Patents

Literature

32 results about "Piezoresistive accelerometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

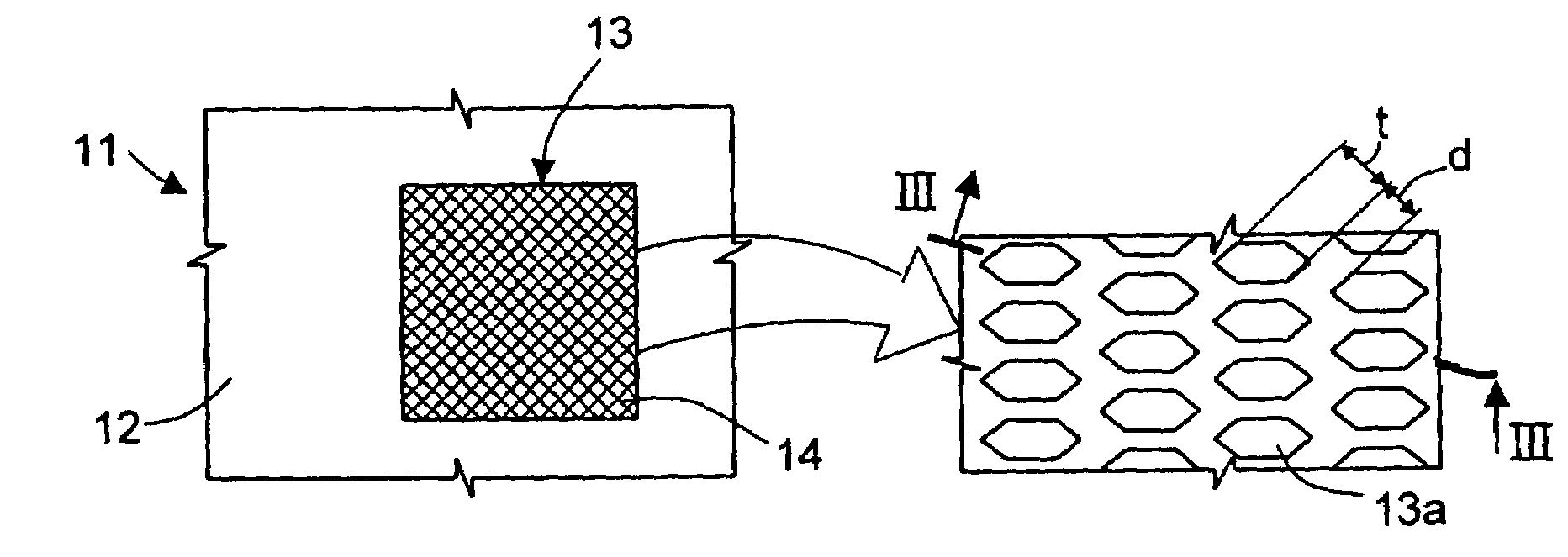

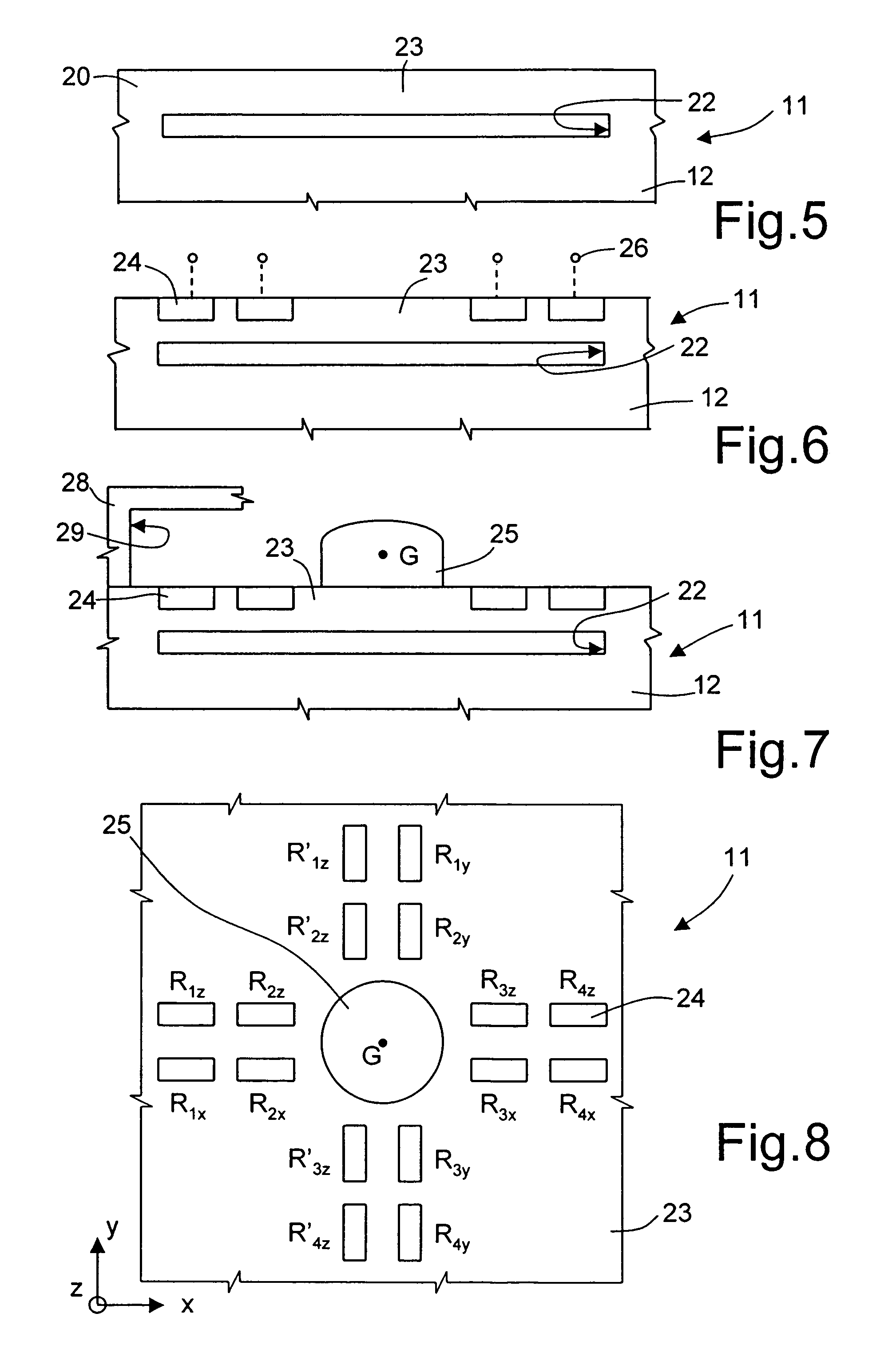

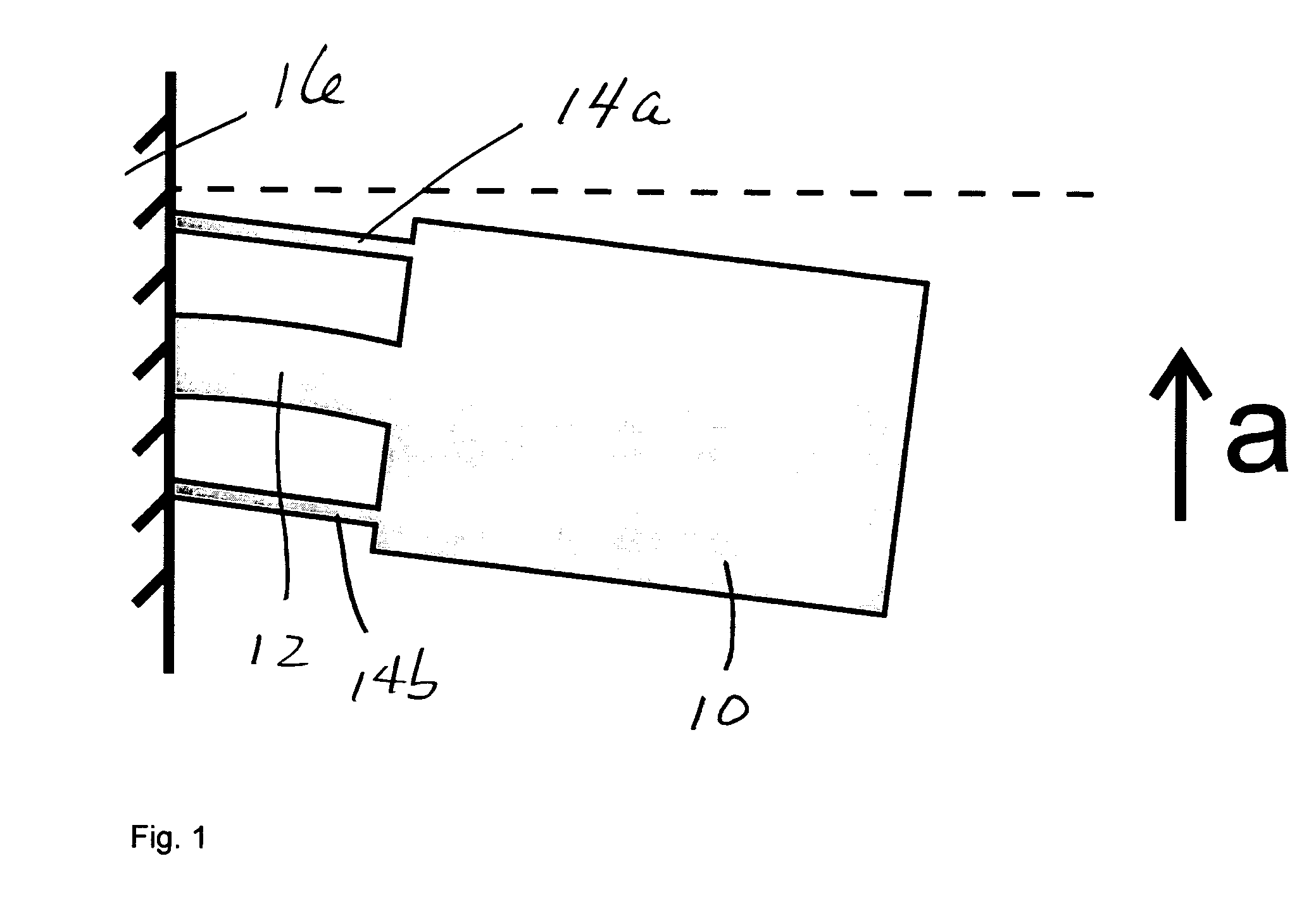

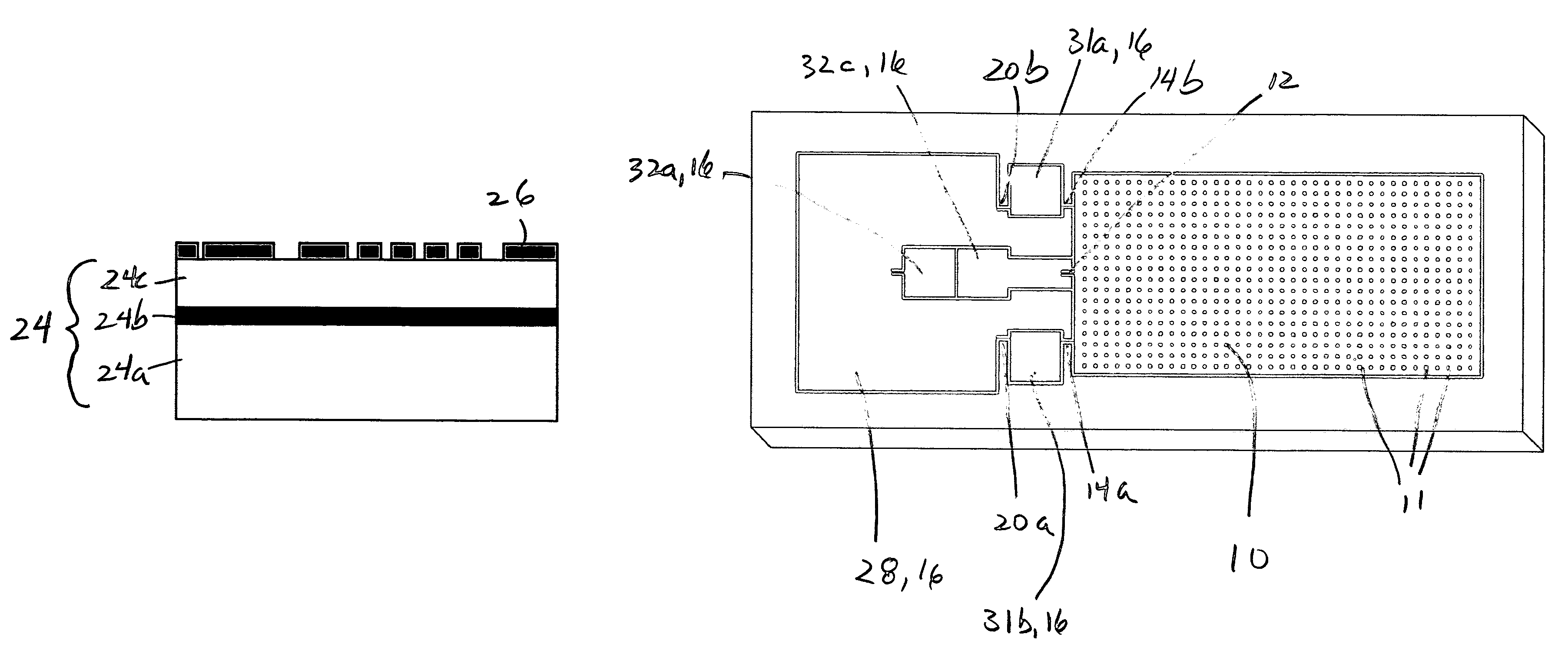

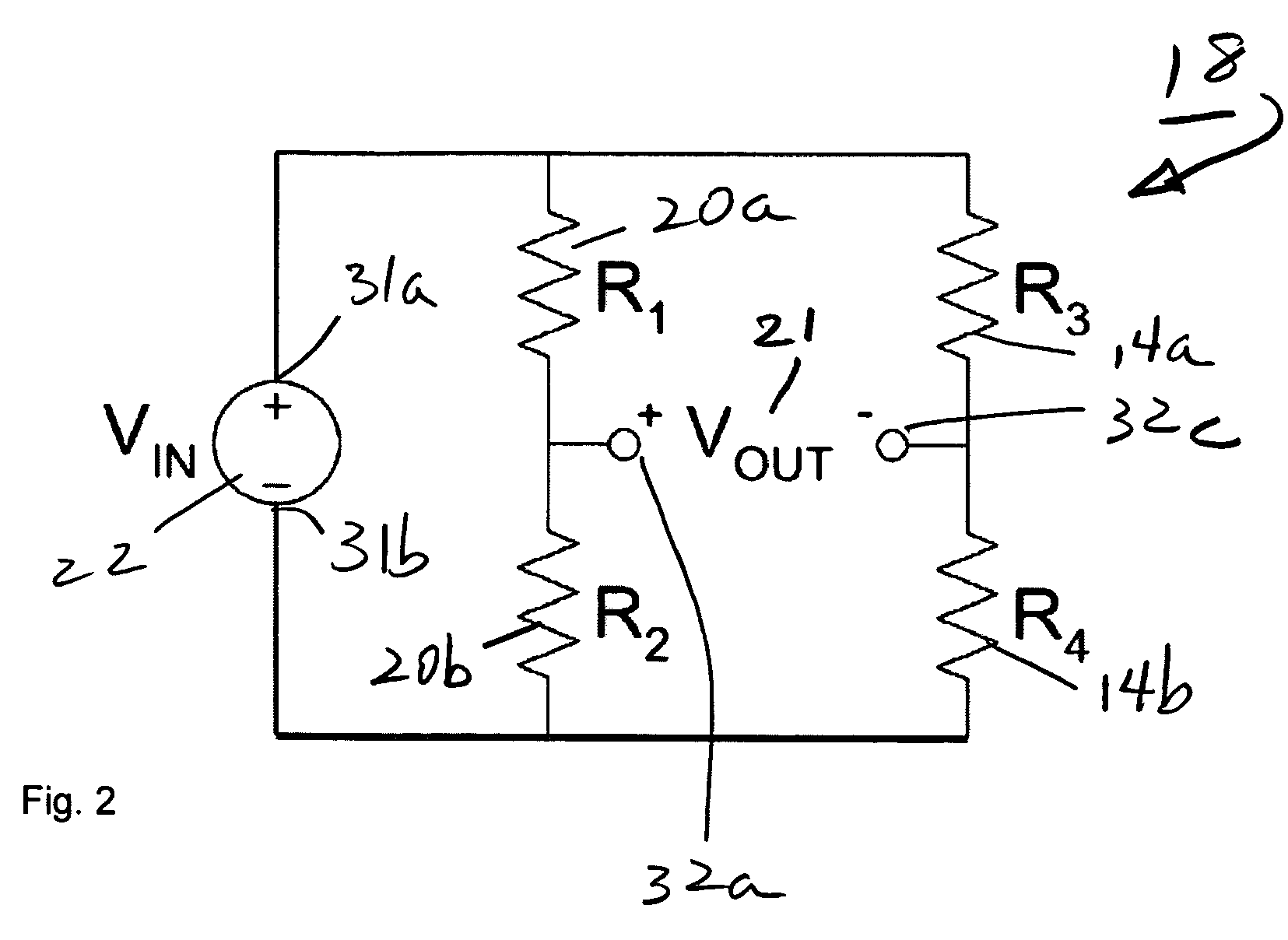

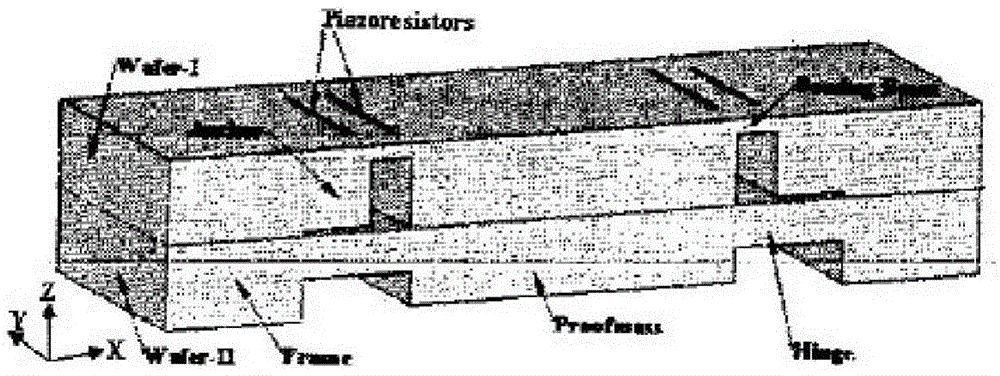

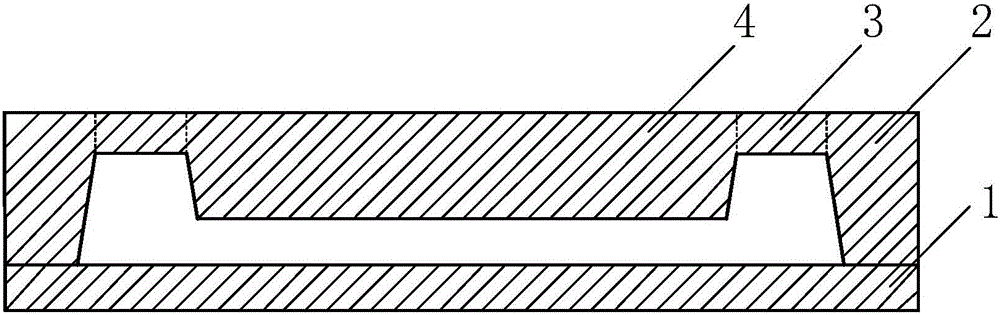

Process for manufacturing a triaxial piezoresistive accelerometer and relative pressure-monitoring device

ActiveUS7322236B2Simple and inexpensive to manufactureEasy to integrateAcceleration measurement using interia forcesNavigation instrumentsInertial massRelative pressure

