Patents

Literature

237results about "Paper articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

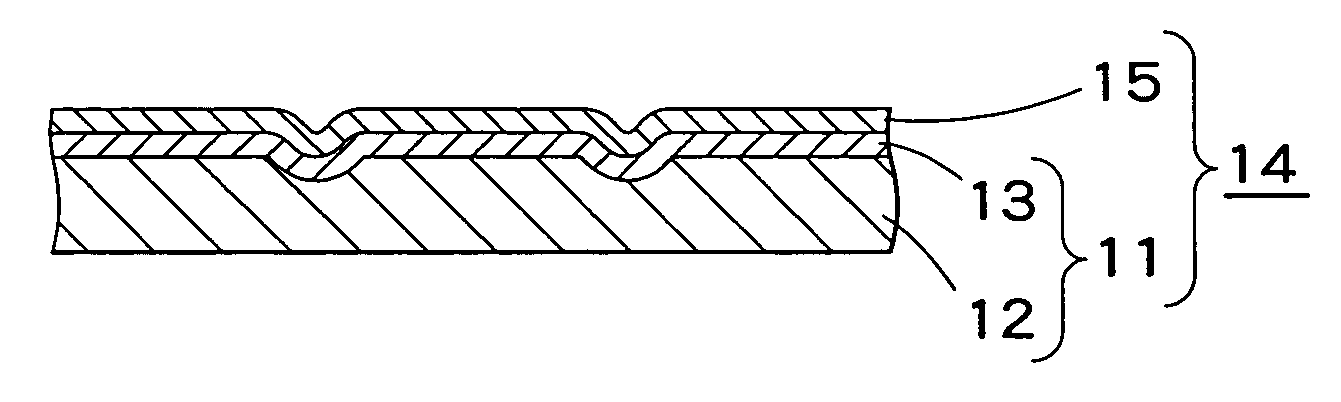

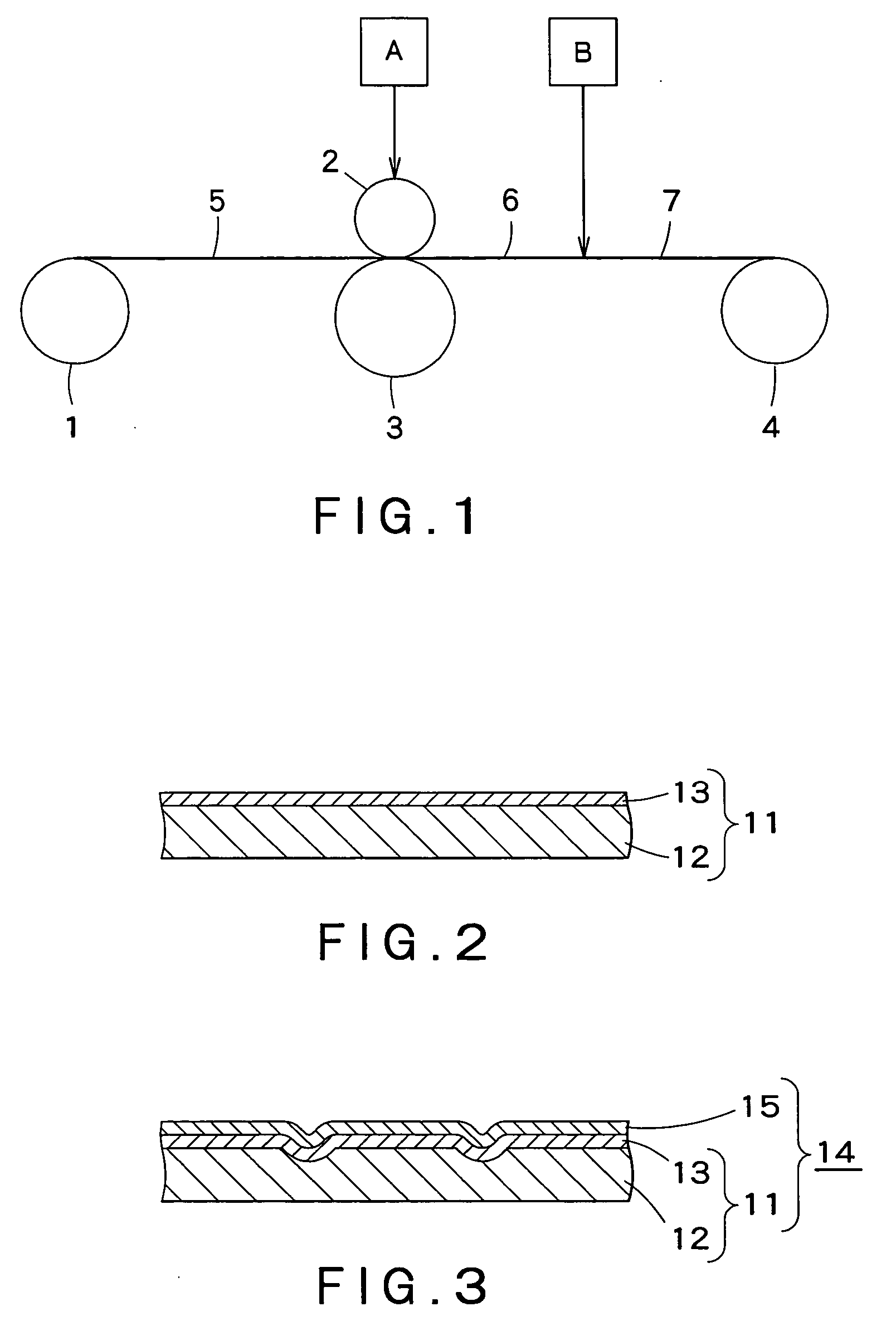

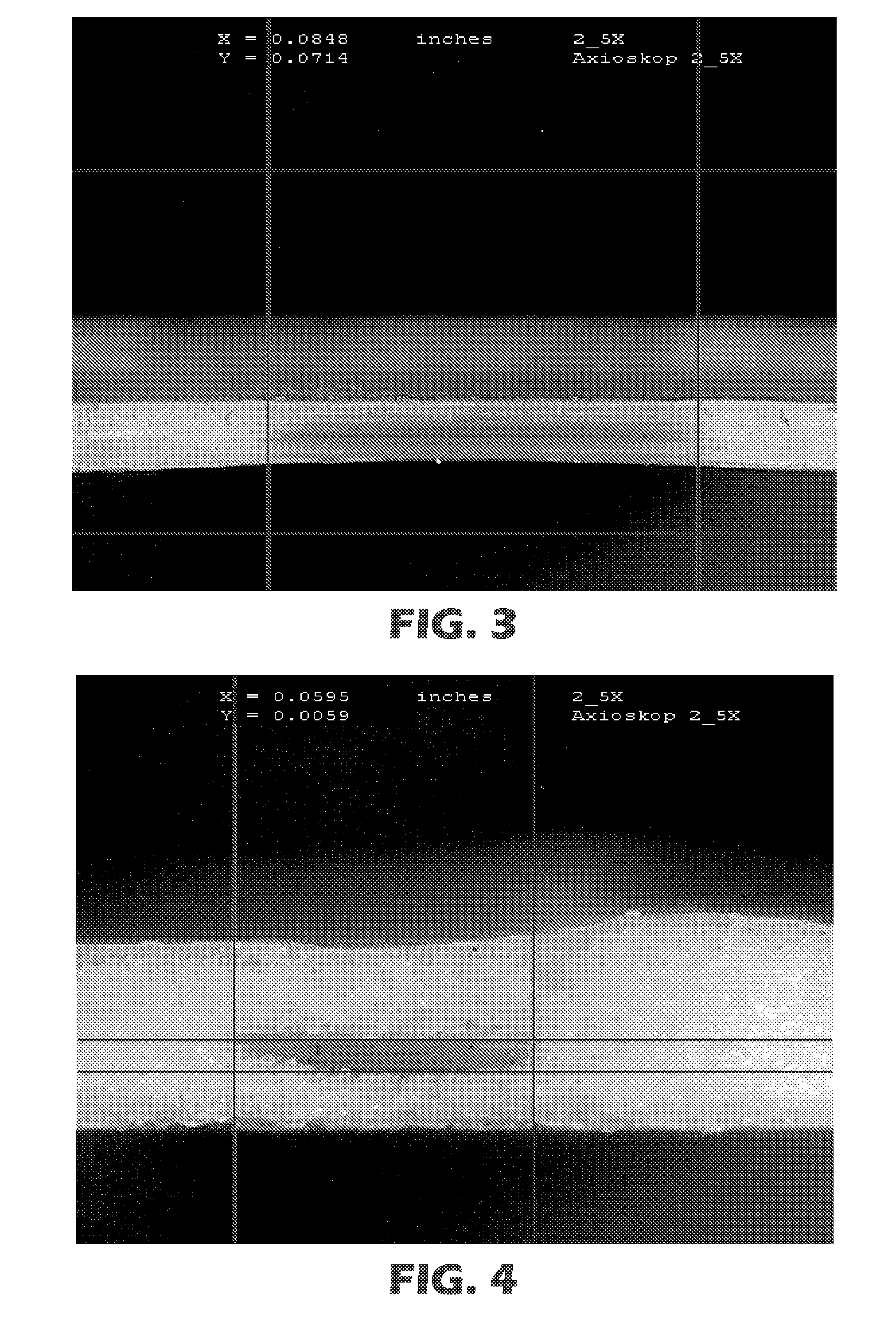

Multiple layer laminate

InactiveUS20060198987A1Stable and intimate bondComplicate adhesion of ink and inkSpecial paperSynthetic resin layered productsFiberMultiple layer

