Method for producing alcohol by solid fermentation of stalks

A technology for solid-state fermentation and straw, applied in fermentation and other directions, can solve the problems of high energy consumption of cellulosic raw material pretreatment, high production cost of cellulase, and immature fermentation process, so as to change production conditions and optimize fermentation process. Route, effect of shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach approach 1

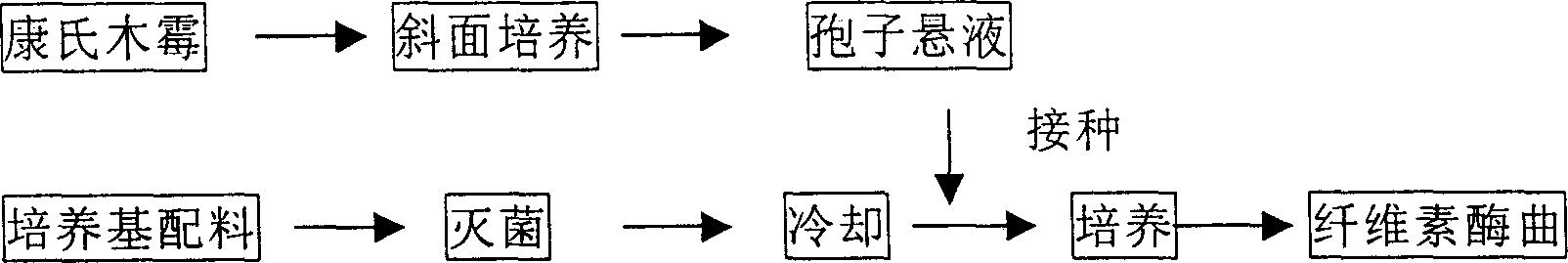

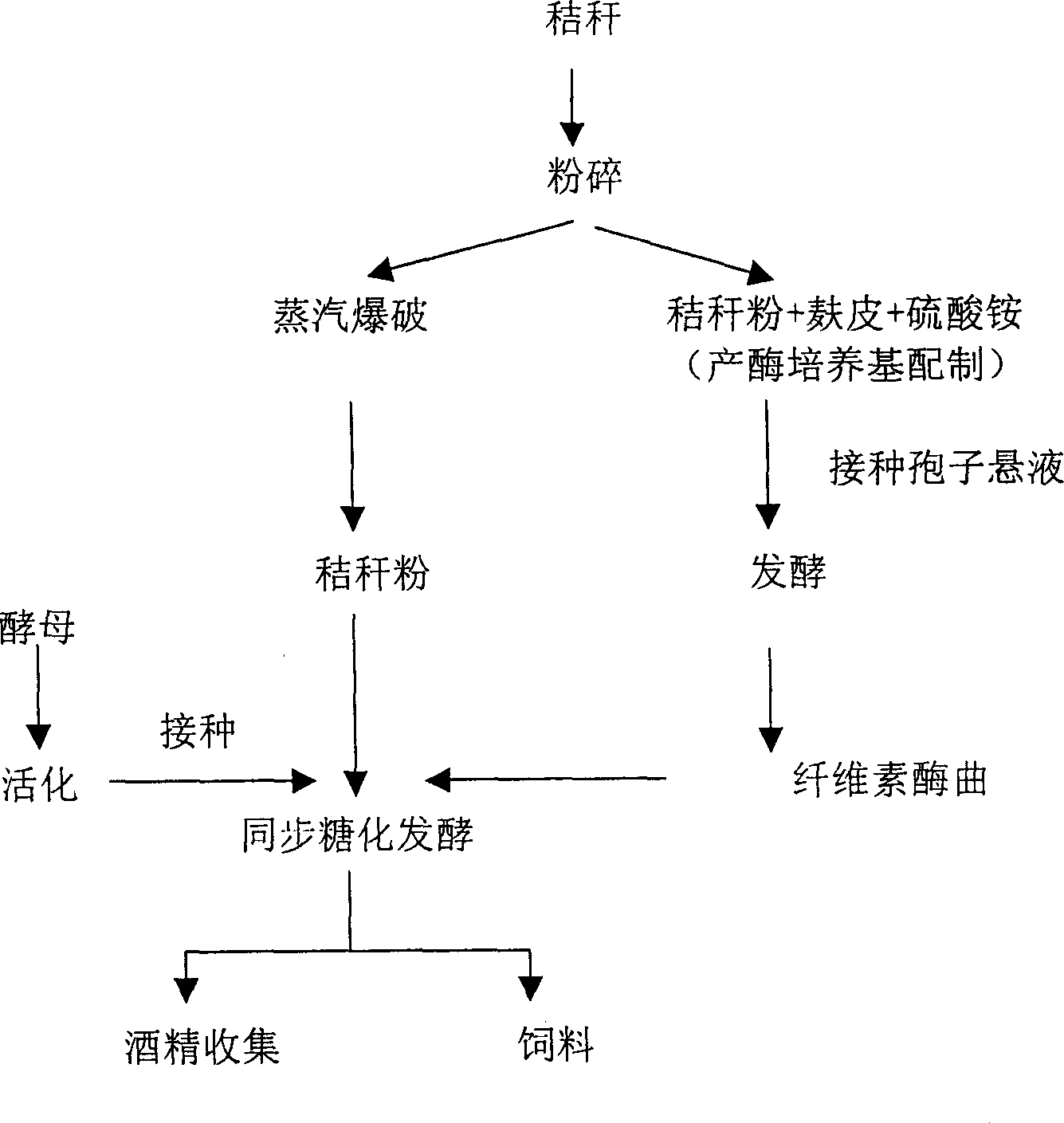

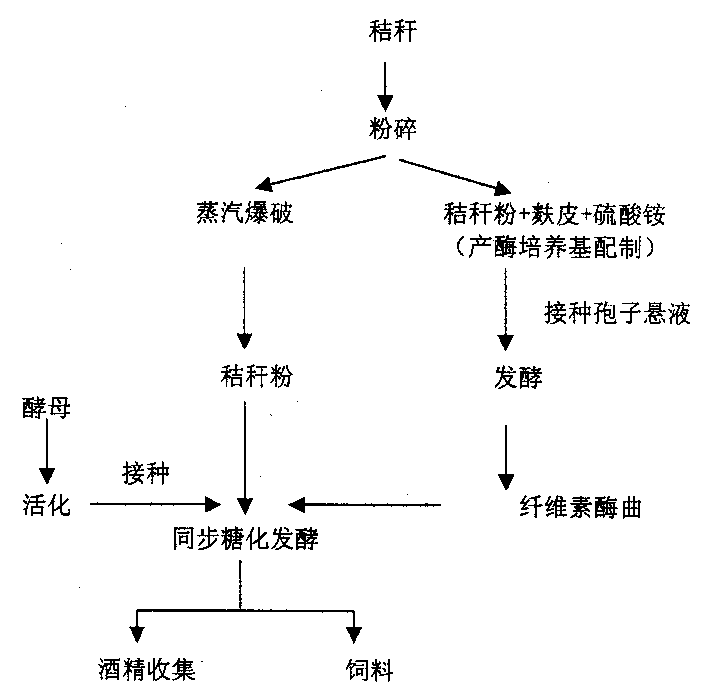

[0026] Specific implementation plan Option 1: if figure 1 , figure 2 as shown,

[0027] (1) Knead the straw with a kneading cutter and coarsely crush it to 20 mesh; pour the crushed straw into the reactor of the blasting device, feed saturated water vapor, increase the pressure to 1.2MPa, start timing, and react for 5 minutes Lower the valve and recycle the straw into the receiver;

[0028] (2) Trichoderma konshii is inoculated into the slant medium and cultivated until the mycelium grows vigorously, scraping a few rings of spores from the slant and inserting them into sterile water with glass beads, shaking, and dispersing the spores; the concentration of the spore suspension is 107 / mL ;

[0029] (3) Add straw powder and bran, water, ammonium sulfate in container; Make straw powder and bran weight ratio be 1: 1, solid-liquid weight ratio be 1: 3, ammonium sulfate addition is 2% of gross weight , mix evenly, sterilize, inoculate a spore suspension with a total weight of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com