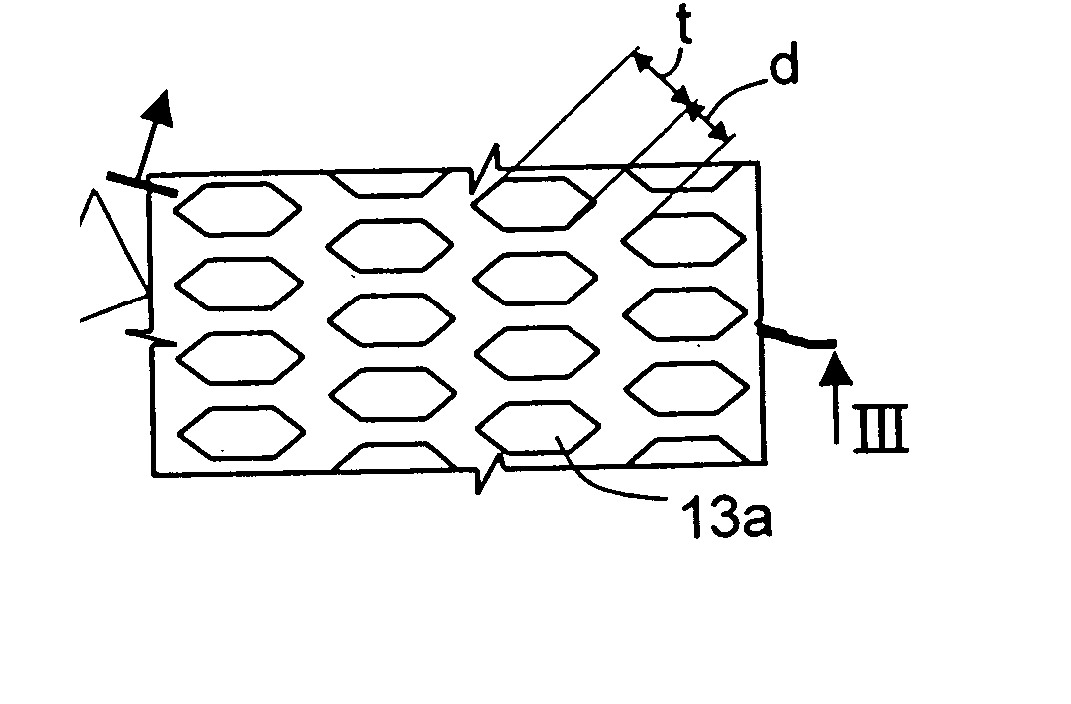

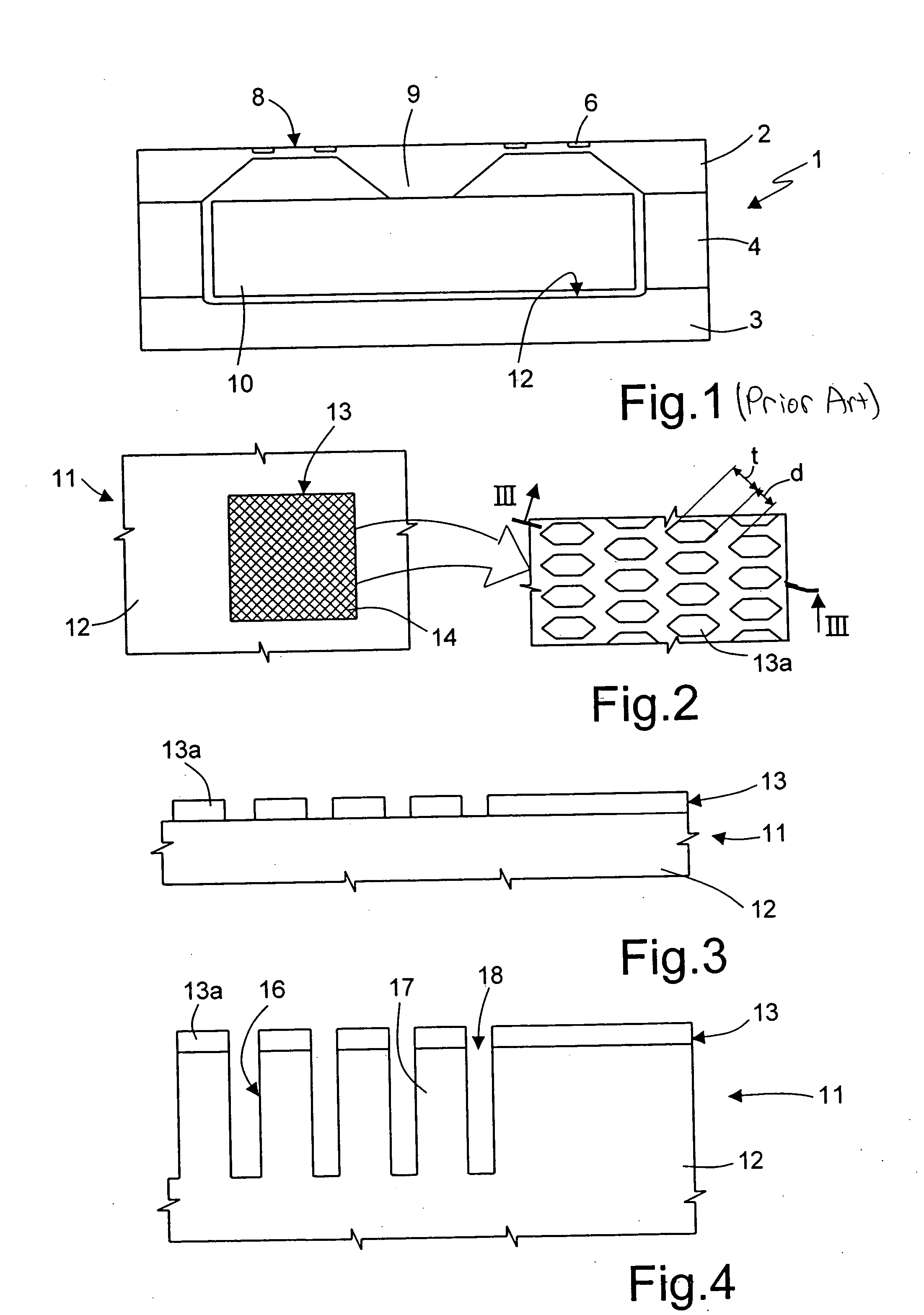

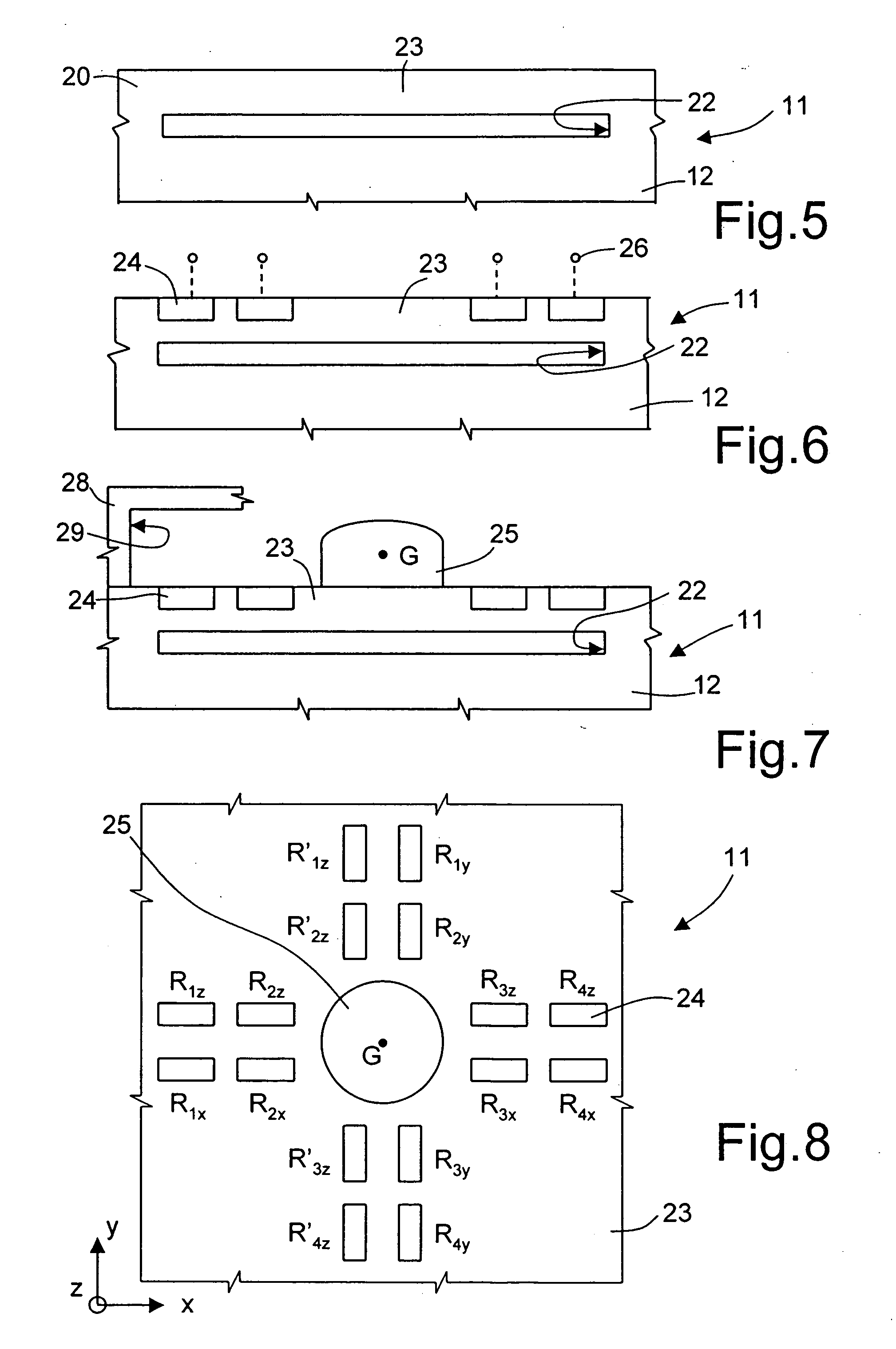

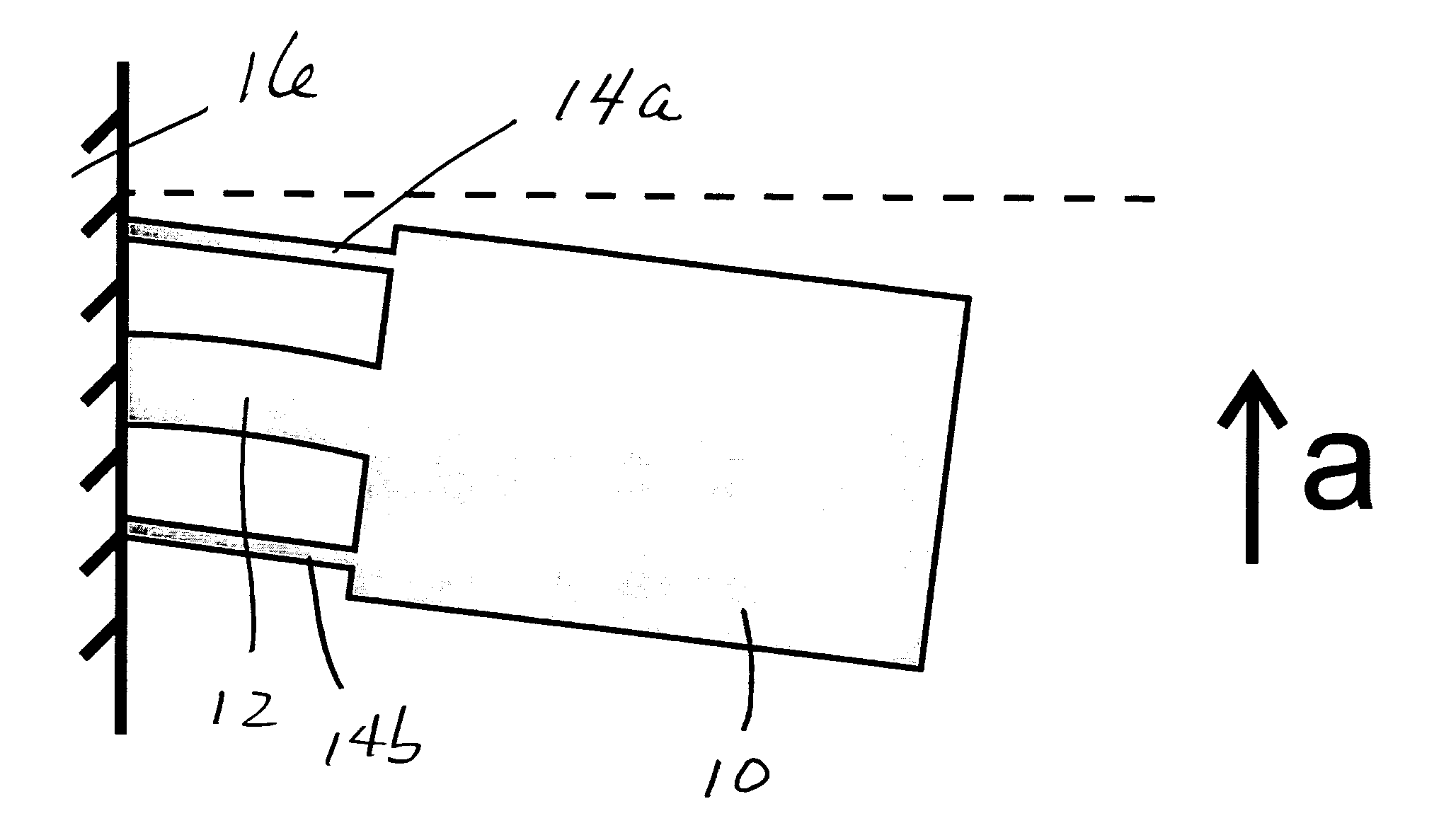

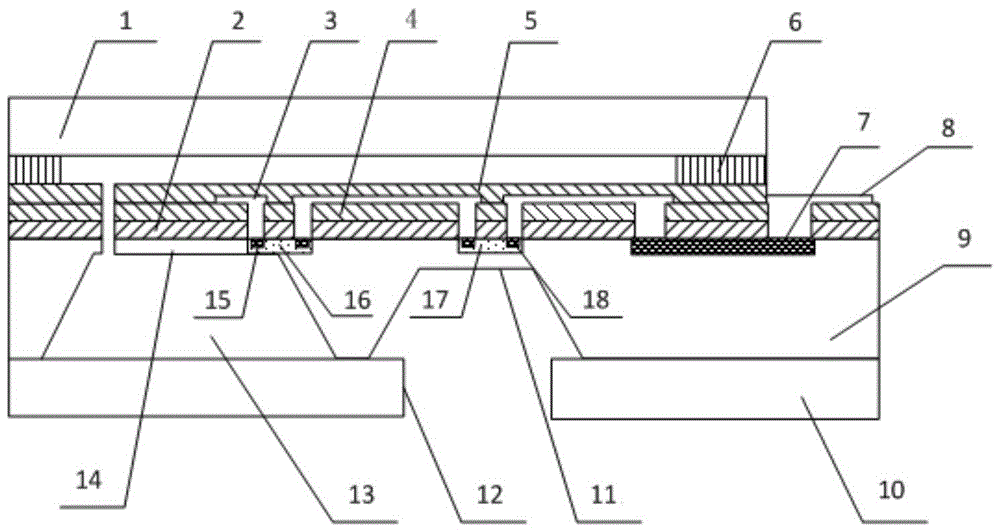

A manufacturing process of a semiconductor piezoresistive accelerometer includes the steps of: providing a wafer of semiconductor material; providing a membrane in the wafer over a cavity; rigidly coupling an inertial mass to the membrane; and providing, in the wafer, piezoresistive transduction elements, that are sensitive to strains of the membrane and generate corresponding electrical signals. The step of coupling is carried out by forming the inertial mass on top of a surface of the membrane opposite to the cavity. The accelerometer is advantageously used in a device for monitoring the pressure of a tire of a vehicle.

