability and improve dispersibility, optimize production environment, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

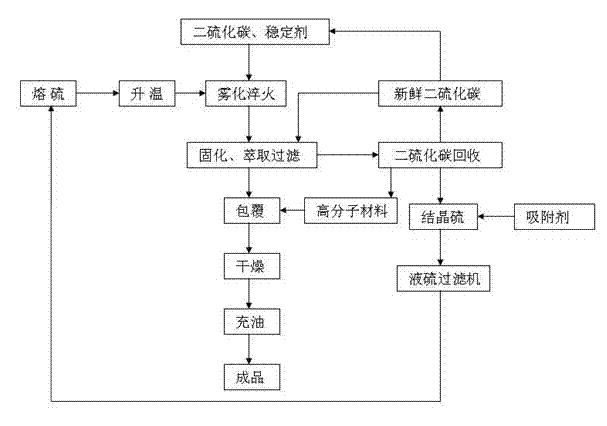

Image

Examples

Embodiment 1

[0025] The present invention is a kind of production method of high-quality insoluble sulfur, comprises the following steps:

[0026] (1) Put the solid sulfur or liquid sulfur of ordinary sulfur into the molten sulfur pool for melting or heat preservation, and the temperature is controlled at 120-150°C; the molten liquid sulfur is pumped into the heating tank with a sulfur metering pump, and the temperature is automatically raised and controlled The temperature is 350-360°C.

[0027] (2) In the two-flow sulfur atomizing nozzle, high-pressure N 2 The high-temperature liquid sulfur flowing out in the form of a liquid film is uniformly atomized, then fully contacted with the quenching liquid from all directions in the quenching synthesizer, and cooled rapidly to form uniform insoluble sulfur particles and suspend in the quenching liquid. The quenching liquid is carbon disulfide containing stabilizer.

[0028] (3) The mixed suspension enters into a reactor equipped with a stirri...

Embodiment 2

[0036] The present invention is a kind of production method of high-quality insoluble sulfur, comprises the following steps:

[0037] (1) Put the solid sulfur or liquid sulfur of ordinary sulfur into the molten sulfur pool for melting or heat preservation, and the temperature is controlled at 120-150°C; the molten liquid sulfur is pumped into the heating tank with a sulfur metering pump, and the temperature is automatically raised and controlled The temperature is 400-410°C.

[0038] (2) In the two-flow sulfur atomizing nozzle, high-pressure N 2 The high-temperature liquid sulfur flowing out in the form of a liquid film is uniformly atomized, then fully contacted with the quenching liquid from all directions in the quenching synthesizer, and cooled rapidly to form uniform insoluble sulfur particles and suspend in the quenching liquid. The quenching liquid is carbon disulfide containing stabilizer.

[0039] (3) The mixed suspension enters the reactor with a stirring device, a...

Embodiment 3

[0046] The present invention is a kind of production method of high-quality insoluble sulfur, comprises the following steps:

[0047] (1) Put the solid sulfur or liquid sulfur of ordinary sulfur into the molten sulfur pool for melting or heat preservation, and the temperature is controlled at 120-150°C; the molten liquid sulfur is pumped into the heating tank with a sulfur metering pump, and the temperature is automatically raised and controlled The temperature is 440-450°C.

[0048] (2) In the two-flow sulfur atomizing nozzle, high pressure N 2The high-temperature liquid sulfur flowing out in the form of a liquid film is uniformly atomized, then fully contacted with the quenching liquid from all directions in the quenching synthesizer, and cooled rapidly to form uniform insoluble sulfur particles and suspend in the quenching liquid. The quenching liquid is carbon disulfide containing stabilizer.

[0049] (3) The mixed suspension enters the reactor with a stirring device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com