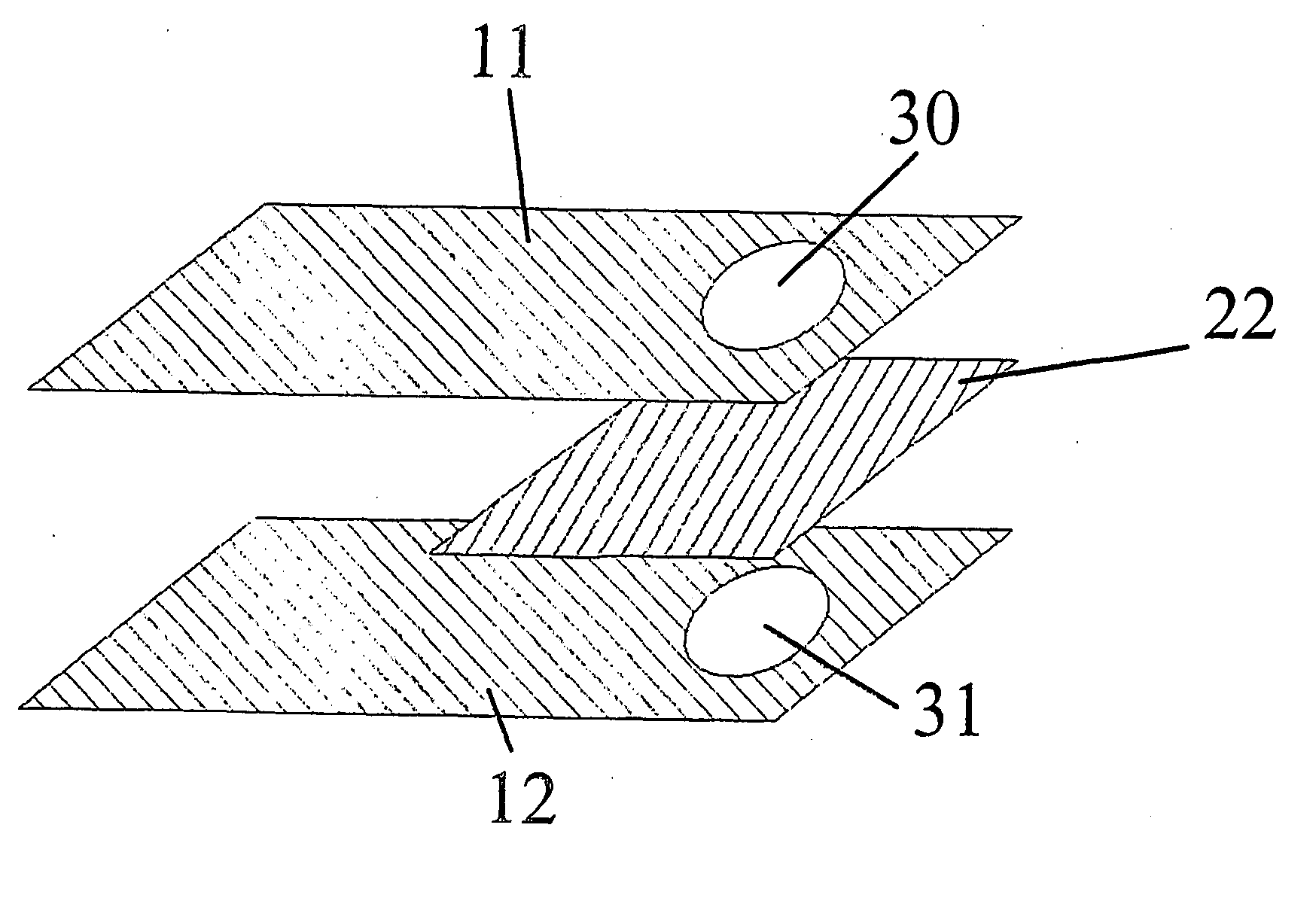

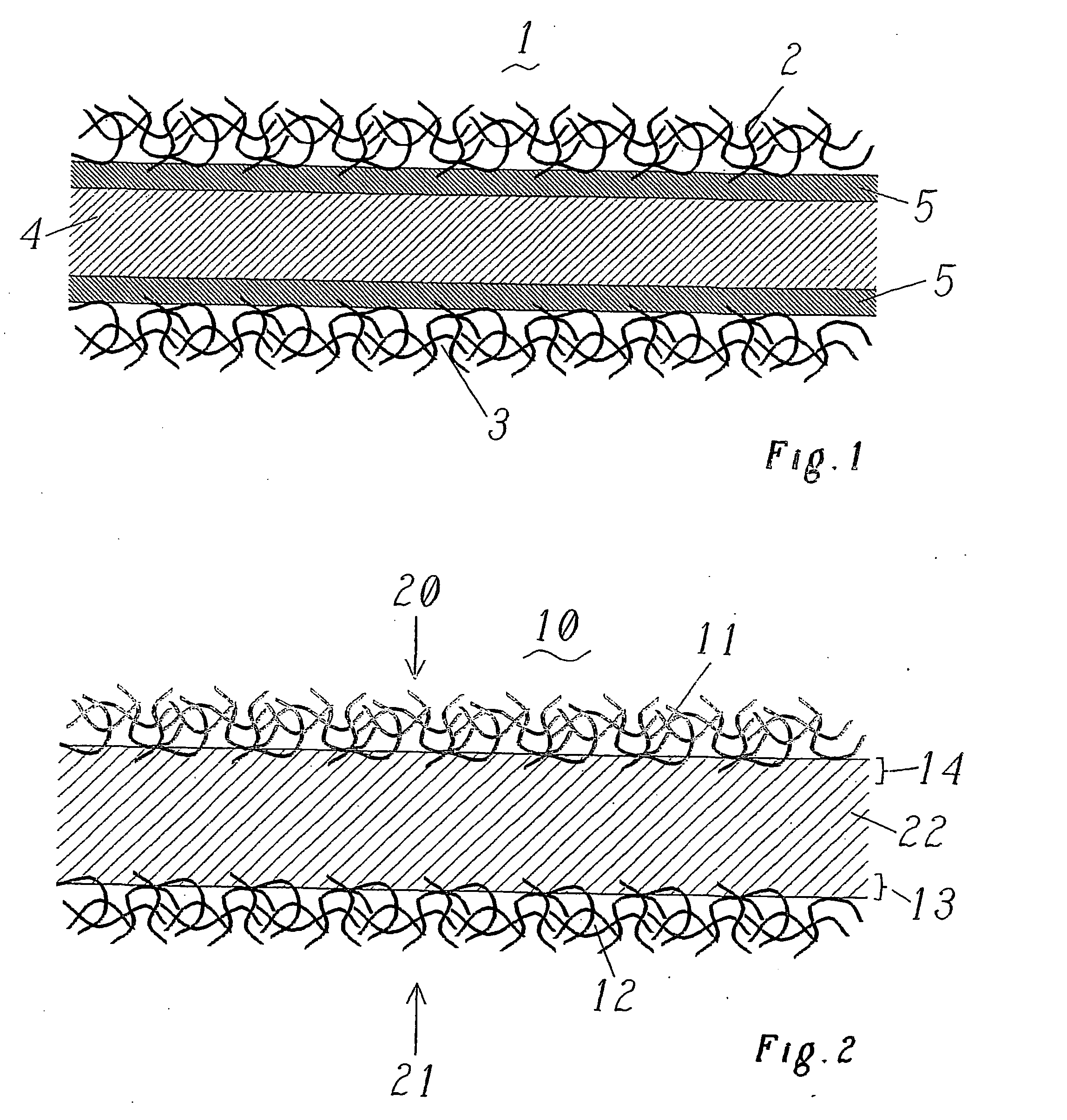

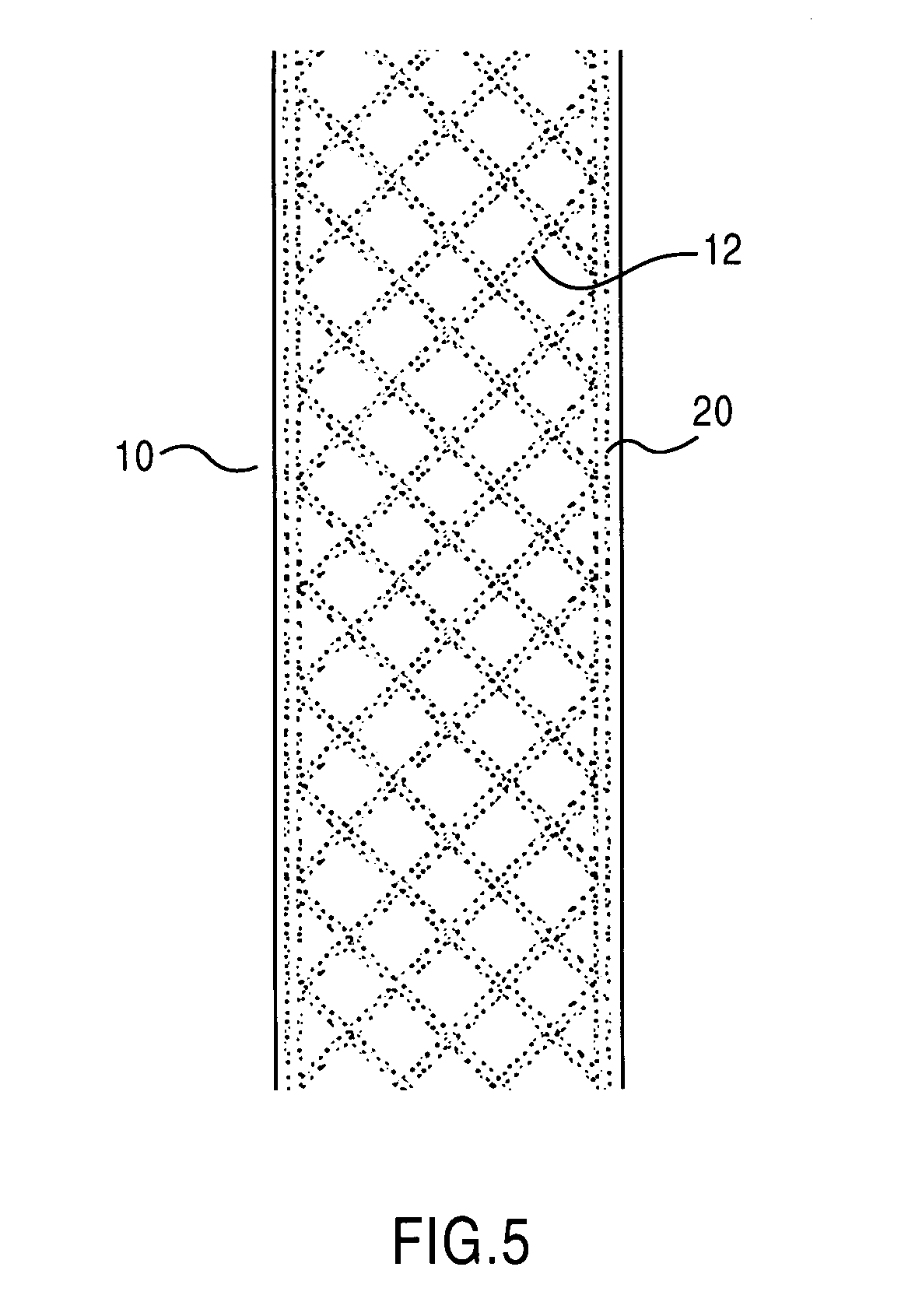

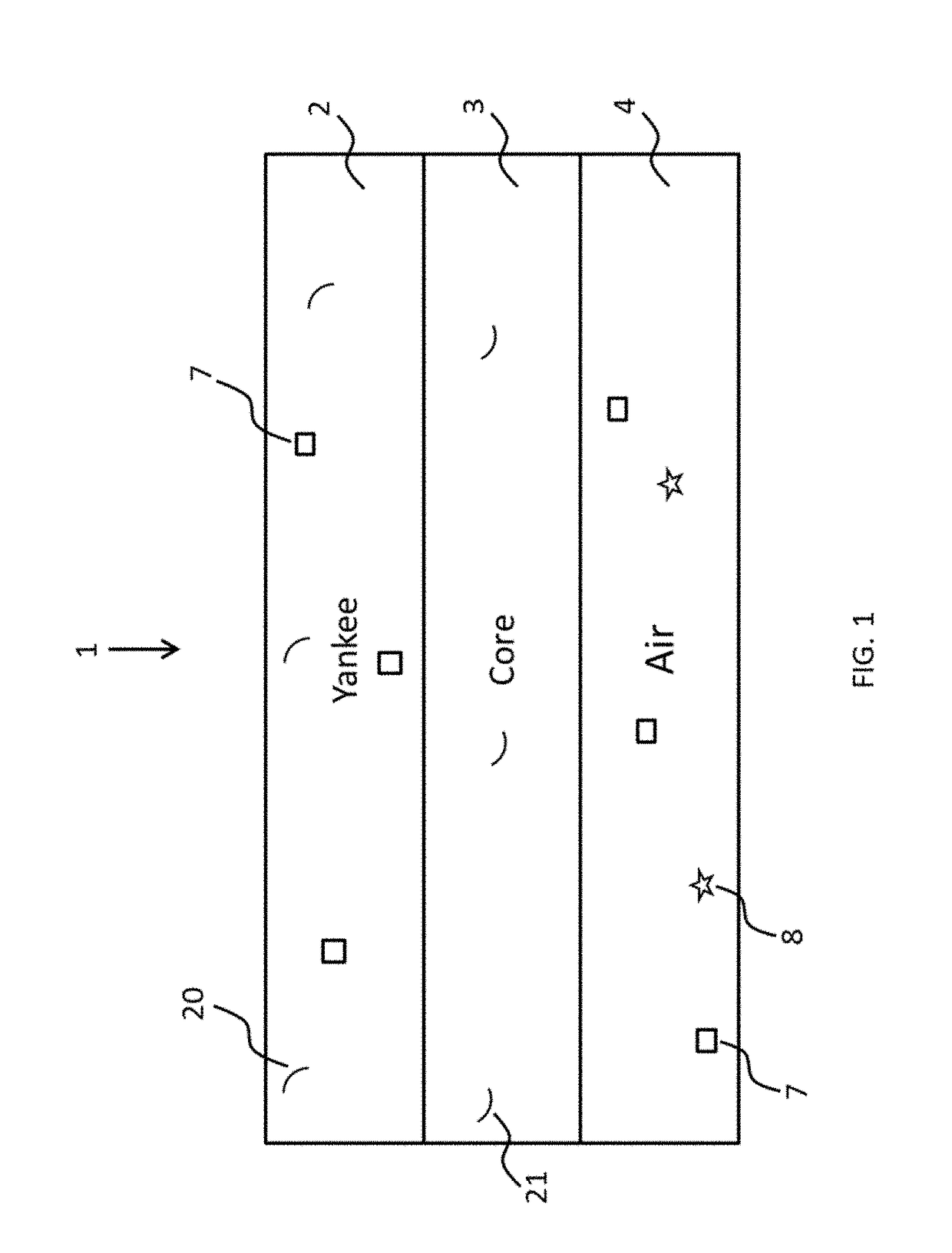

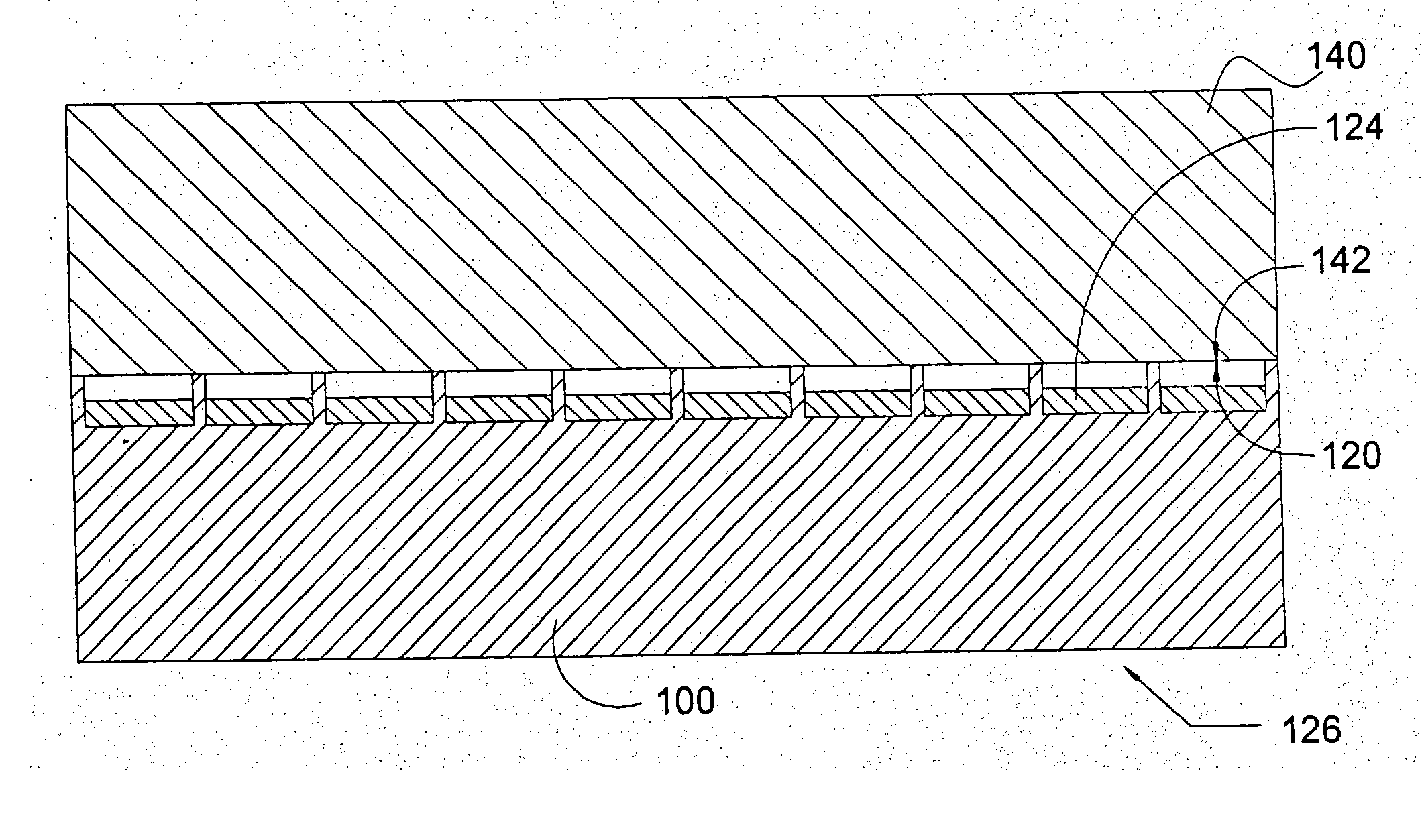

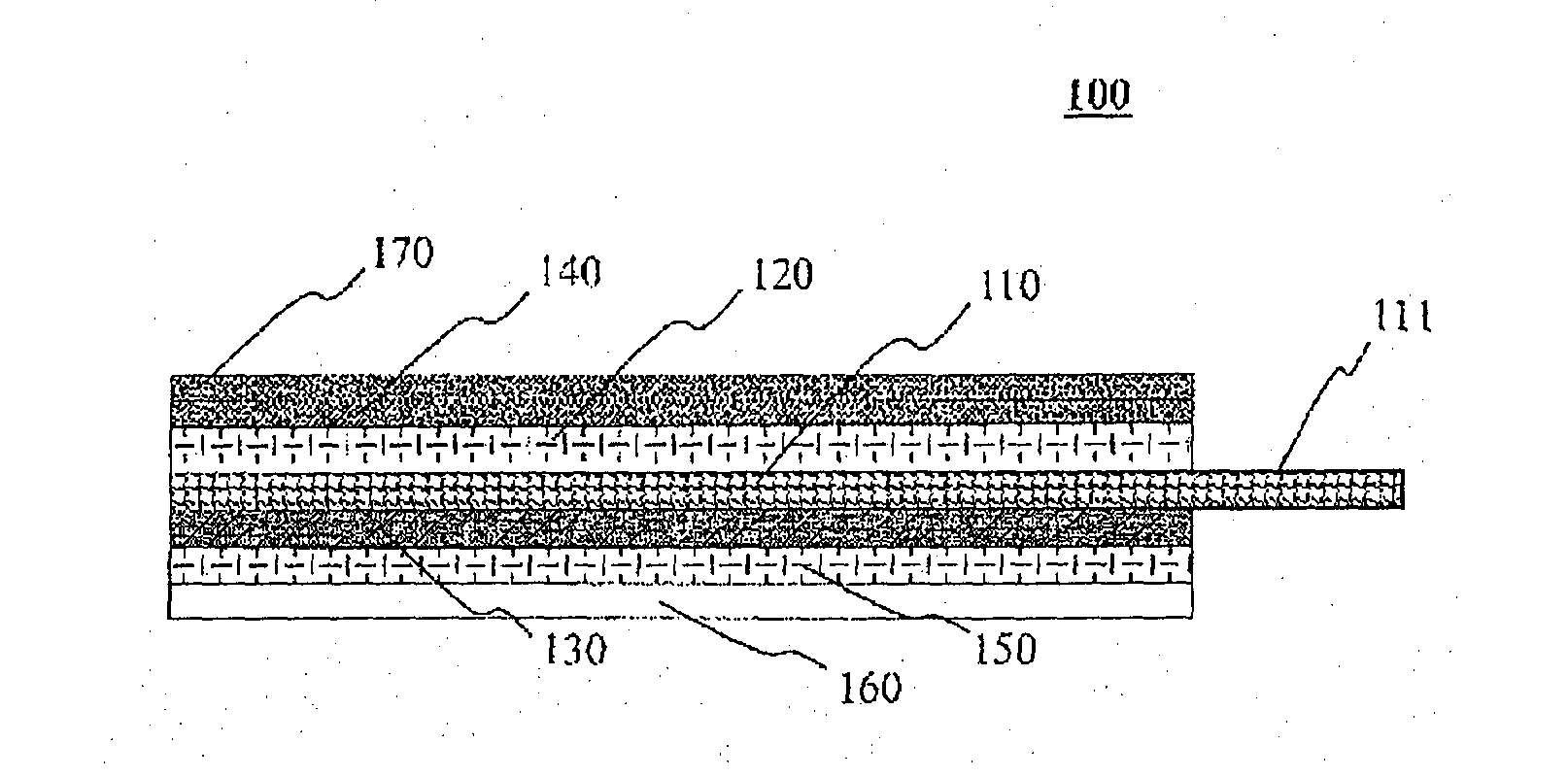

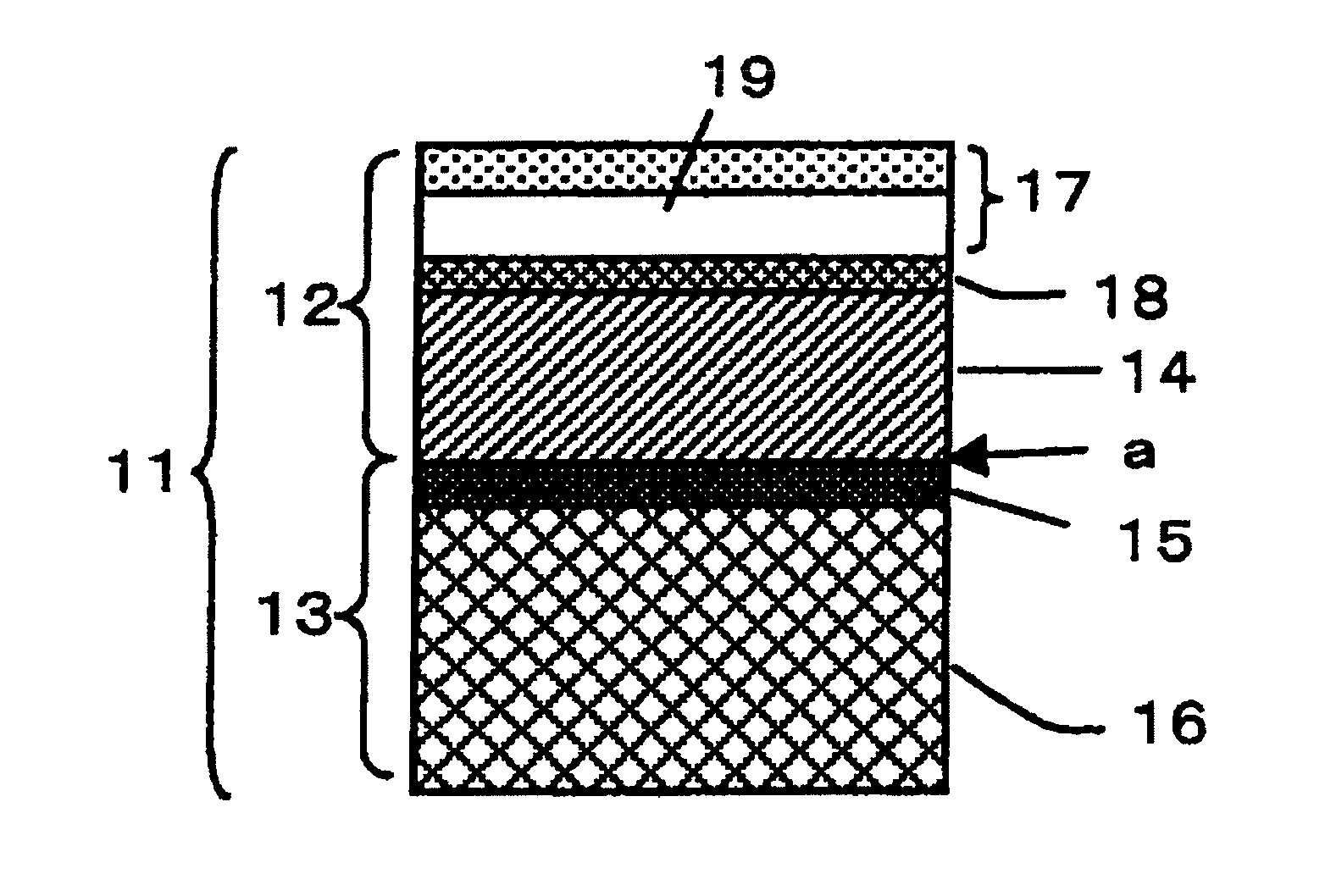

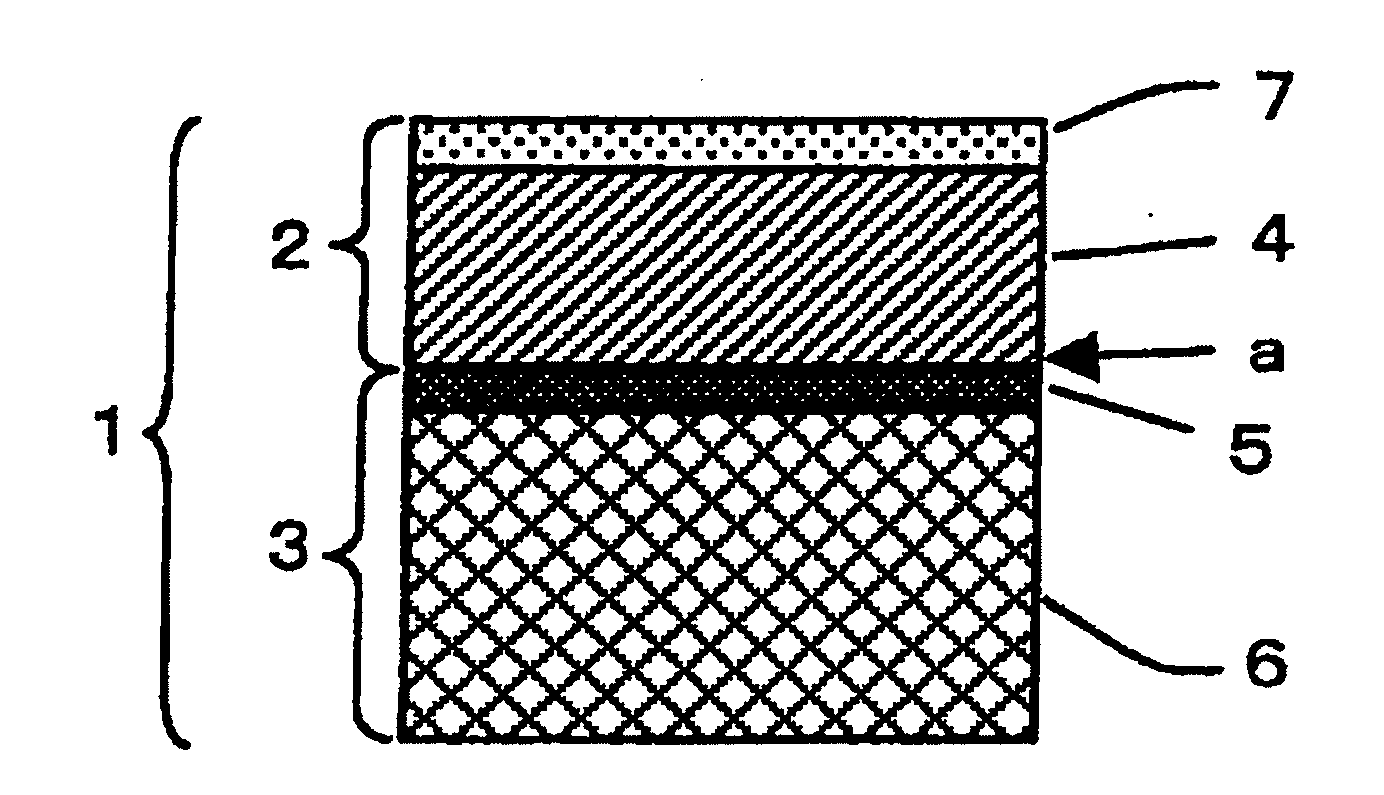

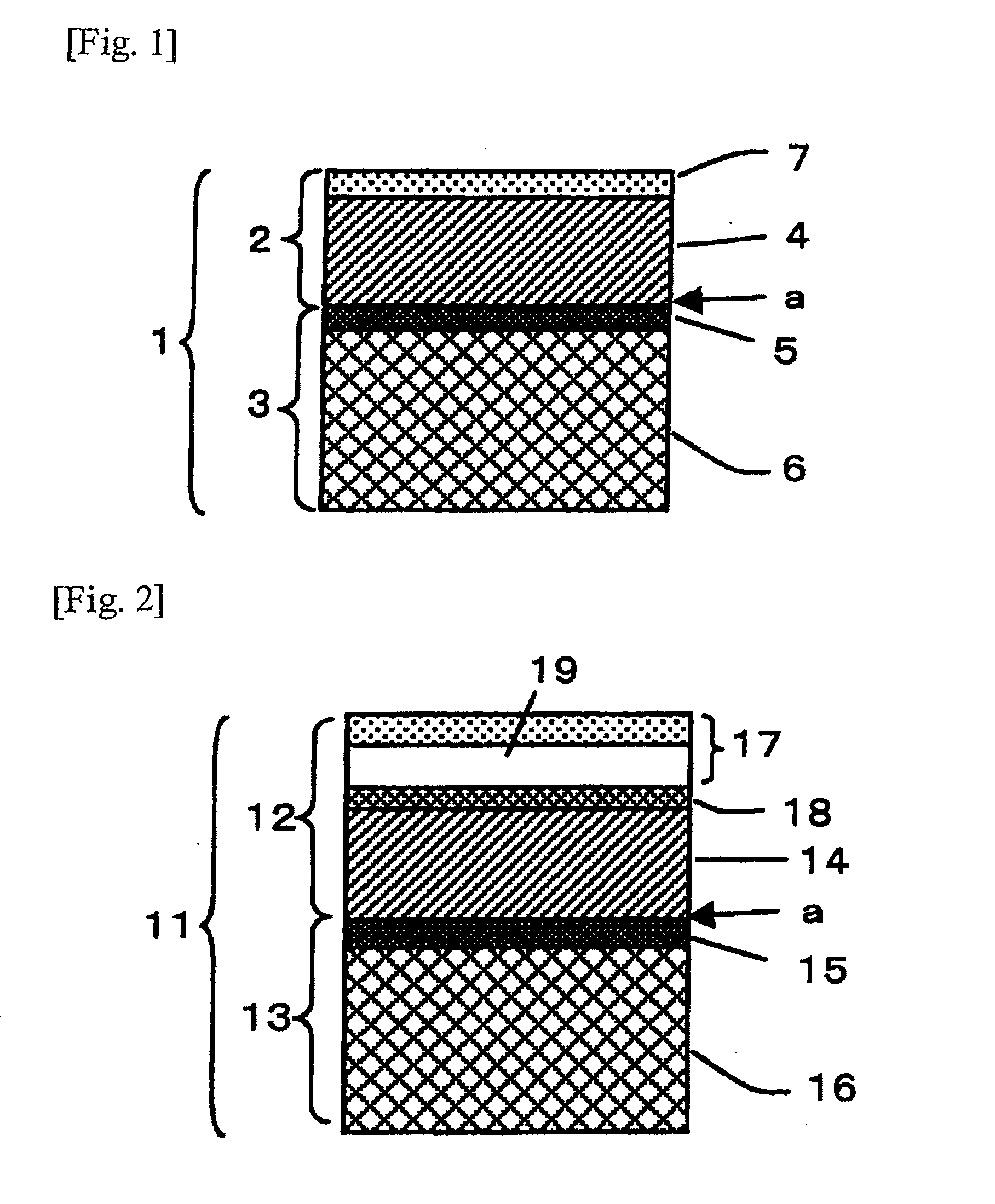

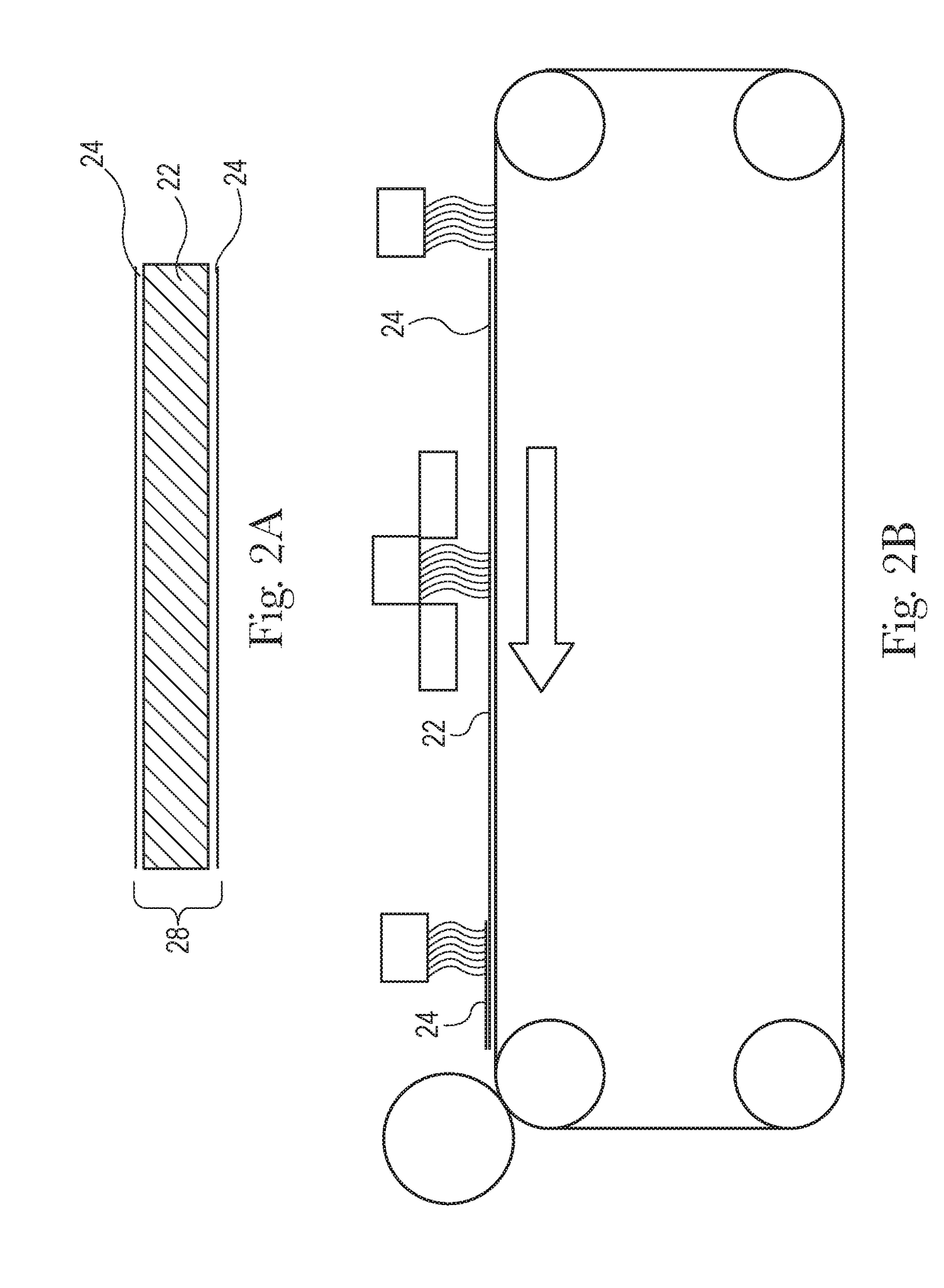

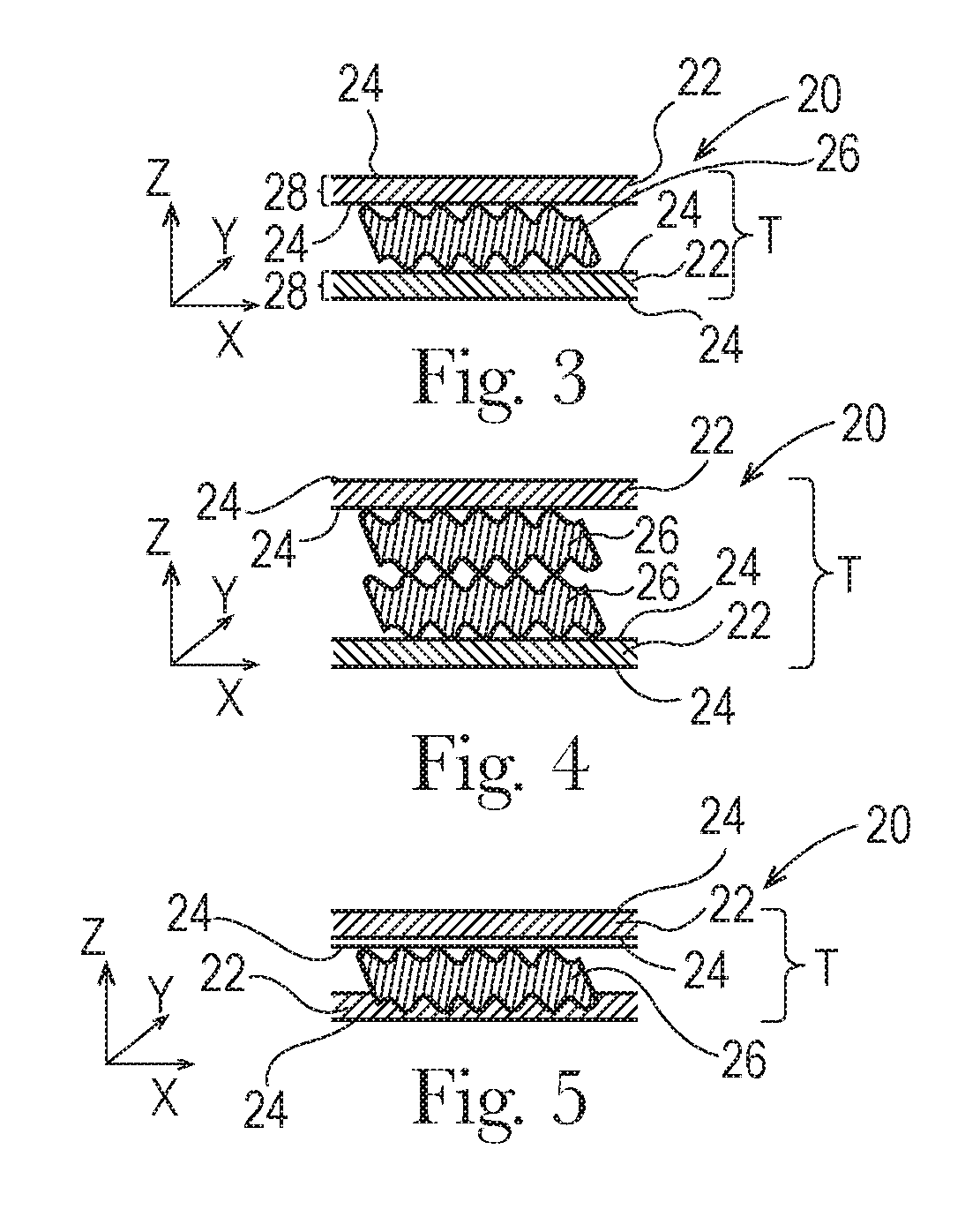

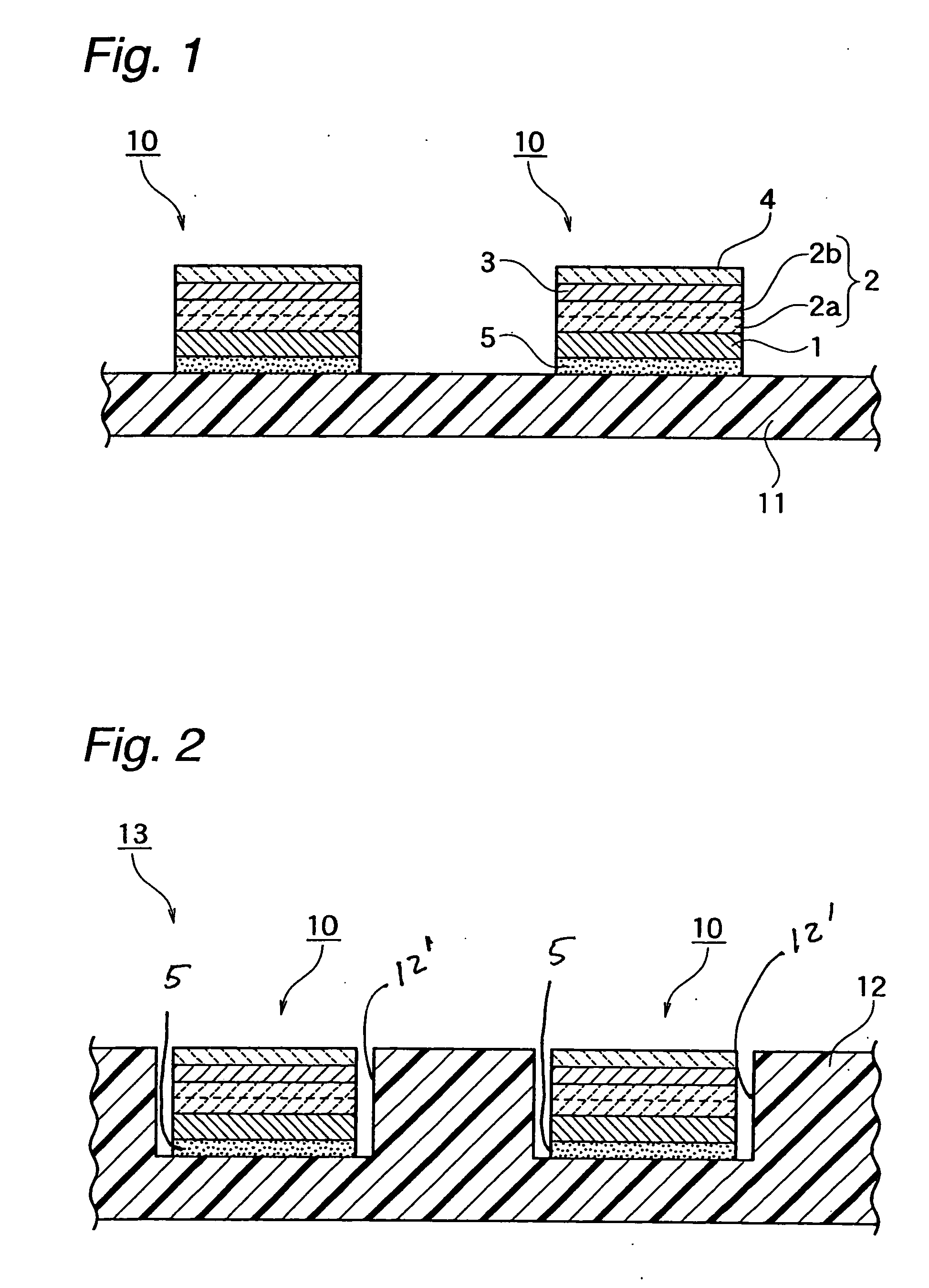

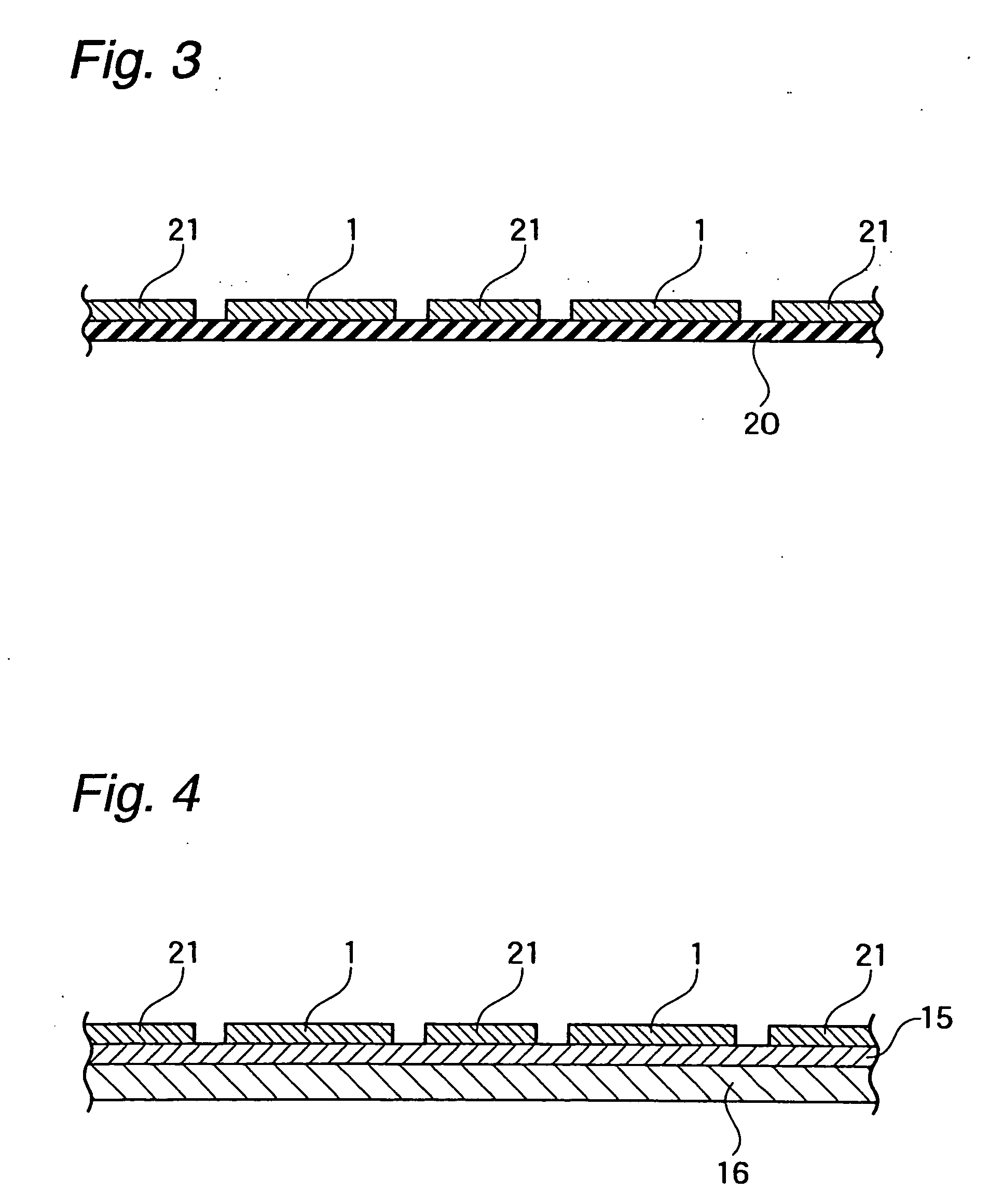

The invention relates to a multiple layer laminate such as a printing carrier, especially in the form of antifalsification paper such as bank notes. Said multiple layer laminate or more precisely the printing carrier comprises at least one plastic layer (22) having an upper side (20) and a lower side (21), an upper paper layer (11) which is connected to the upper side (20) of the plastic layer (22), and optionally a lower paper layer (12) which is connected to the lower side (21) of the plastic layer (22). The aim of the invention is to achieve an especially intimate connection between the individual layers, with simultaneously good printability and with similar haptic characteristics such as those of pure paper carriers. To this end, a thermoplastic polymer material is used as the plastic layer (22), and the connection between the paper layers (11, 12) and the plastic layer (22) is ensured, essentially without additional bonding agents, by means of penetration regions (13, 14) in which parts of the plastic layer (22) are melted with the mass of fibre composite of the paper layers (11, 12). To this end, the penetration regions (13, 14) essentially do not extend to the surfaces of the paper layers opposing the plastic layer (22).