Owner:STMICROELECTRONICS SRL

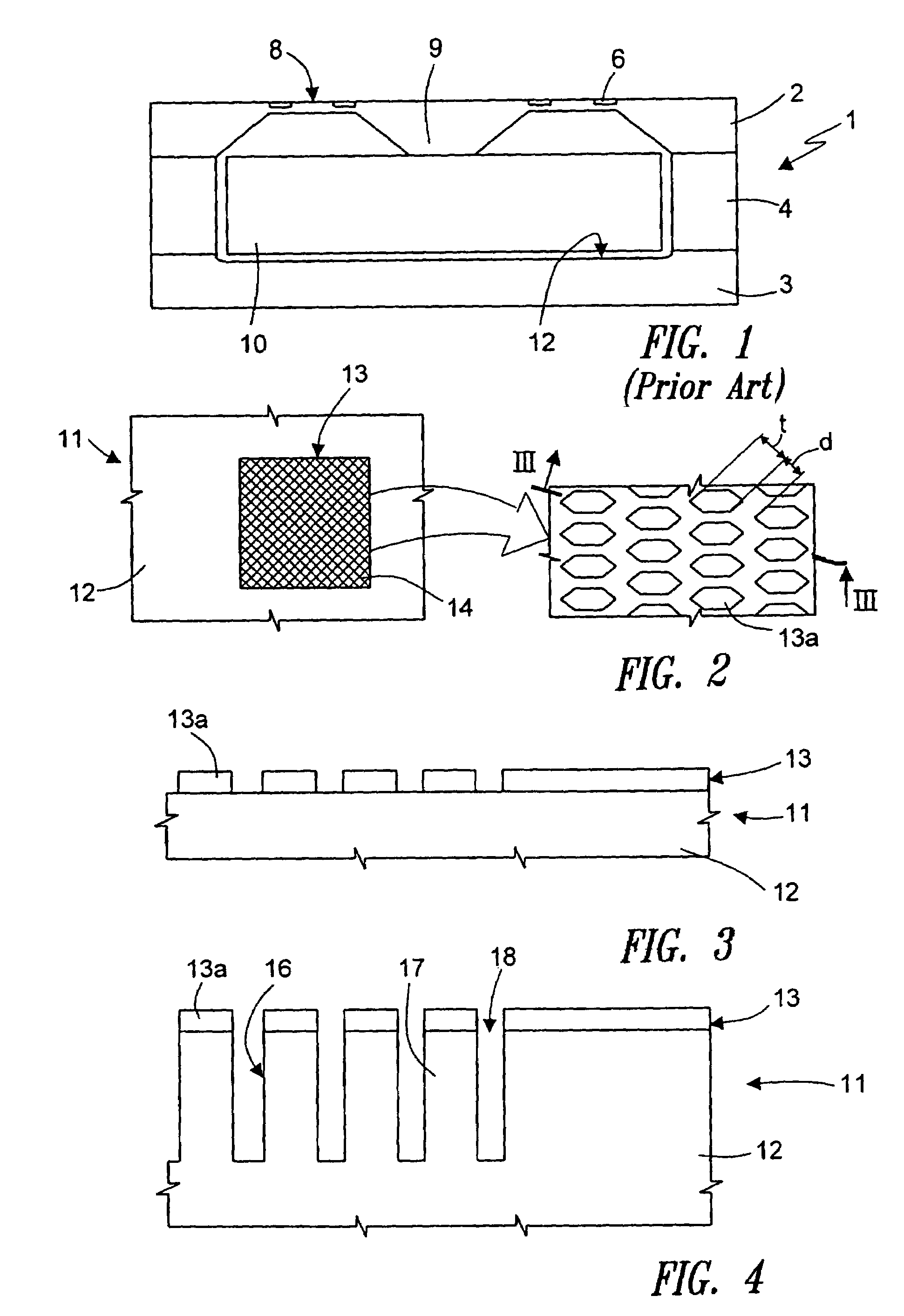

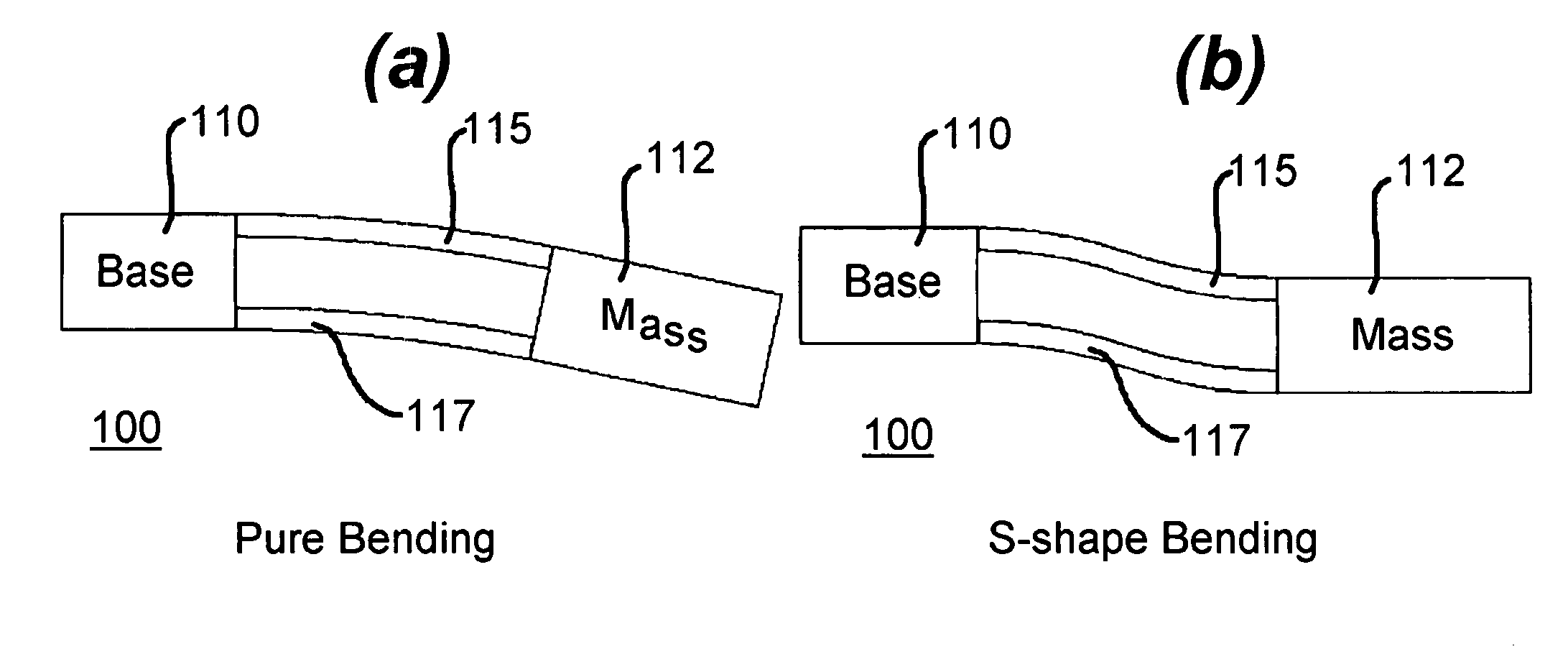

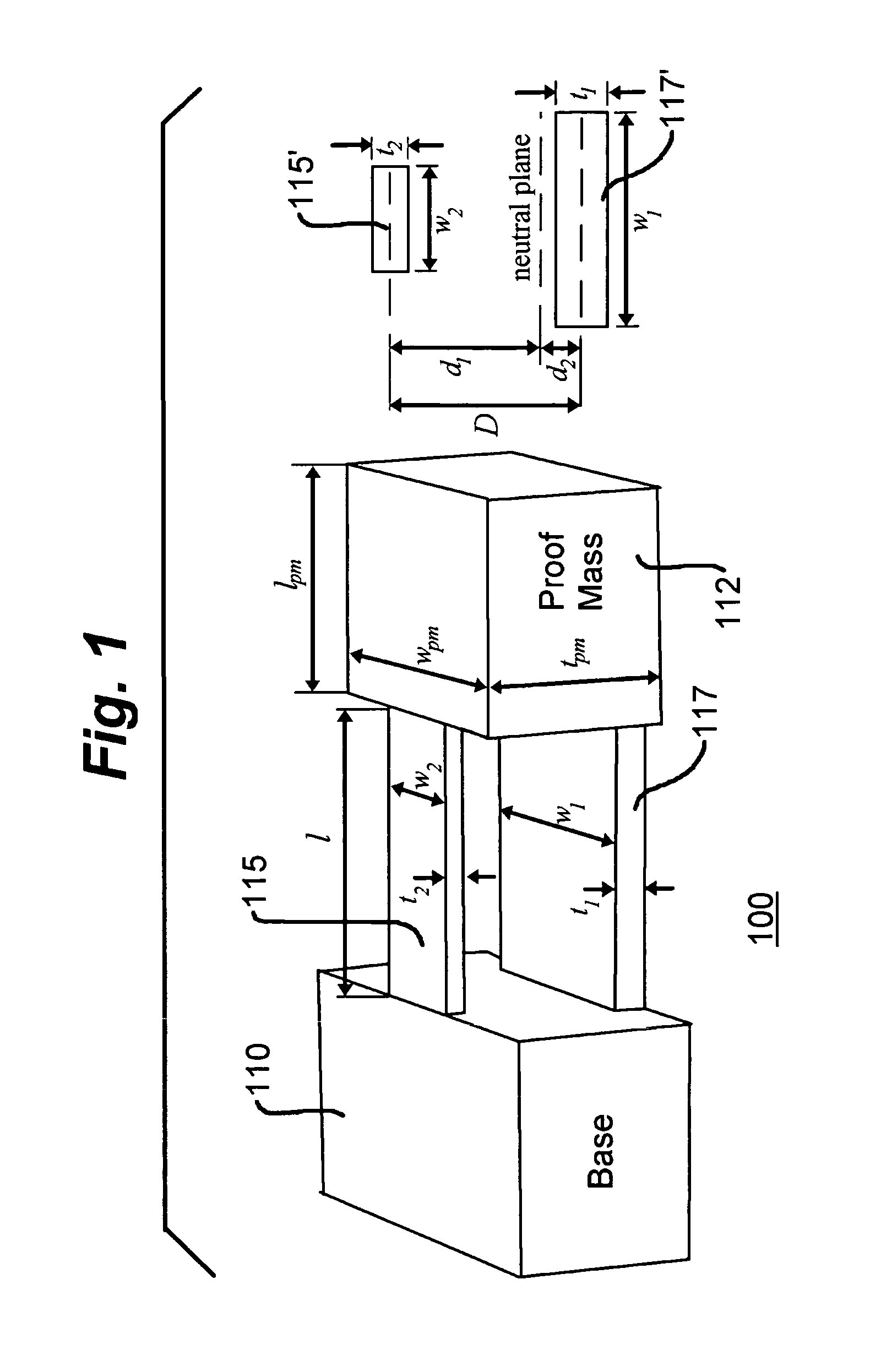

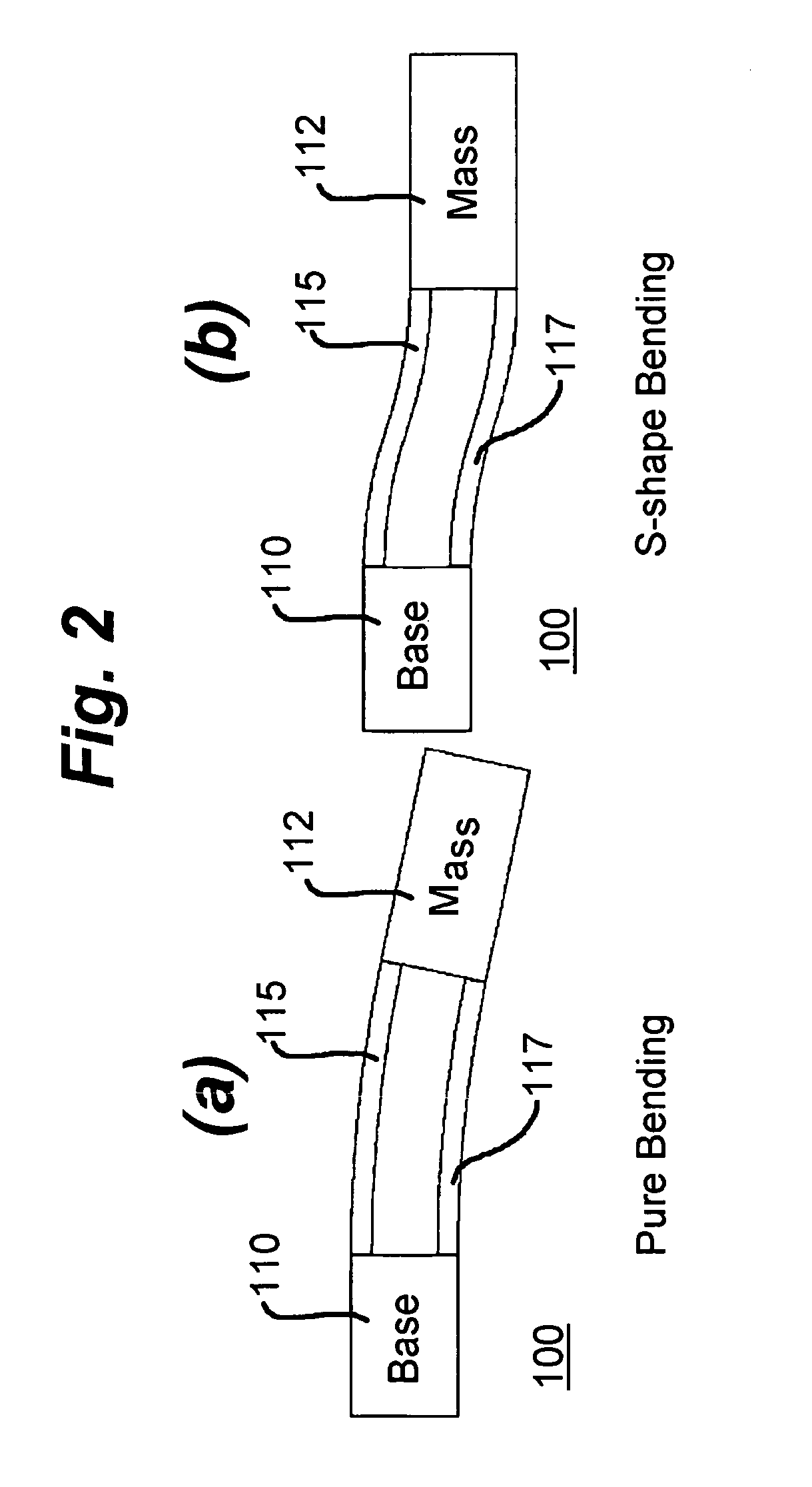

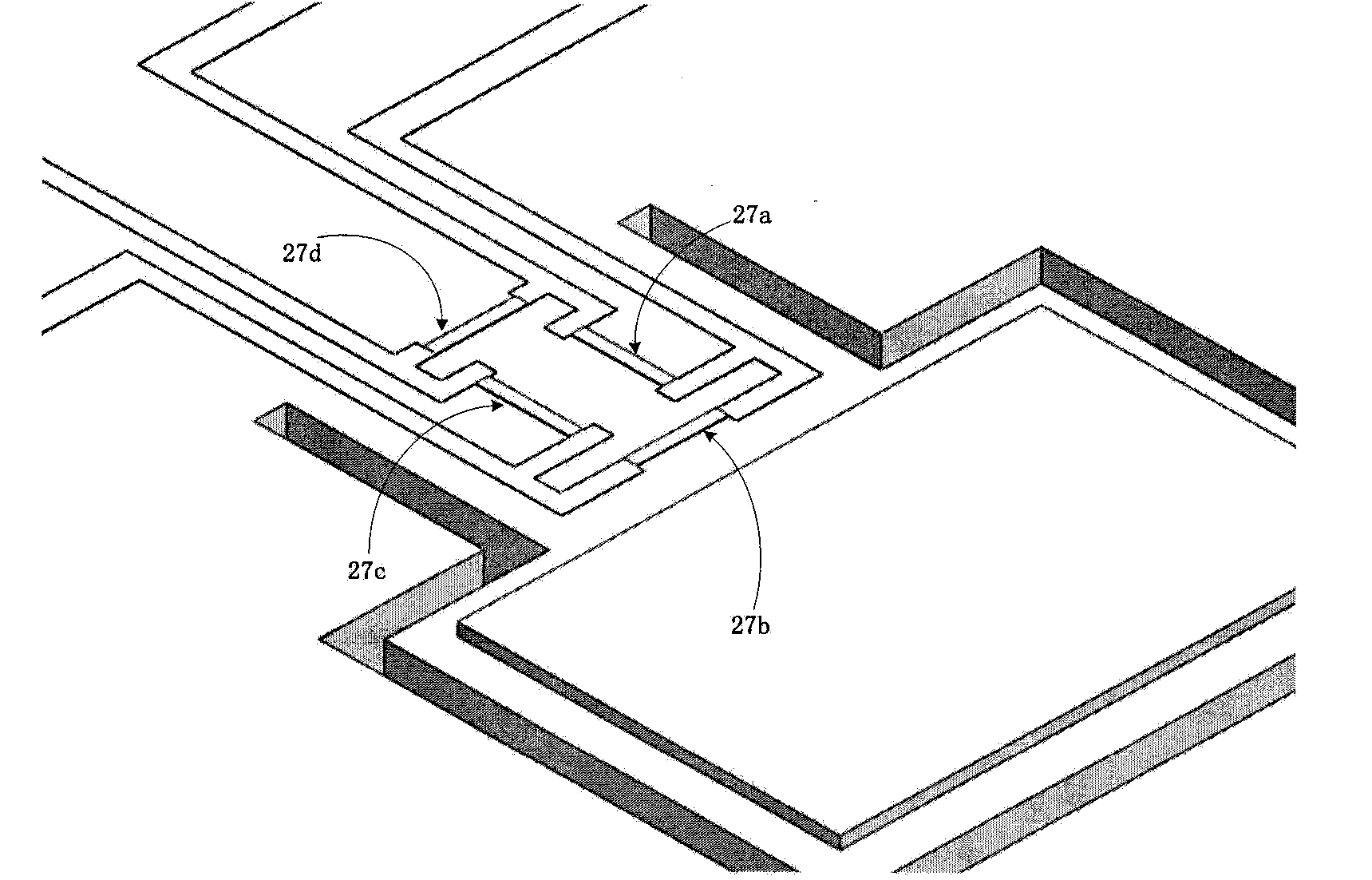

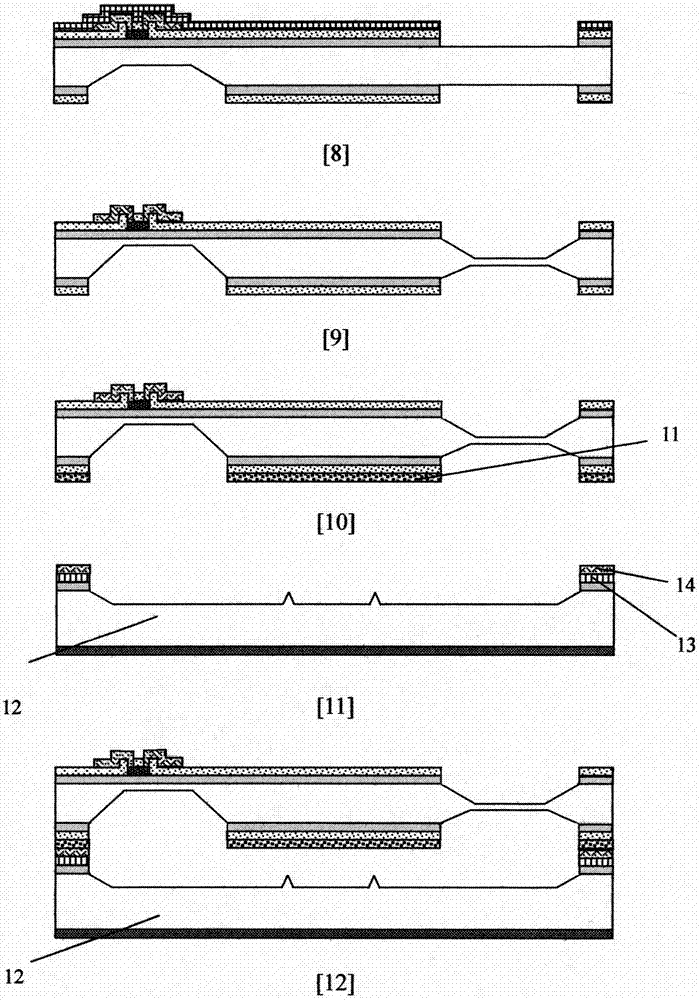

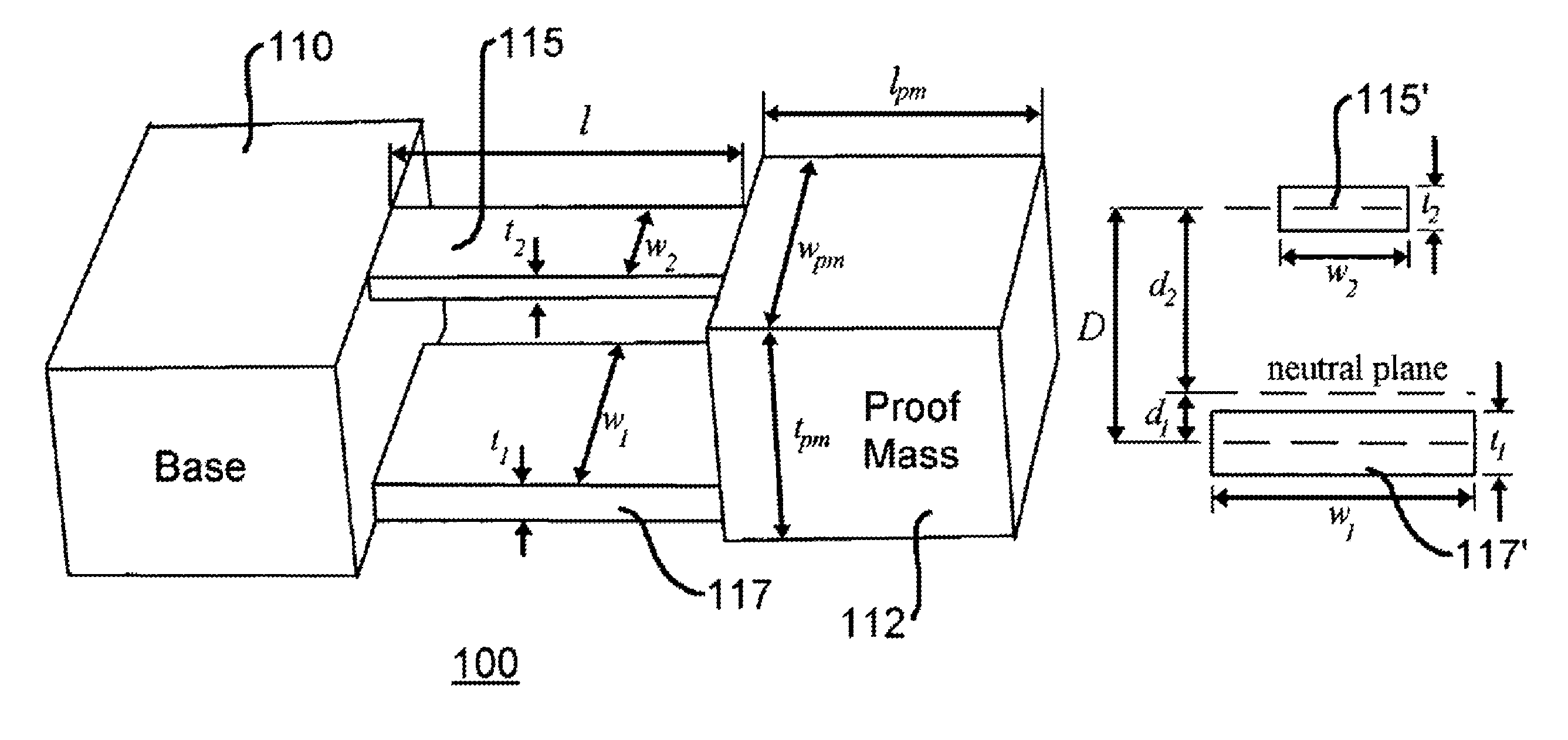

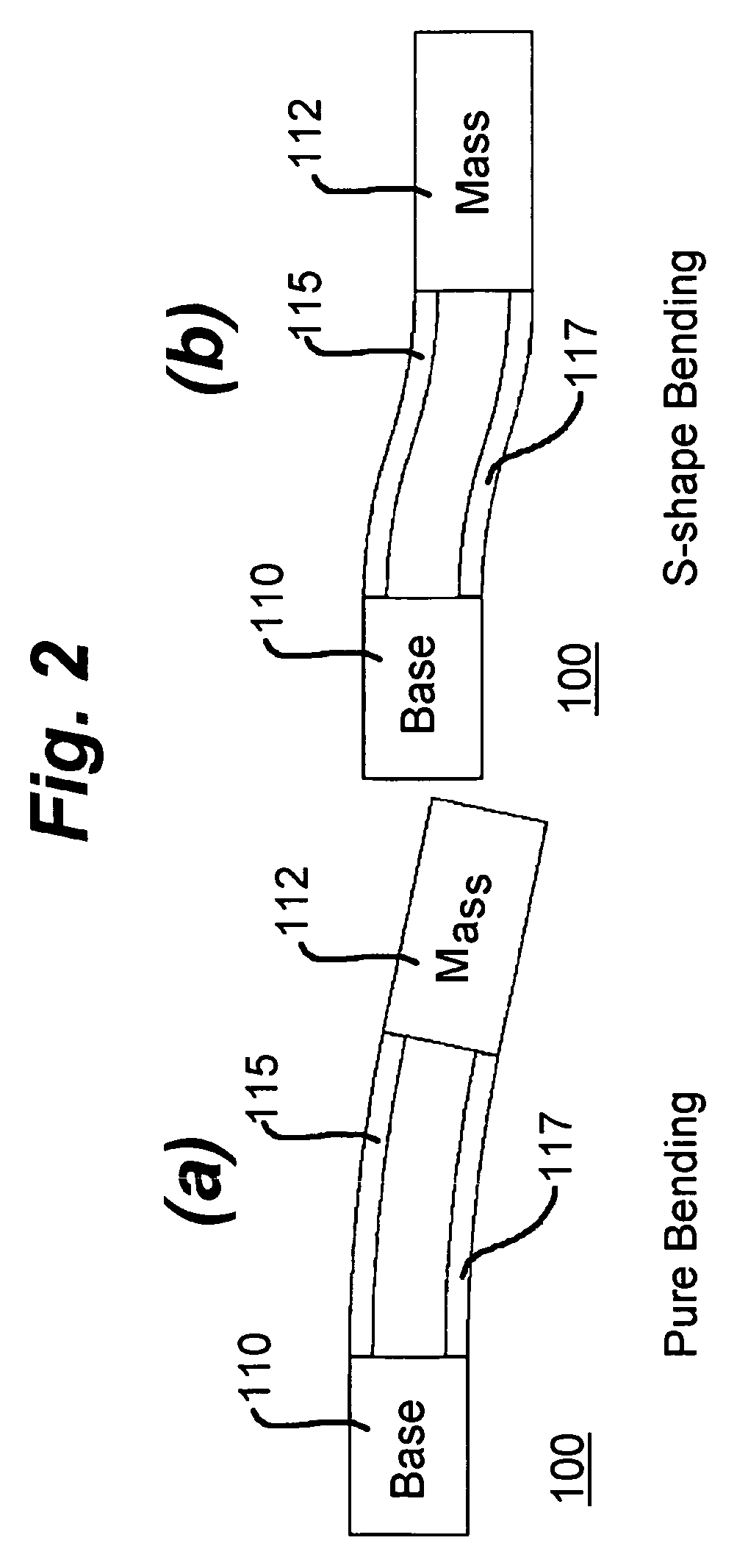

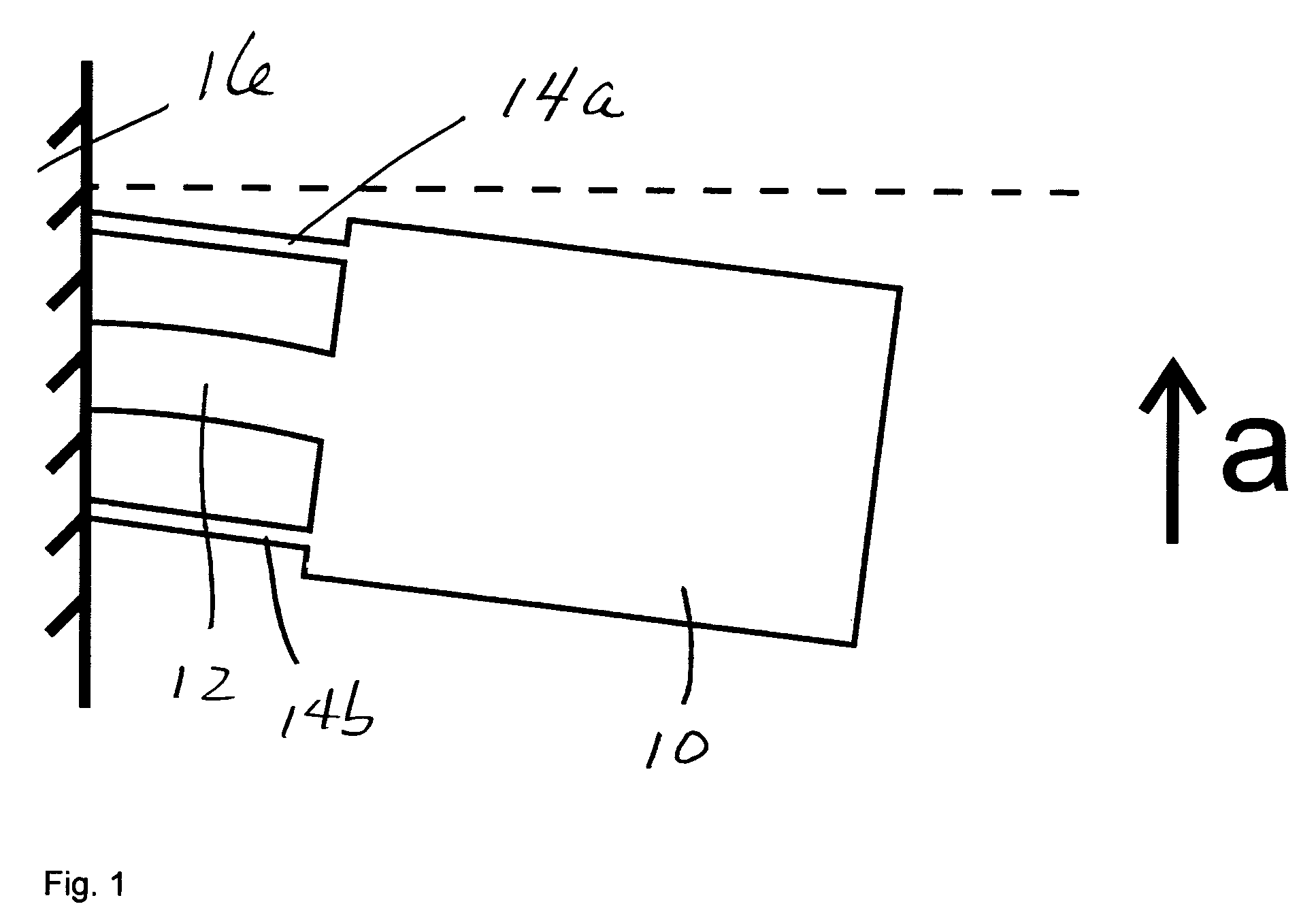

Piezo devices with air-spaced cantilever

ActiveUS20100270889A1High voltageDistanceAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesLead zirconate titanateMechanical energy

An arrangement that converts mechanical energy into electrical energy employs a base member and a cantilever member coupled thereto. The cantilever member has two piezoelectric layers with an air space therebetween. A proof mass is coupled to the cantilever member distal from the base member. The first and second piezoelectric layers are formed of lead zirconate titanate (PZT), and the output voltage of the cantilever member is proportional to the height of the air gap. A piezoresistive accelerometer that is useful for measuring mechanical vibration has a suspension beam and a piezoresistive layer be separated from the suspension beam. A method of monitoring an acoustic vibration utilizes a piezoresistive element having an air-spaced cantilever formed of a piezoelectric material in the vicinity of the system to be monitored and obtains an alternating voltage form the air-spaced cantilever of the piezoresistive element.

Owner:WAYNE STATE UNIV

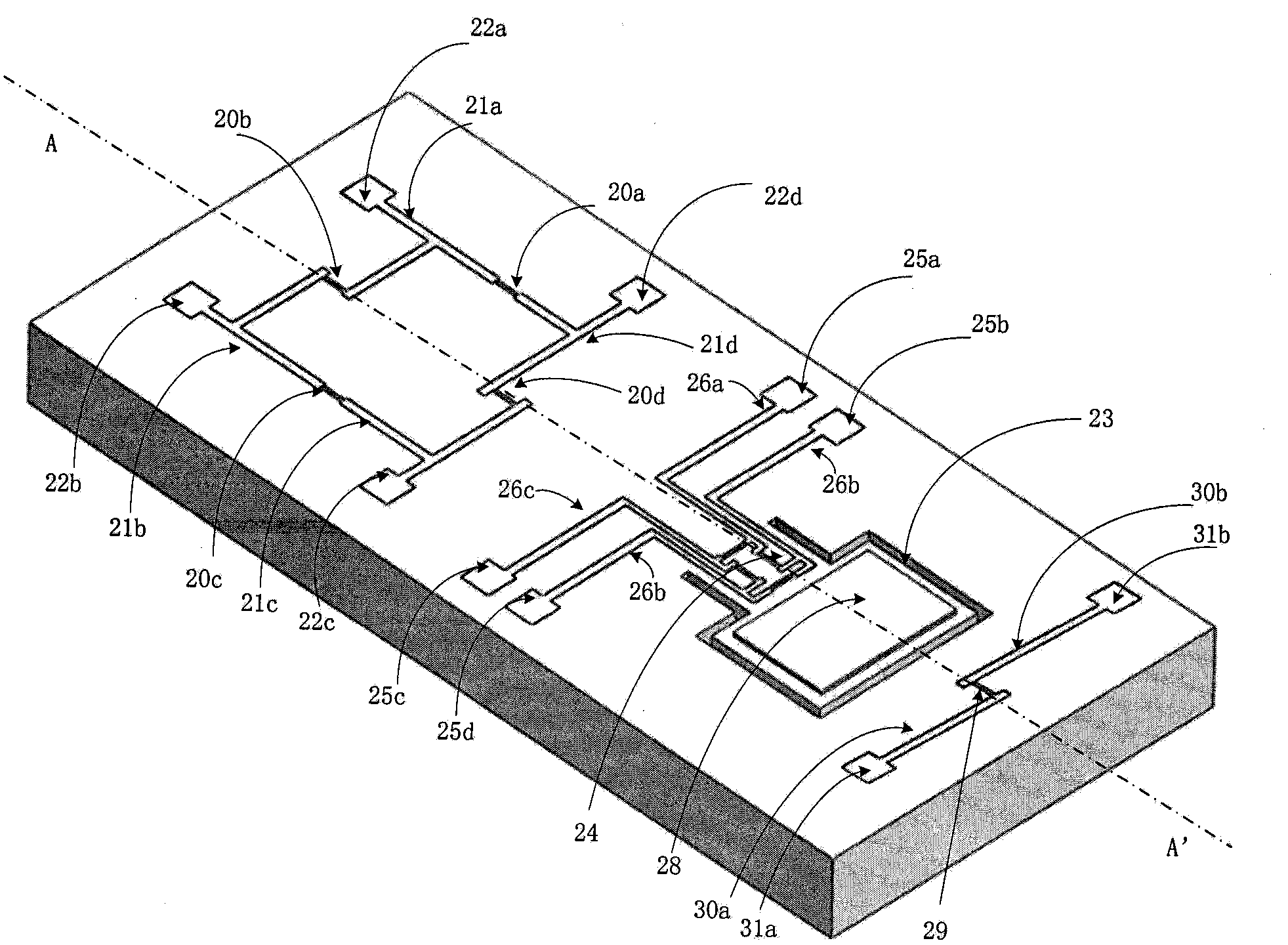

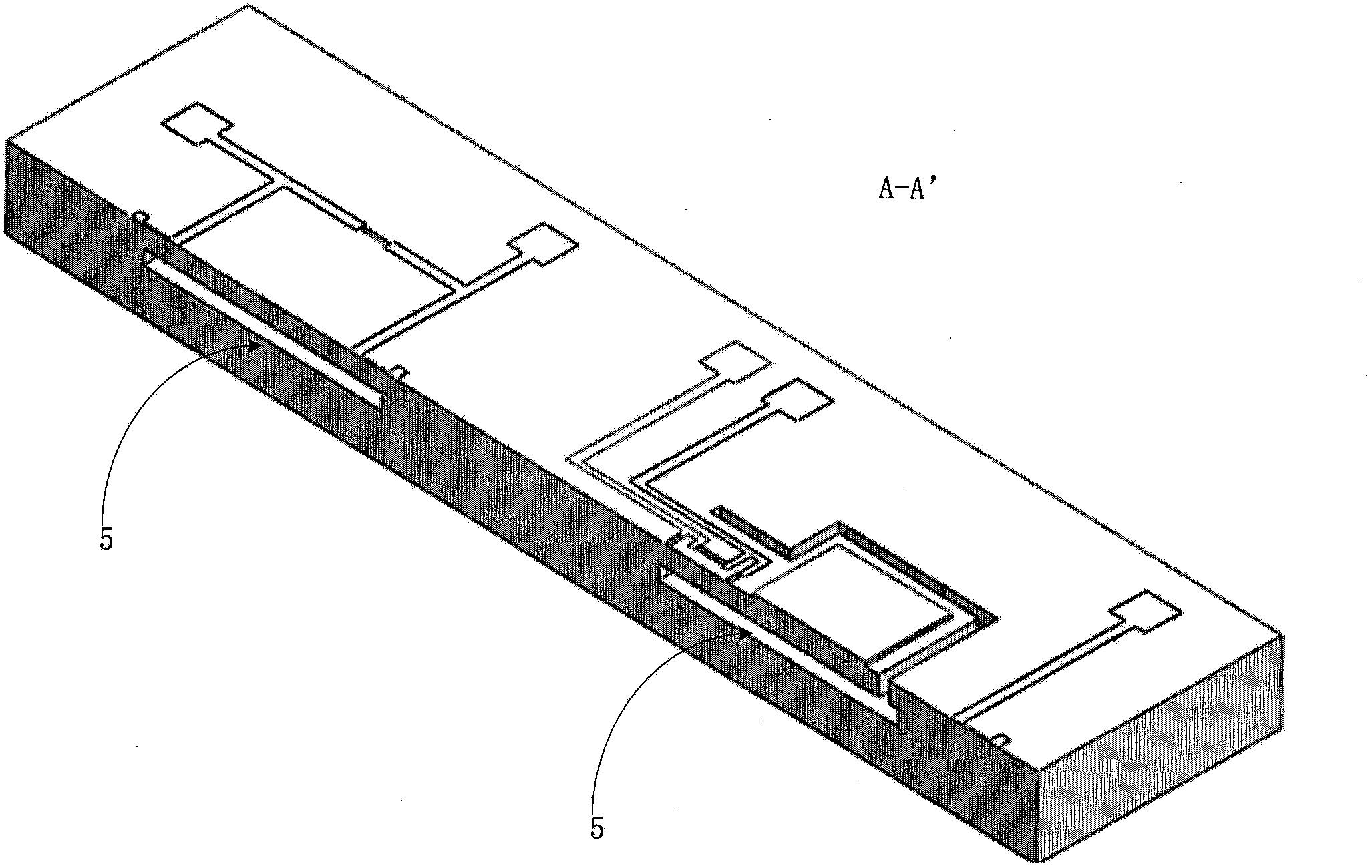

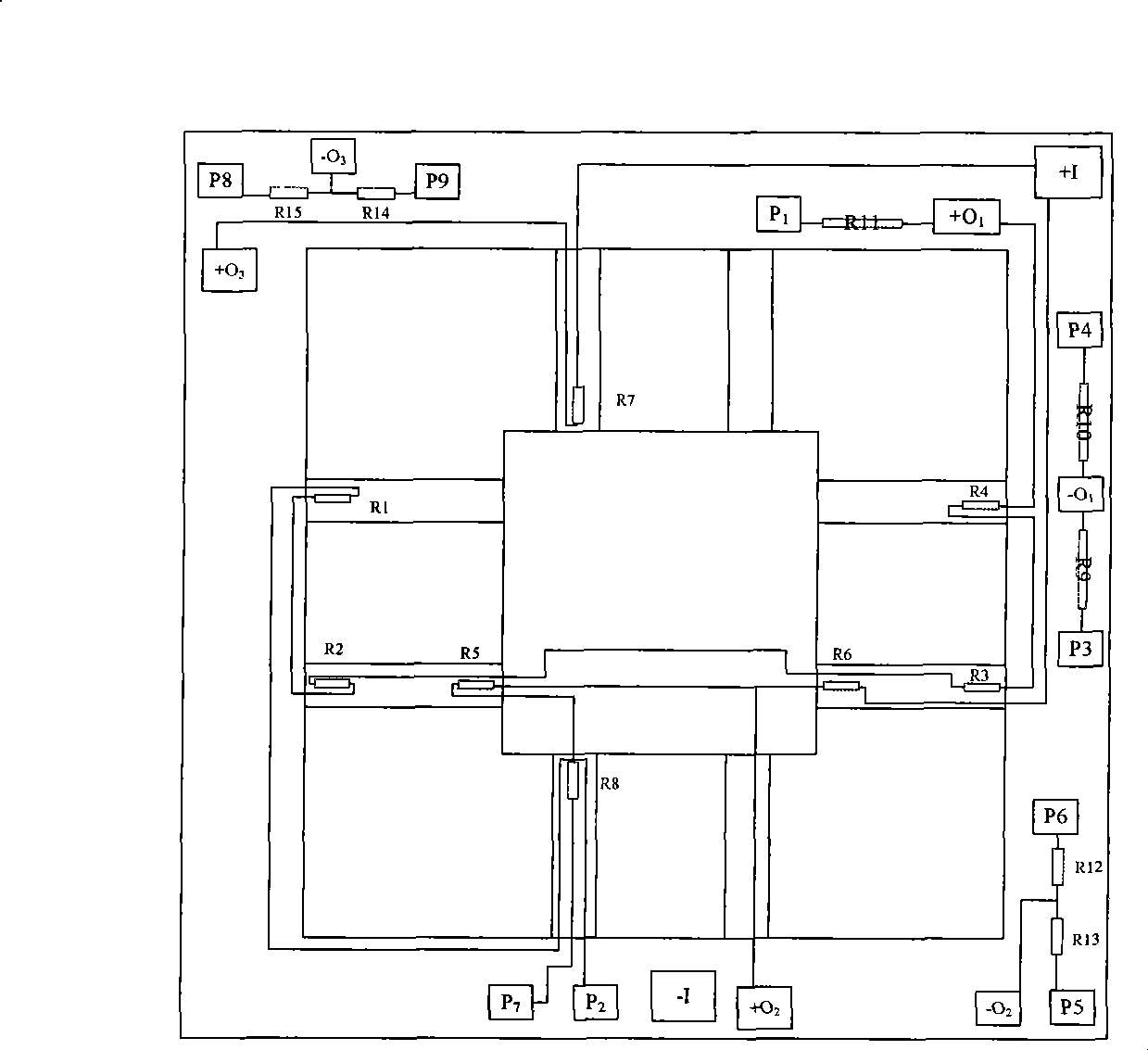

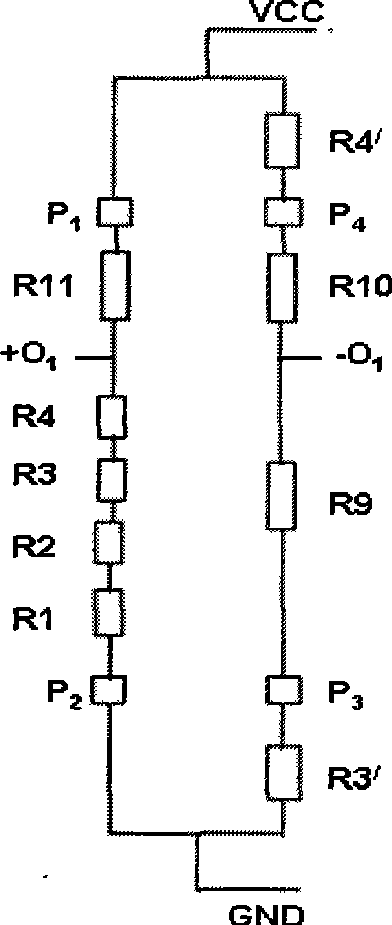

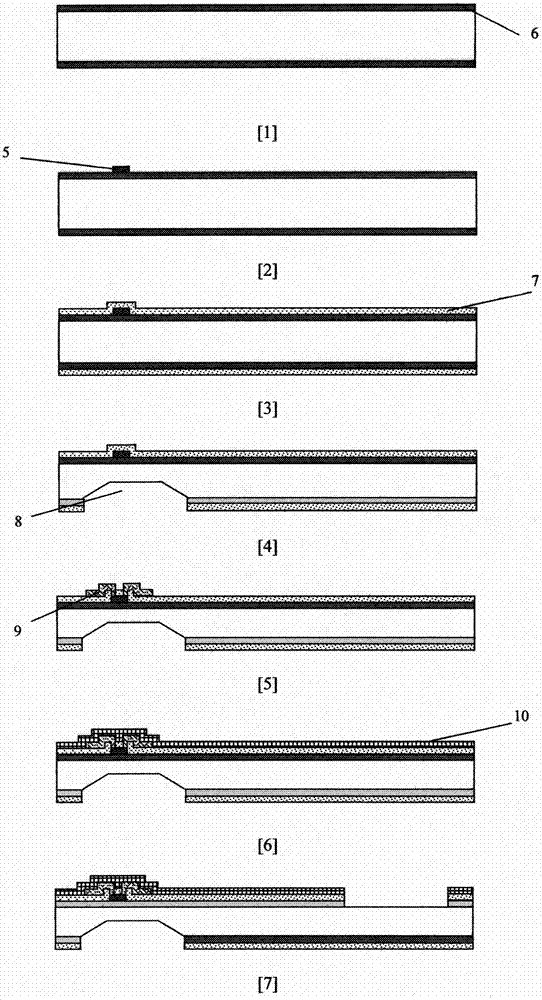

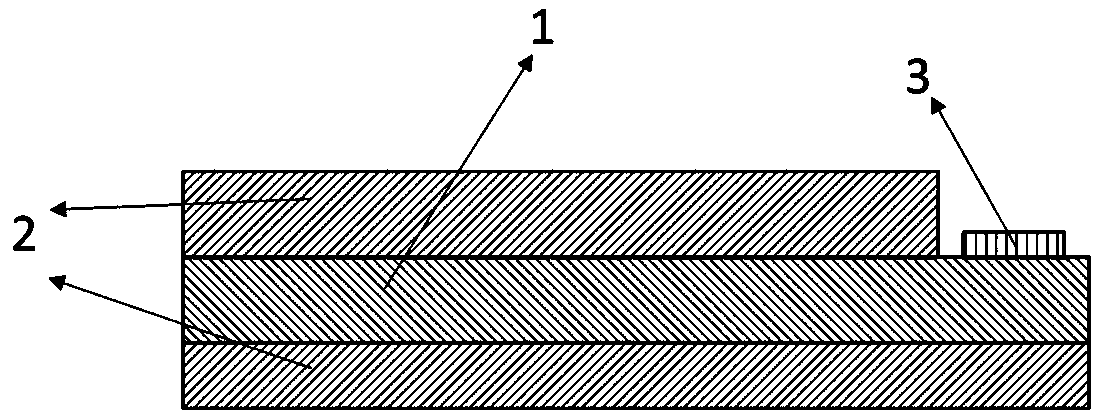

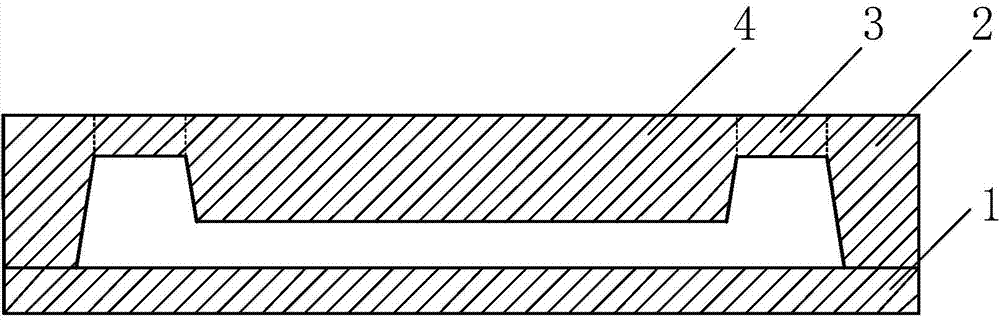

Processing method of integrated piezoresistive accelerometer and pressure meter which are based on prefabricated cavity SOI (silicon on insulator) substrate

InactiveCN104058361ARealize precise controlAccurate thicknessAcceleration measurement using interia forcesDecorative surface effectsPiezoresistive accelerometerEngineering

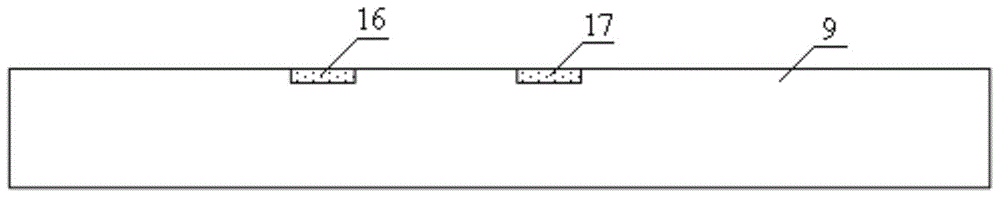

The invention discloses a processing method of an integrated piezoresistive accelerometer and a pressure meter which are based on a prefabricated cavity SOI (silicon on insulator) substrate. The accelerometer comprises an elastic beam-mass block structure with a force sensitive resistor, and the pressure meter comprises a pressure sensitive diaphragm with a force sensitive resistor. The method is as follows: preparing dosage concentration resistor stripes as the force sensitive resistor and a temperature sensitive resistor on a device layer of the SOI substrate; processing a metal wire layer and a passivation layer; deeply etching to the prefabricated cavity, releasing the elastic beam-mass block structure; and bonding a cover sheet cover to protect the movable structure. Compared with the prior art, according to the processing method, the symmetrical elastic beam-mass block structure with precise size can be processed by a single-surface and single-step process, a monocrystalline silicon sensitive resistor and the temperature sensitive resistor of the accelerometer and the pressure meter can be processed, the device sensitivity is high, the process repeatability is good, a vacuum packaging step of a traditional absolute-pressure pressure meter is omitted; and the prepared elastic beam-mass block structure is universal.

