Single-mask fabrication process for linear and angular piezoresistive accelerometers

a piezoresistive accelerometer and fabrication process technology, applied in the field of single-mask fabrication of piezoresistive accelerometers, can solve the problems of not knowing the prior art, piezoresistive accelerometers have never before been fabricated using a single mask, etc., and achieve the effect of reducing both complexity and cost and less temperature sensitive sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

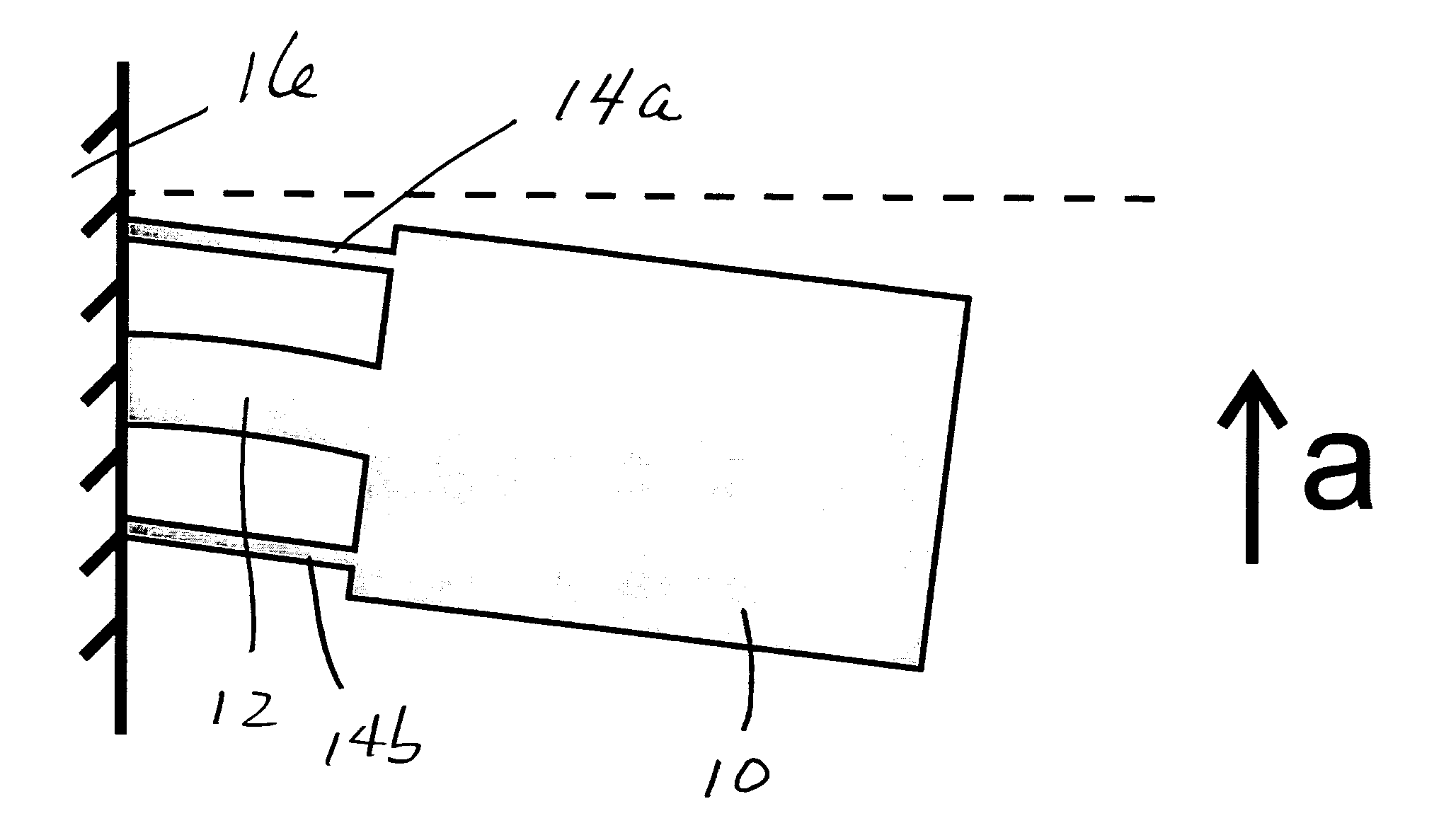