Owner:LANDQUART +1

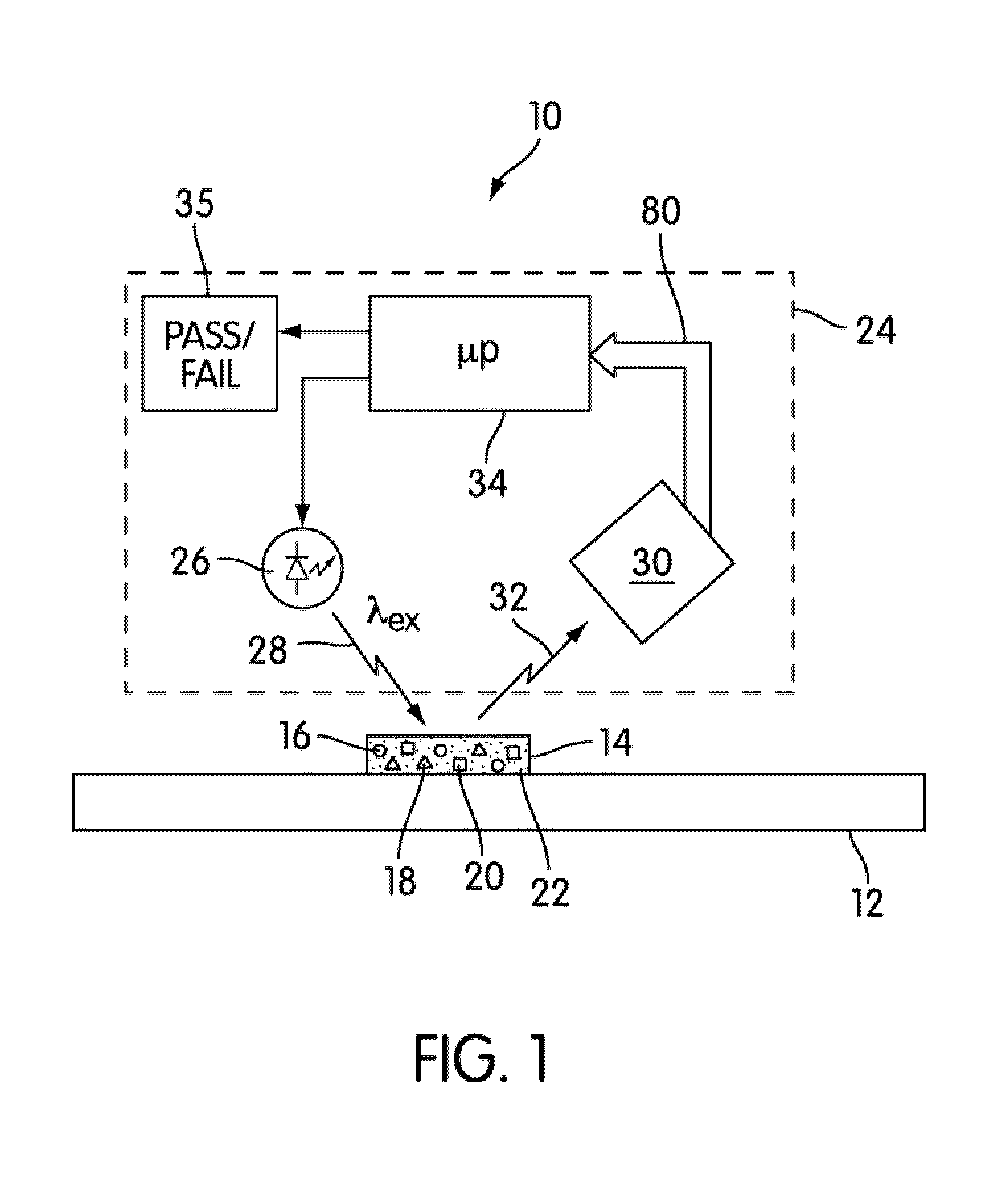

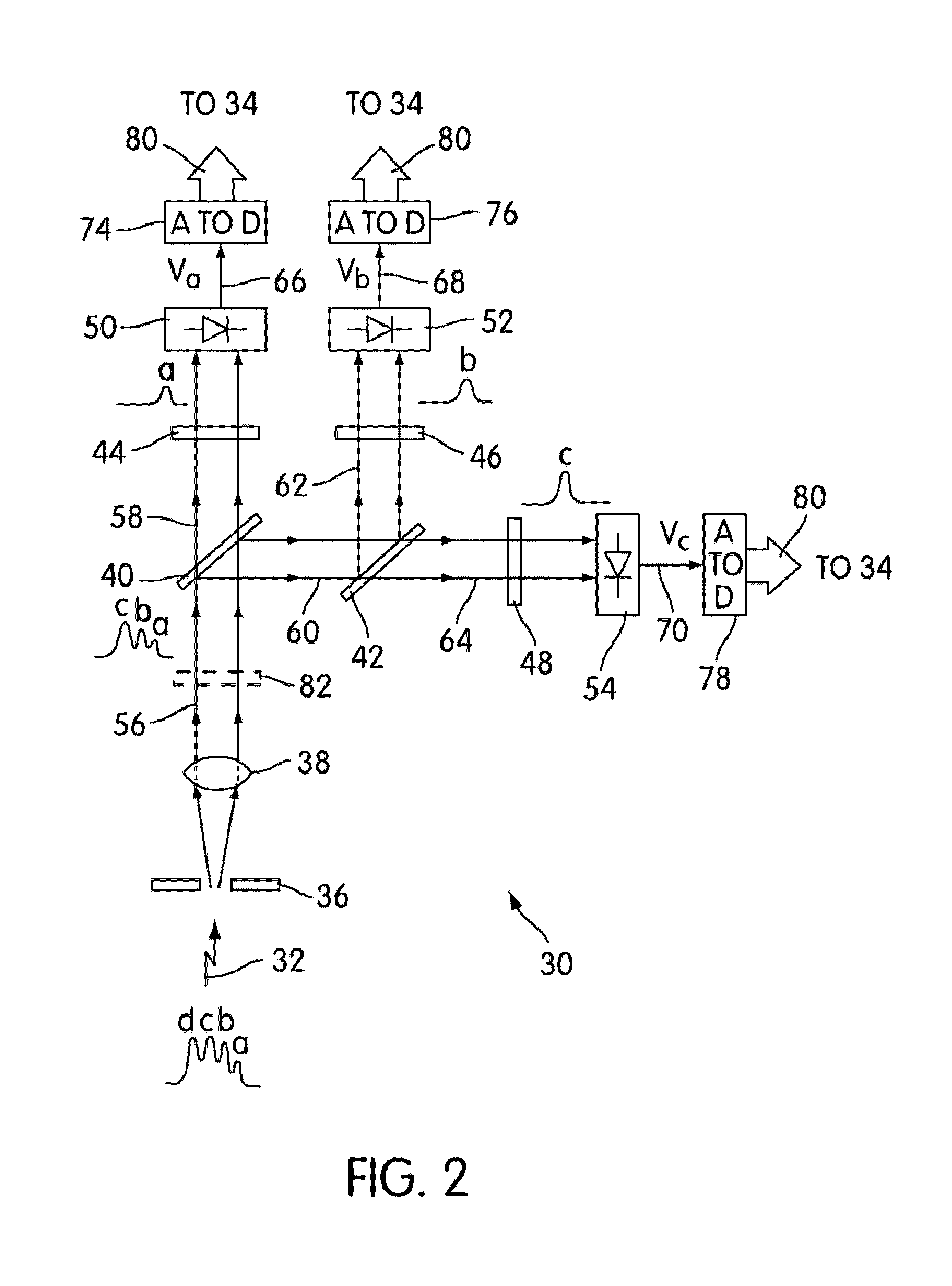

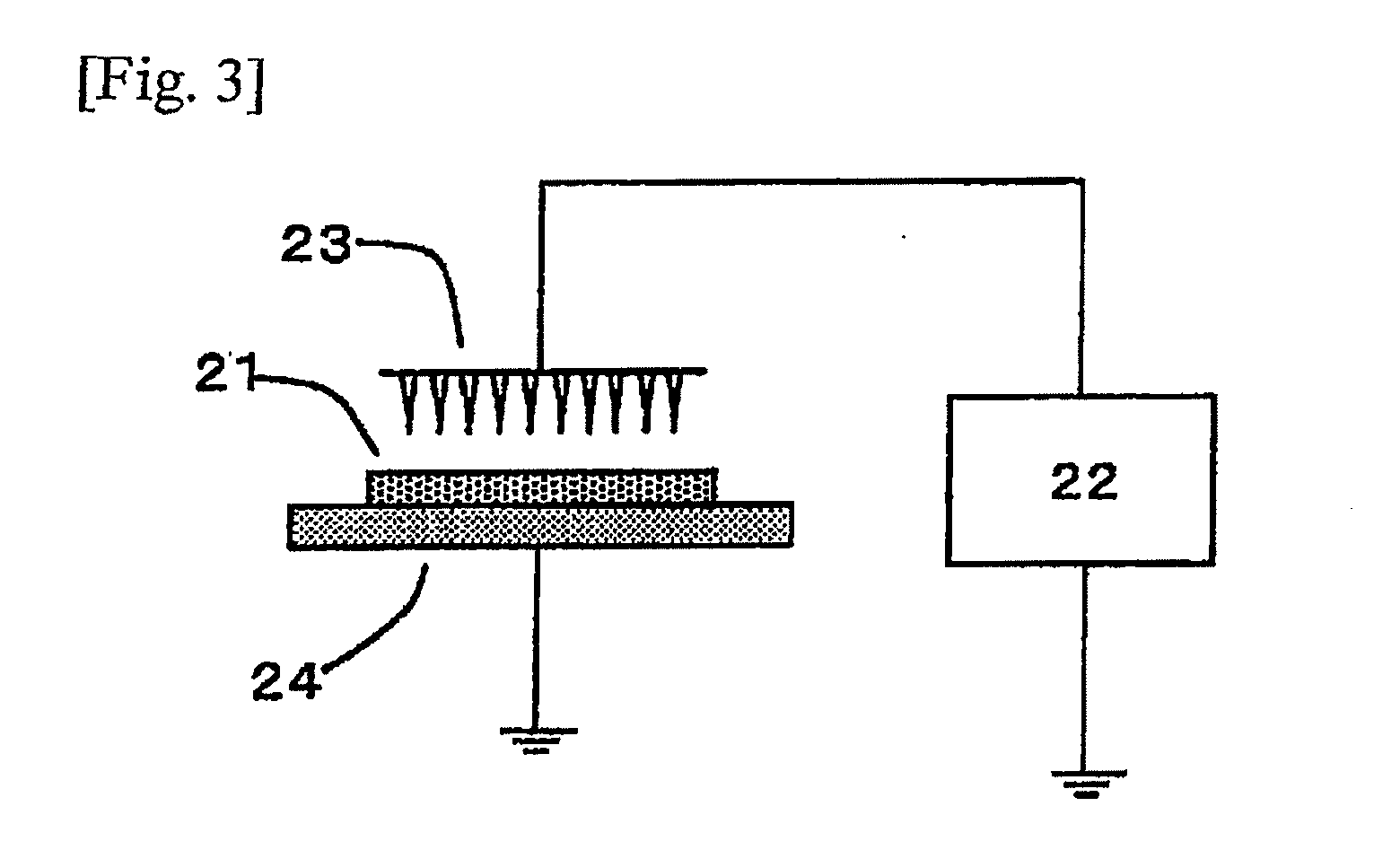

Phosphor based authentication system

InactiveUS20100102250A1Eliminate risk of damageMinimize risk of damageOptical radiation measurementDecorative surface effectsPhotoluminescencePhosphor

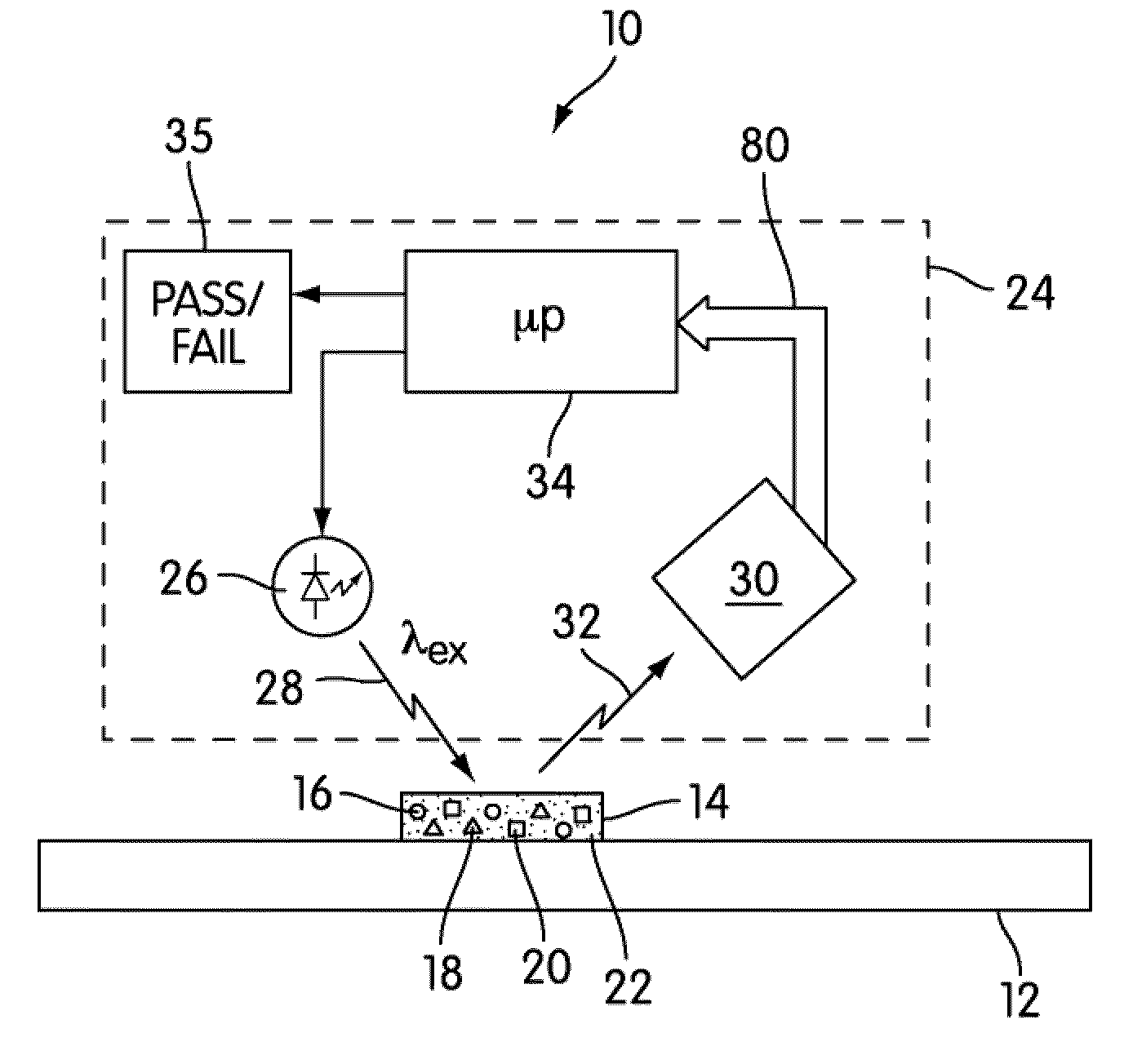

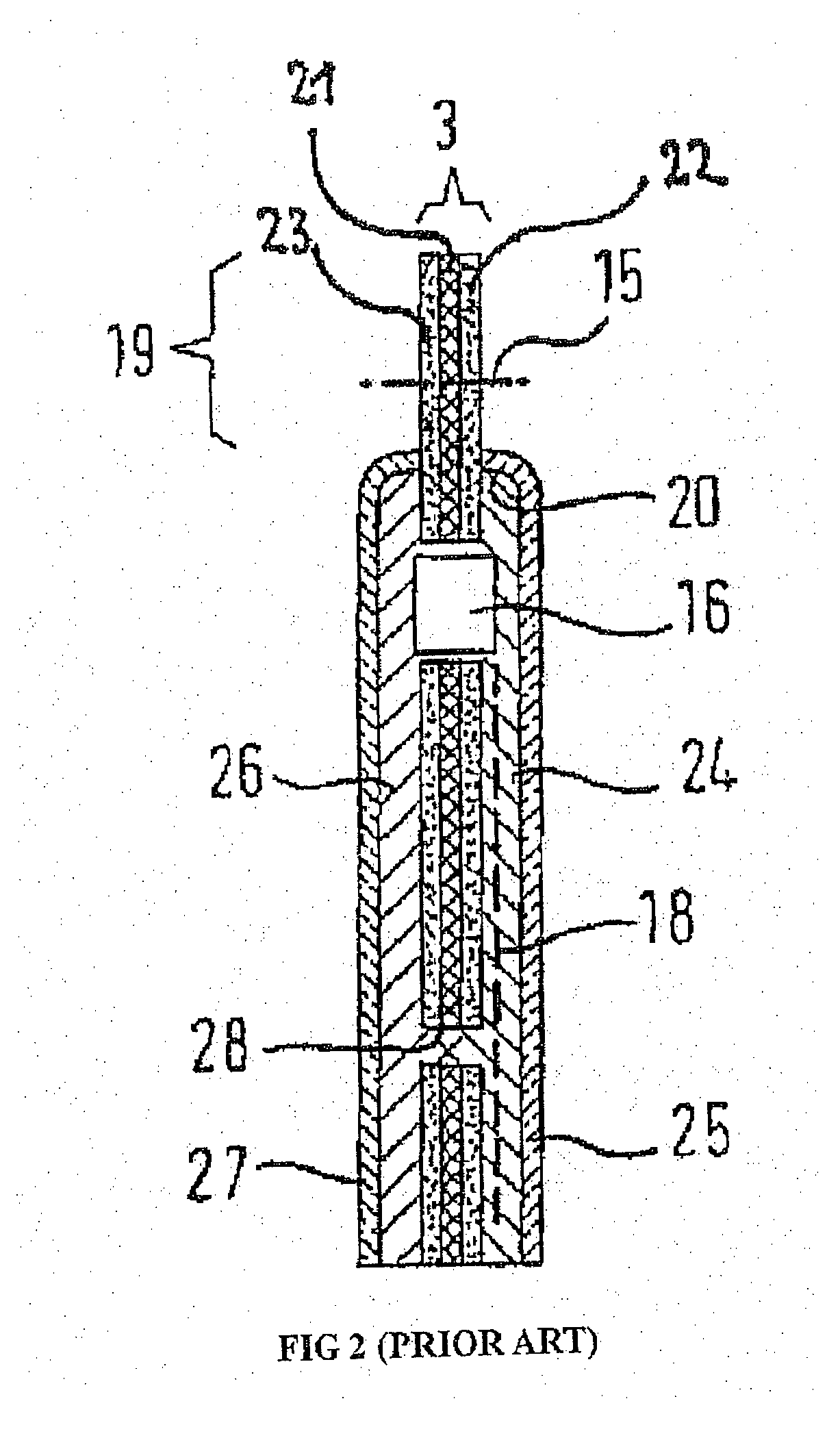

A phosphor (photo-luminescent) material based authentication system in which a blend (mixture) of at least two, preferably three or more, phosphor materials are used as a photo-luminescent security marking which is applied to or incorporated within an article / document to be authenticated. Preferably, the phosphor materials are each excitable by “eye safe” excitation radiation comprising visible light of wavelength 380 nm to 780 nm. Moreover, when excited the security marking preferably also emits visible light thereby minimizing any risk of damage to an operator's eye in the event of accidental exposure to the excitation radiation and / or light generated by the photo-luminescent marking. The authenticity of the article / document can be authenticated by verification of the composition of the phosphor by exciting the marking and comparing one or more selected parameters of light emitted by the security marking with corresponding parameters of the characteristic emission spectrum of the authentic phosphor blend.

Owner:INTEMATIX

Embossed release paper for synthetic leather production and support therefor, and synthetic leather using the release paper and process for producing the synthetic leather

InactiveUS20070116929A1Excellent embossabilityExcellent releasabilityPaper coatingPaper/cardboardAdhesiveHeat resistance

This invention provides an embossed release paper for synthetic leather production, which has embossability, heat resistance and durability and, at the same time, has excellent separability from a two-pack curing type PU adhesive and can be used in all of synthetic leathers such as PU, PVC, and semisynthetic leathers, and a process for producing the same. The embossed release paper for synthetic leather production comprises at least paper as a support and an ionizing radiation cured film provided on the paper. The upper part of the cured film has been embossed. The ionizing radiation cured film has been formed by applying an ionizing radiation to a coating liquid having a specific composition to cure the coating liquid.