Owner:PEKING UNIV

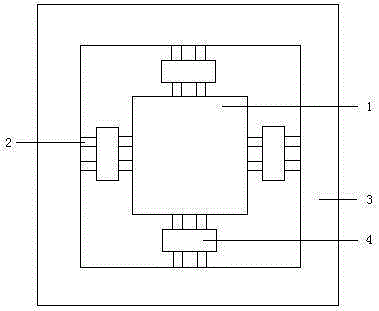

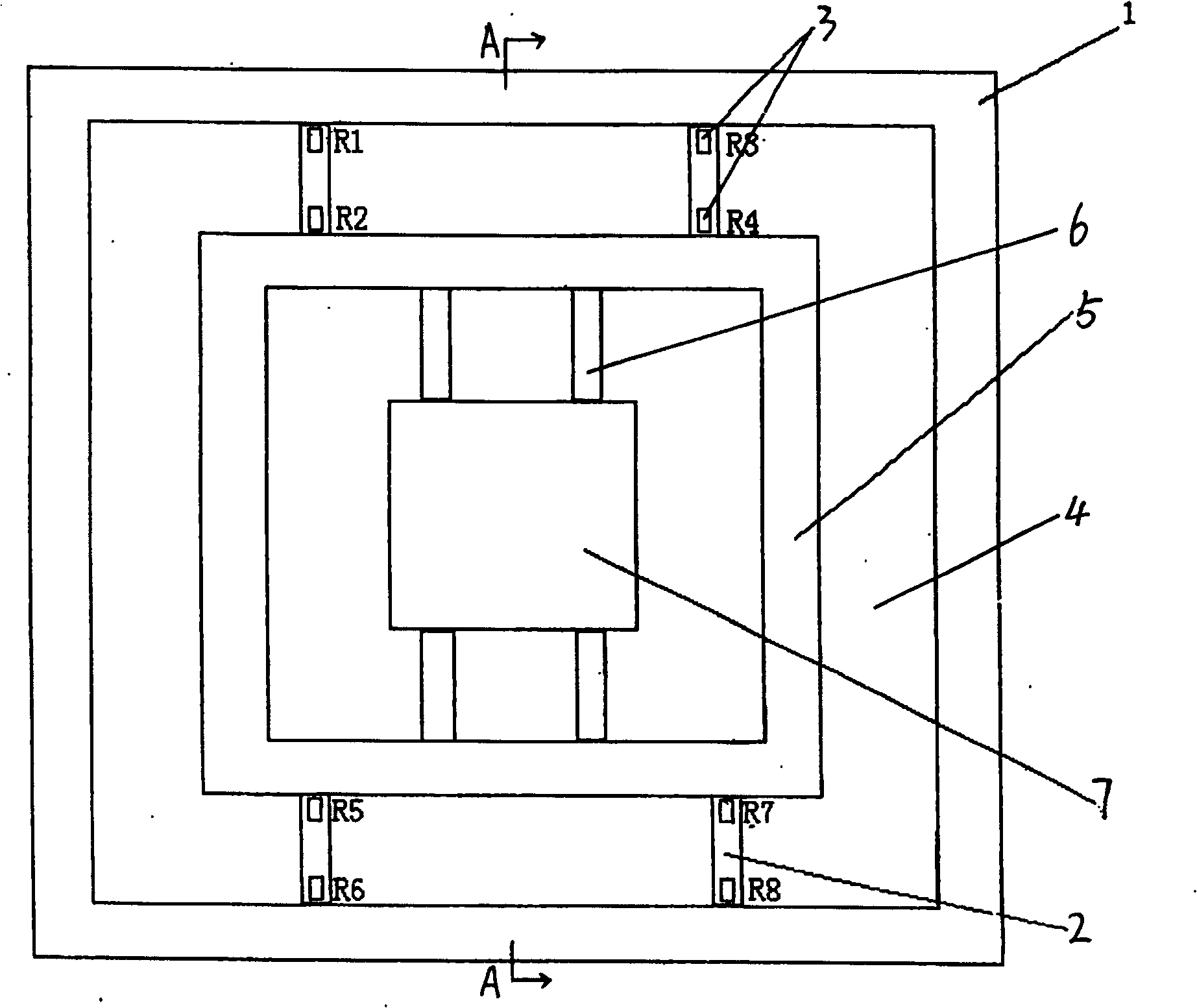

Composite beam piezoresistive accelerometer

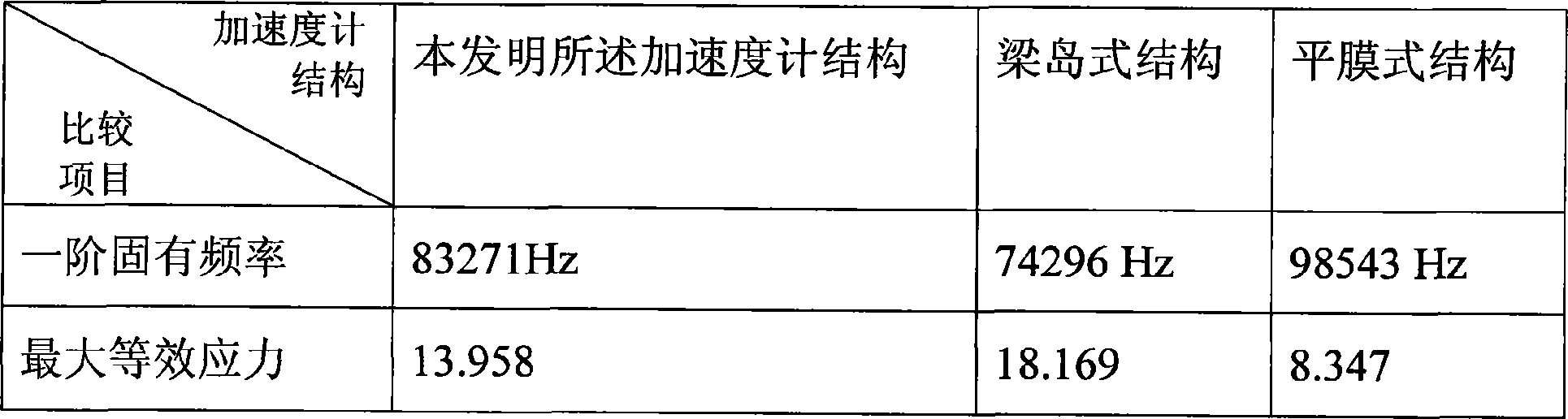

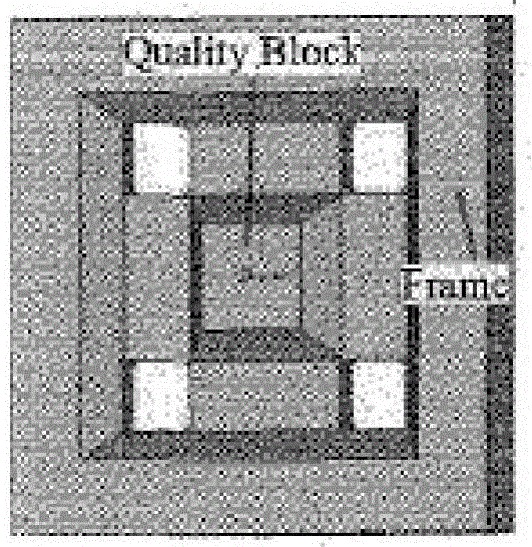

InactiveCN101034094APlay a buffer roleReduce displacementAcceleration measurement using interia forcesElectrical resistance and conductancePiezoresistive accelerometer

This invention relates to a composite beam pressure drag accelerometer; belong to micro machine electronic technology. This invention solves existing problem of that structure of high g accelerometer can not satisfy characteristic request of first order's high inherent rate, wide frequency response scope and worse shock resistance. this accelerometer includes silica-based support carriage shell, spring beam, quality piece that through spring beam overhung in middle of carriage shell, varistor diffused on tip of spring beam. Silica-based support carriage shell undersurface by electrostatic link glass bottom cap. Quality piece is composed by frame body and quality core that through bridge hooked to frame body.

Owner:ZHONGBEI UNIV

Process for manufacturing a triaxial piezoresistive accelerometer and relative pressure-monitoring device

ActiveUS20060185428A1Simple and inexpensive to manufactureEasy to integrateAcceleration measurement using interia forcesNavigation instrumentsRelative pressureInertial mass

Owner:STMICROELECTRONICS SRL

Single-mask fabrication process for linear and angular piezoresistive accelerometers

ActiveUS20070084041A1Reduce complexityLow costWave amplification devicesSolid-state devicesEngineeringPiezoresistive accelerometer

An accelerometer and a method of fabricating an integrated accelerometer comprises the steps of providing an SOI wafer with a selected resistivity to eliminate any need for additional doping of the SOI wafer, providing a single mask on the SOI wafer, and simultaneously defining all components of the accelerometer in the SOI wafer without using any pn-junctions to define any piezoresistive components and to provide the same resistivity of all components. The step of simultaneously defining all components of the accelerometer in the SOI wafer comprises defining all components of a linear or angular accelerometer.

Owner:RGT UNIV OF CALIFORNIA

Silicon micro-piezoresistive accelerometer capable of reducing temperature excursion

InactiveCN101430340AReduce volumeReduce output errorAcceleration measurement using interia forcesSolid-state devicesCantilevered beamElectrical resistance and conductance

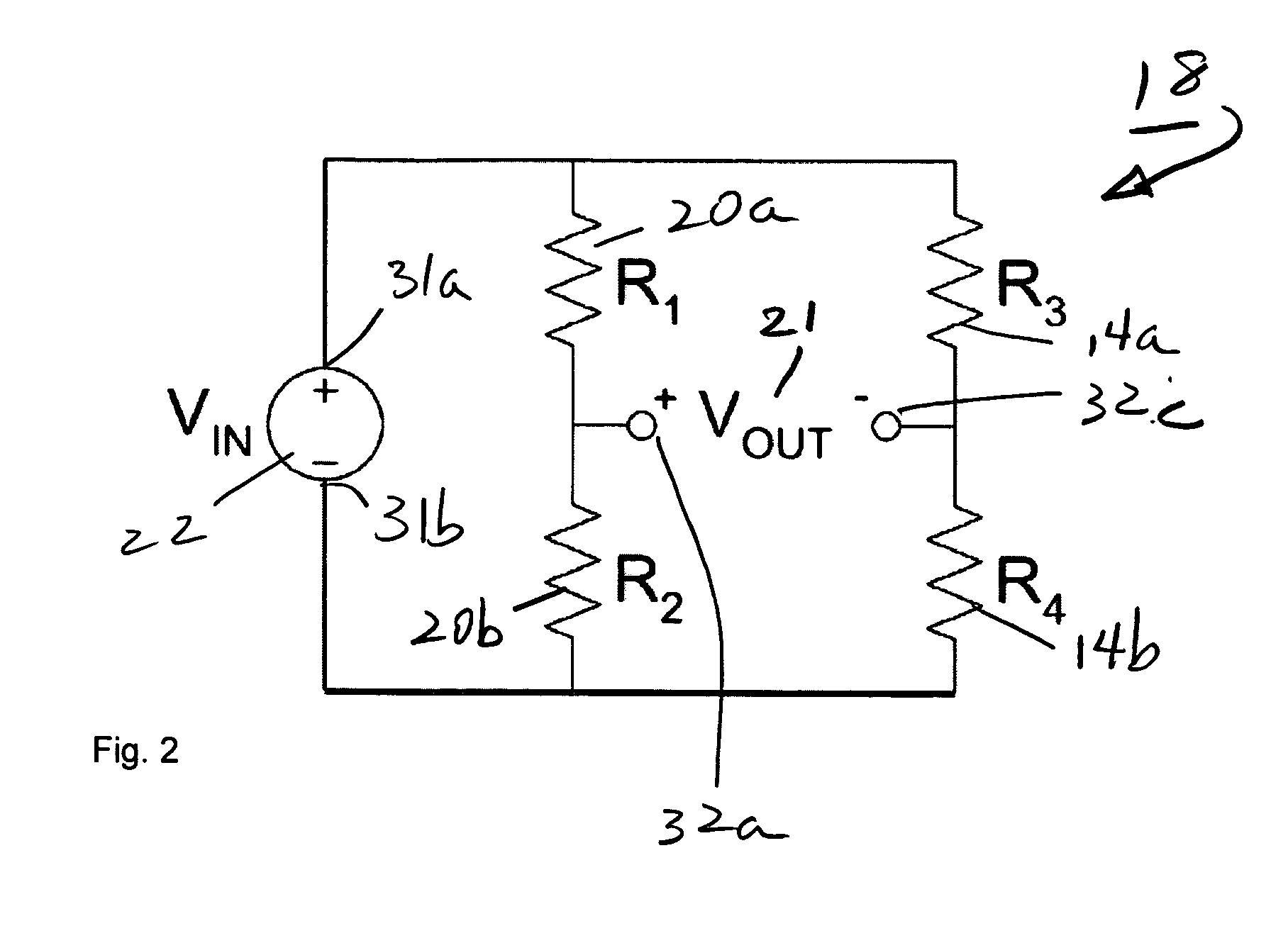

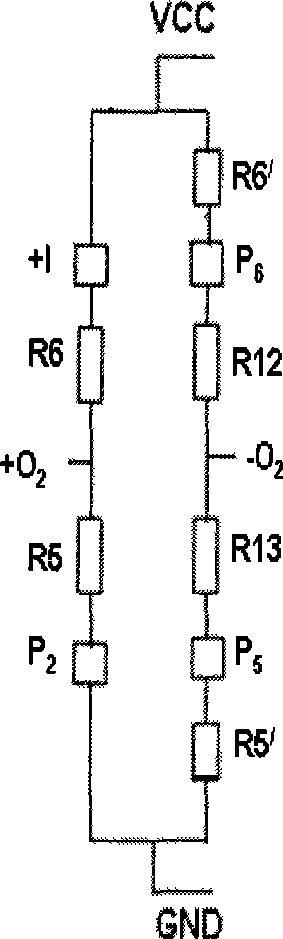

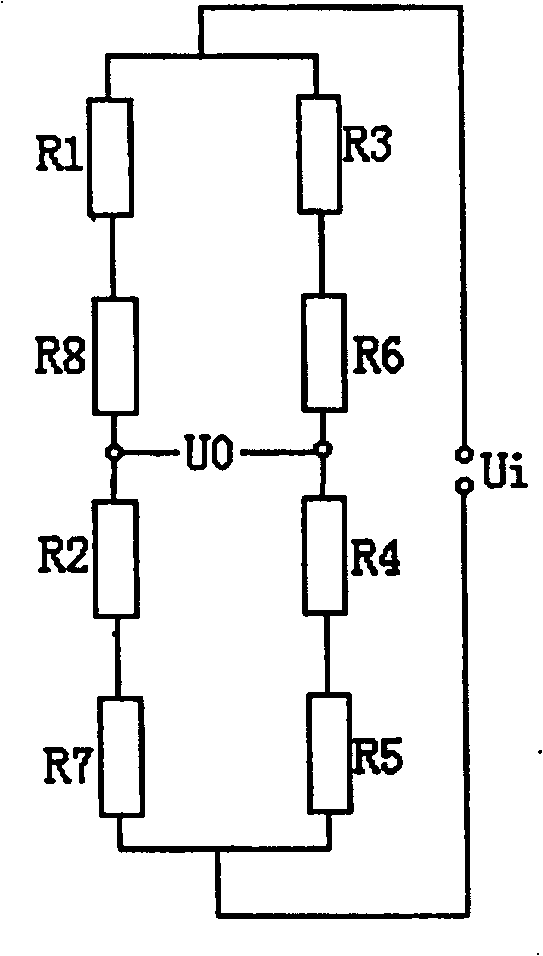

The invention relates to a piezoresistive silicon-micro-accelerometer, in particular to the piezoresistive silicon-micro-accelerometer which can reduce temperature drift. The temperature property of the piezoresistive silicon-micro-accelerometer is improved, and the temperature drift is reduced. The accelerometer comprises a silicon basal framework, a socle beam, a mass block, a strain varistor arranged at the fixed end part of the socle beam, the mass block and the silicon basal framework, a reference varistor arranged on the silicon basal framework and a peripheral zero-regulating resistor arranged outside the silicon basal framework; the peripheral zero-regulating resistor, the strain varistors and the reference varistor are connected to form a wheatstone bridge, the peripheral zero-regulating resistor is independently taken as a bridge arm of the wheatstone bridge; and the peripheral zero-regulating resistor is a varistor which is produced on anther silicon substrate with the same property by adopting an ion injection technology, and the wheatstone bridge containing the varistor is zeroed by controlling the ion injection speed when the varistor is produced. The invention has the advantages of convenient zeroing, low temperature drift, small error output and large operation temperature range.

Owner:ZHONGBEI UNIV

Piezoresistance type accelerometer with high g values

InactiveCN101118249AHigh sensitivityRaise the natural frequencyAcceleration measurement using interia forcesElectrical resistance and conductanceEngineering

The present invention relates to the technical field of the micro mechanical electronics, in particular to a piezoresistive high g-value accelerometer which resolves the problems that the structure of the existing accelerometer can not meet the demand of properties like high fixed frequencies, high flexibility and high bearing of lateral acceleration at the same time. The accelerometer comprises a Silicon-based frame, an elastic girder, and a quality block that is hung at the middle of the silicon-based frame by dint of the elastic girder; wherein, the end part of the elastic girder is provided with a voltage-dependent resistor that forms a Wheatstone bridge, the width of the elastic girder is the same with the width of the quality block, but the thickness of the elastic girder is smaller than the thickness of the quality block, the backside of the quality block is provided with a concave slot. The present invention has simple reasonable structure and good anti-overloading ability; and avoids being disabled under the circumstance of serious striking. Moreover, the production technique is quite simple, which is suitable for high-range accelerometer.

Owner:ZHONGBEI UNIV

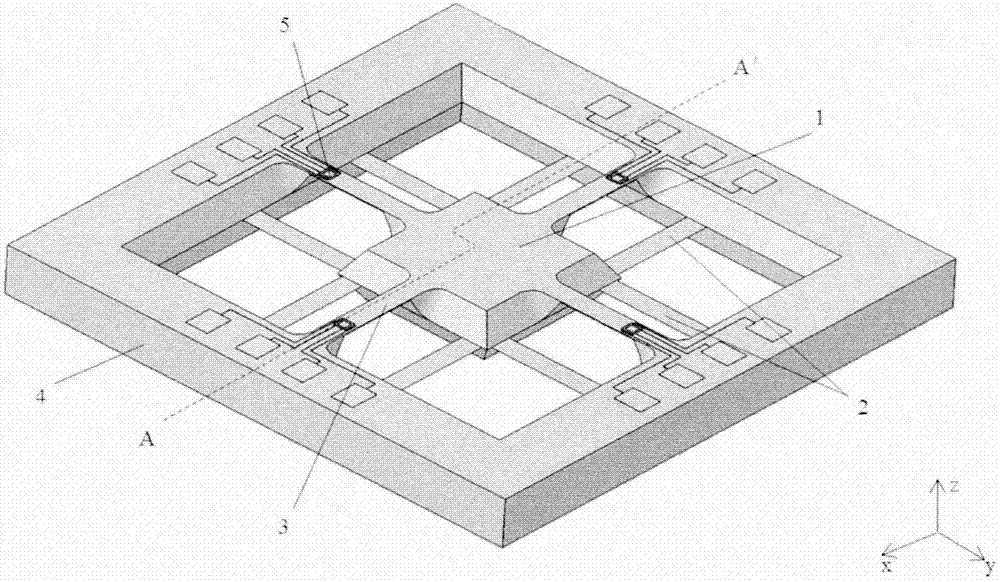

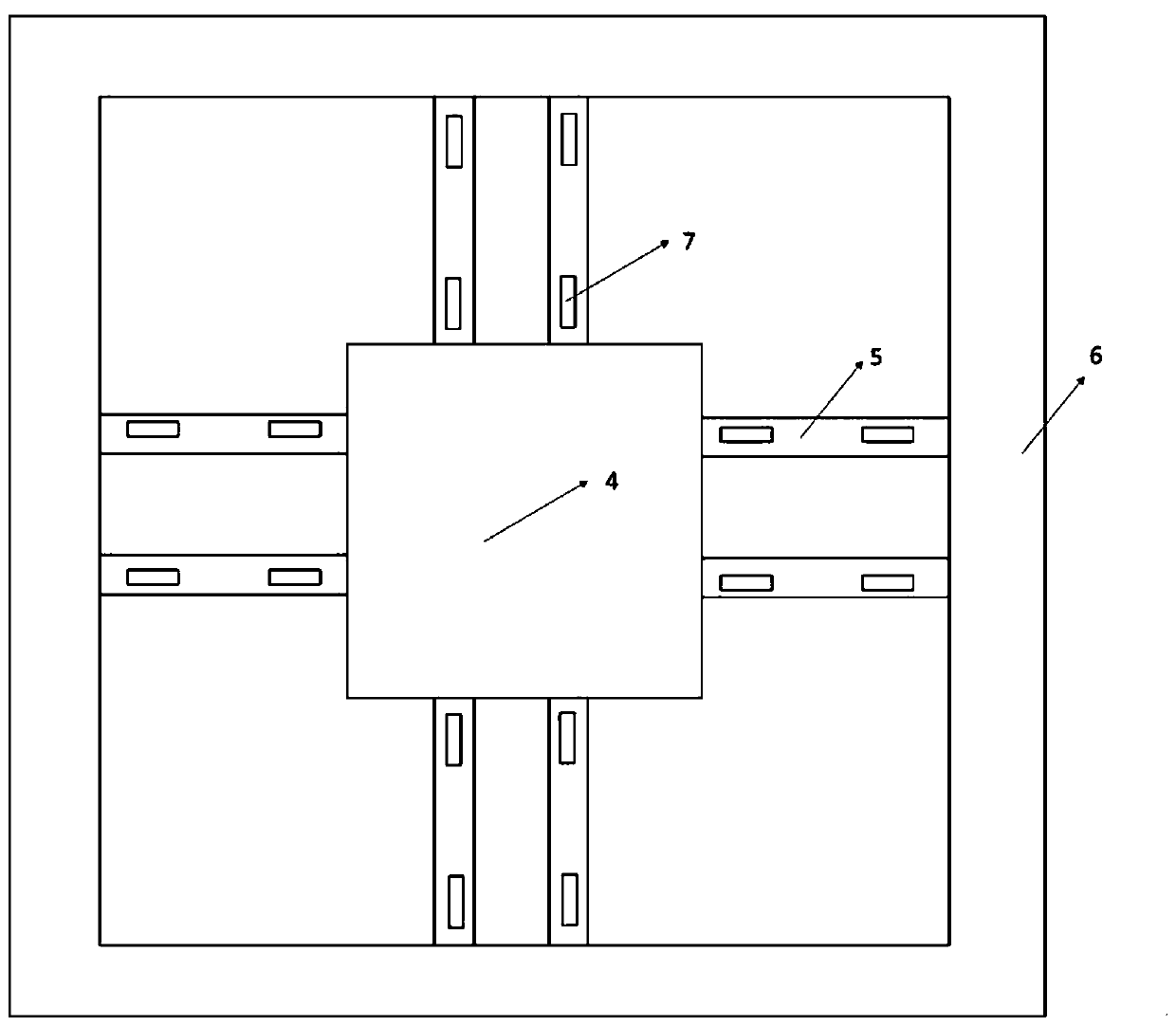

MEMS piezoresistive accelerometer

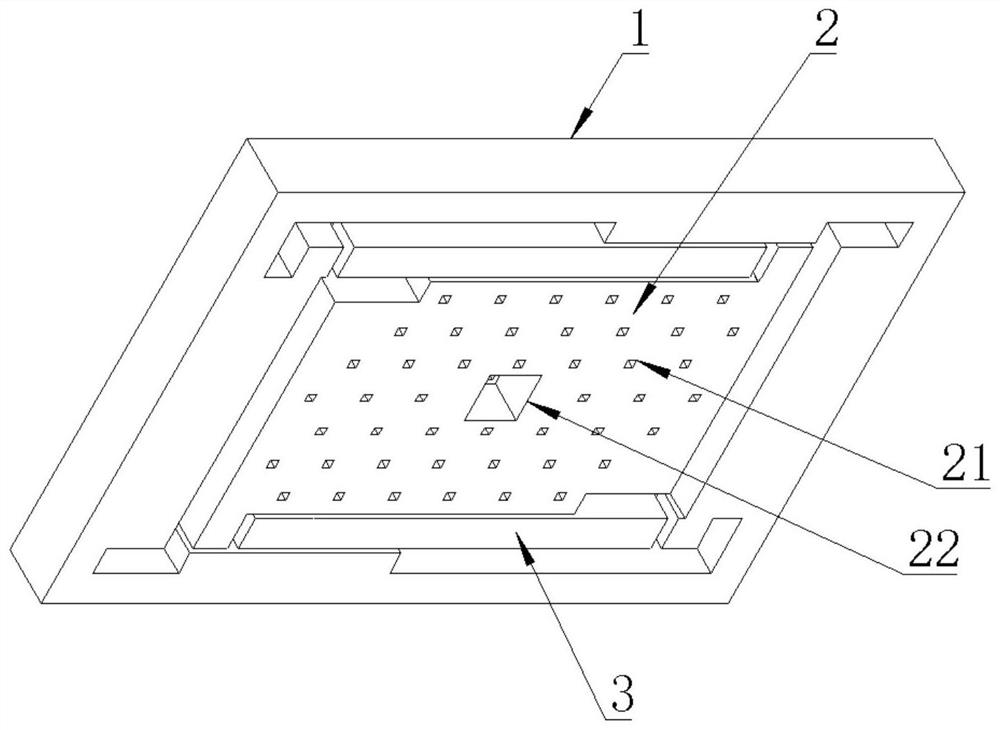

InactiveCN103575932AHigh sensitivityReduce volumeAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElectrical resistance and conductanceEngineering

The invention discloses an MEMS piezoresistive accelerometer. The MEMS piezoresistive accelerometer comprises a substrate, a frame, elastic beams, a main mass block, secondary mass blocks, an upper sealing cap and a plurality of sets of piezoresistors, wherein the main mass block is arranged in the center of the frame through the elastic beams in a supporting suspension mode, the frame is fixed to the upper end of the substrate, the secondary mass blocks are arranged on the elastic beams respectively, a specially-shaped elastic beam structure is formed by the secondary mass blocks and the elastic beams, the piezoresistors are arranged in the middle of the elastic beams and the positions of connection between the elastic beams and the frame respectively, the main mass block and the elastic beams are the same in thickness, the upper sealing cap is fixed to the upper end face of the frame, a groove structure is arranged inside the upper sealing cup, and the main mass block is arranged inside a groove in a suspended mode, and can freely move when sensing inertia force in all the directions. According to the MEMS piezoresistive accelerometer, due to the facts that the structure that the elastic beams and the single main mass block are arranged is adopted, and changes of stress, at different positions, of the specially-shaped elastic beams are reflected when the main mass block senses the inertia force in different directions, the size of a device is effectively reduced, and the MEMS piezoresistive accelerometer has the advantages of being high in sensitivity and natural frequency, good in high-overload resistant capacity and the like.

