A piezoresistive acceleration and pressure integrated sensor and its manufacturing method

A technology of acceleration sensor and pressure sensor, applied in the field of pressure integrated sensor and its manufacture, piezoresistive acceleration, can solve the problems of difficult sensor integration, very different sensor structure solutions, etc., to achieve the effect of reducing cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

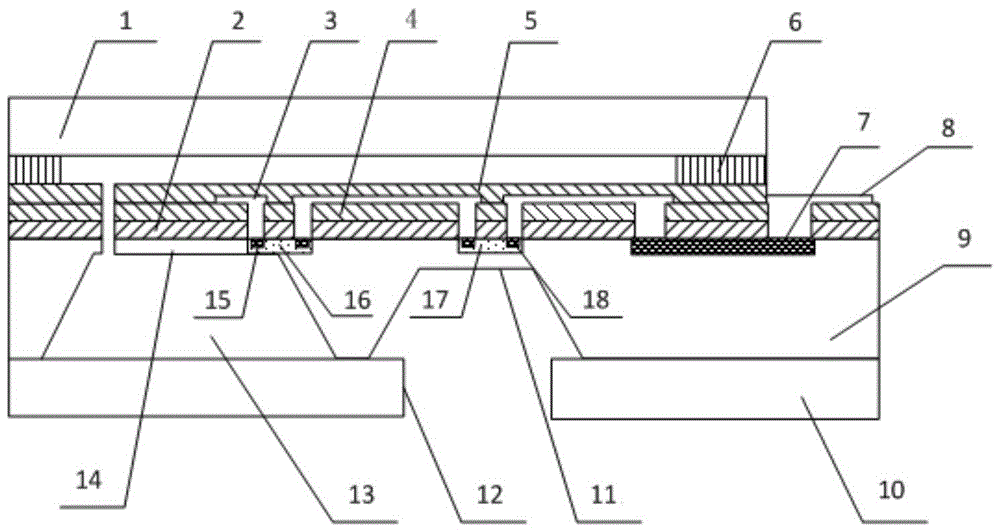

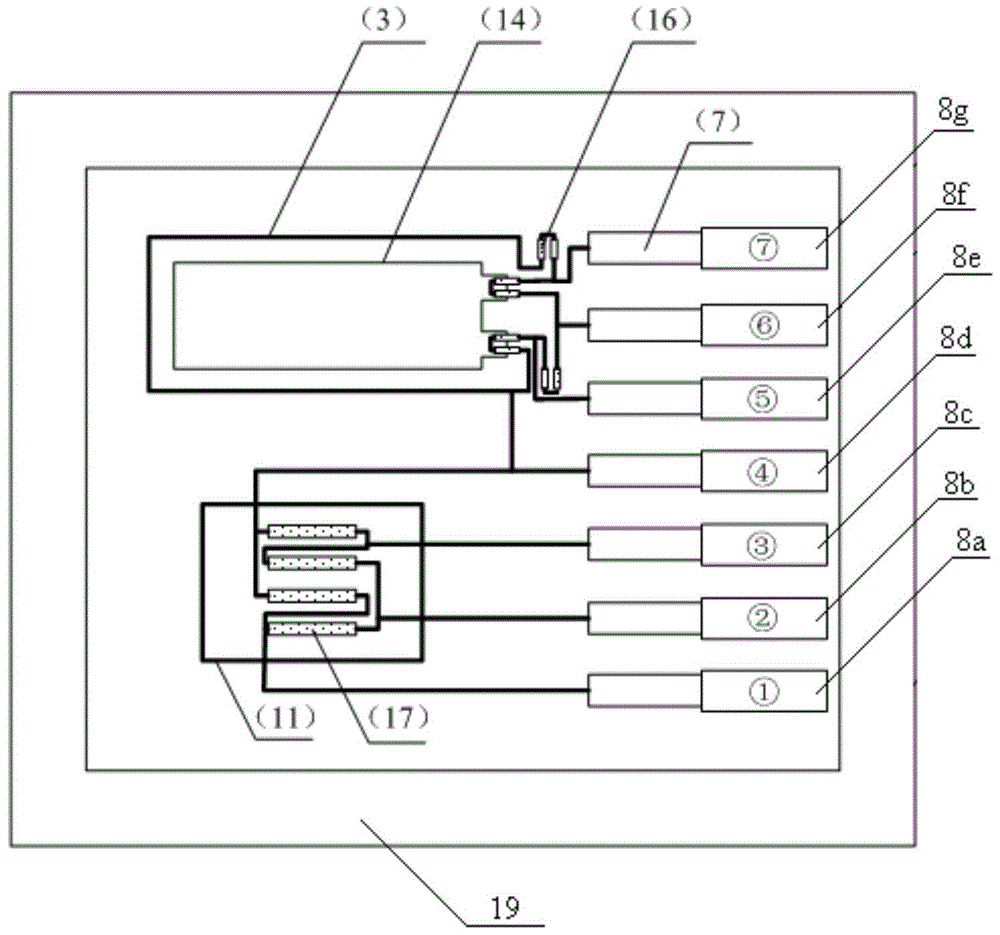

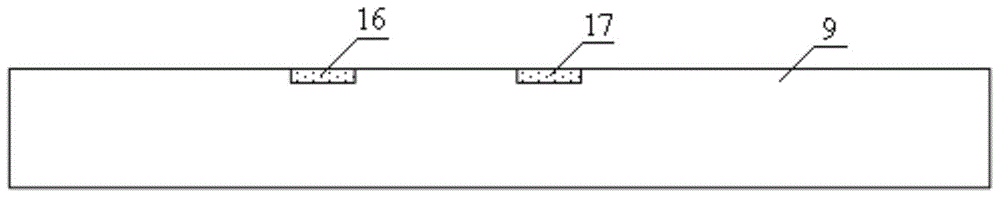

[0053] Such as figure 1 As shown, the MEMS piezoresistive acceleration and pressure integrated sensor based on anodic bonding package adopts the first bonded glass-silicon base-second bonded glass sandwich structure, and the piezoresistive acceleration and pressure integrated The sensor mainly includes: a silicon base (9), a piezoresistive acceleration sensor cantilever beam (14) for measuring uniaxial acceleration, a piezoresistive pressure sensor diaphragm (11) for measuring pressure, and a boron-concentrated wire (7) , a metal pin (8), a second bonding glass (10) for anode bonding with the silicon base, and a first bonding glass (1) for anode bonding with the amorphous silicon (6).

[0054] Wherein, the upper surface root of the piezoresistive acceleration sensor cantilever beam (14) used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com