Owner:DAI NIPPON PRINTING CO LTD

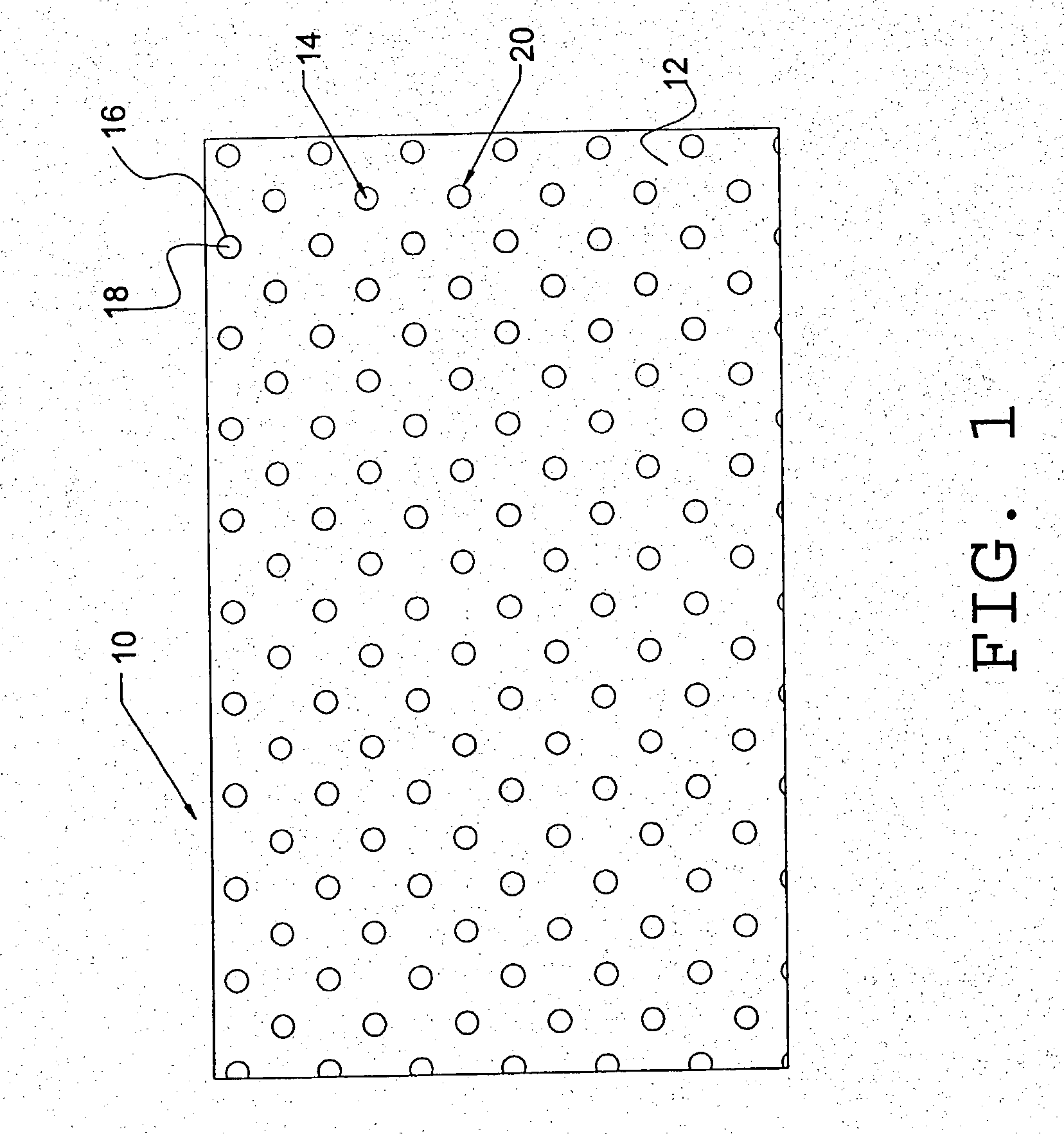

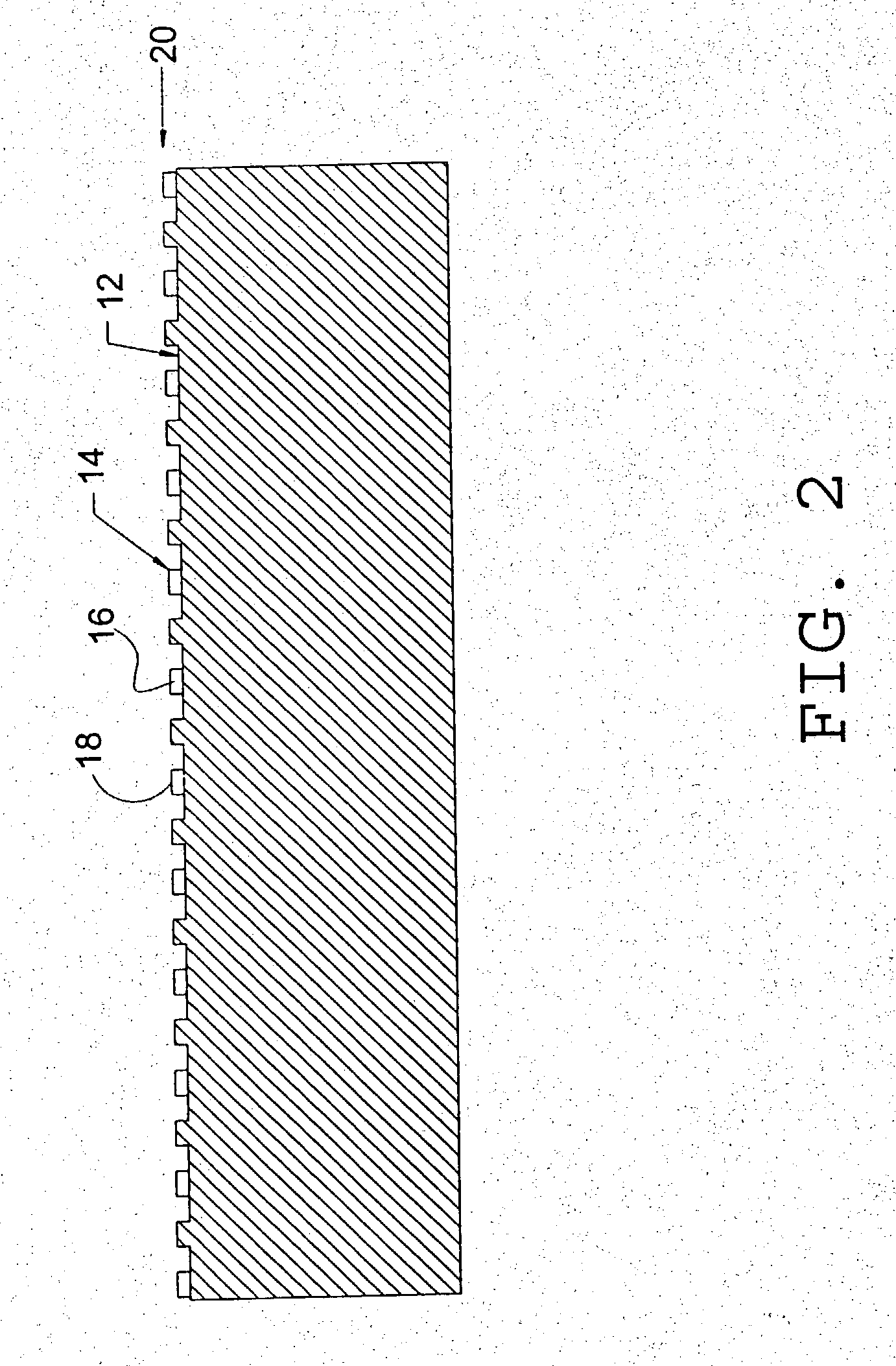

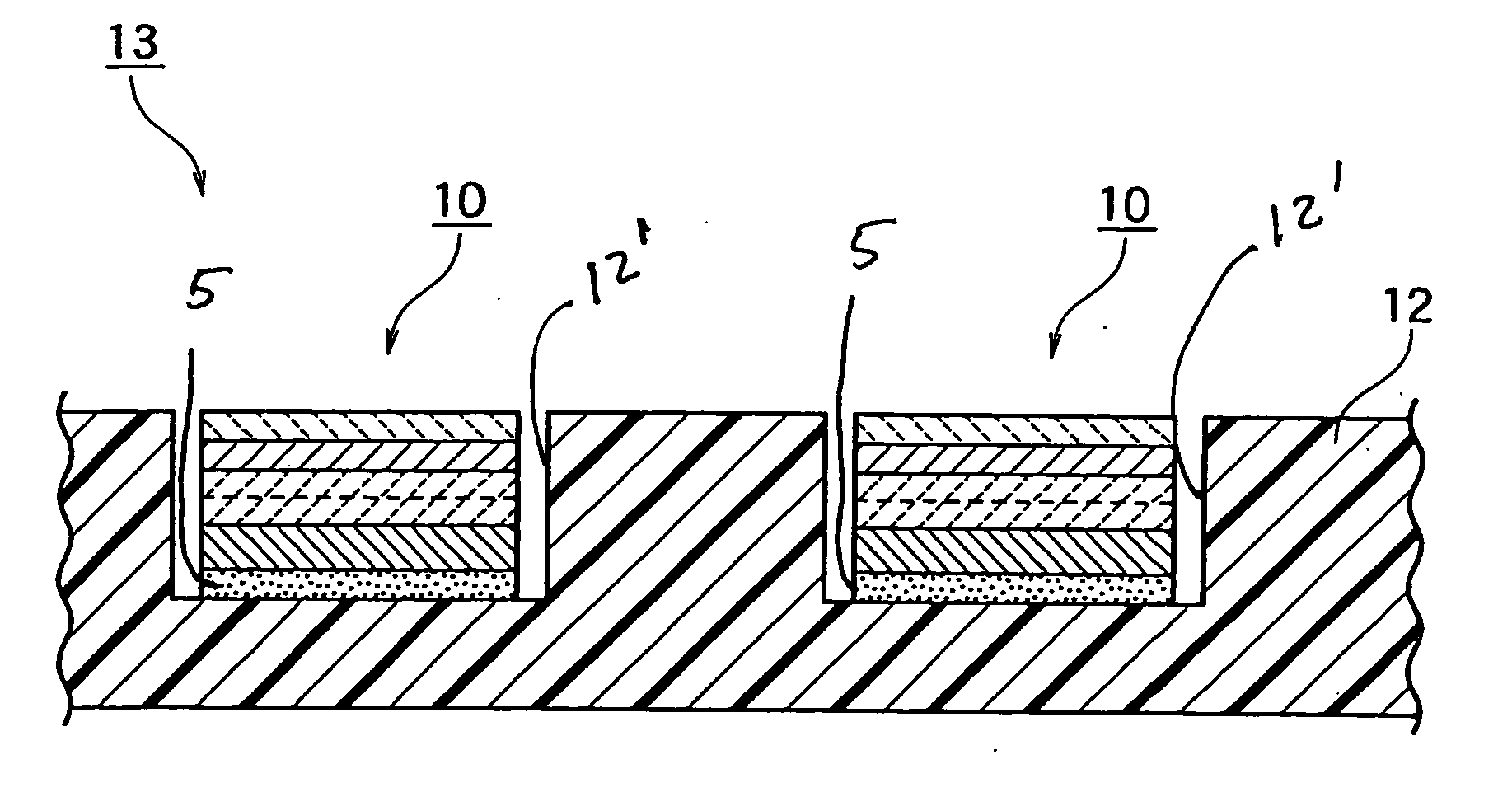

Patterning on surface with high thermal conductivity materials

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

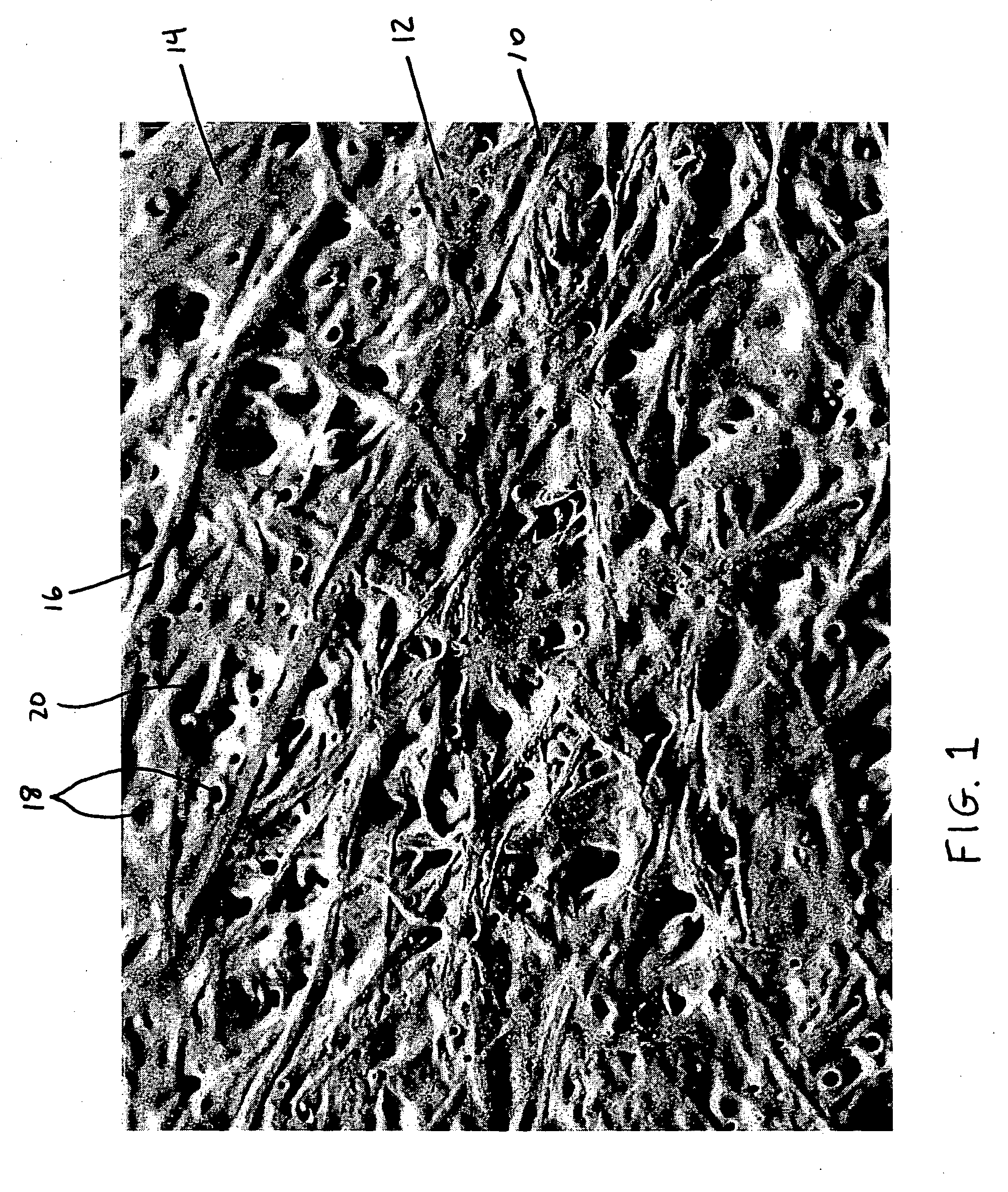

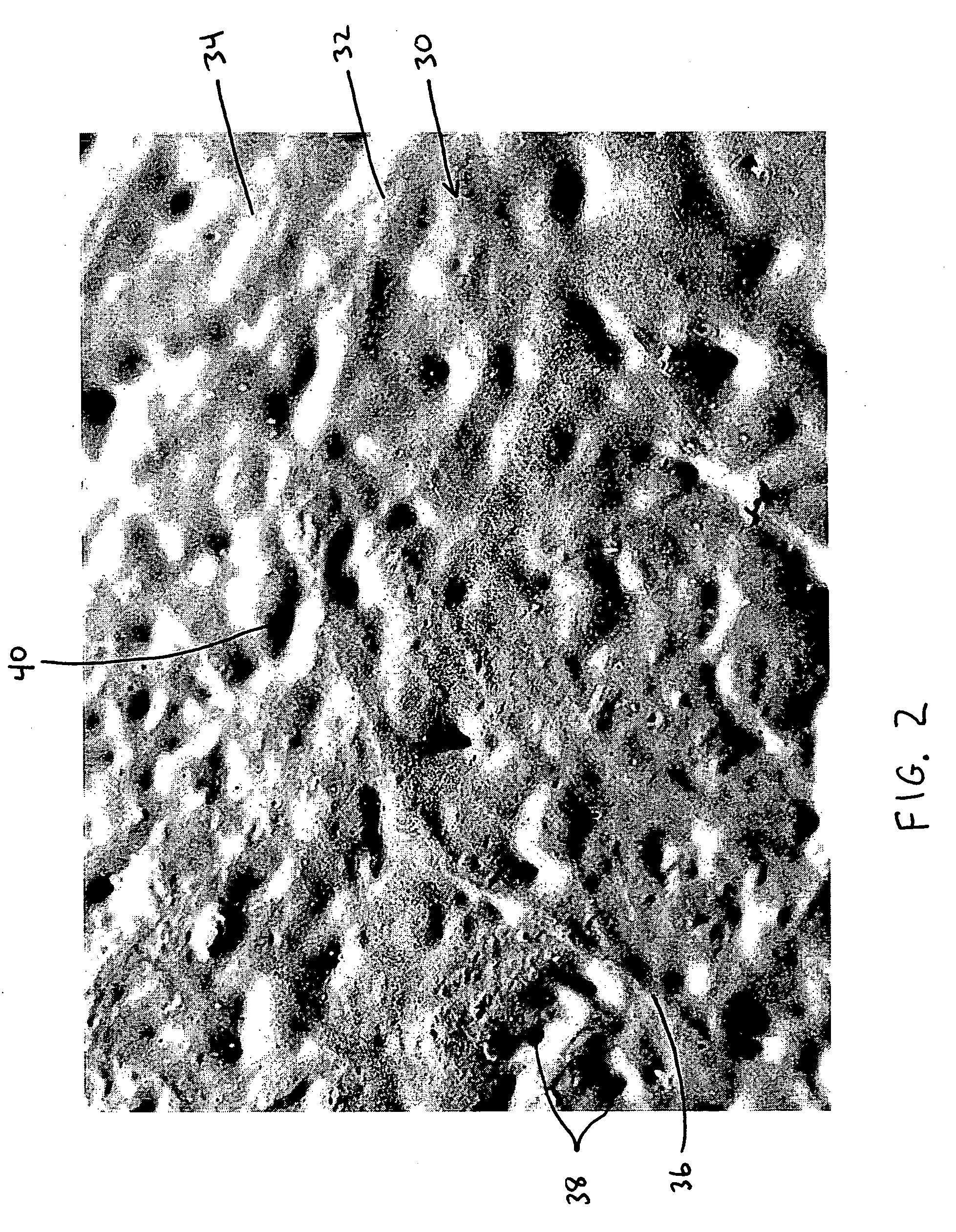

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

Foam security substrate

InactiveUS7820282B2Deter counterfeitingIncreased durabilitySynthetic resin layered productsPaper articlesPolymer sciencePaper document

Owner:3M INNOVATIVE PROPERTIES CO

Ink-receptive foam article

InactiveUS7655296B2Increased durabilityIncrease resistanceDecorative surface effectsSynthetic resin layered productsPolymer scienceFlame treatment

Owner:3M INNOVATIVE PROPERTIES CO

Document laminate formed from different polyester materials

InactiveUS20050084693A1Reduce adverse effectsImproved safety and durabilityRecord carriersDecorative surface effectsPolyesterAdhesive

A polyester laminate for an identification document is formed from different polyester materials. One of the polyester materials, such as PCTA, provides a durability property. Another of the polyester materials, such as PETG, provides a layer having a surface with a bonding property for bonding directly to a core without adhesive. The polyester material with the bonding property is selected to enable direct bonding to a printed core layer of TESLIN or polyester through a roll to roll or platen press process.

Owner:L 1 SECURE CREDENTIALING

Disposable towel produced with large volume surface depressions

A disposable tissue or paper towel product including at least two plies, an exposed outer surface of at least one of the two plies comprising a plurality of pockets, the plurality of pockets having an average volume greater than 0.4 mm3 and an average surface area of 2.5 mm2, wherein the product is formed using a structured fabric with both a left handed and right handed twill pattern that reverses itself periodically.

Owner:STRUCTURED I

Polypropylene impact copolymer based hot melt adhesive

ActiveUS20150024649A1High bond strength levelImproved performance characteristicsPersonal careSynthetic resin layered productsElastomerPlasticizer

A hot melt adhesive using polypropylene impact copolymers that is particularly well suited for elastic attachment and stretch films in diaper structures. The hot melt adhesive composition is a blend of about 2.5% to about 30%, by weight, of a polypropylene impact copolymer; about 2.5% to about 30%, by weight, of an olefin based elastomer; about 10% to about 70%, by weight, of a tackifying resin having a softening point of at least about 80° C. and up to about 140° C.; about 0% to about 60%, by weight, of a plasticizer; and about 0.1% to about 5% of a stabilizer or antioxidant.