Owner:DALIAN UNIV OF TECH

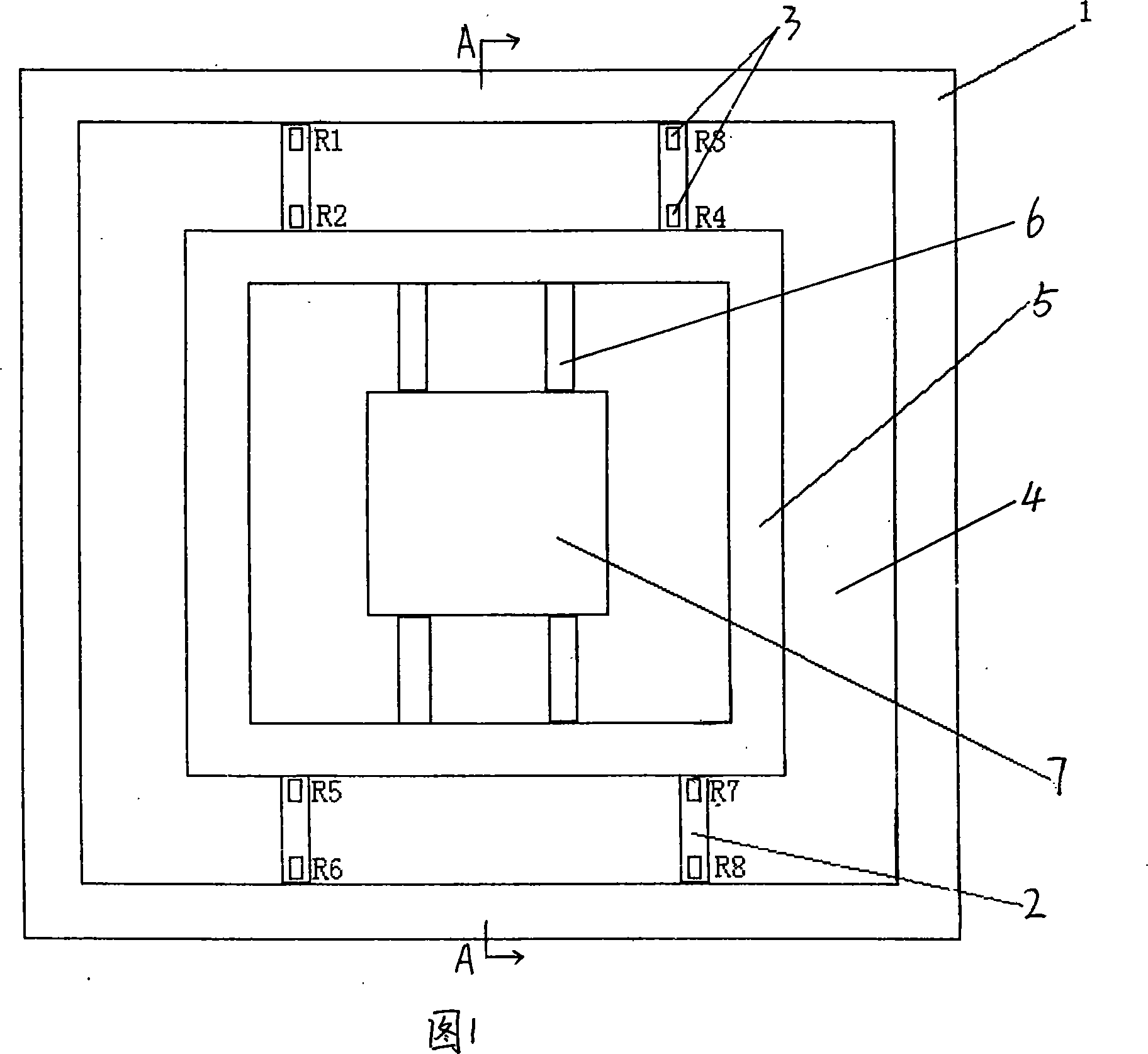

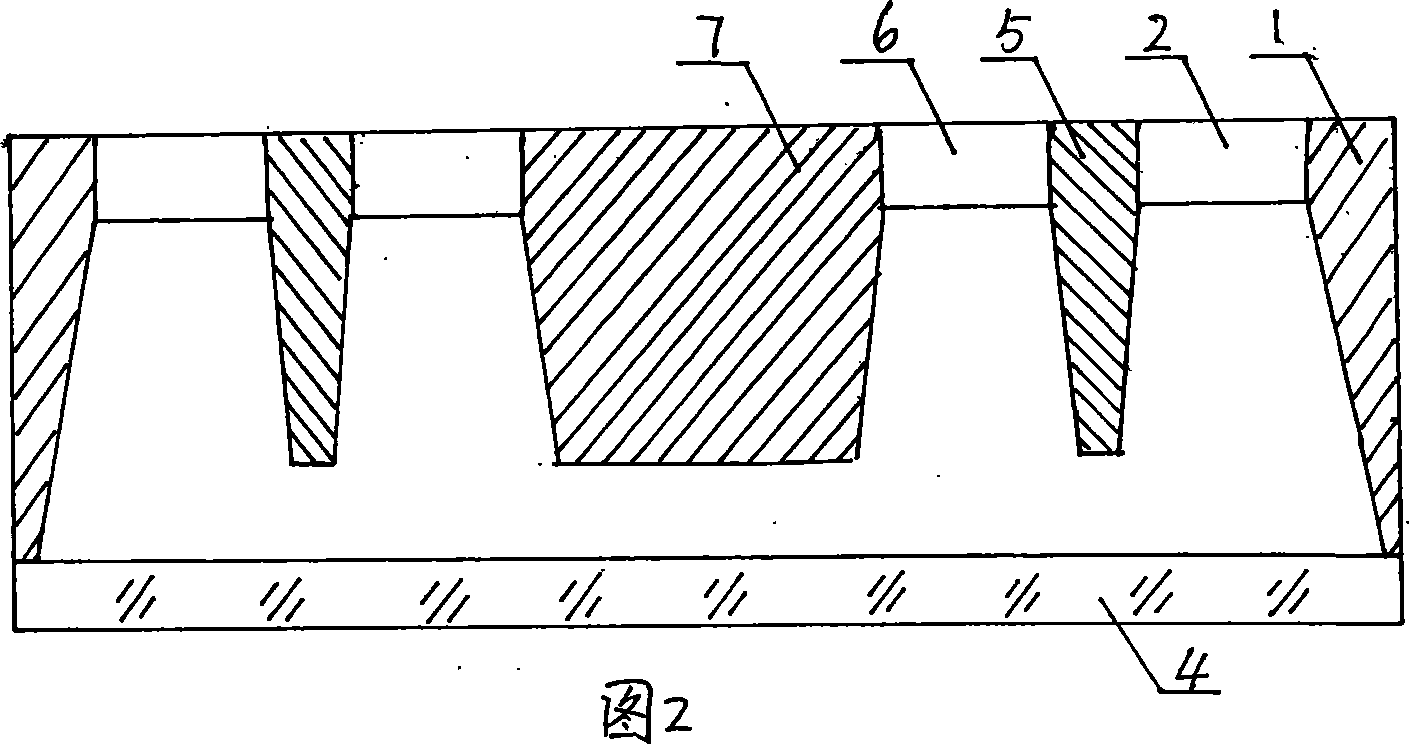

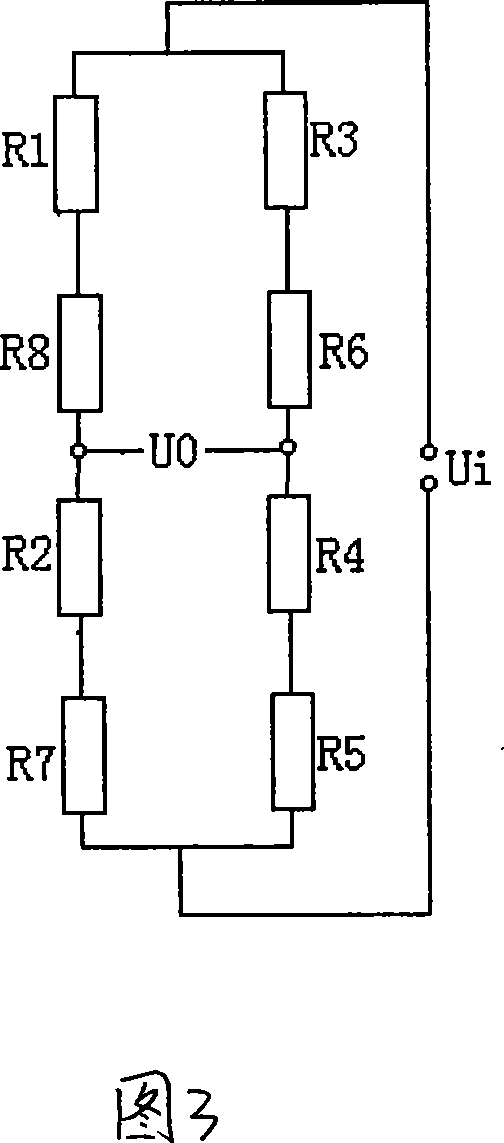

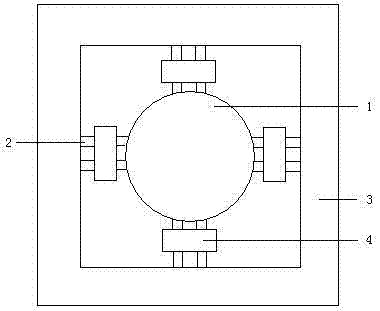

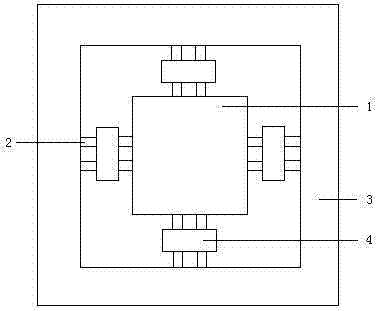

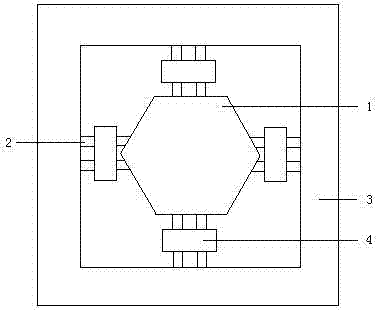

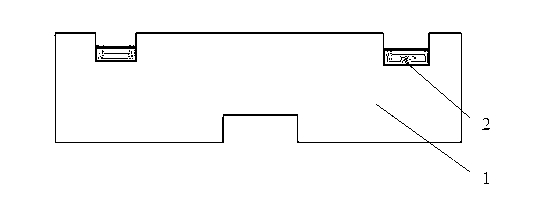

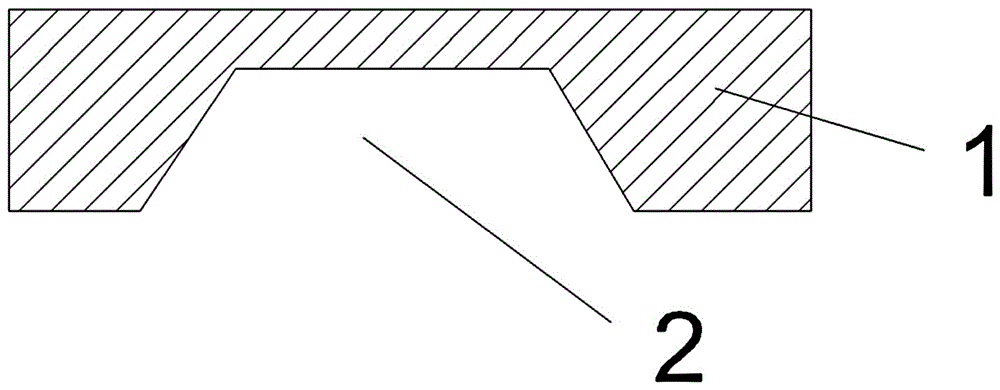

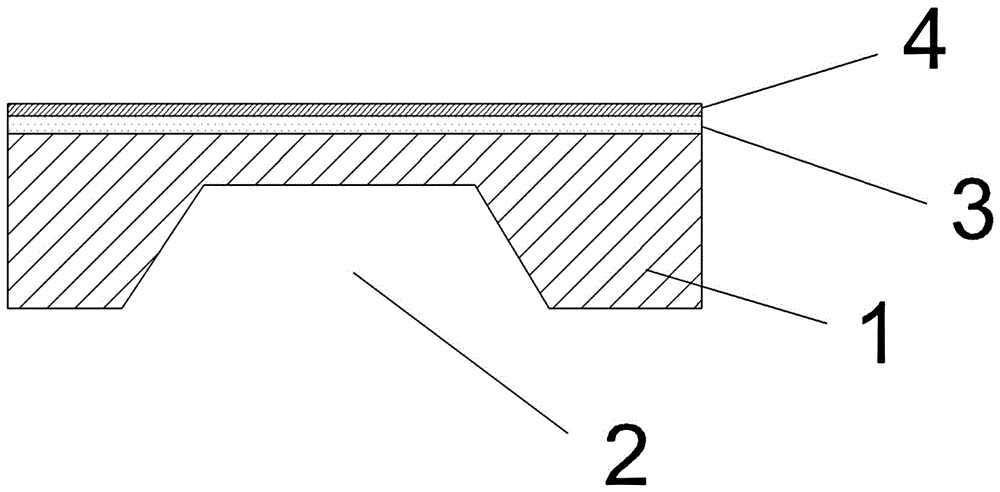

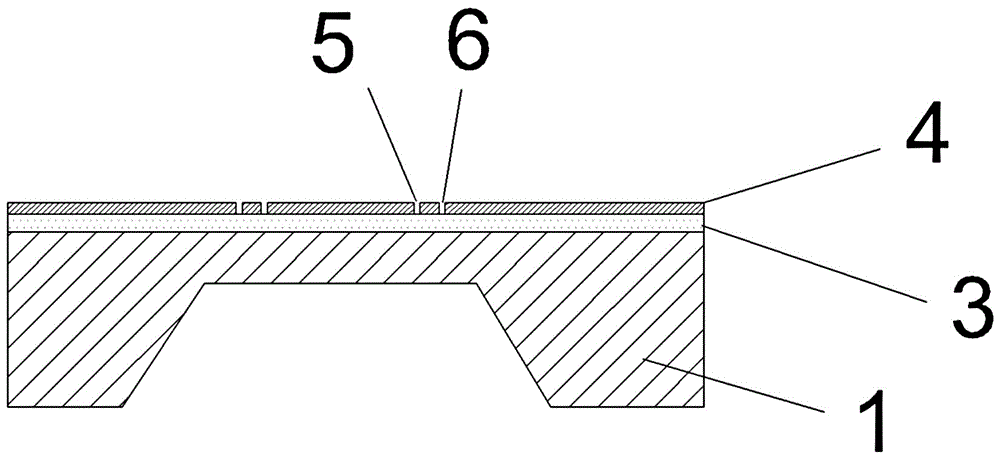

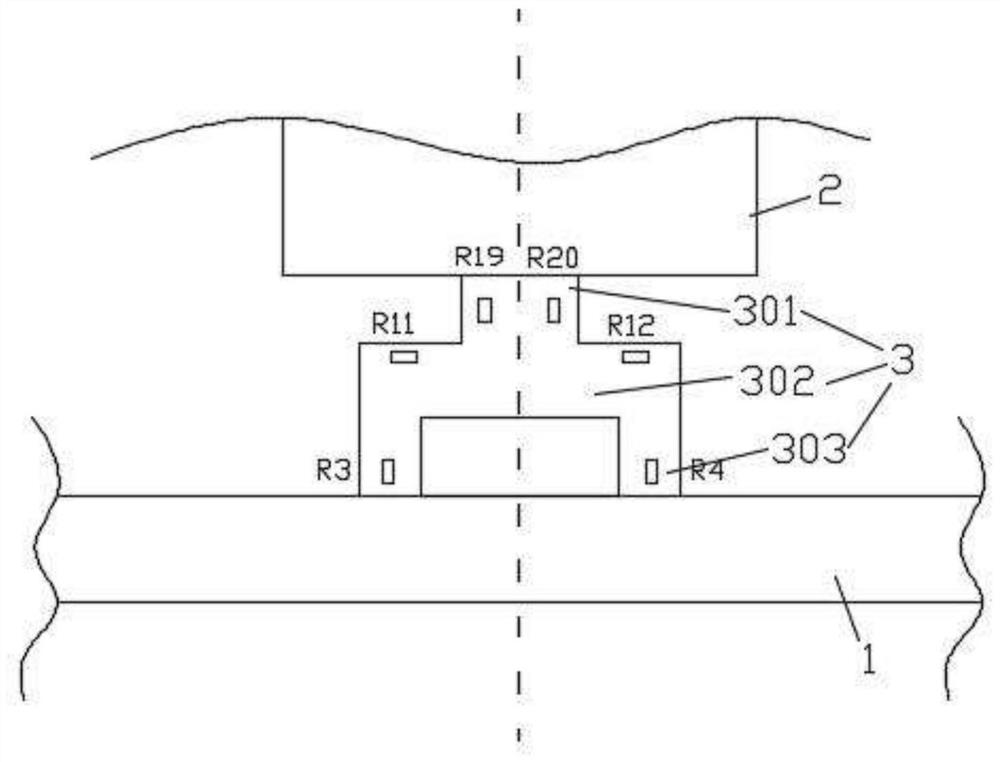

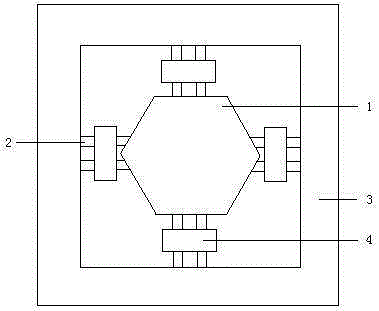

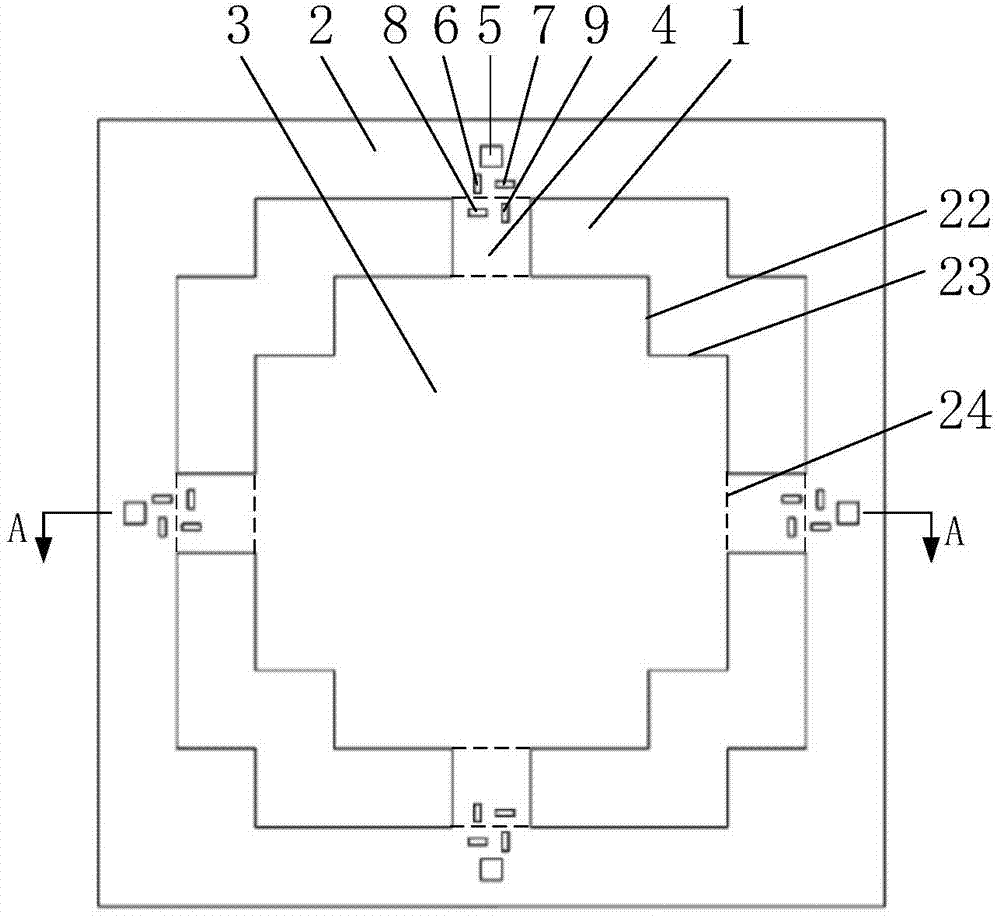

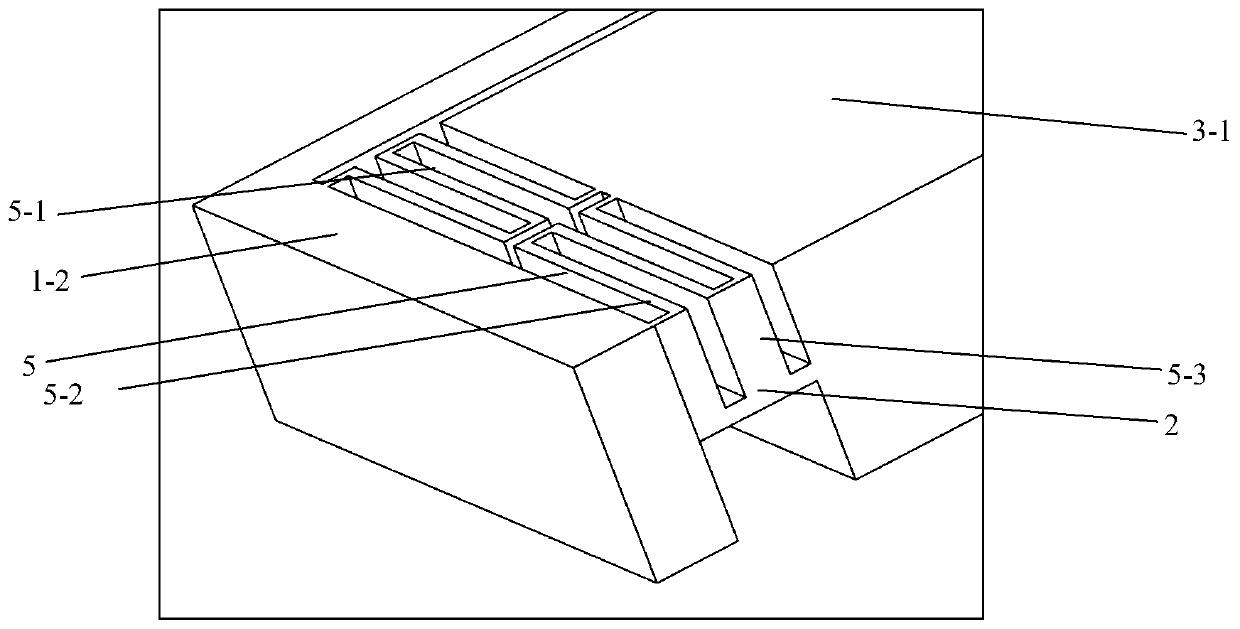

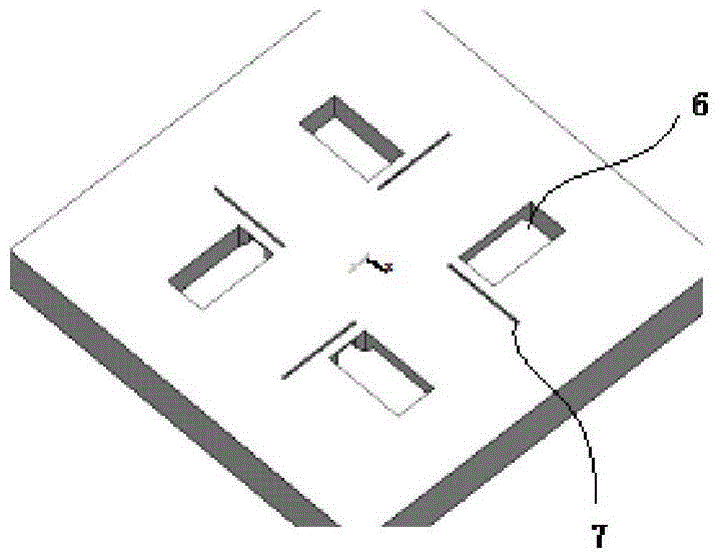

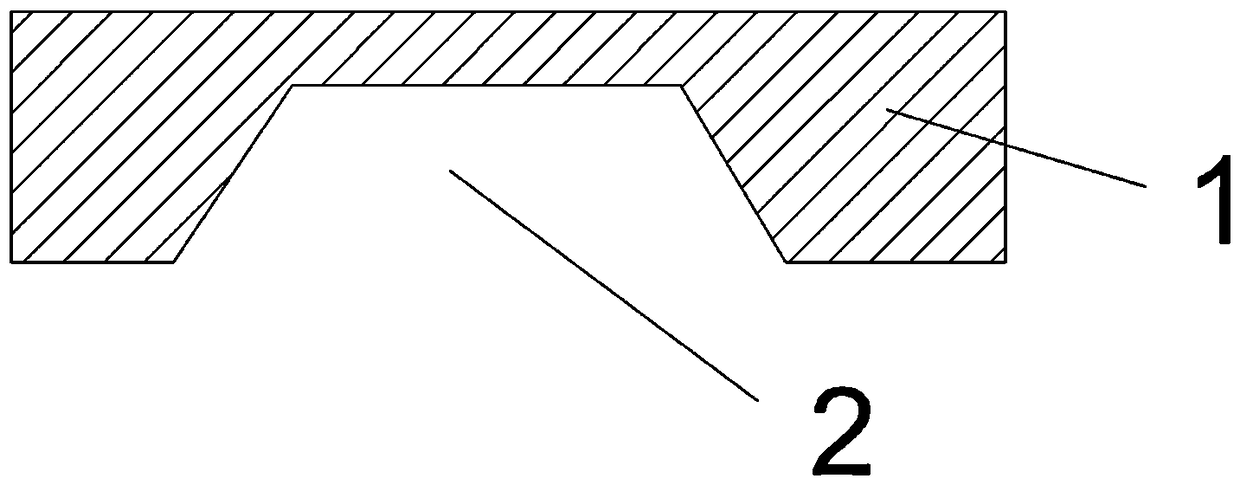

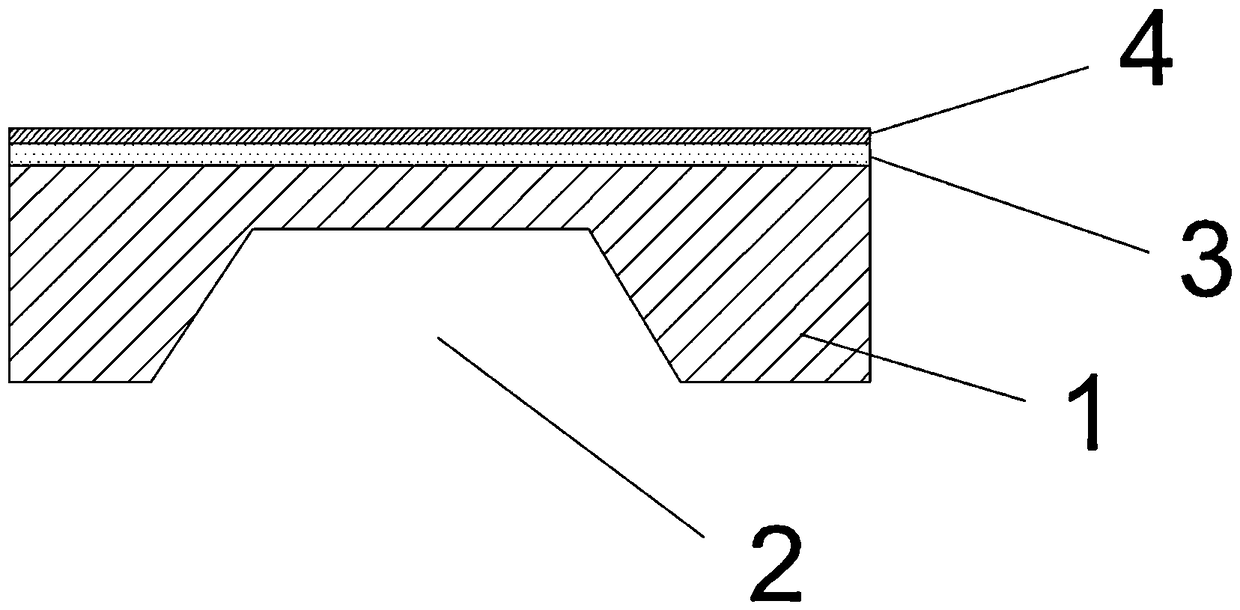

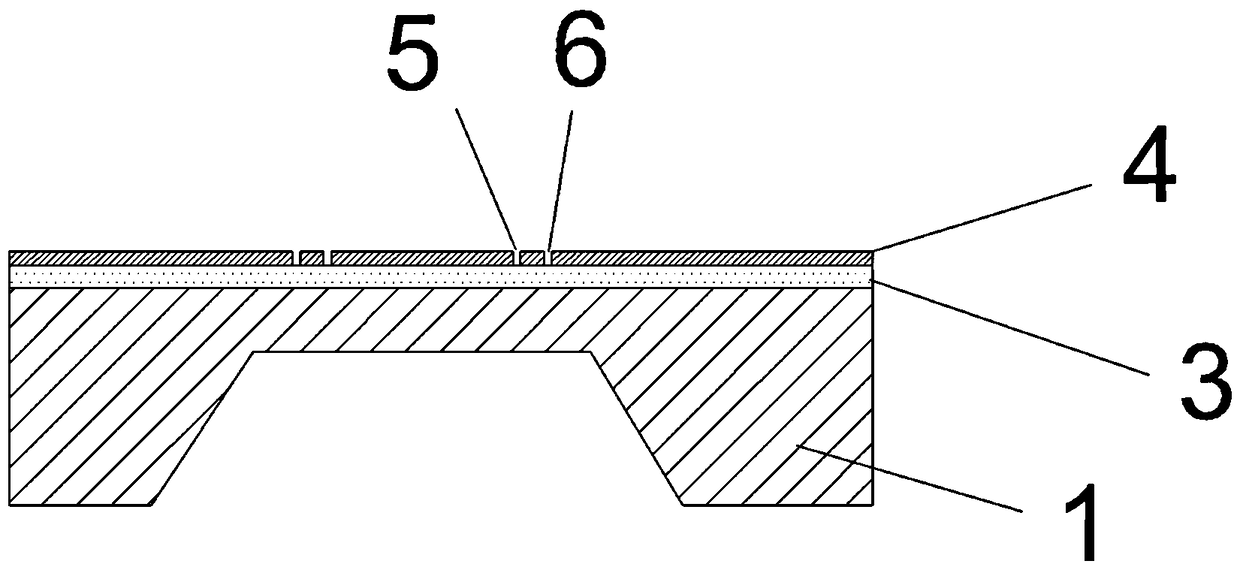

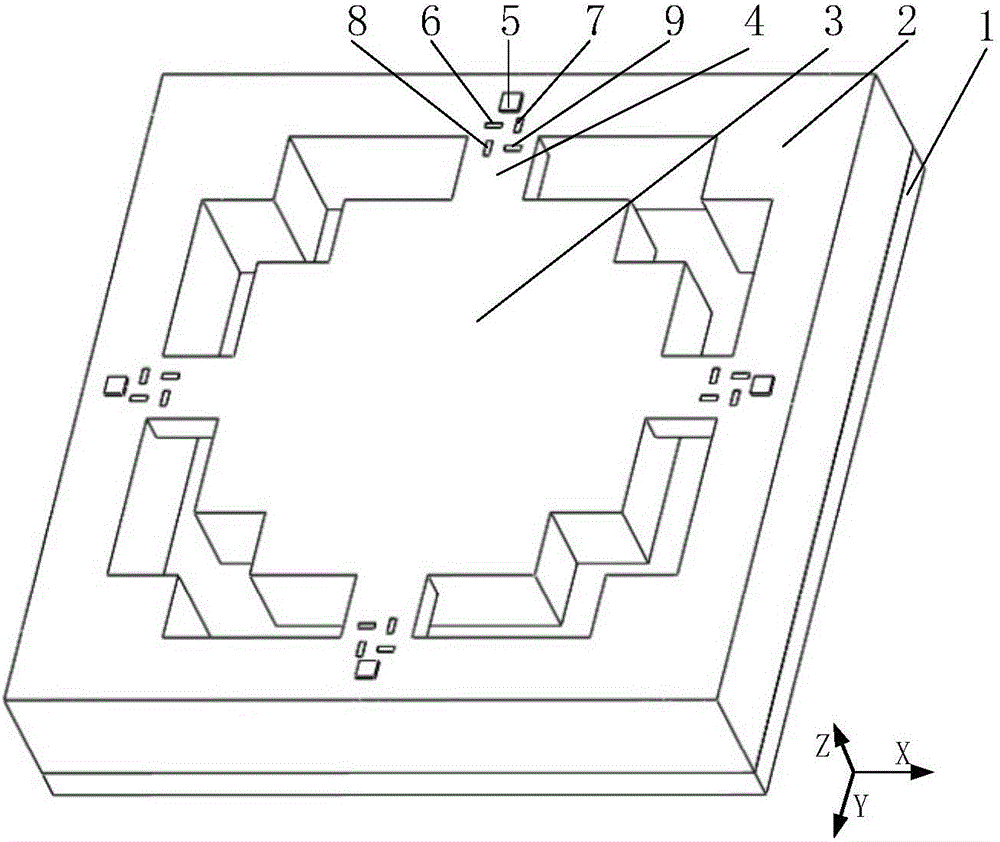

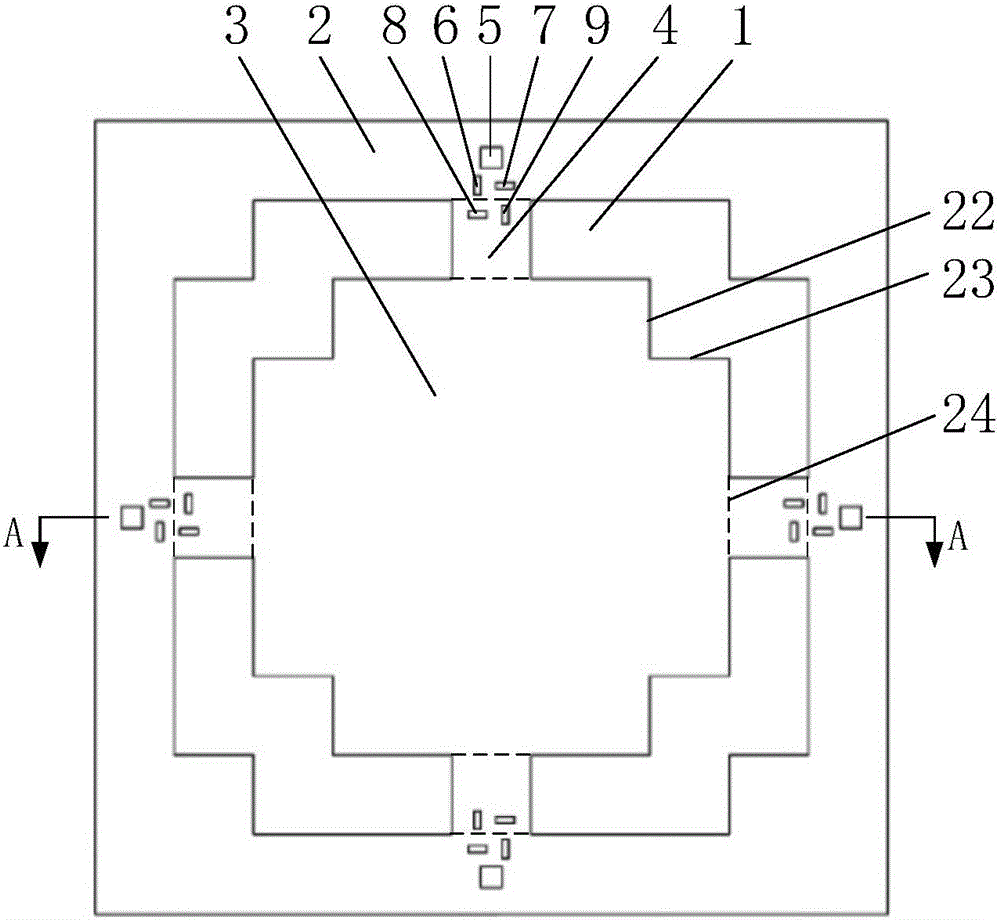

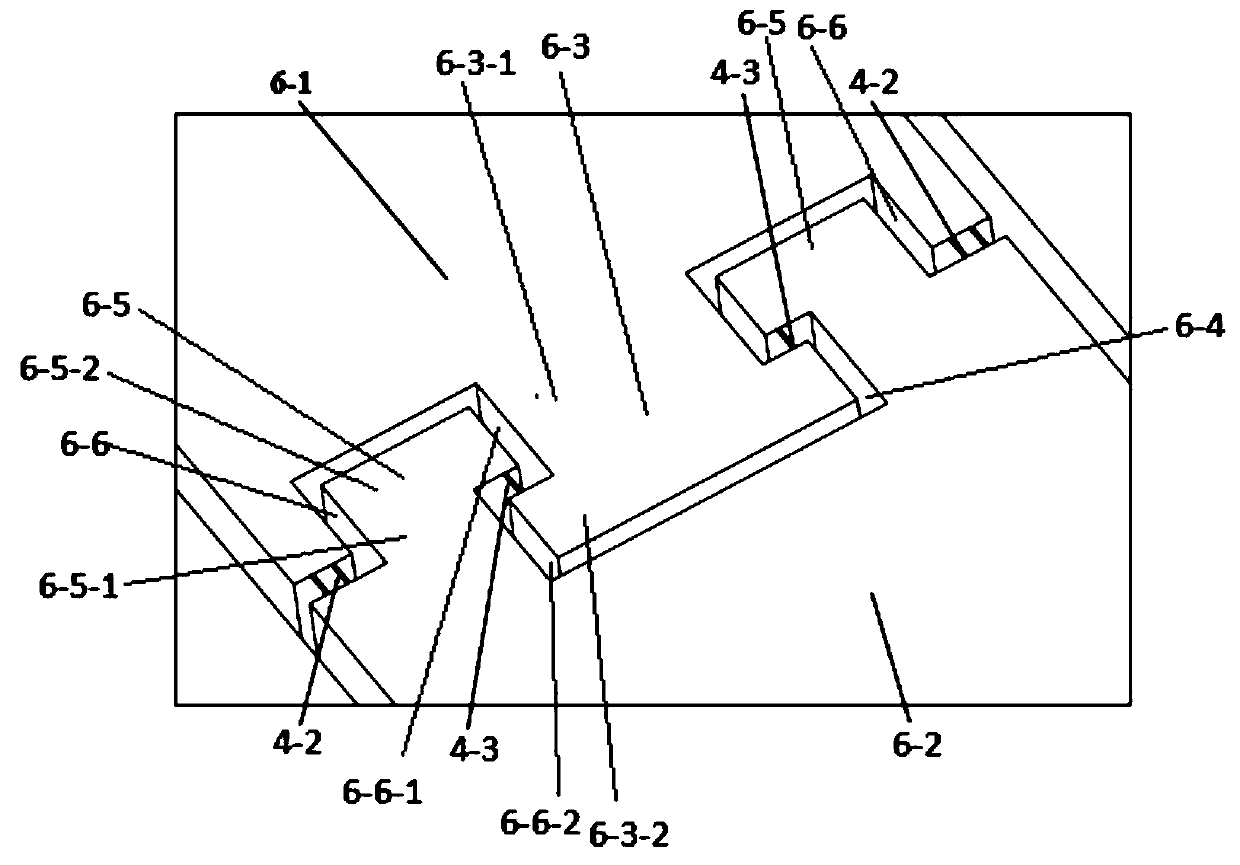

Low cross-axis sensitivity piezoresistive accelerometer structure and manufacturing method thereof

InactiveCN108008150AReduce deflection angleCross axis sensitivity is smallAcceleration measurement using interia forcesElectrical resistance and conductancePiezoresistive accelerometer

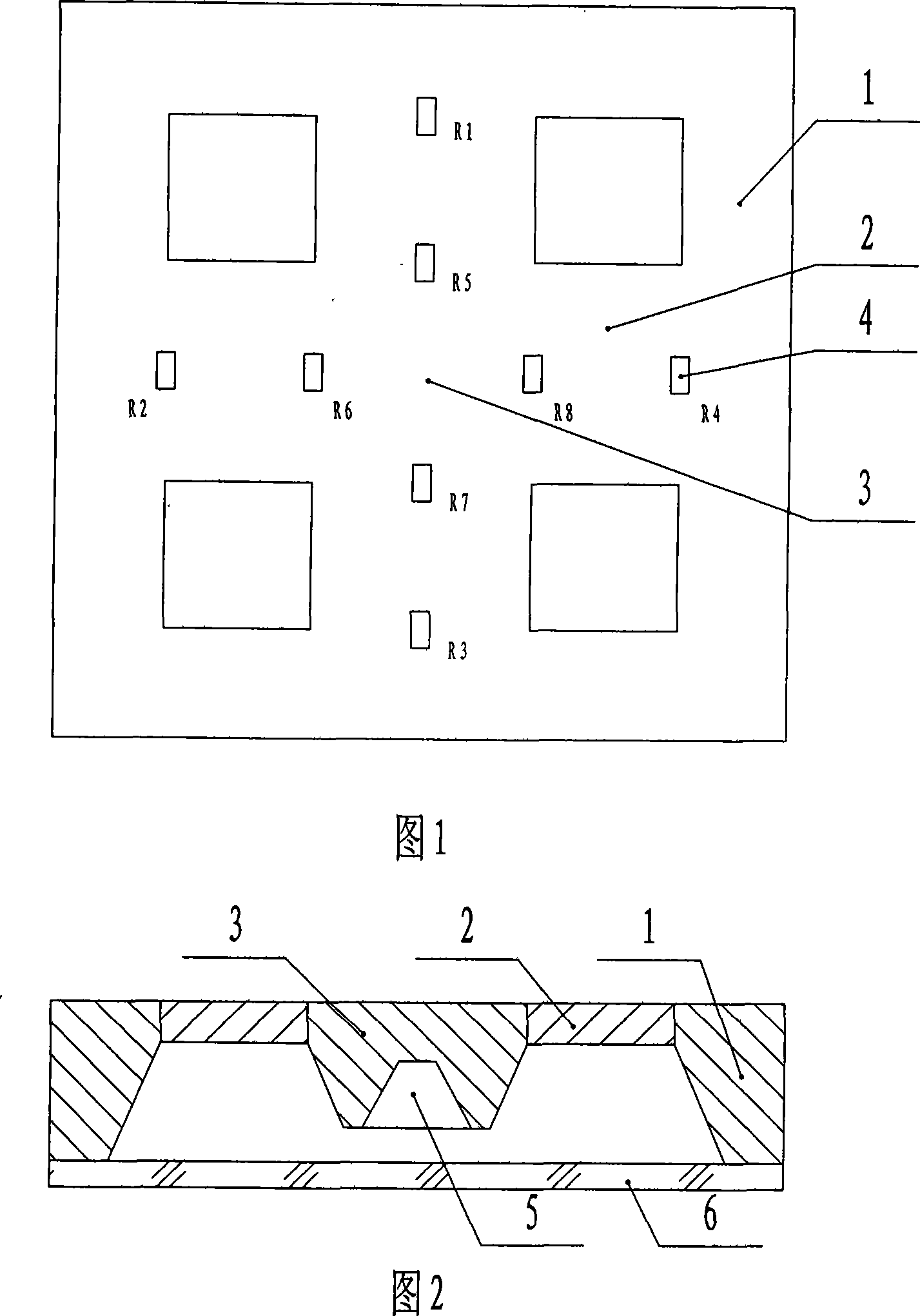

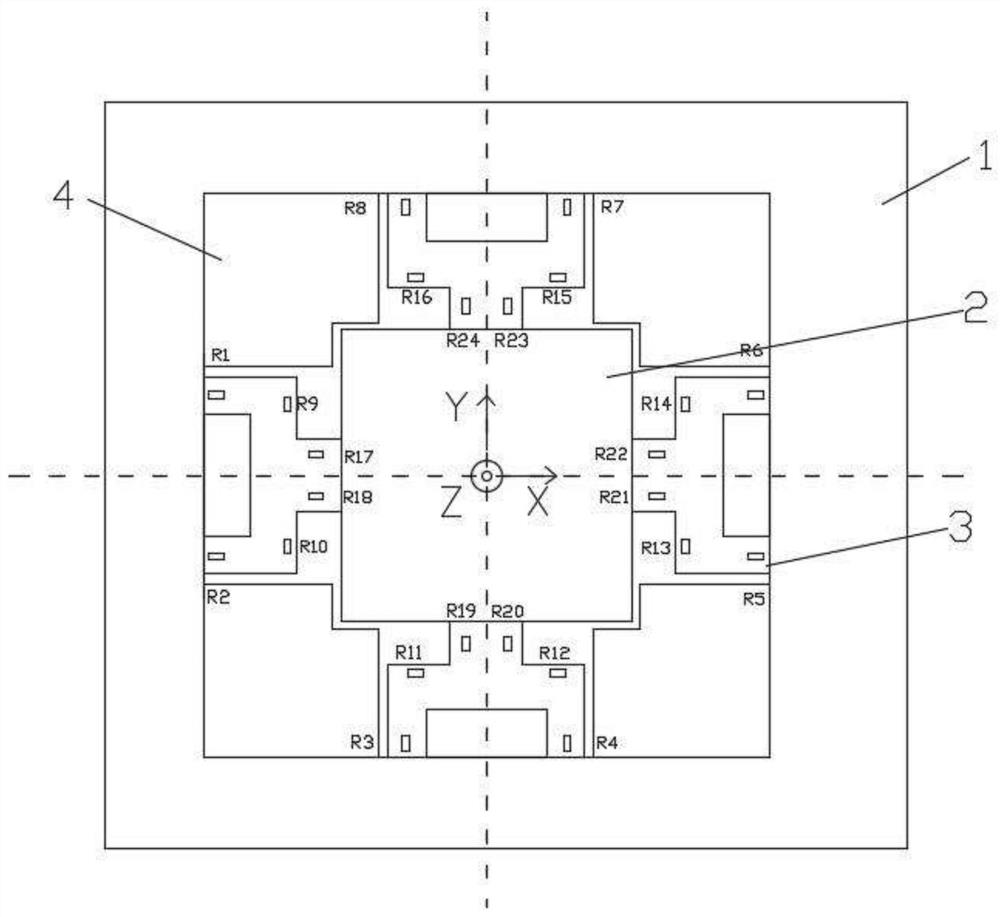

The invention discloses a low cross-axis sensitivity piezoresistive accelerometer structure and a manufacturing method thereof and belongs to the field of micro-electro-mechanical systems. A low cross-axis sensitivity piezoresistive accelerometer is formed by a mass block (1), eight support beams (2), four sensing beams (3) and a frame (4). The center of gravity of the mass block (1) is located ina neutral plane of the support beams (2). The upper surfaces of the sensing beams (3) are located on the surface of a chip such that piezoresistors (5) are made on the surfaces of the sensing beams.The thickness of the sensing beams is far smaller than that of the support beams. Under the action of Z-axis acceleration on the surface of a vertical chip, the mass block (1) moves in a Z-axis direction and drives the sensing beams (3) to move together, the strain of the sensing beams (3) is detected by the piezoresistors (5), thus Z-axis acceleration is obtained. Since the center of gravity of the mass block (1) is located in the neutral plane of the support beams (2), the deflection angle of the mass block (1) under X-axis or Y-axis acceleration within the chip surface is small, and so thestructure has small cross-axis sensitivity.

Owner:CHINA JILIANG UNIV

Piezo devices with air-spaced cantilever

ActiveUS9048419B2High voltageDistanceAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesElectricityLead zirconate titanate

