Starch environment-friendly paper and preparation method thereof

A starch paper, environmentally friendly technology, applied in the field of papermaking, can solve problems affecting the health of workers and nearby residents, and achieve the effect of reducing specific gravity and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

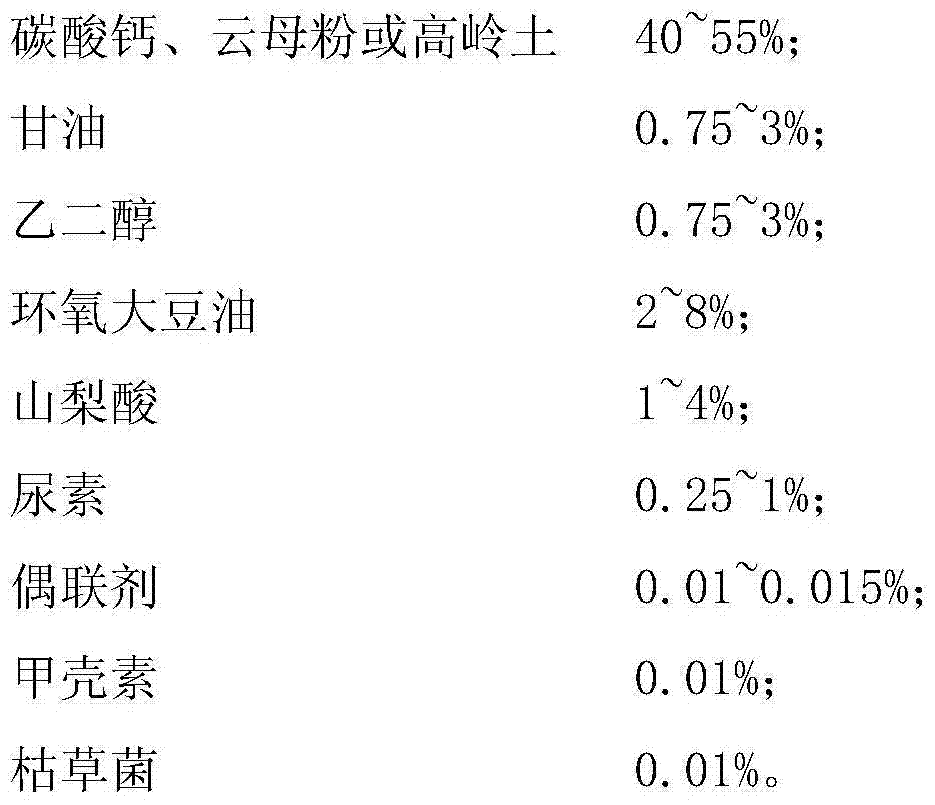

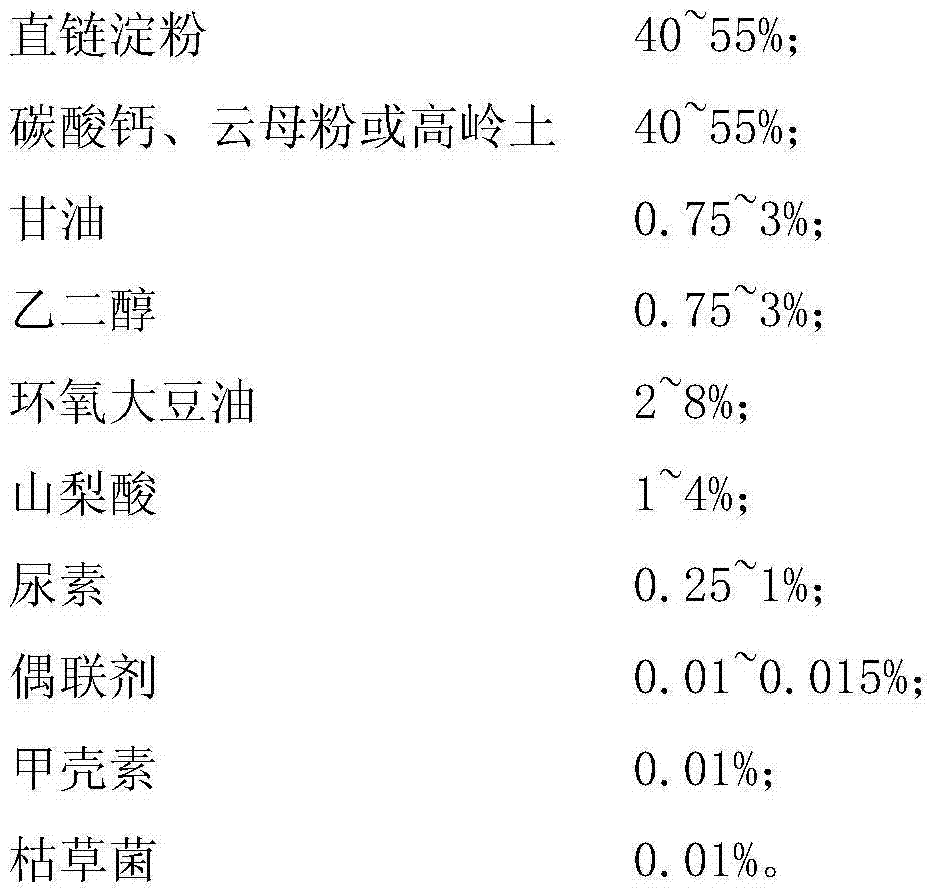

Method used

Image

Examples

Embodiment Construction

[0025] The environment-friendly starch paper of the present invention will be further introduced below through specific examples.

[0026] 1. The acquisition and usage of raw materials:

[0027] (1) Starch raw material:

[0028] First, starch is made by adding industrial starch (90% by mass) to glycerin (10% by mass), cooking at high temperature (120-160°C) and catalyzed (catalyzed by heating without catalyst), and then After cooling, it enters the internal mixer and kneads at a temperature of 110 degrees for one hour before making pellets, and then waits for the next stage after cooling. This material helps to achieve the special function of rapid cracking and biodegradation after use when it is made into paper in the future.

[0029] (2) Polylactic acid polymer raw material: use glycerol ester to break the polymer structure of polylactic acid, adjust its molecular structure to the required molecular weight, and then link it to become the required raw material . In the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com