Owner:BOSTIK INC

Ink-receptive foam article

InactiveUS20060257594A1High crystallinityIncreased durabilityDecorative surface effectsSynthetic resin layered productsPolymer scienceFlame treatment

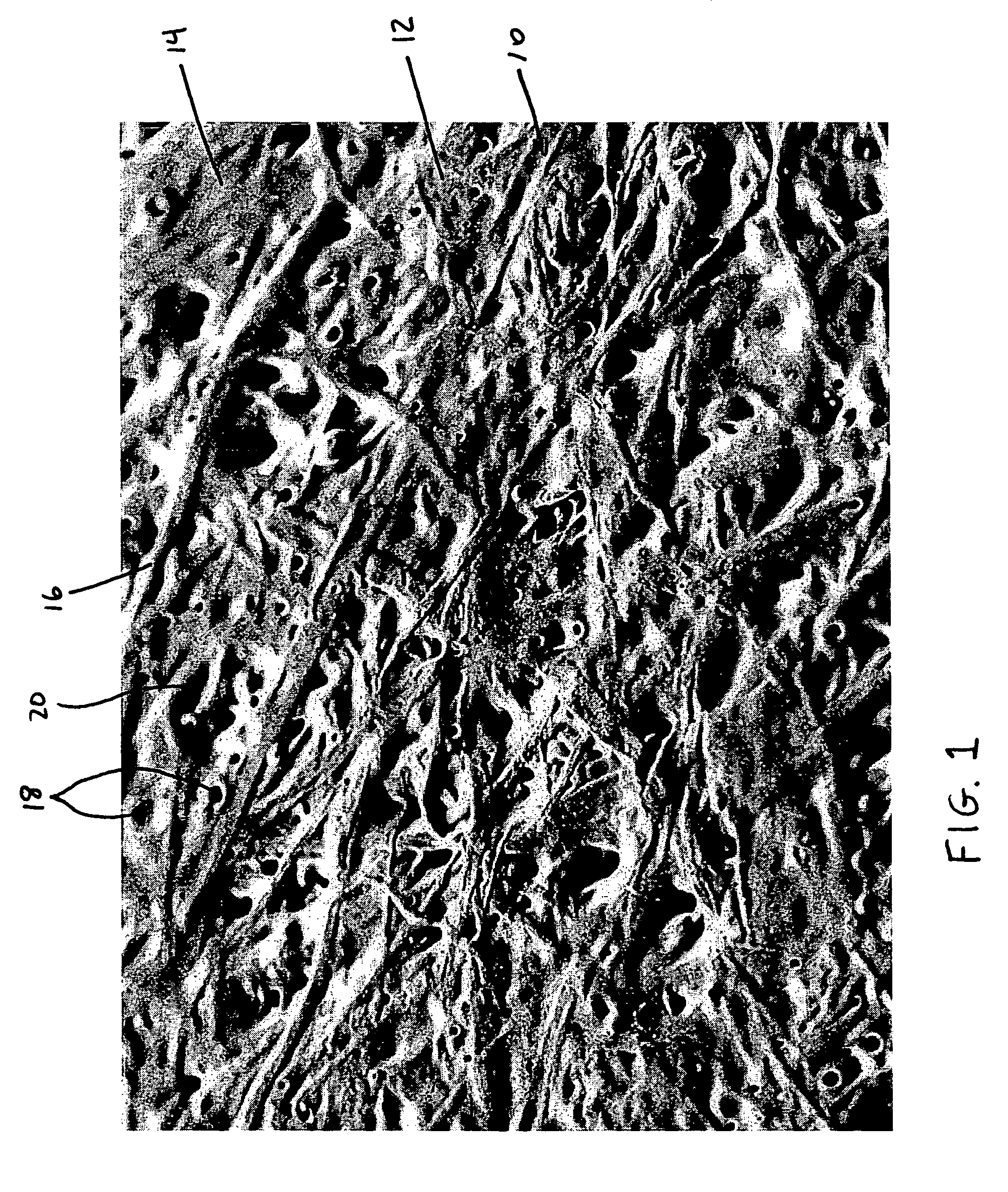

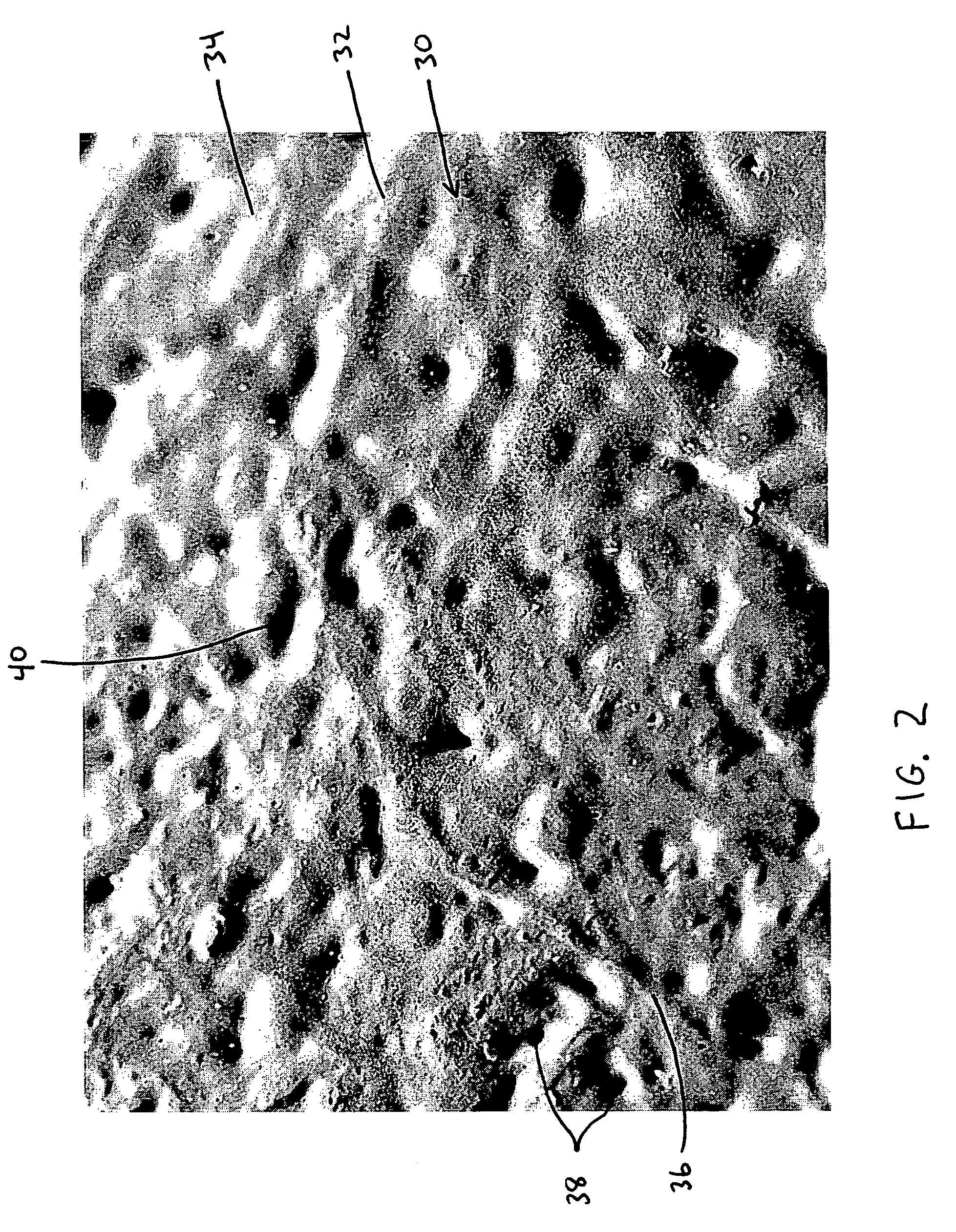

The present invention is directed an oriented, foamed article having an ink-receptive surface, and a method of making the article. The invention provides a printable substrate comprising at least one high melt-strength, oriented polypropylene foam layer having an ink-receptive surface. The high melt-strength polypropylene having a melt strength of of 25 to 60 cN at 190° C. The ink-receptive surface may comprise and oxidizing treatment, such as corona or flame-treatment of the foam surface, or may comprise an ink-receptive coating, such as a primer coating, on the foam surface. The oriented foam article is particularly useful in the preparation of printed security documents such as currency, stock and bond certificates, birth and death certificates, land titles and abstracts and the like.

Owner:3M INNOVATIVE PROPERTIES CO

Fibrous structure product with high bulk

InactiveUS20070256802A1Non-fibrous pulp additionMechanical working/deformationEngineeringFiber structure

A fibrous structure product having two or more plies of fibrous structure having a High Load Caliper from 17 mils to about 45 mils. In addition a multiply fibrous structure product having two or more plies, a High Load Caliper from about 17 mils to about 45 mils; a basis weight from about 26 lbs / 3000 ft2 to about 50 lbs / 3000 ft2; and a Flex Modulus from about 0.1 to about 0.8.

Owner:THE PROCTER & GAMBLE COMPANY

Fine abrasive paper backing material and method of making thereof

In one embodiment is provided a method of making an abrasive backing having a smooth surface comprising the steps of providing a paper having a first paper surface and a second paper surface; applying a first synthetic polymeric layer comprising a first synthetic polymeric composition to the first paper surface; and applying a second synthetic polymeric layer comprising a second synthetic polymeric composition to the first synthetic polymeric layer. The method is used to prepare fine abrasive backings having a smooth exterior surface for preparation of fine abrasive papers.

Owner:NEENAH PAPER INC

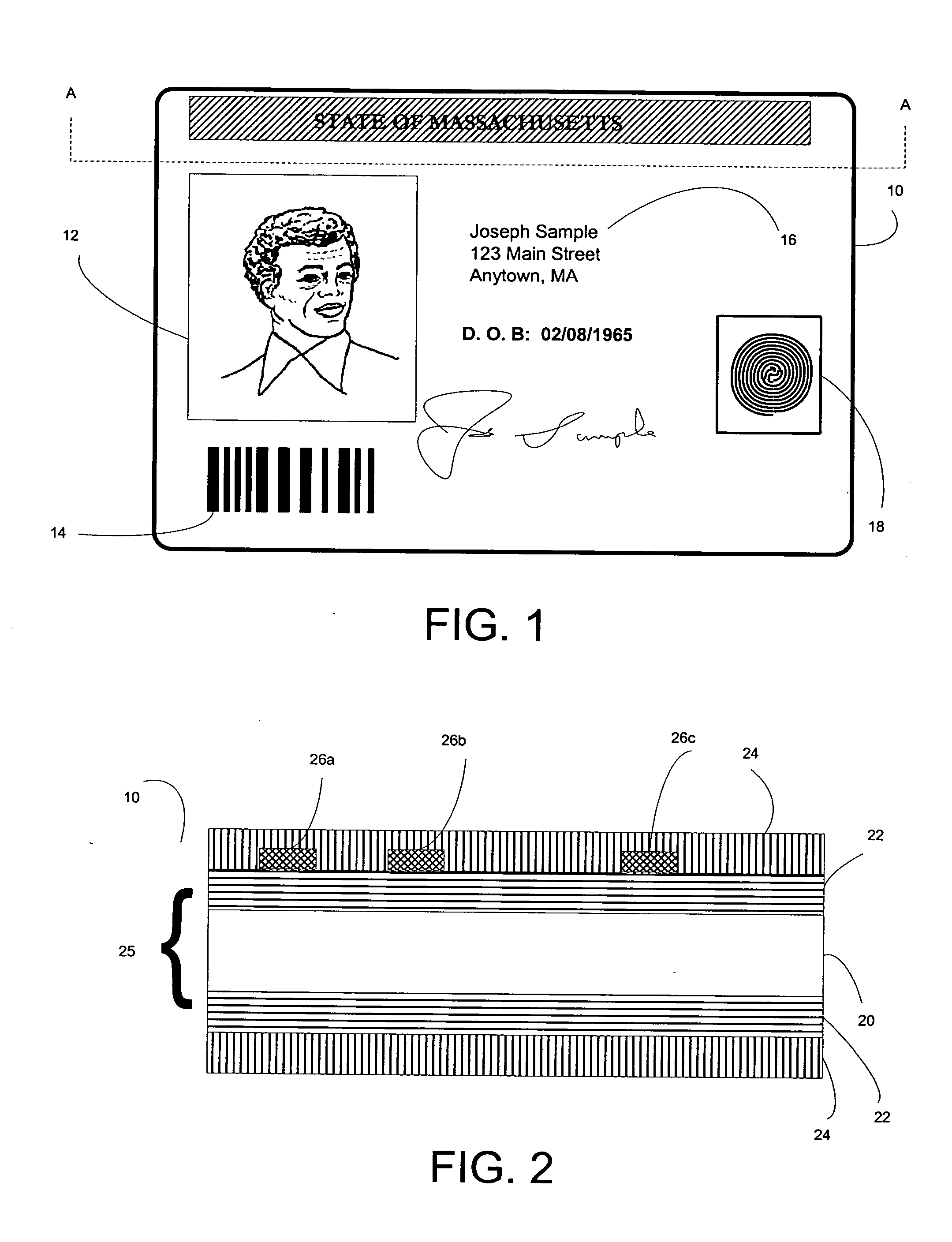

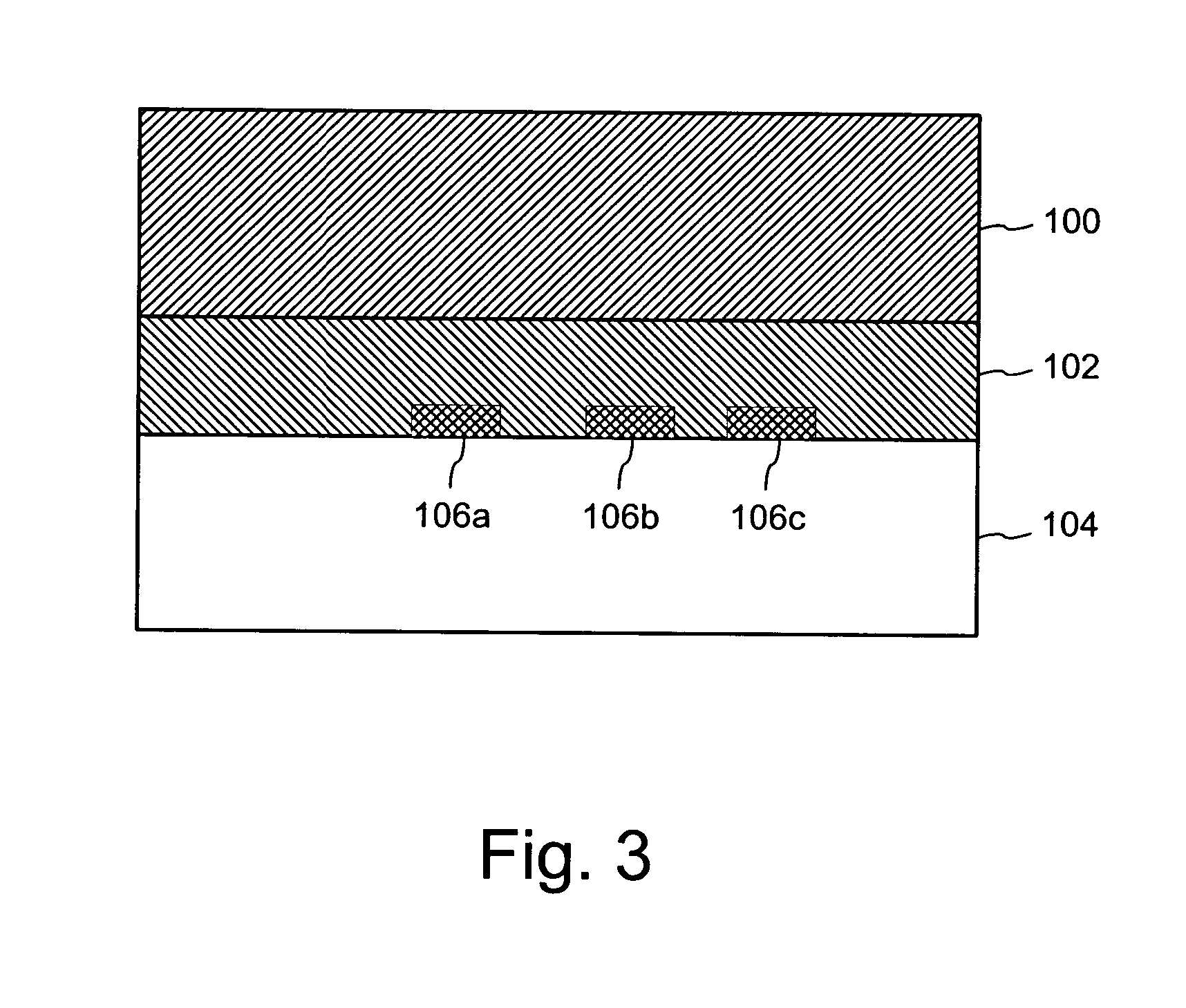

Secure id badge construction utilizing inkjet printing

InactiveUS20030194532A1Increased durabilityAbrasion resistance enoughOther printing matterLayered productsEngineeringInkjet printing

Owner:3M INNOVATIVE PROPERTIES CO

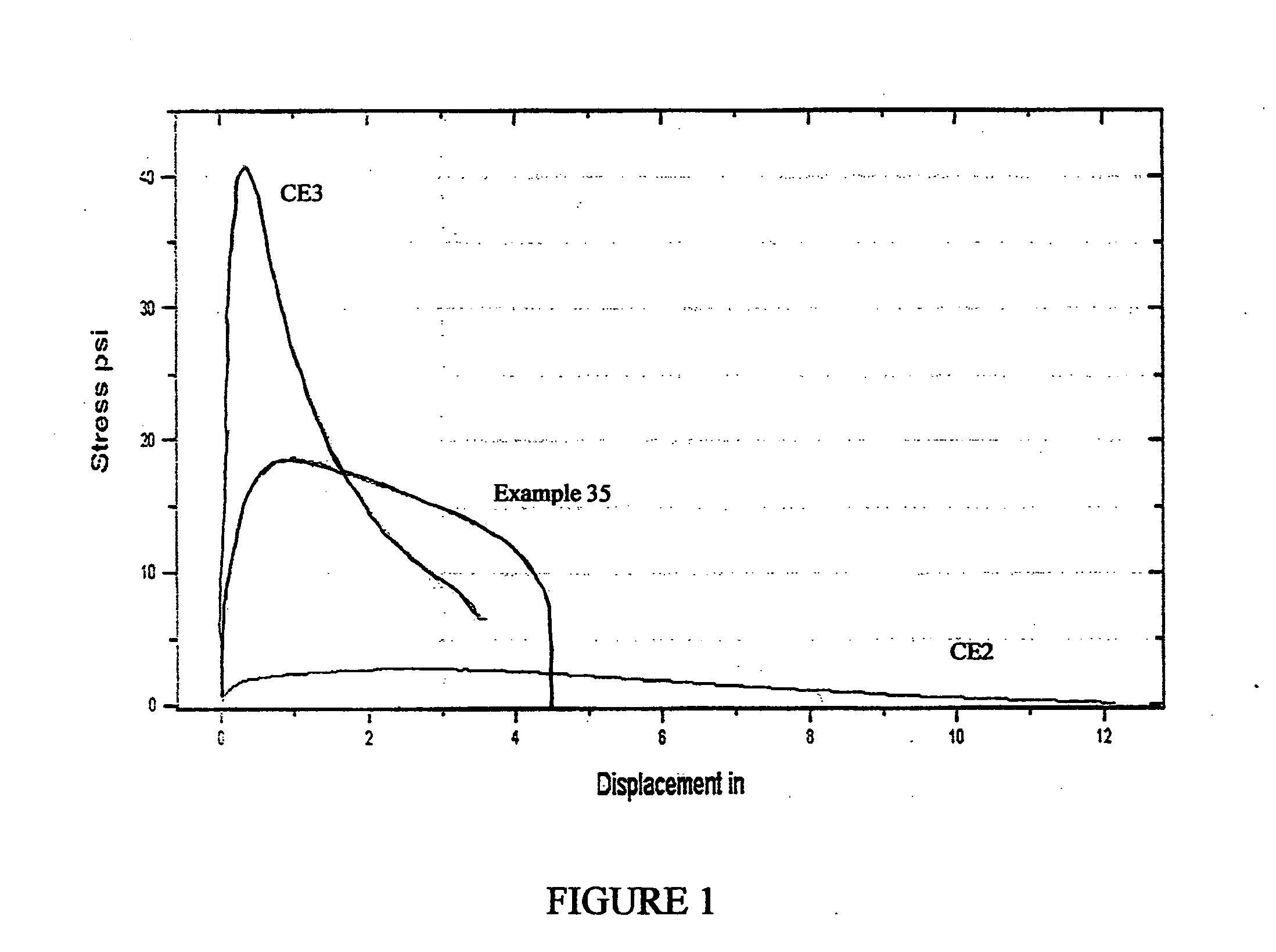

Absorbent paper products having unique physical strength properties

An absorbent towel paper web having a machine direction and a cross-machine direction orthogonal to the machine direction, the web comprising from about 20% to about 90% by weight of the dry fiber basis of the paper web of a refined soft wood pulp fiber mixture comprising from about 18.5% to about 88.5% by weight of the dry fiber basis of the tissue paper web of soft wood pulp fiber, wherein the soft wood pulp fiber is optionally refined before being added to the mixture; from about 0.25% to about 5.0% by weight of the dry fiber basis of the tissue paper web of cationic strengthening polymer, from about 10% to about 60% by weight of the dry fiber basis of the tissue paper web of a hard wood pulp fiber mixture; and not more than about 8% by weight moisture; wherein the paper web has a Mean Square Tensile Strength ranging from about 6 N·m / g to about 12 N·m / g; and wherein the paper web has a Cross-directional Wet Tensile Strength to Cross-directional Dry Tensile Strength Ratio value ranging from about 0.295 to about 0.35.