An arrangement that converts mechanical energy into electrical energy employs a base member and a cantilever member coupled thereto. The cantilever member has two piezoelectric layers with an air space therebetween. A proof mass is coupled to the cantilever member distal from the base member. The first and second piezoelectric layers are formed of lead zirconate titanate (PZT), and the output voltage of the cantilever member is proportional to the height of the air gap. A piezoresistive accelerometer that is useful for measuring mechanical vibration has a suspension beam and a piezoresistive layer be separated from the suspension beam. A method of monitoring an acoustic vibration utilizes a piezoresistive element having an air-spaced cantilever formed of a piezoelectric material in the vicinity of the system to be monitored and obtains an alternating voltage form the air-spaced cantilever of the piezoresistive element.

Owner:WAYNE STATE UNIV

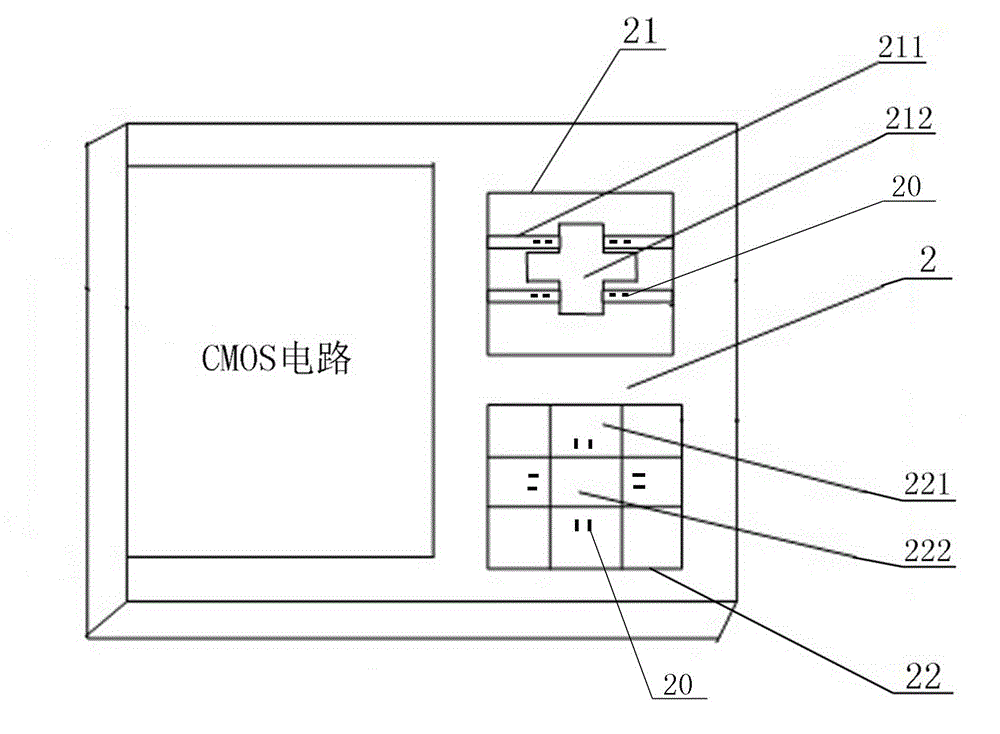

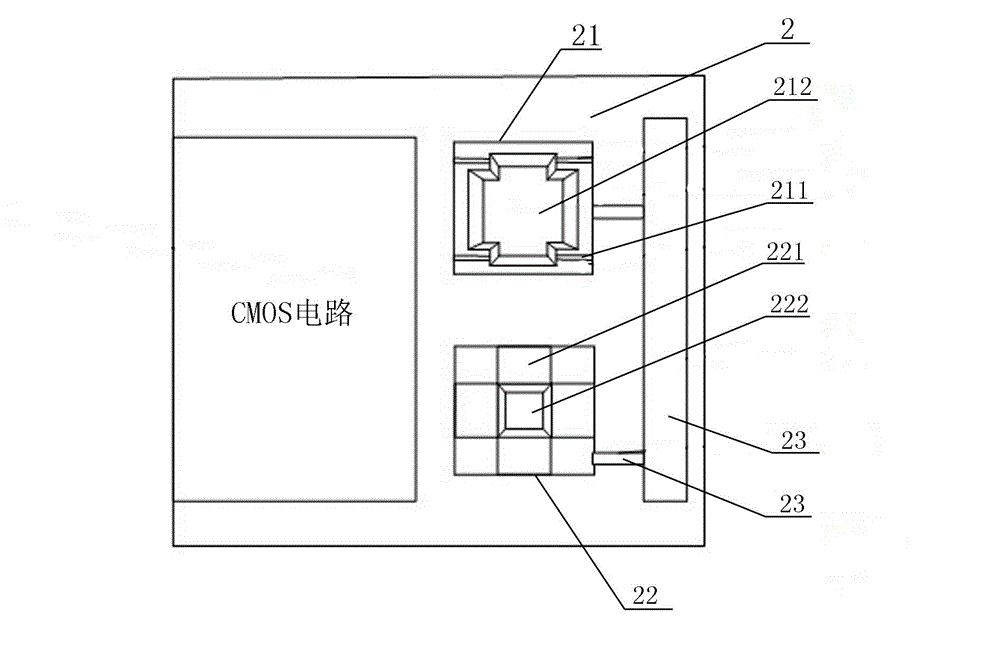

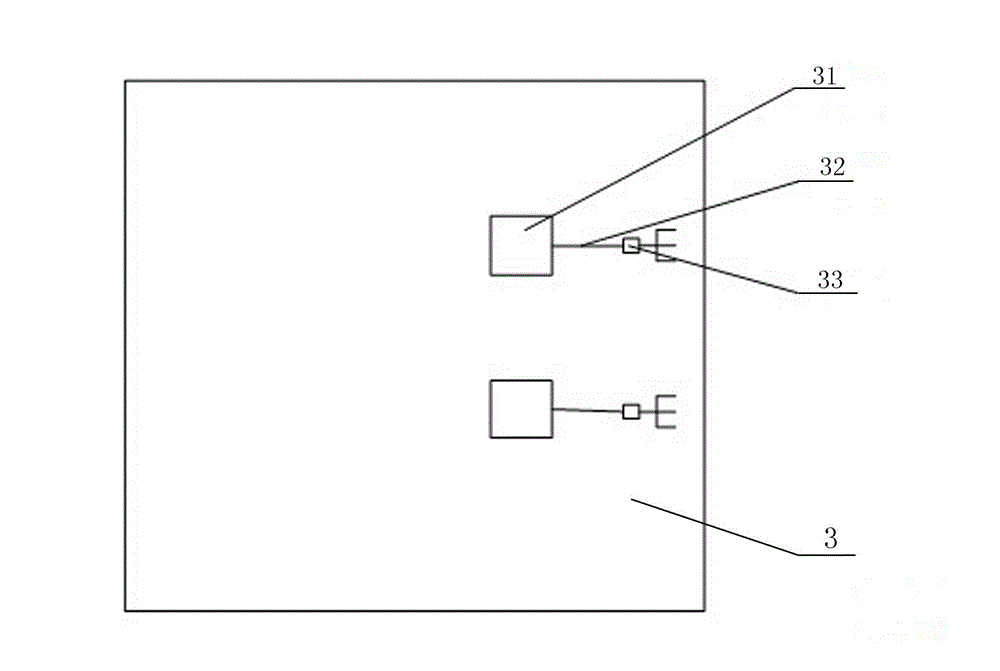

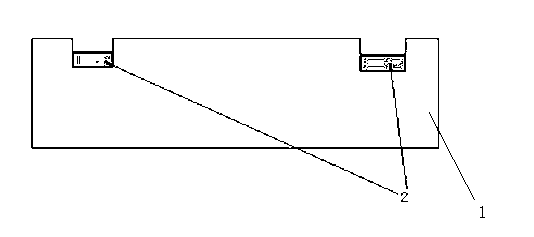

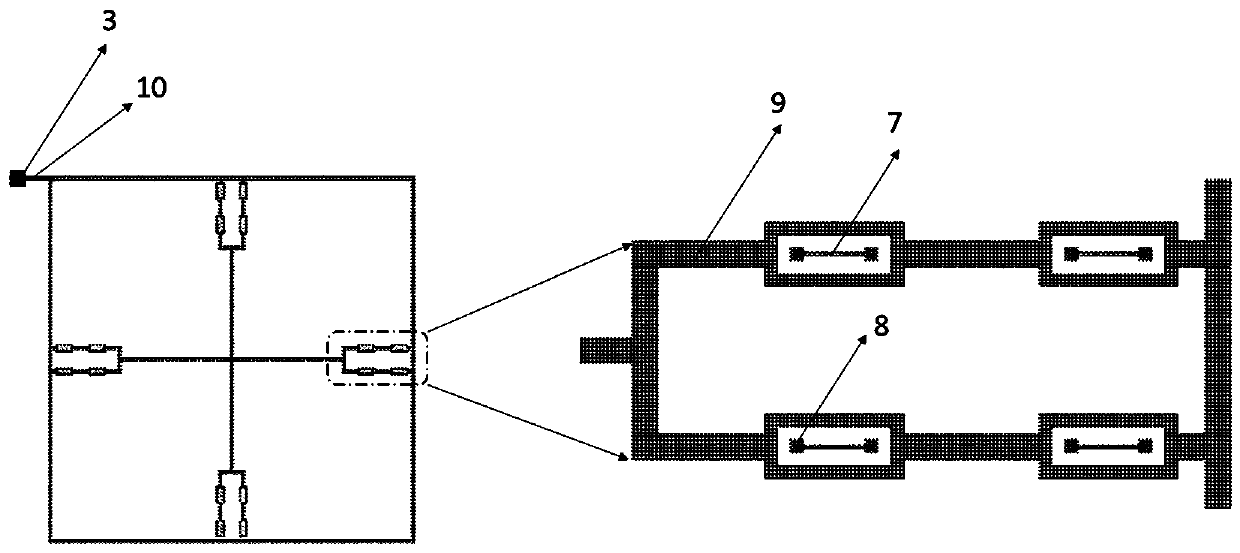

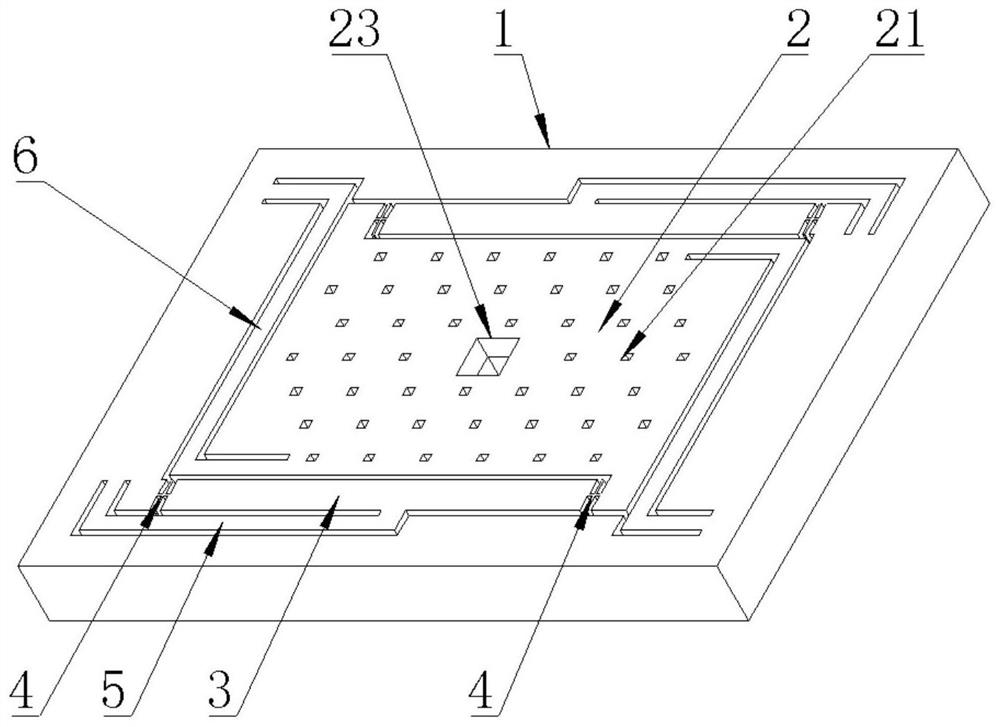

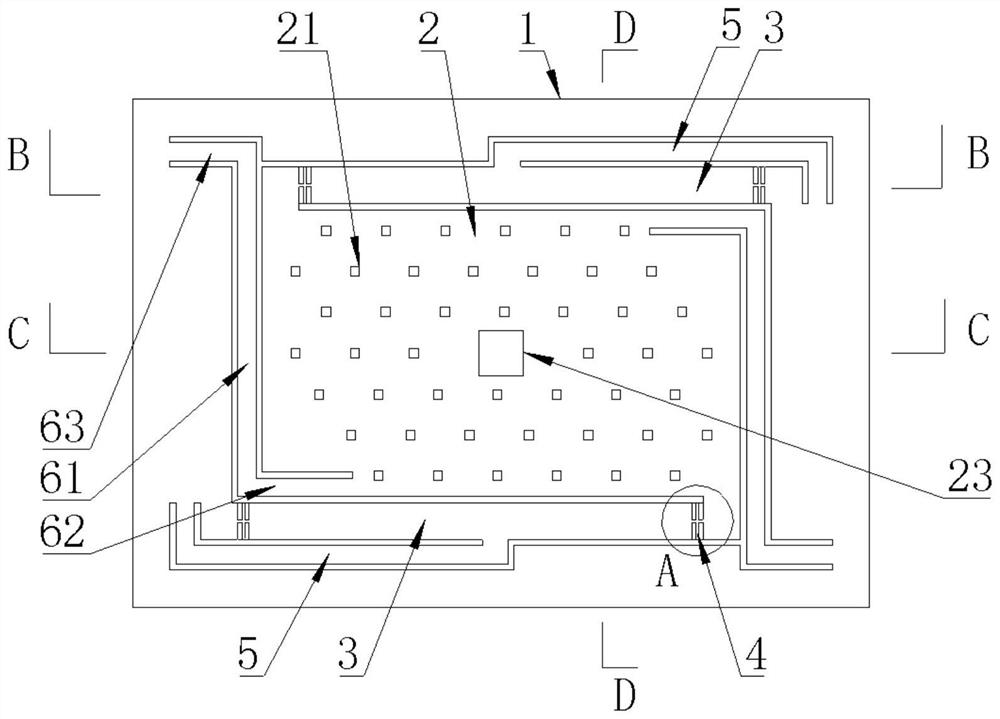

Array type single-chip integrated digital microaccelerometer

InactiveCN102866262AReduce volumeReduce weightAcceleration measurement using interia forcesCMOSSignal processing circuits

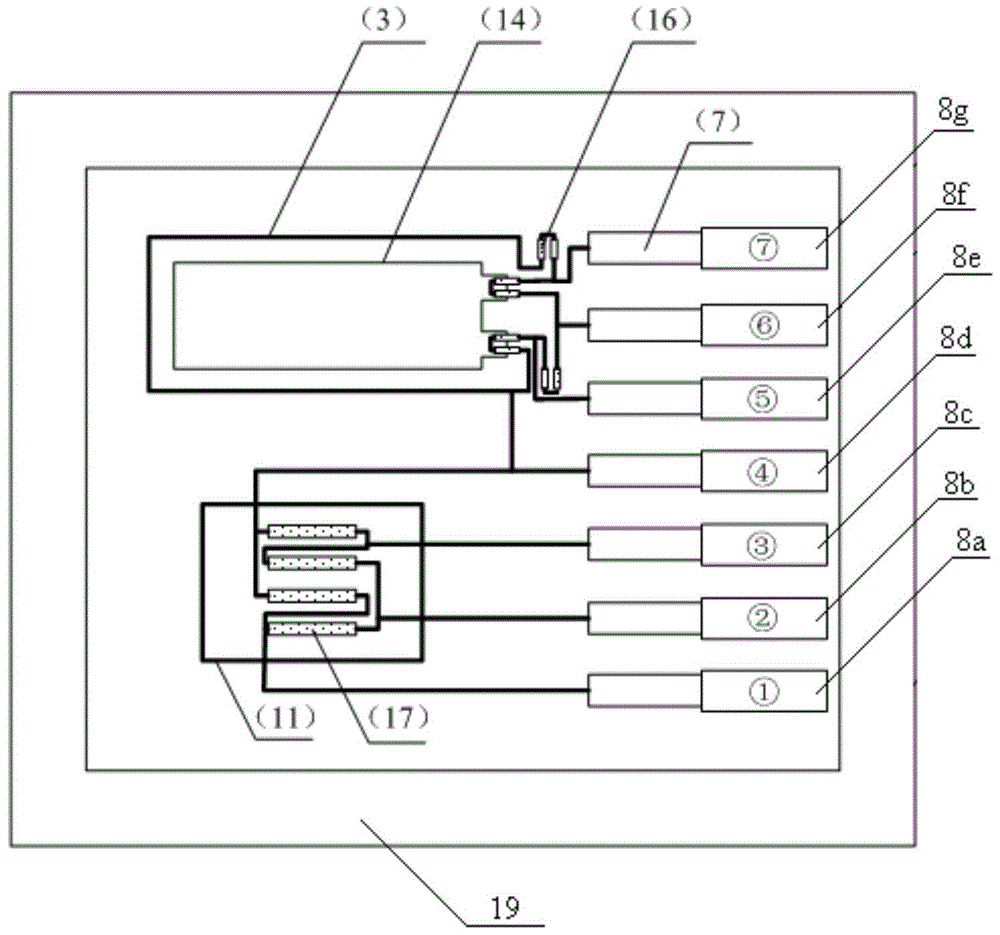

The invention relates to a microaccelerometer, in particular to an array type single-chip integrated microaccelerometer. The technical problems of large size of the conventional acceleration sensor, incapability of realizing the full scale output of the conventional accelerometer unit, high breakage rate of the root of a clamped beam and incapability of realizing the optimal configuration of a high-low-range accelerator are solved. The array type single-chip integrated microaccelerometer comprises a monocrystalline silicon material structural layer (2), and the structural layer (2) is divided into a left part and a right part. A first piezoresistive accelerometer unit (21) and a second piezoresistive accelerometer unit (22) are integrated on the upper and lower parts of the right part of the structural layer (2) respectively, and have different ranges. A complementary metal oxide semiconductor (CMOS) circuit for amplifying and filtering output signals of the first and second piezoresistive accelerometer units (21 and 22) is integrated on the left part of the structural layer (2). Accelerometer array units and a signal processing circuit are integrated on the same chip, so that the microaccelerometer is miniaturized and integrated.