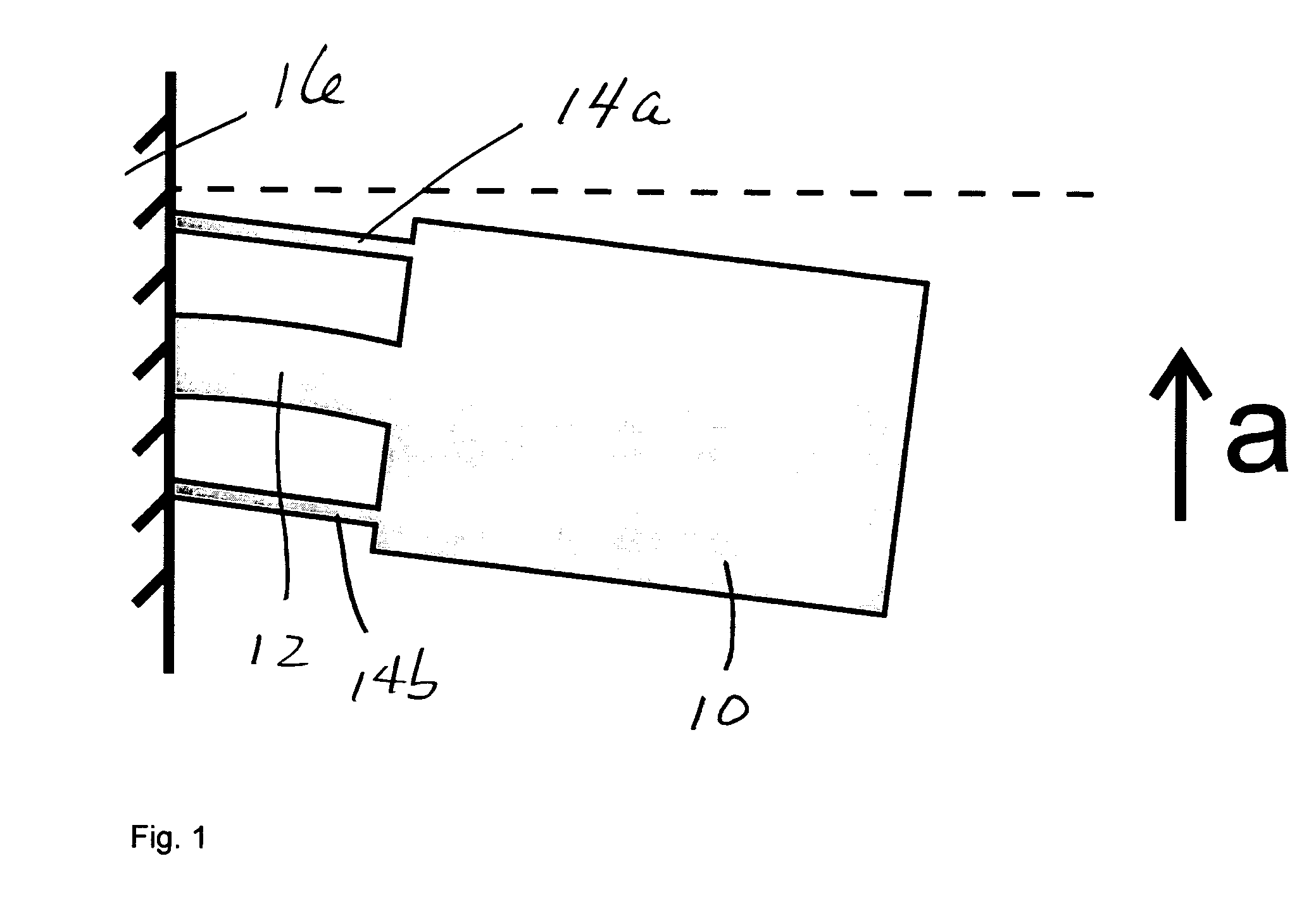

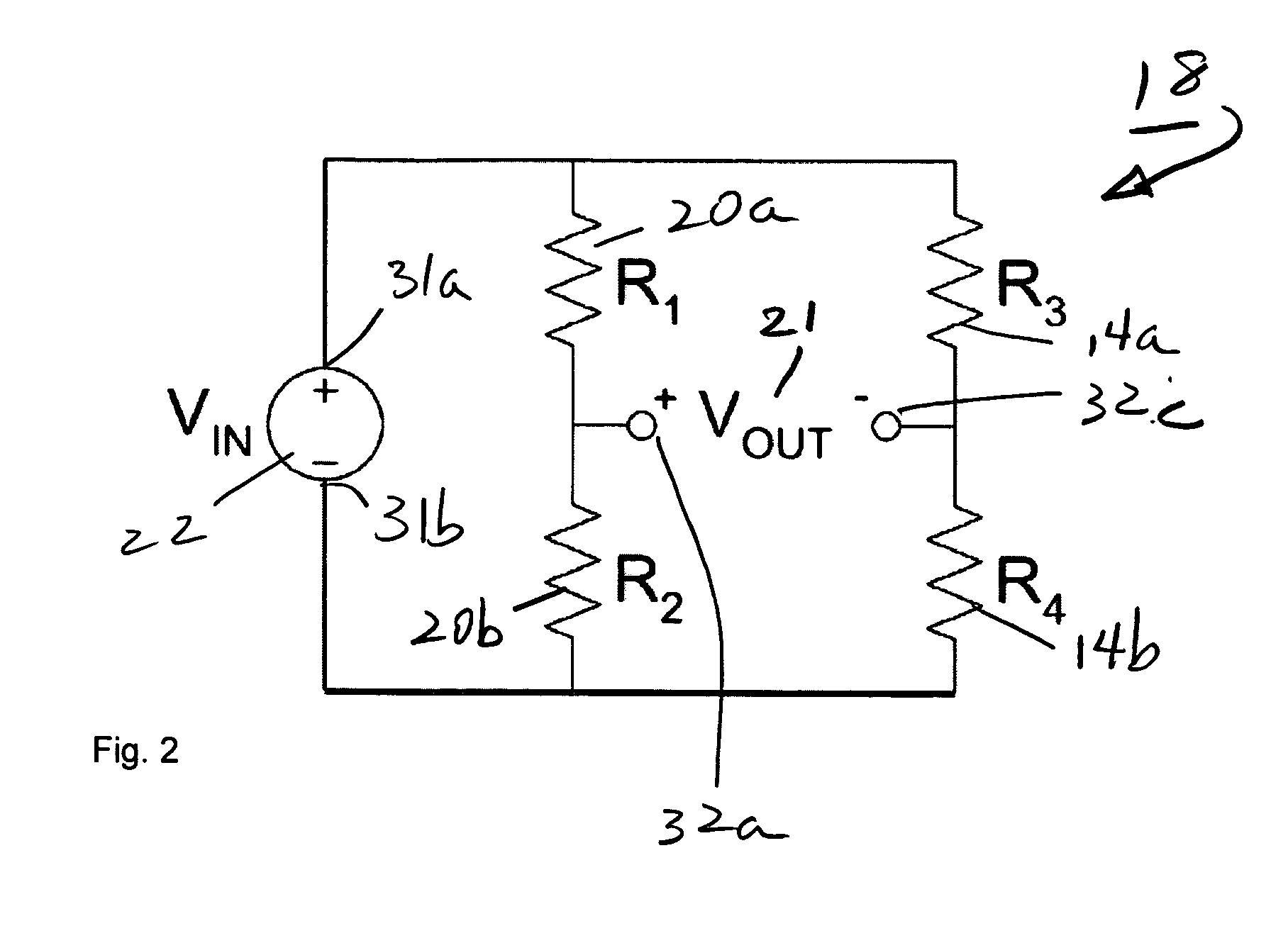

[0031] The illustrated embodiment is a method for fabricating piezoresistive accelerometers based on using Silicon-on-Insulator (SOI) wafers. By choosing wafers with a certain resistivity, the need for doping steps can be eliminated from the fabrication process and the devices can be fabricated using only a single photomask. Below we provide a description of piezoresistivity and the operation of piezoresistive accelerometers and then the illustrated embodiment of the invention is described in detail.

[0032] Piezoresistivity

[0033] Assume that a force is applied to the end of a long isotropic bar. The stress, σ, is then defined as F / A, where F is the applied force, and A the cross-sectional area. The resulting strain, ε, is the change in length divided by the initial length, ΔL / L0. As long as the strain is not too large, many solid materials behave like linear springs, meaning that the displacement is proportional to the applied force or acceleration. The piezoresistive effect causes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com