Owner:MERCER INT

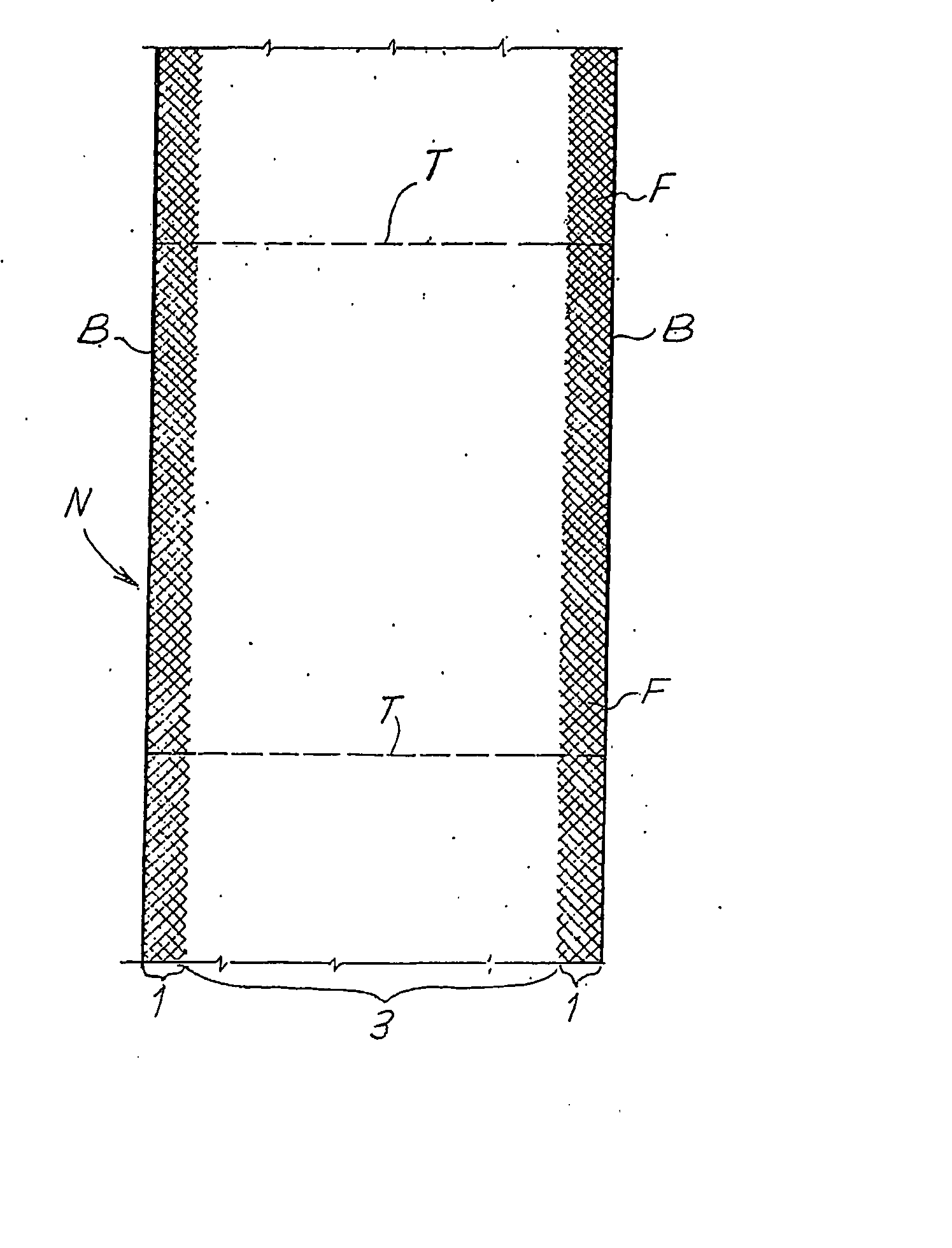

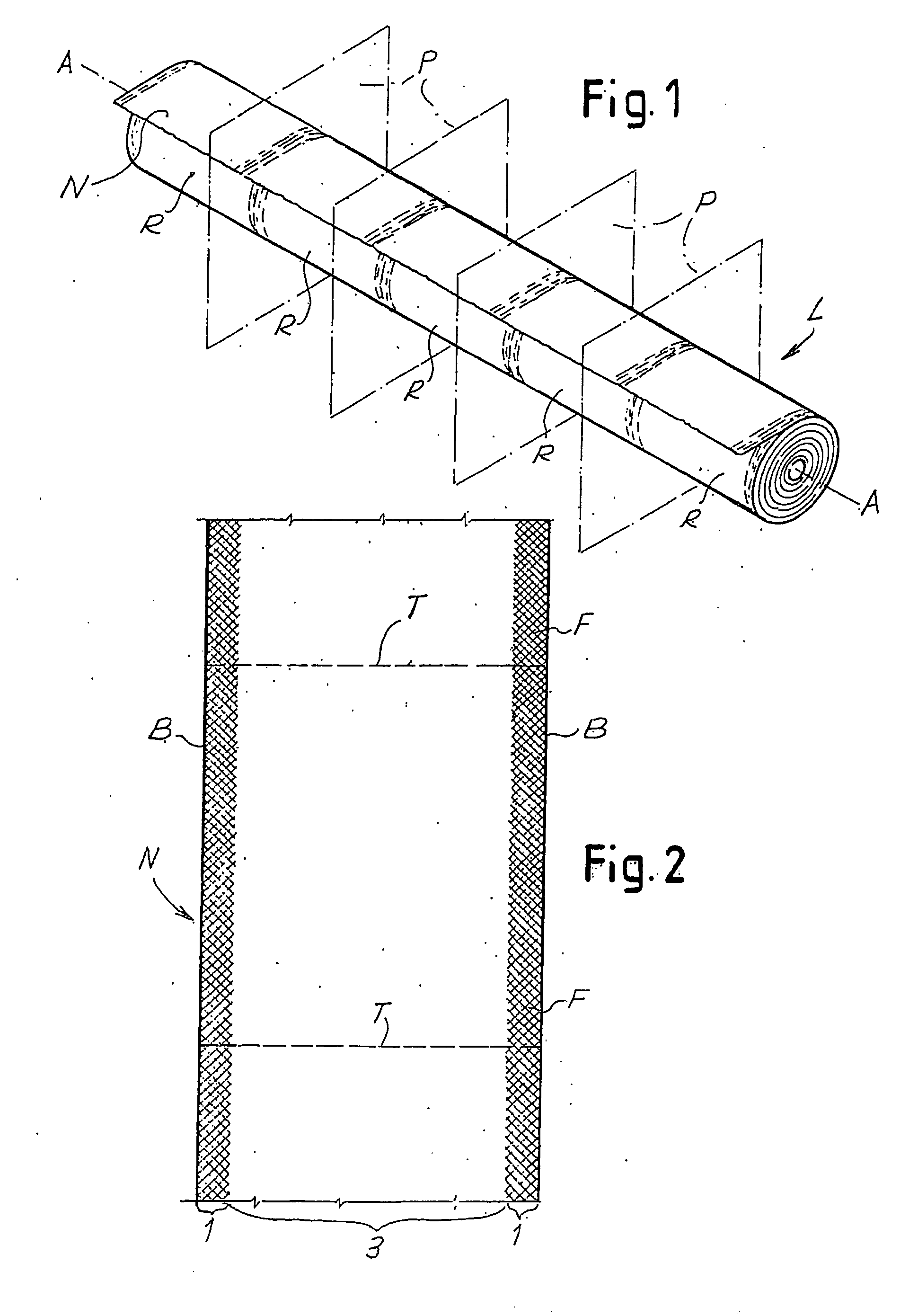

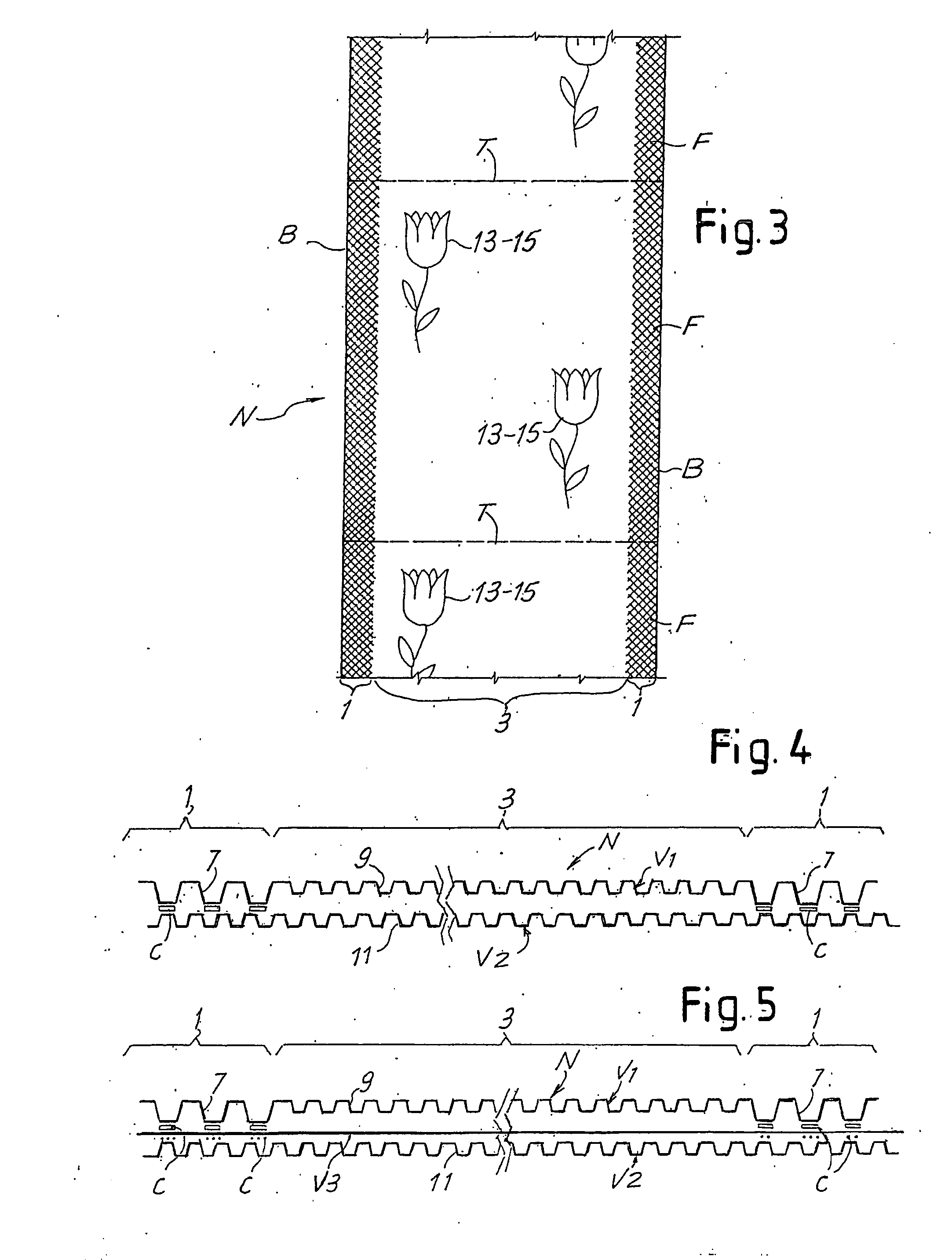

Sheet Product Comprising at Least Two Plies Joined by Gluing with Non-Uniform Distribution of the Glue

InactiveUS20070264461A1Reduce absorptionReduction of consequencesStampsFlexible coversLongitudinal bandsEngineering

The sheet product, such as paper, wound in a roll, comprises at least two plies (V1, V2) joined together by gluing, at least one of which is embossed. The product has longitudinal bands or areas (1, 3) which are characterized by a different quantity of glue, with more glue in proximity to the edges.

Owner:FABIO PERINI SPA

Machine-Readable Passport With A Polycarbonate (PC) Datapage And Method For Making The same

InactiveUS20140326789A1Other printing matterPaper/cardboard layered productsPersonalizationComputer science

The present invention provides a multi-layered personalized page comprising a PET incsti / PU hinge layer; a PC inlay with chip antenna layer with an electric component with personal data of a holder of a passport; two PC core layers with artwork; and two PC overlay layers. The present invention also provides a passport tint contains the multi-layered personalized

Owner:IRIS CORP BERHAD

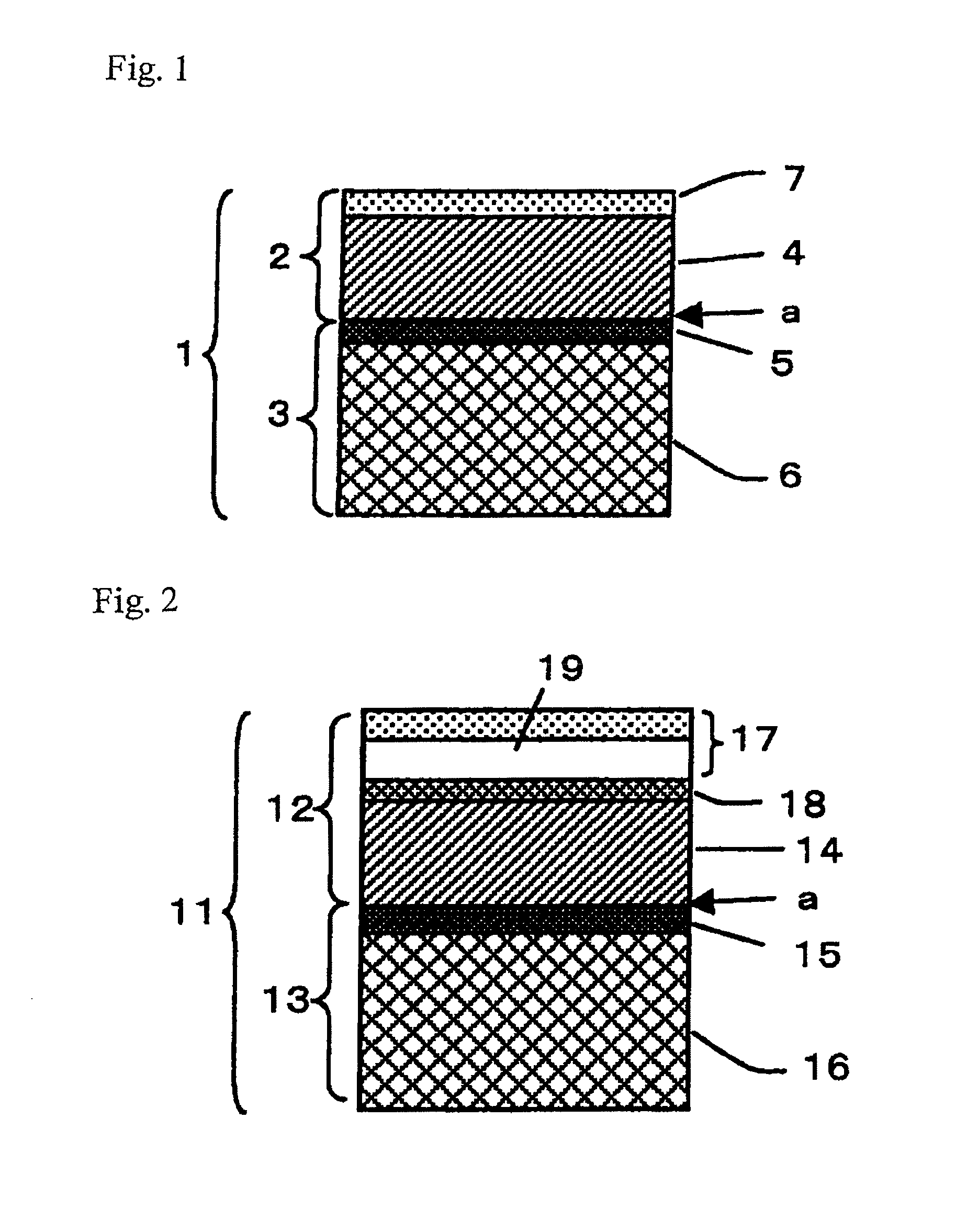

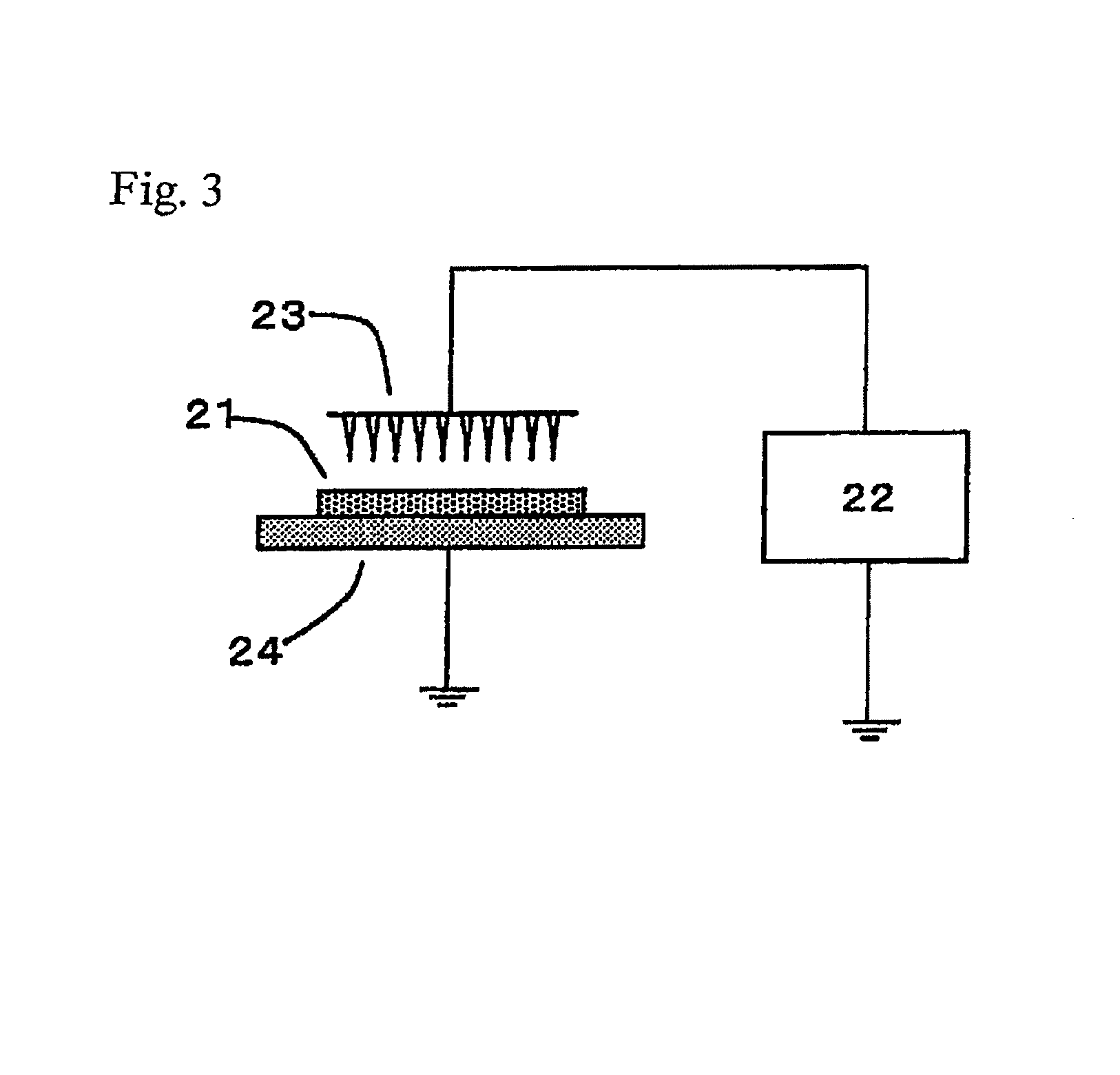

Electrostatic adsorbable sheet

ActiveUS9044916B2Not trouble in printing processStampsDecorative surface effectsThin membraneEngineering