Owner:ZHONGBEI UNIV

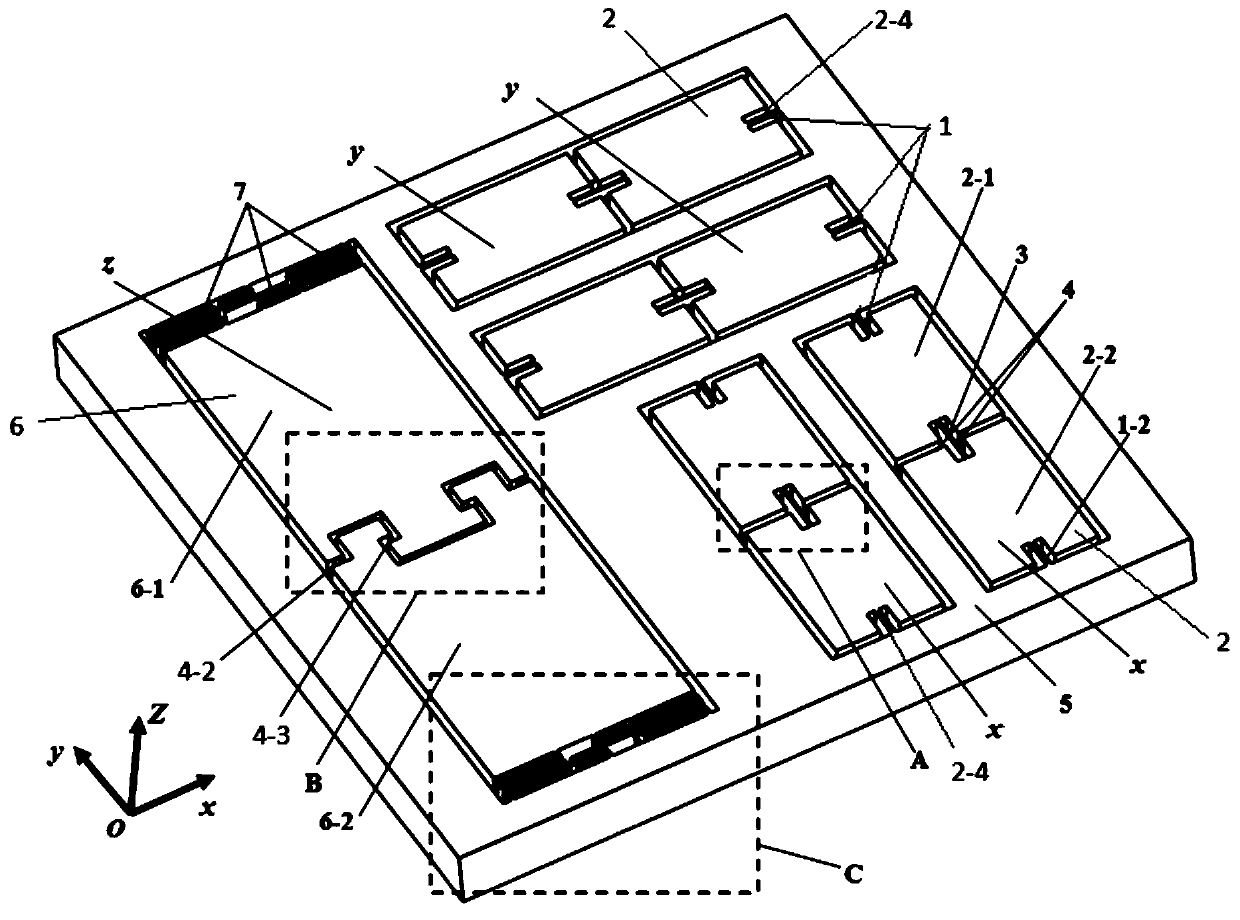

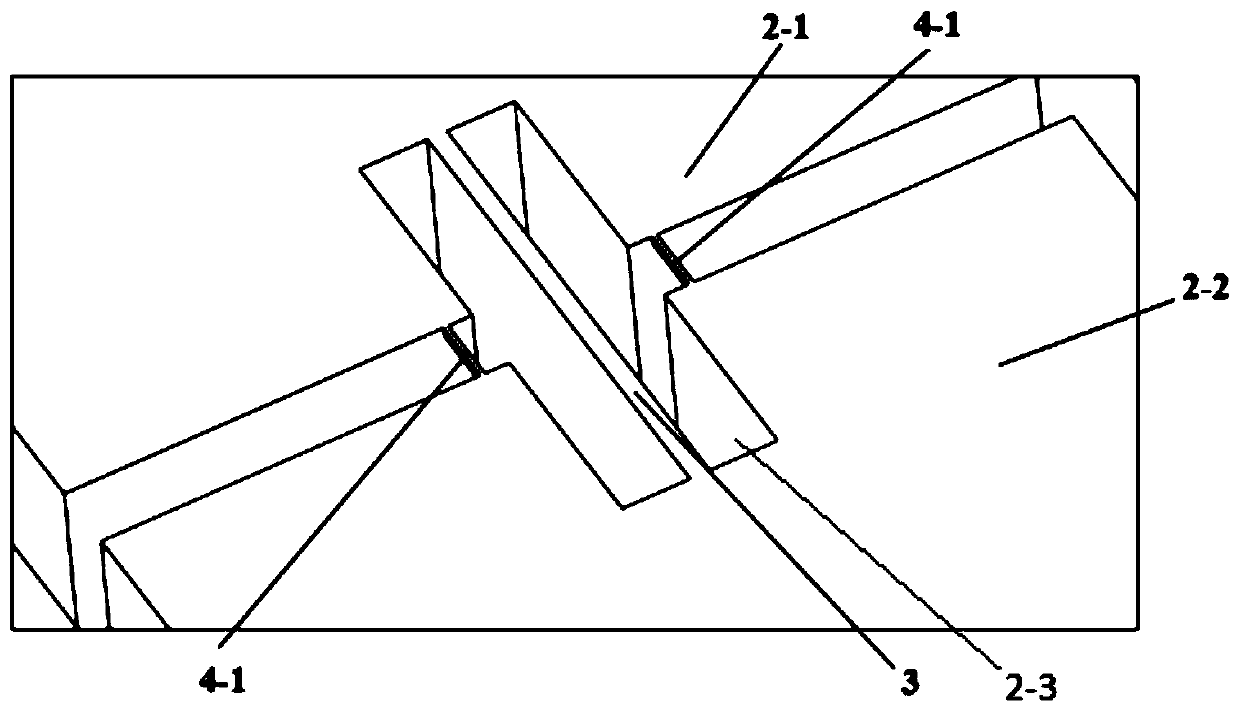

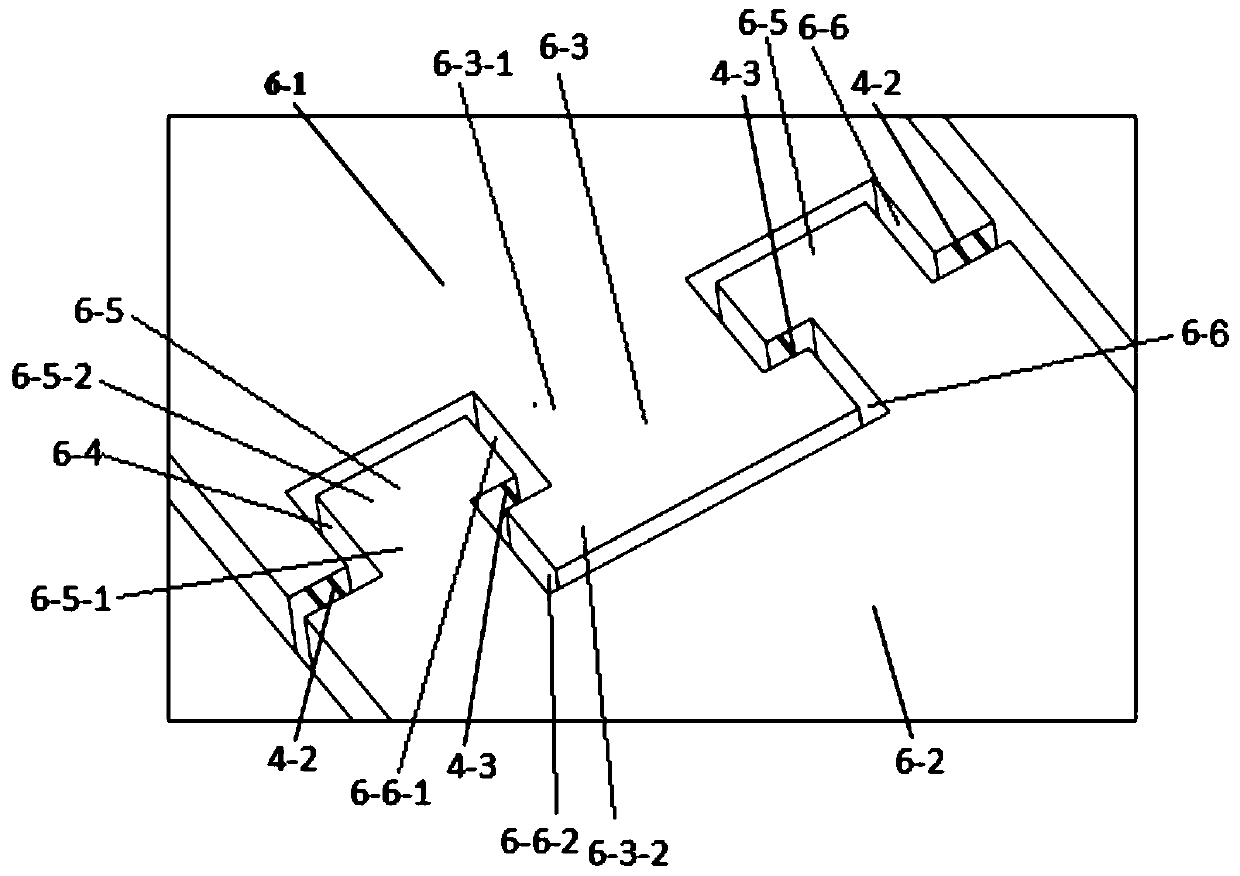

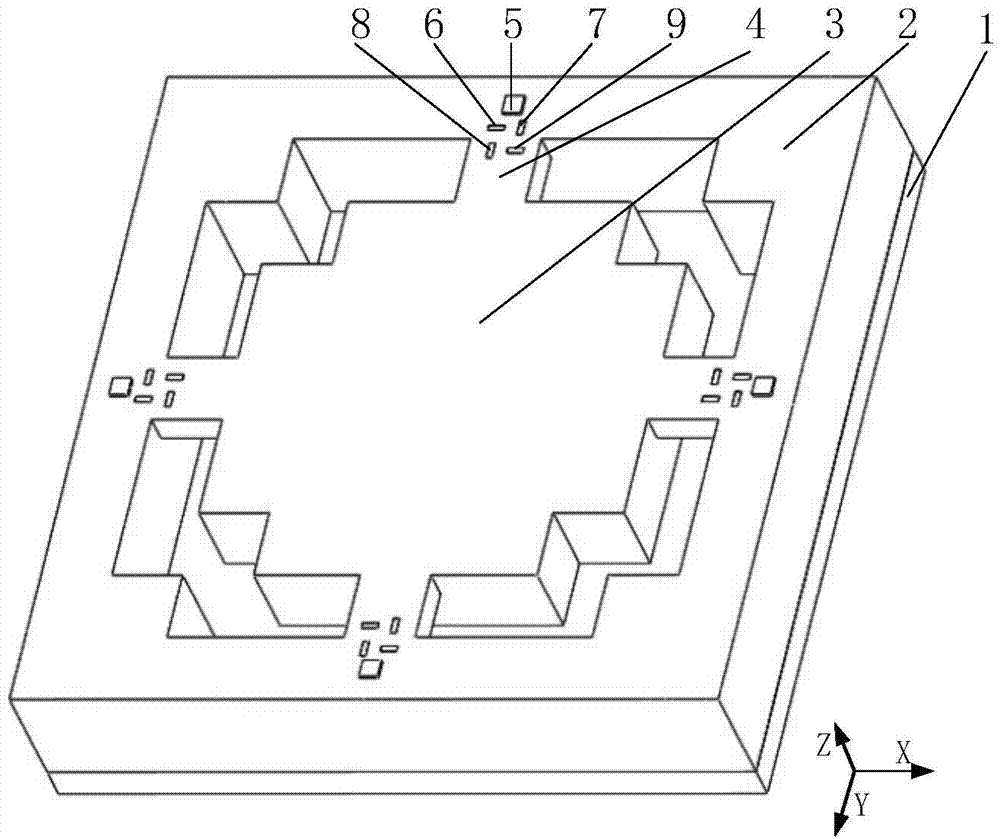

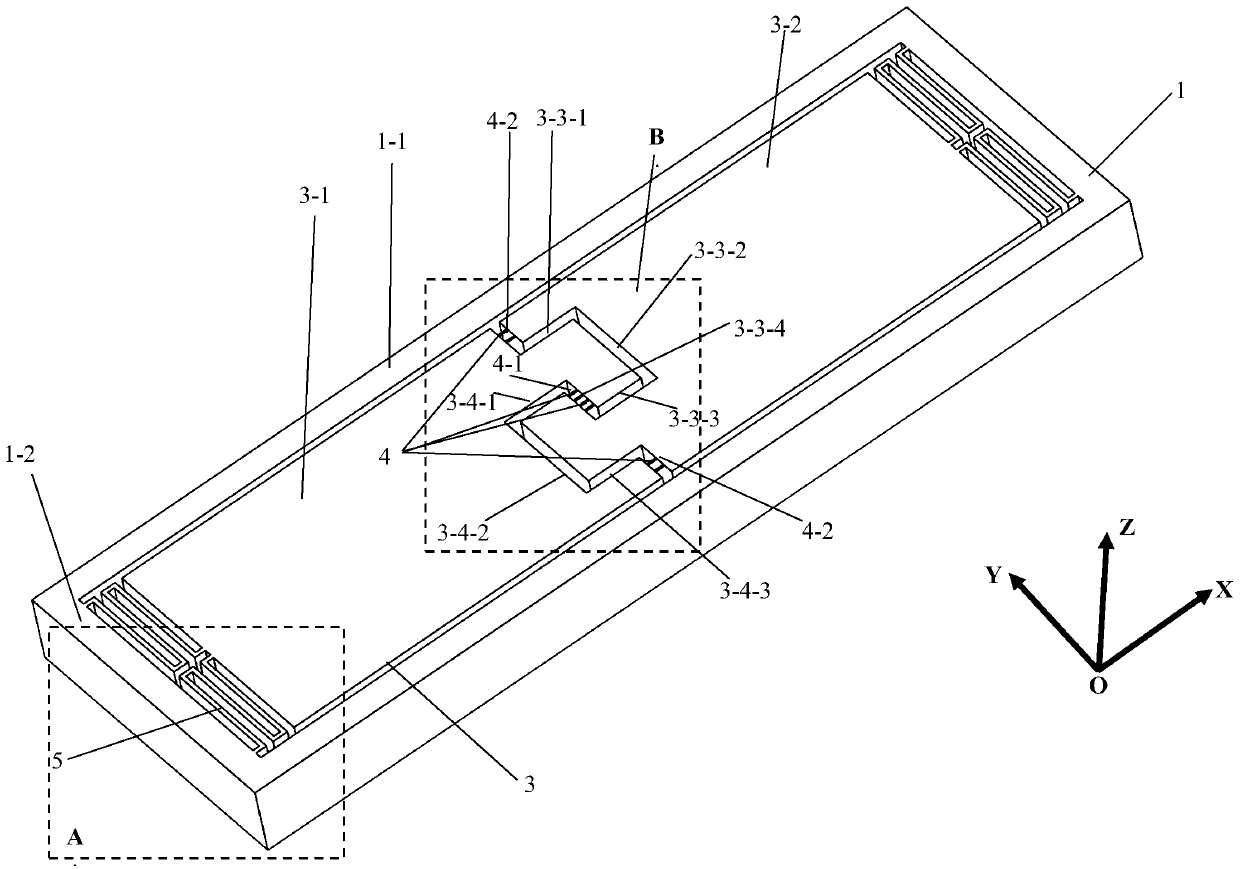

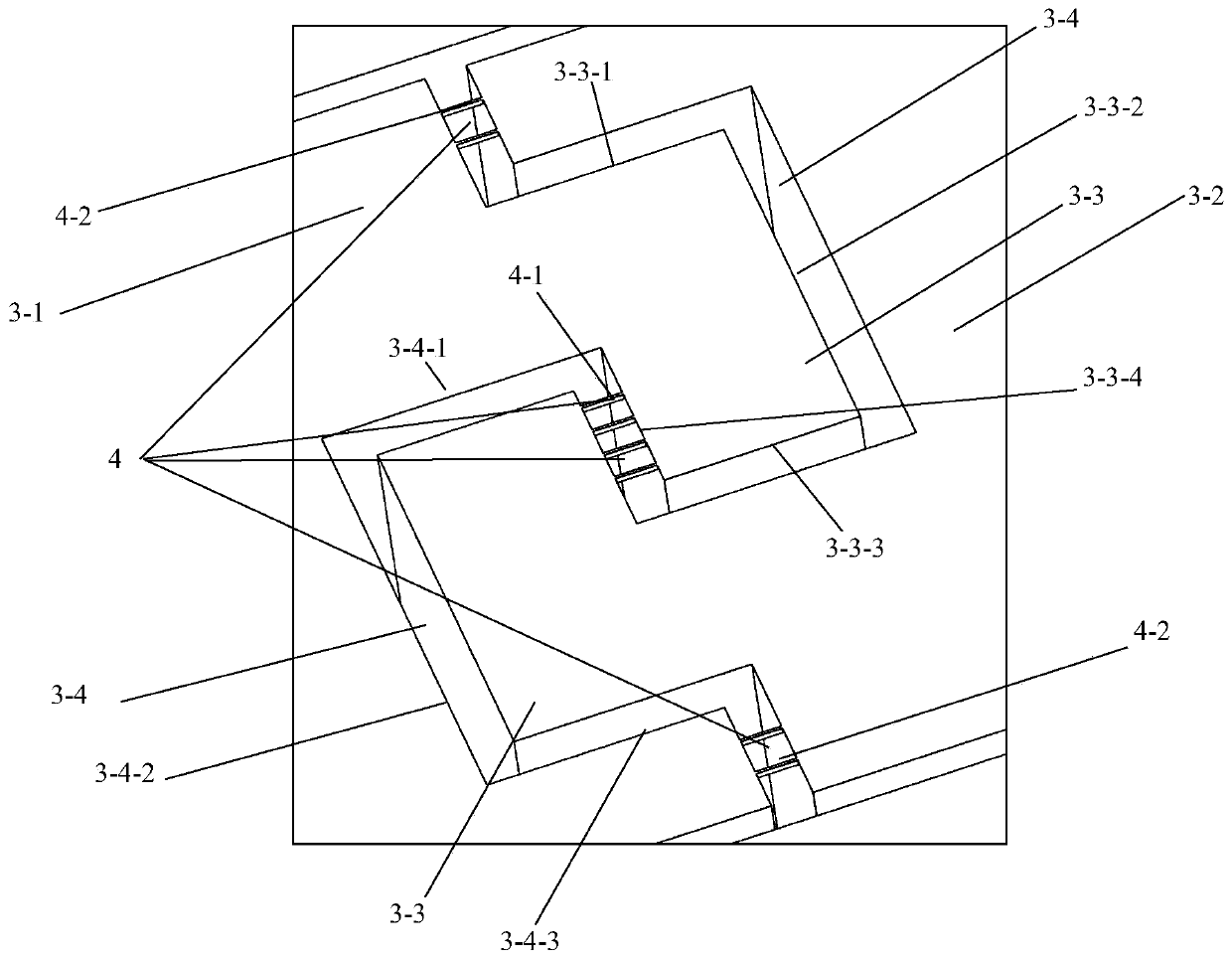

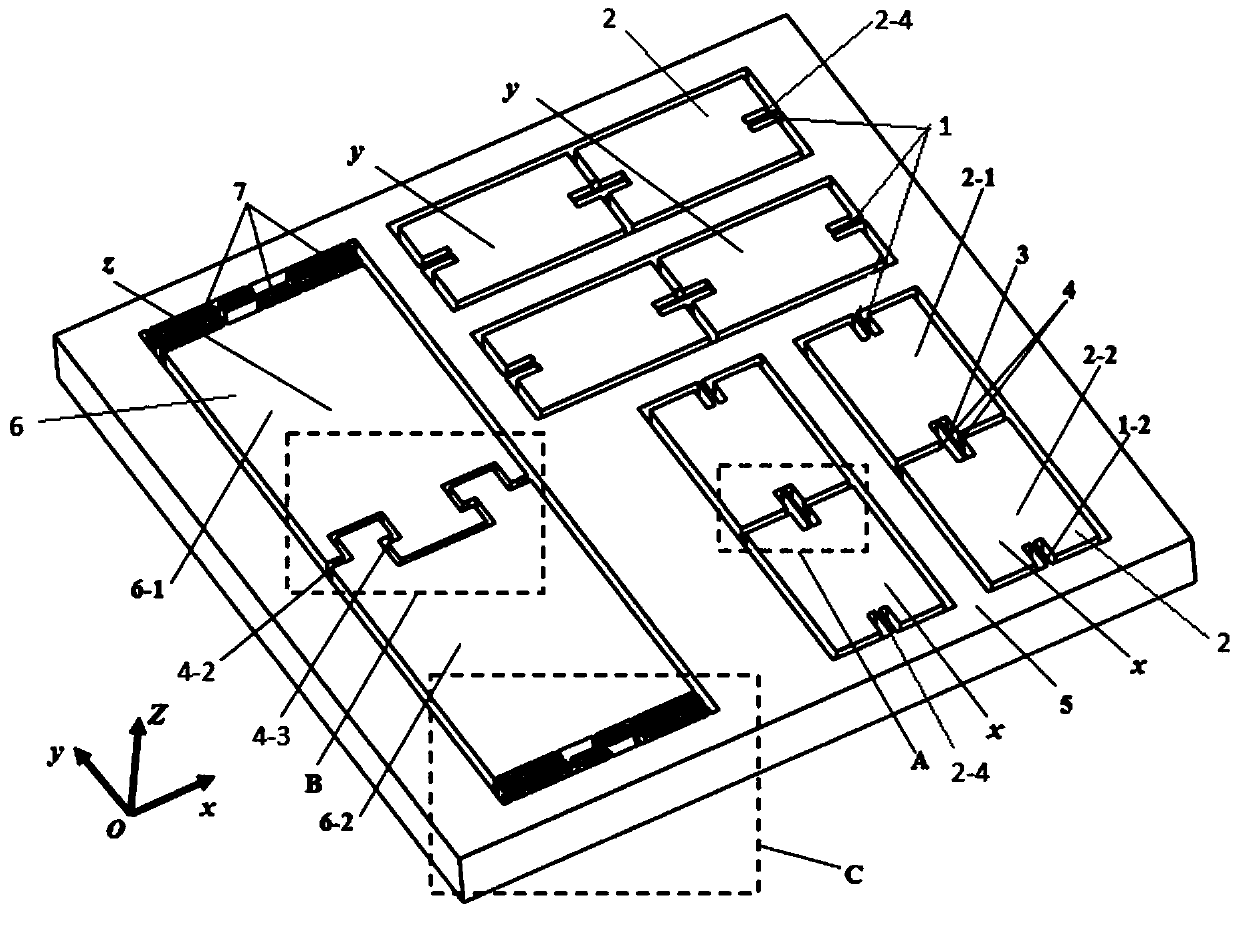

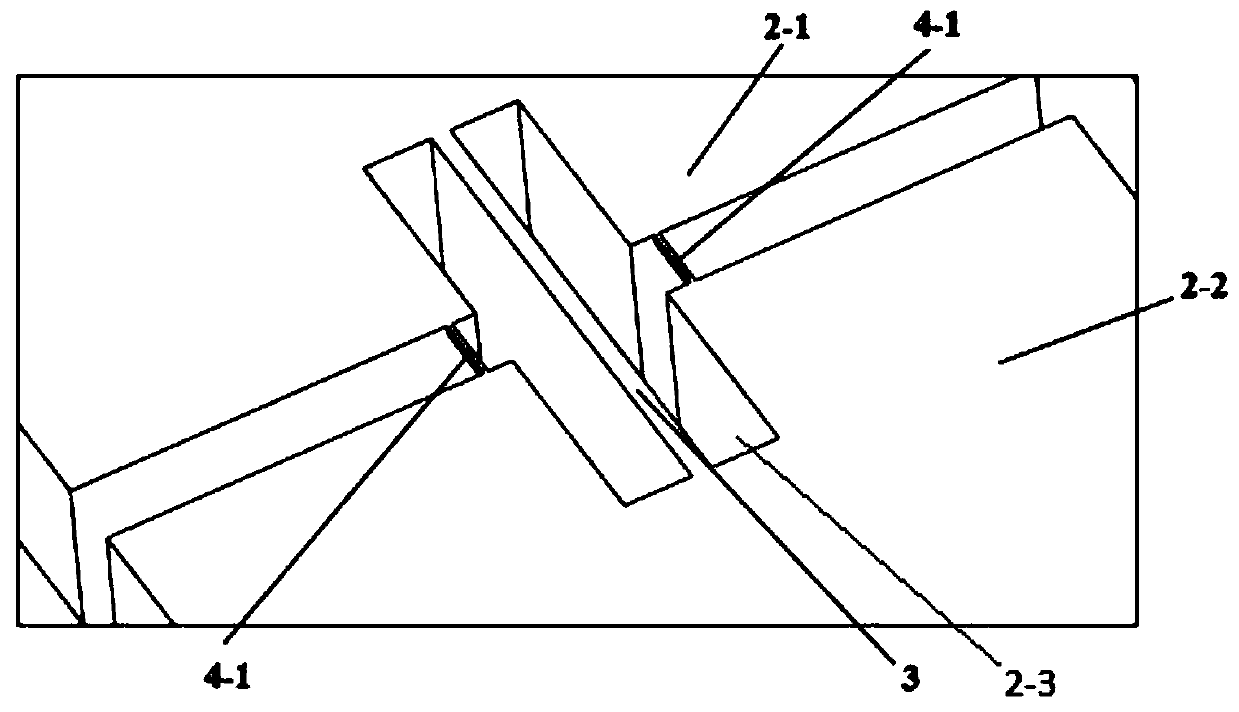

Pure axial deformation based MEMS three-axis piezoresistive accelerometer chip and preparation method thereof

ActiveCN110531114AExcellent performance indexEnables separate measurementsTelevision system detailsAcceleration measurement using interia forcesClassical mechanicsDirect coupling

The invention discloses a pure axial deformation based MEMS three-axis piezoresistive accelerometer chip and a preparation method thereof. An X measurement unit, a Y measurement unit and a Z measurement unit in a sensor are used for measuring the accelerations in the X direction, the Y direction and the Z direction respectively, so that the separate measurement of the accelerations in the three directions is realized; each measurement unit comprises mass blocks, a supporting beam and a sensitive beam; for no matter which of the measurement units, the supporting beam and the sensitive beam areseparately arranged through the mass blocks, the supporting beam supports the mass blocks to move, and the stress is mainly concentrated in the sensitive beam, so that the resistance value of a piezoresistor strip on the sensitive beam is changed; the supporting beam and the sensitive beam perform respective functions, so that the direct coupling relation between the sensitivity and the resonant frequency is greatly weakened; meanwhile, due to the synchronous movement of the two mass blocks, the two ends of the sensitive beam fixed with the mass blocks synchronously move, and the sensitive beam always meets the pure axial deformation condition; and under the same resonant frequency, the sensitivity of the sensor is optimal, so that the sensor chip has good performance indexes.

Owner:XI AN JIAOTONG UNIV

Single-mask fabrication process for linear and angular piezoresistive accelerometers

ActiveUS7939355B2Reduce complexityLow costWave amplification devicesSolid-state devicesPiezoresistive accelerometerEngineering

An accelerometer and a method of fabricating an integrated accelerometer comprises the steps of providing an SOI wafer with a selected resistivity to eliminate any need for additional doping of the SOI wafer, providing a single mask on the SOI wafer, and simultaneously defining all components of the accelerometer in the SOI wafer without using any pn-junctions to define any piezoresistive components and to provide the same resistivity of all components. The step of simultaneously defining all components of the accelerometer in the SOI wafer comprises defining all components of a linear or angular accelerometer.

Owner:RGT UNIV OF CALIFORNIA

Three-dimensional MEMS (Micro-electromechanical Systems) accelerometer measurement part for petroleum well logging and preparation method thereof

InactiveCN103184862ADoes not affect workHigh precisionSurveyDecorative surface effectsWell loggingWorking environment

The invention provides a three-dimensional MEMS (Micro-electromechanical Systems) accelerometer measurement part for petroleum well logging and a preparation method thereof. The three-dimensional MEMS accelerometer measurement part comprises six cube silicon substrates of which the surfaces are all provided with accelerometers; the cube silicon substrates are packaged by insulating materials and are connected with an external circuit by wires; and each accelerometer comprises n*n measurement units which are connected in parallel. A piezoresistive accelerometer on the basis of an MEMS technology can measure three-dimensional dynamic acceleration of a drill bit in the well logging process during drilling, can be adapted to the harsh underground working environment, has a small size and has higher accuracy.

Owner:CHINA NAT ACAD NANOTECH & ENG

Method of making self-aligned MEMS piezoresistive accelerometer

ActiveCN106564857AAchieve self-alignmentGood symmetryAcceleration measurement using interia forcesDecorative surface effectsElectrical resistance and conductanceLithography process

The invention discloses a method of making a self-aligned MEMS piezoresistive accelerometer, comprising the following steps: making a cavity at the bottom of a silicon substrate through a KOH etching process; growing an oxide layer and a silicon nitride layer on the top of the silicon substrate in sequence from bottom to top; making a piezoresistive pattern and a structure release pattern on the silicon nitride layer at the same time through a lithography process, and etching the silicon nitride layer at the piezoresistive pattern and at the structure release pattern; etching the oxide layer at the piezoresistive pattern, and forming a piezoresistor through an injecting process and an annealing process; etching the oxide layer at the structure release pattern to form a structure release area; deeply etching the silicon substrate in the structure release area to form a movable structure, thus getting an MEMS piezoresistive accelerometer. The piezoresistive pattern and the structure release pattern are formed in the same lithography process. There is no need for equipment to carry out alignment in the machining process. Self-alignment of the piezoresistor and a device structure is realized. Thus, the symmetry of devices is improved, error caused by position deviation of the piezoresistor is reduced, and the performance of devices is improved.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

Piezoresistive triaxial accelerometer

PendingCN111766401AEasy resetReduce the impactAcceleration measurement using interia forcesCantilevered beamTriaxial accelerometer

The invention discloses a piezoresistive triaxial accelerometer. The piezoresistive triaxial accelerometer comprises a supporting frame, a mass block, and an elastic cantilever beam; the mass block issuspended at the central position of the support frame through the elastic cantilever beam; a plurality of strain piezoresistors with equal resistance values are symmetrically distributed on the elastic cantilever beam between the support frame and the mass block; limiting modules are arranged at the four inner corners of the supporting frame correspondingly. X-direction anti-overload gaps and Y-direction anti-overload gaps are formed between the limiting modules and the adjacent elastic cantilever beams and between the limiting modules and the mass blocks, an upper cover plate and a lower cover plate are arranged on the upper side and the lower side of the supporting frame respectively, and Z-direction anti-overload gaps are formed between the mass blocks and the lower cover plate and between the mass blocks and the upper cover plate. The piezoresistive triaxial accelerometer has higher sensitivity, accuracy and rigidity, facilitates resetting of the mass block, reduces system errors, improves measurement precision and reduces interaxial coupling of the accelerometer.

Owner:HUZHOU JOUKING ELECTRONICS

A mems piezoresistive accelerometer

InactiveCN103575932BHigh sensitivityReduce volumeAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElectrical resistance and conductancePiezoresistive accelerometer

Owner:DALIAN UNIV OF TECH

Piezoresistance-type triaxial accelerometer with high output stability

InactiveCN107727885AReasonable designSimple structureAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsTriaxial accelerometerGlass cover

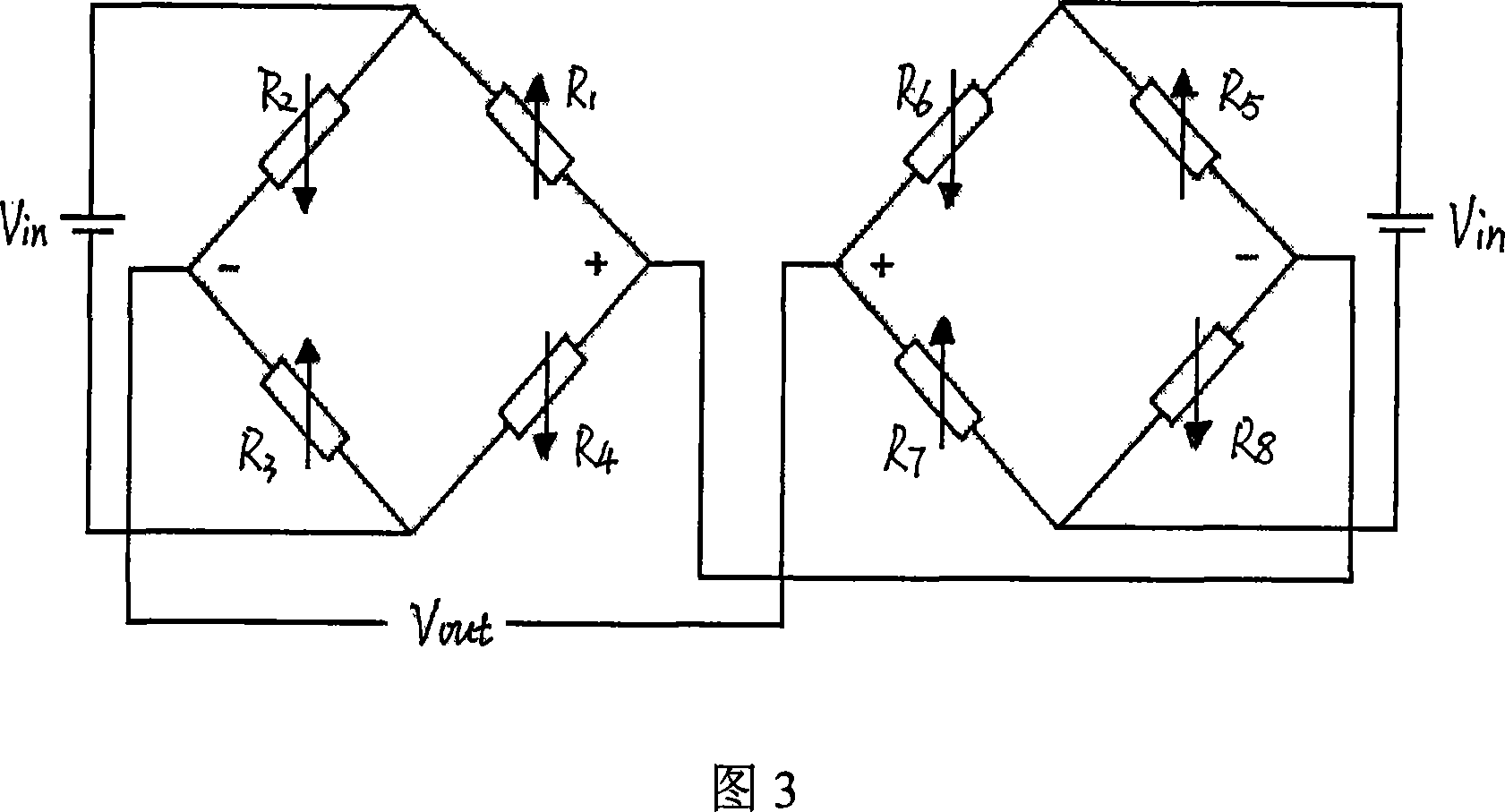

The invention discloses a piezoresistance-type triaxial accelerometer with high output stability. The accelerometer comprises an SOI substrate, an upper glass cover plate and a lower glass cover plate, and a center quality block is supported on a zigzag frame through eight rectangular beams. A phosphorus element is poured into the periphery of each piezoresistor on the corresponding beam through icons, heavy doping is conducted, electric potential which is higher than or equal to the power supply voltage of the wheatstone bridge is accessed to the periphery of each piezoresistor through a welding disk, the electric leakage phenomenon of a piezoresistor strip is avoided, and the output stability of the piezoresistance-type accelerometer is achieved.

Owner:ZHONGBEI UNIV

Silicon piezoresistive type accelerometer carrying out detection based on Josephson effect

ActiveCN103592464AReasonable structureHigh sensitivityAcceleration measurement using interia forcesImage resolutionHemt circuits

The invention discloses a silicon piezoresistive type accelerometer carrying out detection based on the Josephson effect. The silicon piezoresistive type accelerometer carrying out detection based on the Josephson effect comprises a bonding substrate, a supporting frame body, a Josephson device, an elastic beam, a mass block and a piezoresistor. The silicon piezoresistive type accelerometer carrying out detection based on the Josephson effect has the advantages of being capable of converting acceleration signals into strictly consistently compensated current step signals by integrating the Josephson device and a silicon piezoresistive device, reasonable in structure and high in sensitivity, adopting digitized output, and being simple in detection circuit, convenient to use, good in reliability and suitable for microminiaturization, and can effectively solve the problems of low sensitivity, low effective resolution ratio, high threshold detection lower limit and the like of a high overload type sensor.

Owner:ZHONGBEI UNIV

Out-of-plane piezoresistive accelerometer chip with pure axial deformation sensitive beam and preparation method thereof

ActiveCN110526200AReduce stiffnessEvenly distributedTelevision system detailsAcceleration measurement using interia forcesFull bridgeClassical mechanics

The invention discloses an out-of-plane piezoresistive accelerometer chip with pure axial deformation sensitive beams and a preparation method of the out-of-plane piezoresistive accelerometer chip, the chip comprises two symmetrically arranged mass blocks, the outer end faces of the two mass blocks are respectively connected with a chip outer frame, and the inner end faces of the two mass blocks are connected through two groups of sensitive beams; the four sensitive beams form a Wheatstone full-bridge circuit; the mass blocks are used for directly sensing surface applied speed signals, when the chip is subjected to acceleration in the Z direction, the two mass blocks synchronously move, the two mass blocks and the sensitive beam fixed to the two mass blocks also keep synchronous movement,and therefore pure axial deformation of the sensitive beam is met.

Owner:XI AN JIAOTONG UNIV

piezoresistive accelerometer

ActiveCN109596859BReduce stiffnessHigh sensitivityAcceleration measurement using interia forcesPiezoresistive accelerometerMechanical engineering

The invention provides a piezoresistive acceleration sensor, belonging to the field of acceleration sensors, comprising: a frame with a movable chamber inside; a mass block movable in the movable chamber; a sensitive beam with pressure-sensitive The measuring section of the element is connected to the frame and the mass block; and the first support beam, the two ends of the long axis are respectively connected to the sensitive beam and the frame, and the stiffness of the first support beam in the sensing direction of the mass block is smaller than that in the sensing direction of the mass block Stiffness in the vertical direction. Reinforce the sensitive beam by the first support beam, the first support beam has a smaller degree in the sense direction of the mass block, so that the piezoresistive acceleration sensor maintains a higher sensitivity; the first support beam is perpendicular to the sense direction of the mass block The rigidity in the direction is large, so that when the sensor faces the acceleration in a direction other than the sensitive direction, the deformation of the sensitive beam and the measuring section is reduced, and the breaking of the sensitive beam and the measuring section is avoided.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Composite beam piezoresistive accelerometer

InactiveCN100437117CPlay a buffer roleReduce displacementAcceleration measurement using interia forcesElectrical resistance and conductancePiezoresistive accelerometer

This invention relates to a composite beam pressure drag accelerometer; belong to micro machine electronic technology. This invention solves existing problem of that structure of high g accelerometer can not satisfy characteristic request of first order's high inherent rate, wide frequency response scope and worse shock resistance. this accelerometer includes silica-based support carriage shell, spring beam, quality piece that through spring beam overhung in middle of carriage shell, varistor diffused on tip of spring beam. Silica-based support carriage shell undersurface by electrostatic link glass bottom cap. Quality piece is composed by frame body and quality core that through bridge hooked to frame body.

Owner:ZHONGBEI UNIV

A piezoresistive mems high overload accelerometer

ActiveCN103969467BEliminate fragile technical issuesSimple structureTelevision system detailsAcceleration measurement using interia forcesStress concentrationHigh volume manufacturing

The invention discloses a piezoresistive type high overload microelectromechanical system (MEMS) accelerometer. The piezoresistive type high overload MEMS accelerometer comprises a frame, a group of main beams, a group of micro beams and a mass block. The main beams are arranged in the frame and connected with the mass block. The micro beams are respectively arranged on one or two sides of the main beams and parallel to the same. When the micro beams are respectively arranged on one side of the main beams, the whole accelerometer is of a centrosymmetric structure. When the micro beams are respectively arranged on two sides of the main beams, the whole accelerometer is of a full symmetric structure. As structures of the main beams and the micro beams are simply combined with one silicon wafer, a contradiction of a negative correlation between a high range and a high sensitivity is overcome, and the technology is simplified to achieve production in a large scale; meanwhile, stress concentration in corners caused by direct connection between the beams and the mass block is eliminated through buffer locks, and accordingly the accelerometer is less prone to damage.

Owner:SOUTHEAST UNIV

A self-aligning mems piezoresistive accelerometer manufacturing method

ActiveCN106564857BAchieve self-alignmentGood symmetryAcceleration measurement using interia forcesDecorative surface effectsLithography processPiezoresistive accelerometer

The invention discloses a method of making a self-aligned MEMS piezoresistive accelerometer, comprising the following steps: making a cavity at the bottom of a silicon substrate through a KOH etching process; growing an oxide layer and a silicon nitride layer on the top of the silicon substrate in sequence from bottom to top; making a piezoresistive pattern and a structure release pattern on the silicon nitride layer at the same time through a lithography process, and etching the silicon nitride layer at the piezoresistive pattern and at the structure release pattern; etching the oxide layer at the piezoresistive pattern, and forming a piezoresistor through an injecting process and an annealing process; etching the oxide layer at the structure release pattern to form a structure release area; deeply etching the silicon substrate in the structure release area to form a movable structure, thus getting an MEMS piezoresistive accelerometer. The piezoresistive pattern and the structure release pattern are formed in the same lithography process. There is no need for equipment to carry out alignment in the machining process. Self-alignment of the piezoresistor and a device structure is realized. Thus, the symmetry of devices is improved, error caused by position deviation of the piezoresistor is reduced, and the performance of devices is improved.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

A Silicon Piezoresistive Accelerometer Based on Josephson Effect Detection

ActiveCN103592464BImprove yieldImprove reliabilityAcceleration measurement using interia forcesElectrical resistance and conductanceLower limit

The invention discloses a silicon piezoresistive accelerometer based on Josephson effect detection, which comprises: a bonding substrate, a supporting frame, a Josephson device, an elastic beam, a quality block and a piezoresistor. The beneficial effect of the present invention is that the Josephson device is integrated with the silicon piezoresistor, the acceleration signal can be converted into a current step signal that compensates strictly and consistently, the structure is reasonable, the sensitivity is high, the digital output is simple, the detection circuit is simple, the use is convenient, and the reliability is good. Suitable for miniaturization. It can effectively solve the problems of low sensitivity, low effective resolution, and high detection threshold lower limit in high overload sensors.

Owner:ZHONGBEI UNIV

A pure axial deformation mems triaxial piezoresistive accelerometer chip and its preparation method

ActiveCN110531114BExcellent performance indexEnables separate measurementsTelevision system detailsAcceleration measurement using interia forcesDirect couplingEngineering

The invention discloses a pure axial deformation based MEMS three-axis piezoresistive accelerometer chip and a preparation method thereof. An X measurement unit, a Y measurement unit and a Z measurement unit in a sensor are used for measuring the accelerations in the X direction, the Y direction and the Z direction respectively, so that the separate measurement of the accelerations in the three directions is realized; each measurement unit comprises mass blocks, a supporting beam and a sensitive beam; for no matter which of the measurement units, the supporting beam and the sensitive beam areseparately arranged through the mass blocks, the supporting beam supports the mass blocks to move, and the stress is mainly concentrated in the sensitive beam, so that the resistance value of a piezoresistor strip on the sensitive beam is changed; the supporting beam and the sensitive beam perform respective functions, so that the direct coupling relation between the sensitivity and the resonant frequency is greatly weakened; meanwhile, due to the synchronous movement of the two mass blocks, the two ends of the sensitive beam fixed with the mass blocks synchronously move, and the sensitive beam always meets the pure axial deformation condition; and under the same resonant frequency, the sensitivity of the sensor is optimal, so that the sensor chip has good performance indexes.

Owner:XI AN JIAOTONG UNIV

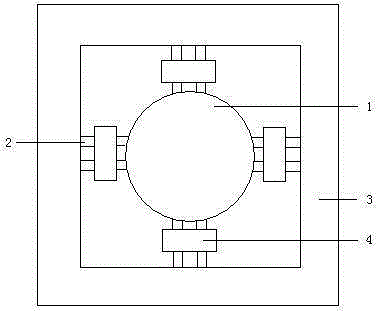

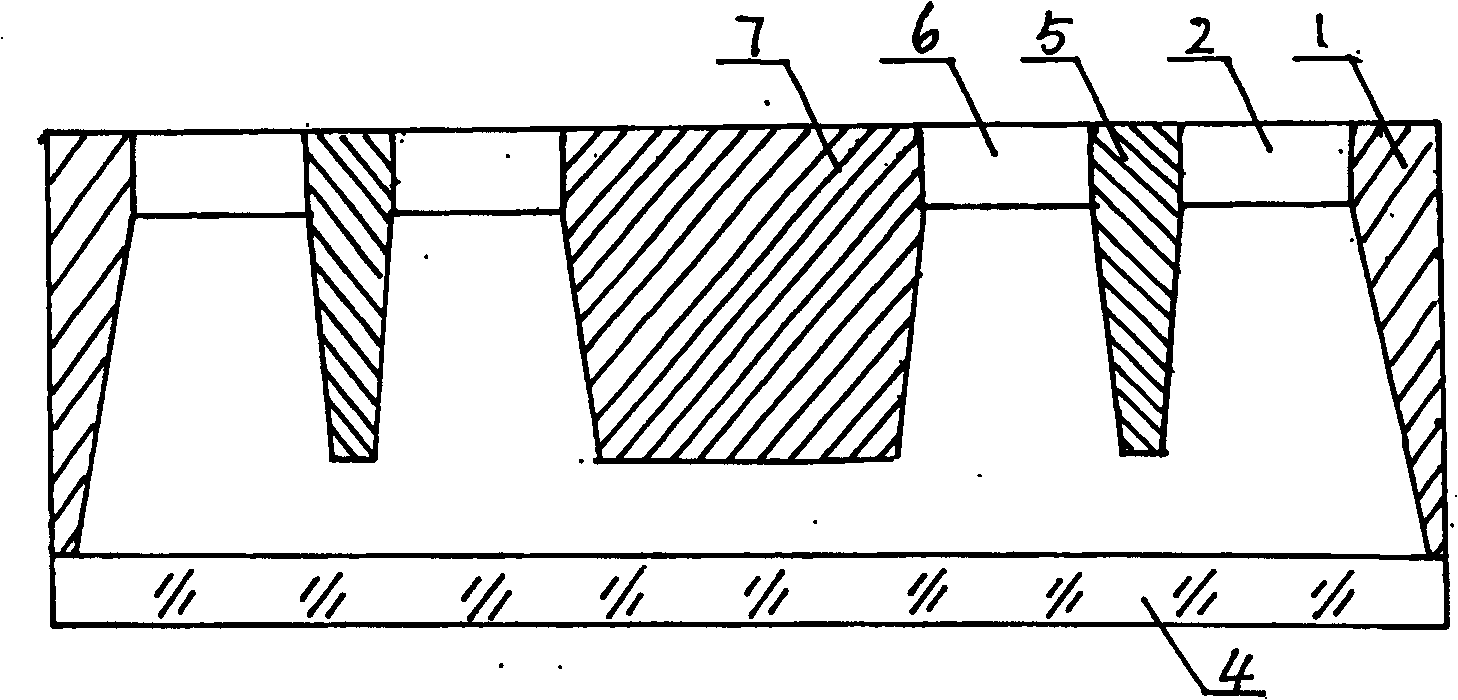

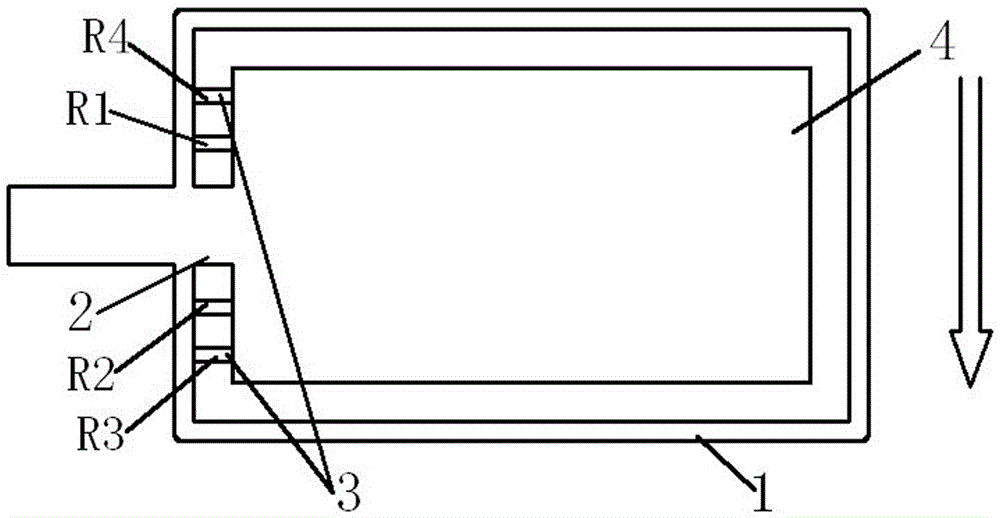

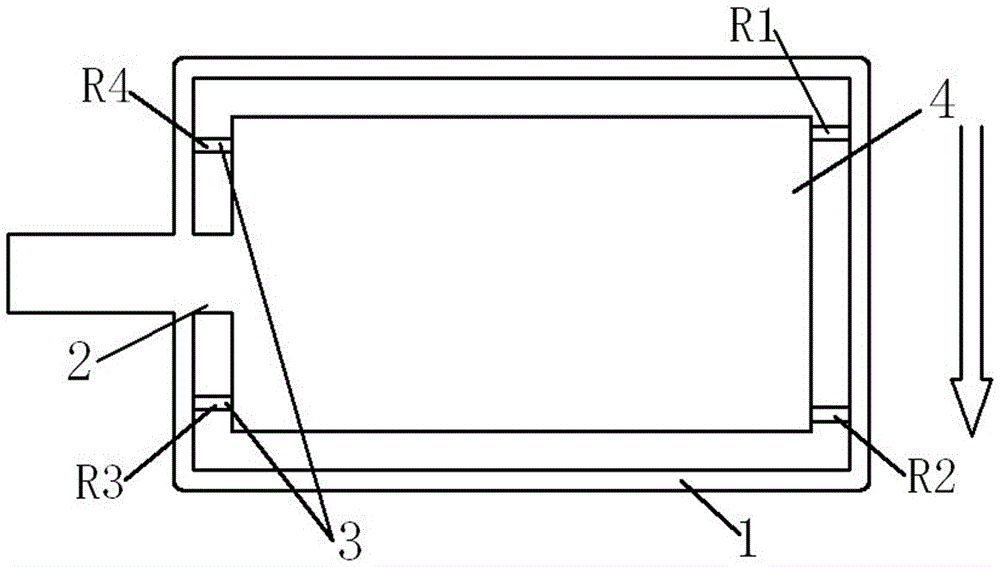

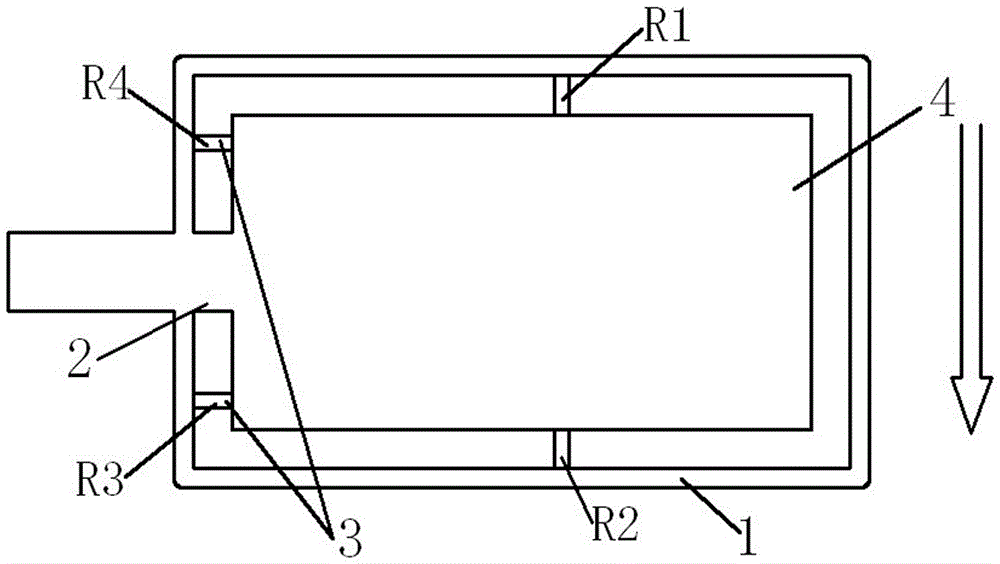

A piezoresistive acceleration sensor with a full-bridge micro-beam structure

ActiveCN103235155BStrain amplificationIncreased Vibration ConstraintsAcceleration measurement using interia forcesElectrical resistance and conductanceAxis of symmetry

Disclosed is a piezoresistive acceleration sensor having a full-bridge microbeam structure, comprising a frame (1), a cantilever beam (2), microbeams (3) and a mass block (4). The cantilever beam (2) is on the axis of symmetry of the mass block (4), the microbeams (3) are four in number, and are axisymmetrically distributed on an edge of the mass block (4) using the axis on which the cantilever beam (2) is located, and piezoresistive sensing resistors are provided on the four microbeams, the four piezoresistive sensing resistors constituting a Wheatstone full bridge circuit. Amplifying the strain of the cantilever beam increases the sensitivity; the four piezoresistive sensing resistors are all within a chip, and because the effects of resistance drift on the circuit caused by measuring changes in the ambient temperature cancel each other out in a full bridge circuit, the temperature stability is increased; and the four microbeams increase the restriction on the vibration of the mass block, raising the first order resonance frequency.

Owner:XIAMEN NIELL ELECTRONICS

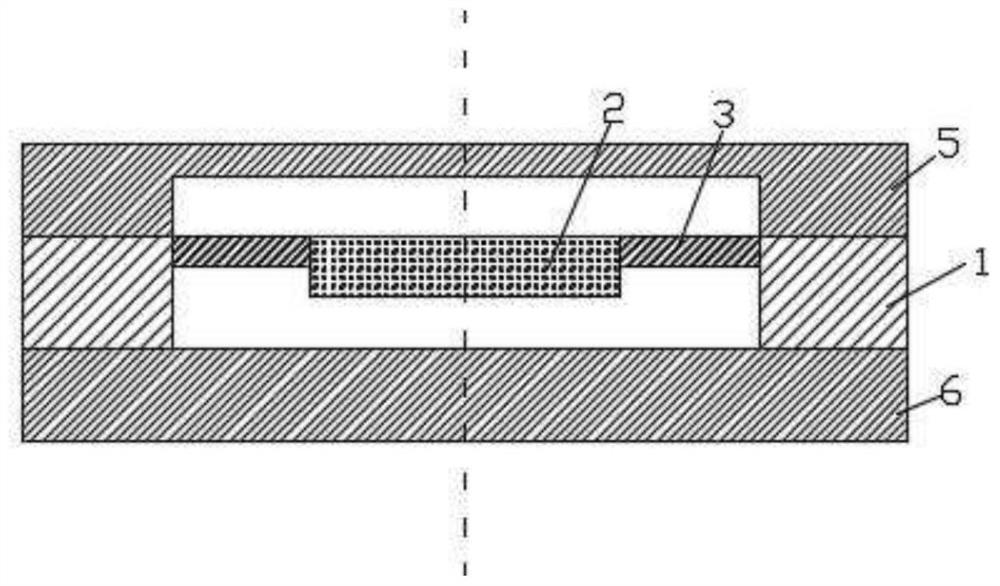

A piezoresistive acceleration and pressure integrated sensor and its manufacturing method

The invention provides a piezoresistive acceleration and pressure integrated sensor based on anodic bonding and packaging and a method for manufacturing the piezoresistive acceleration and pressure integrated sensor. The piezoresistive acceleration and pressure integrated sensor integrates a piezoresistive acceleration sensor and a piezoresistive pressure sensor and is provided with a first bonding glass-silicon substrate-second bonding glass type sandwich structure. The piezoresistive acceleration and pressure integrated sensor is novel in structure, low in weight, small in size, high in stability, and high in anti-pollution capacity. In addition, according to the piezoresistive acceleration and pressure integrated sensor and the method for manufacturing the piezoresistive acceleration and pressure integrated sensor, the same technology is applied to the same chip, the pressure measurement capacity and the acceleration measurement capacity are achieved through different kinds of design, and the technological processes are simple and easy to implement. The piezoresistive acceleration and pressure integrated sensor has a certain application prospect in the fields such as the aviation field, the military field, the automobile field and the environment monitoring field.

Owner:江苏英特神斯科技有限公司

A measuring component of a three-dimensional mems accelerometer used for oil well logging and its preparation method

InactiveCN103184862BDoes not affect workHigh precisionSurveyDecorative surface effectsWell loggingHemt circuits

The invention provides a measuring component of a three-dimensional MEMS accelerometer for petroleum well logging and a preparation method thereof, which includes a cube silicon base with accelerometers on six surfaces, the cube silicon base is encapsulated by a heat-insulating material, and Connect to external circuits by wires. The accelerometer includes n×n measuring units connected in parallel. This piezoresistive accelerometer based on MEMS technology can measure the three-dimensional dynamic acceleration of the drill bit during logging while drilling, and can adapt to the harsh working environment downhole. It is small in size and has higher accuracy.

Owner:CHINA NAT ACAD NANOTECH & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com