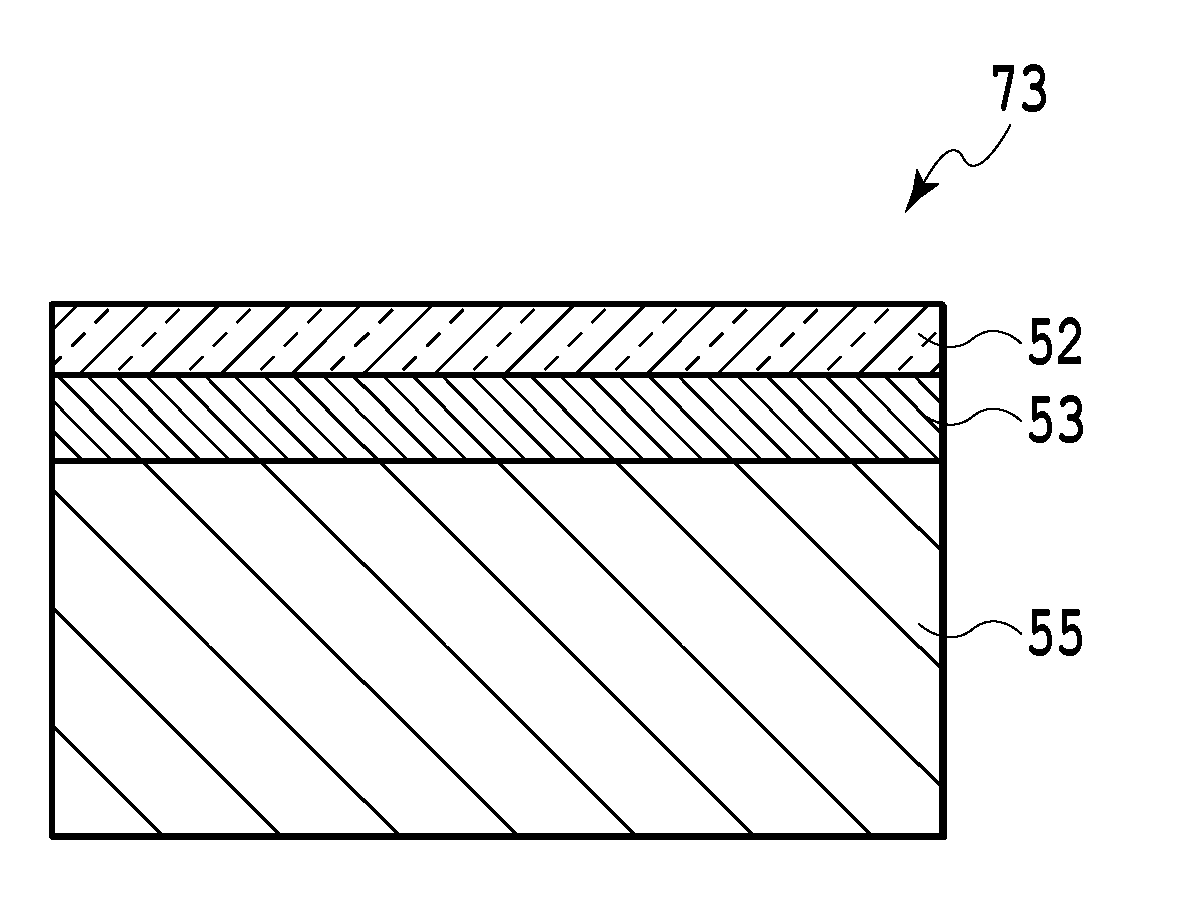

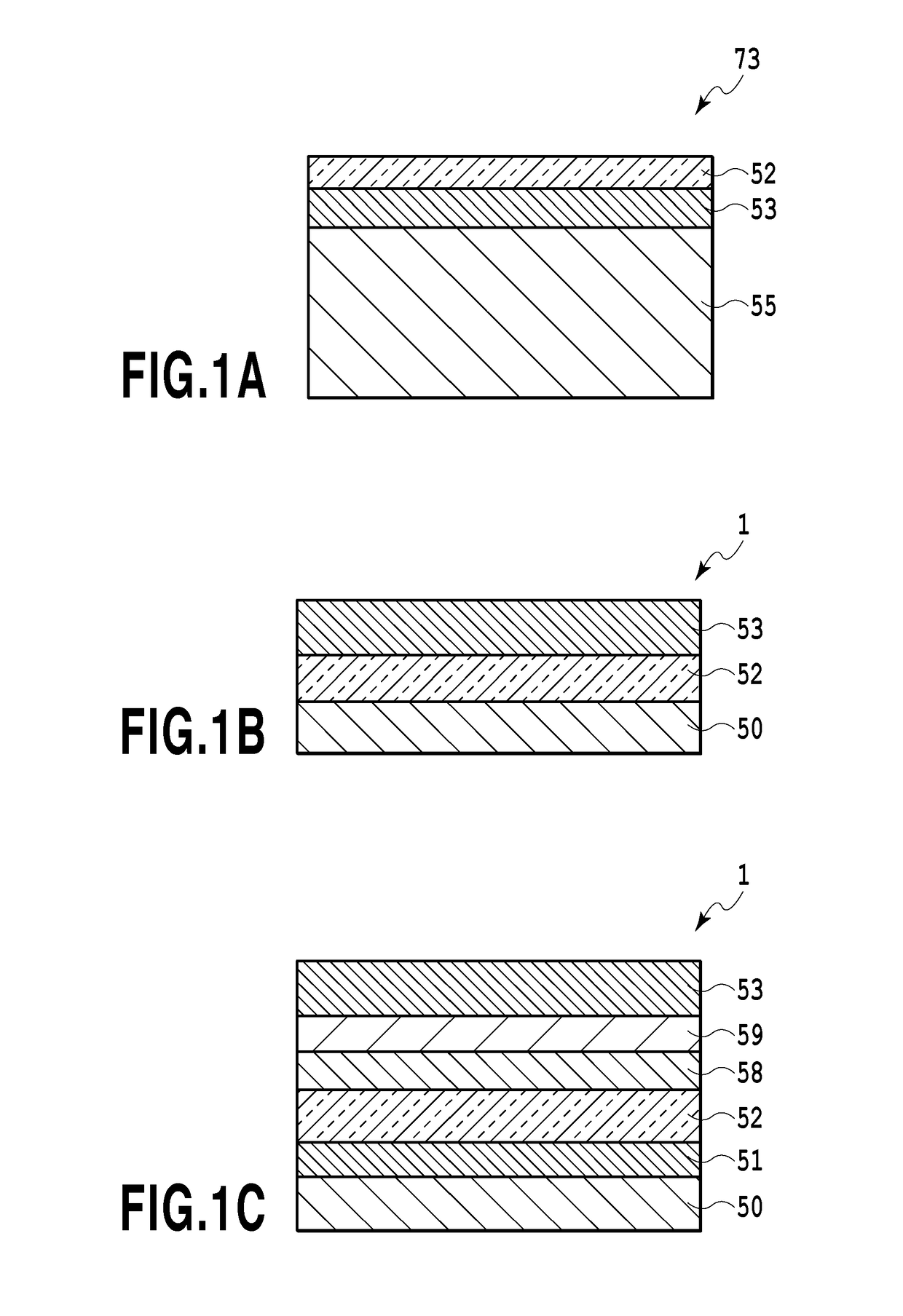

An electrostatic adsorbable sheet (iii), which has a long-lasting adsorbability not easily affected by humidity, secures good ink adhesiveness, and does not generate troubles in a printing process, is provided. The electrostatic adsorbable sheet (iii) comprises a laminate of a label layer (i) containing a resin film layer (A) and a recording layer (D) on one surface of the resin film layer (A), and a peelable sheet layer (ii) containing a peelable layer (B) and a support layer (C), in which the label layer (i) and the peelable sheet layer (ii) are laminated so that the resin film layer (A) and the peelable layer (B) contact with each other. The peeling strength between the label layer (i) and the peelable sheet layer (ii) is from 1 to 50 g / cm, and the label layer (i) peeled from the peelable sheet layer (ii) is electrostatically adsorbable to an object to be attached.

Owner:YUPO CORP

Absorbent paper products having unique physical strength properties

An absorbent towel paper product having a machine direction and a cross-machine direction orthogonal to the machine direction, wherein the absorbent towel paper product comprises two plies of absorbent towel paper webs, wherein each paper web comprises from about 20% to about 90% by weight of the dry fiber basis of the towel paper web of a refined long fiber soft wood pulp fiber mixture comprising from about 18.5% to about 88.5% by weight of the dry fiber basis of the towel paper web of long fiber soft wood pulp fiber, wherein the long fiber soft wood pulp fiber is optionally refined before being added to the mixture; from about 0.25% to about 5.0% by weight of the dry fiber basis of the tissue paper web of cationic strengthening polymer, from about 10% to about 55% by weight of the dry fiber basis of the tissue paper web of a hard wood pulp fiber mixture; and not more than about 10% by weight moisture; wherein the two-ply paper product has a Mean Square Tensile Index value ranging from about 10 N·m / g to about 18 N·m / g; and wherein the two-ply paper product has a Cross-directional Wet Tensile Strength to Cross-directional Dry Tensile Strength Ratio value ranging from about 0.295 to about 0.33.

Owner:MERCER INT

Anti-counterfeiting fiber, its manufacturing method, and security paper and security article using the same

ActiveCN103850144BImprove anti-counterfeiting capabilitiesPrevent copyingNon-fibrous pulp additionPaper/cardboard layered productsFiberEngineering

Owner:KUNSHAN BANKNOTE PAPER +1

Electrostatic adsorbable sheet

ActiveUS20110143104A1Improve ink adhesionNot trouble in printing processStampsDecorative surface effectsThin membraneEngineering

An electrostatic adsorbable sheet (iii), which has a long-lasting adsorbability not easily affected by humidity, secures good ink adhesiveness, and does not generate troubles in a printing process, is provided. The electrostatic adsorbable sheet (iii) comprises a laminate of a label layer (i) containing a resin film layer (A) and a recording layer (D) on one surface of the resin film layer (A), and a peelable sheet layer (ii) containing a peelable layer (B) and a support layer (C), in which the label layer (i) and the peelable sheet layer (ii) are laminated so that the resin film layer (A) and the peelable layer (B) contact with each other. The peeling strength between the label layer (i) and the peelable sheet layer (ii) is from 1 to 50 g / cm, and the label layer (i) peeled from the peelable sheet layer (ii) is electrostatically adsorbable to an object to be attached.

Owner:YUPO CORP

Multi-Ply Fibrous Structure-Containing Articles

ActiveUS20190061302A1Improve bulkImproved absorbent propertyMechanical working/deformationPersonal careFiberPolymer science

Articles, for example multi-ply fibrous structure-containing articles such as multi-ply sanitary tissue products, containing two or more fibrous structure plies, wherein at least one of the fibrous structure plies is embossed and is bonded to at least one other fibrous structure ply by a water-resistant bond such that void volume is created between the bonded fibrous structure plies.

Owner:THE PROCTER & GAMBLE COMPANY

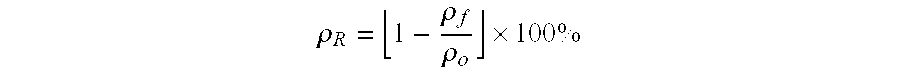

Microporous materials and multi-layer articles prepared therefrom

InactiveUS20090311504A1Improve tensile propertiesIncrease stiffnessSynthetic resin layered productsLabelsPolymer scienceVolumetric Mass Density

A microporous material is provided in the form of a singly extruded microporous sheet having opposing first and second surfaces, comprising:(a) a polymeric matrix component comprising:(i) 25 to 75 weight percent of low melt flow index polypropylene having a melt flow index ranging from 0.1 to 30 grams / 10 minutes;(ii) 12.5 to 25 weight percent of ultrahigh molecular weight polyethylene; and(iii) 0 to 62.5 weight percent of high density polyethylene;(b) a finely divided, inorganic filler component dispersed throughout the polymeric matrix; and(c) a network of interconnecting pores communicating substantially throughout the microporous material, the pores constituting 10 to 80 percent by volume of the microporous material.The sheet typically has a thickness ranging from 3 to 8 mils and a stiffness of greater than 1 g / micron. In certain embodiments, the sheet has a density of greater than 0.75 g / cc. Also provided are multi-layer articles.

Owner:PPG IND OHIO INC

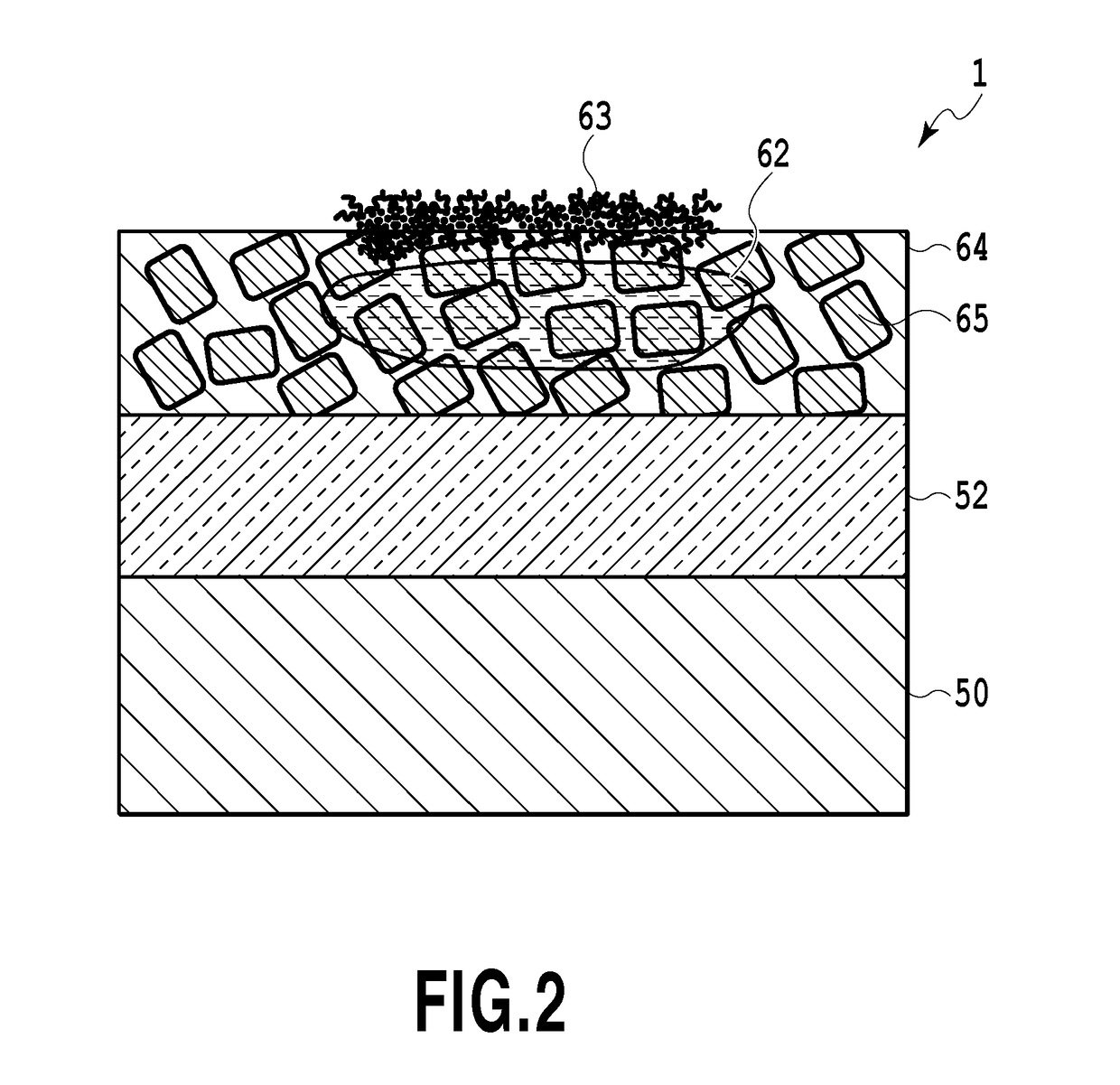

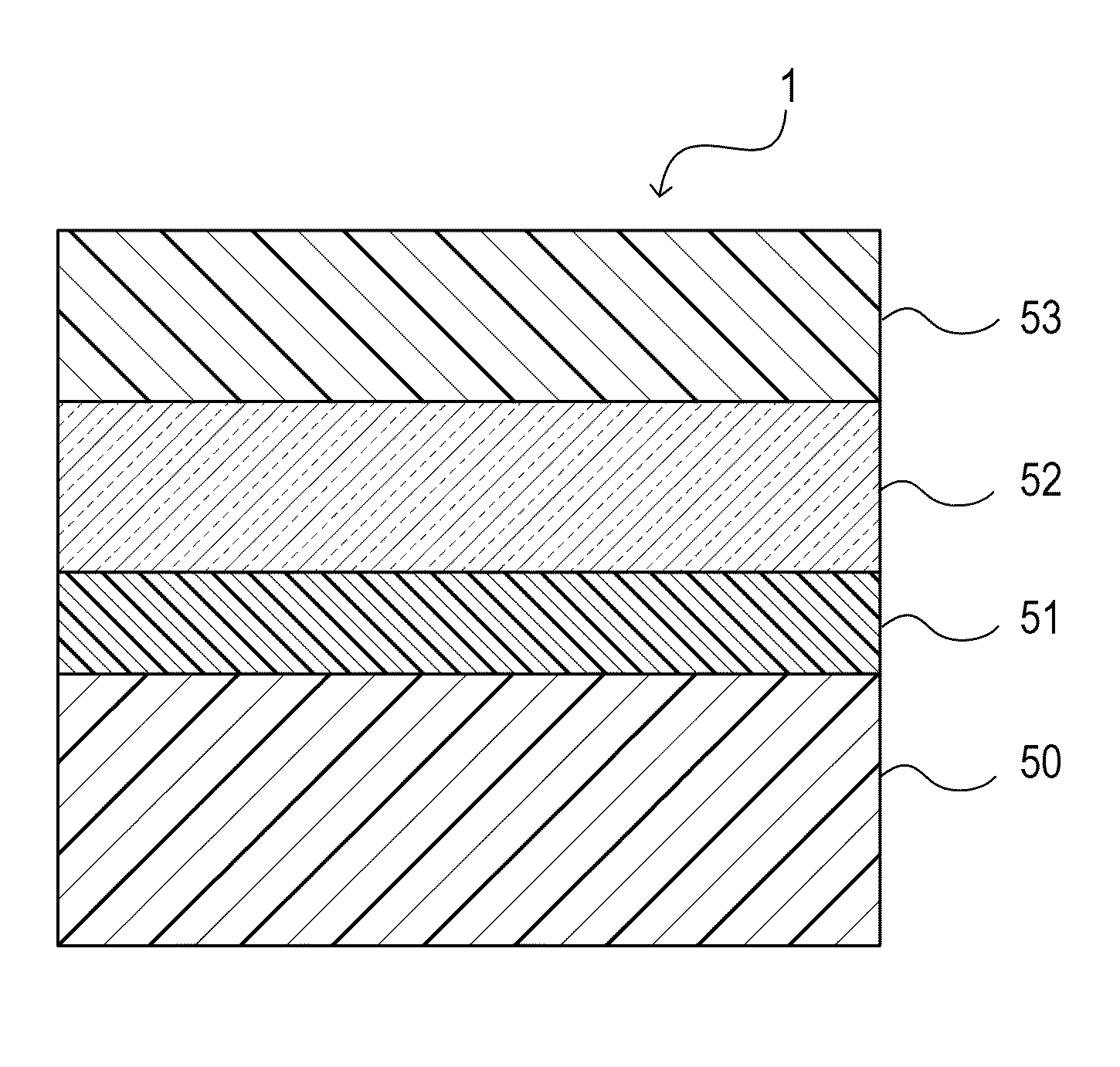

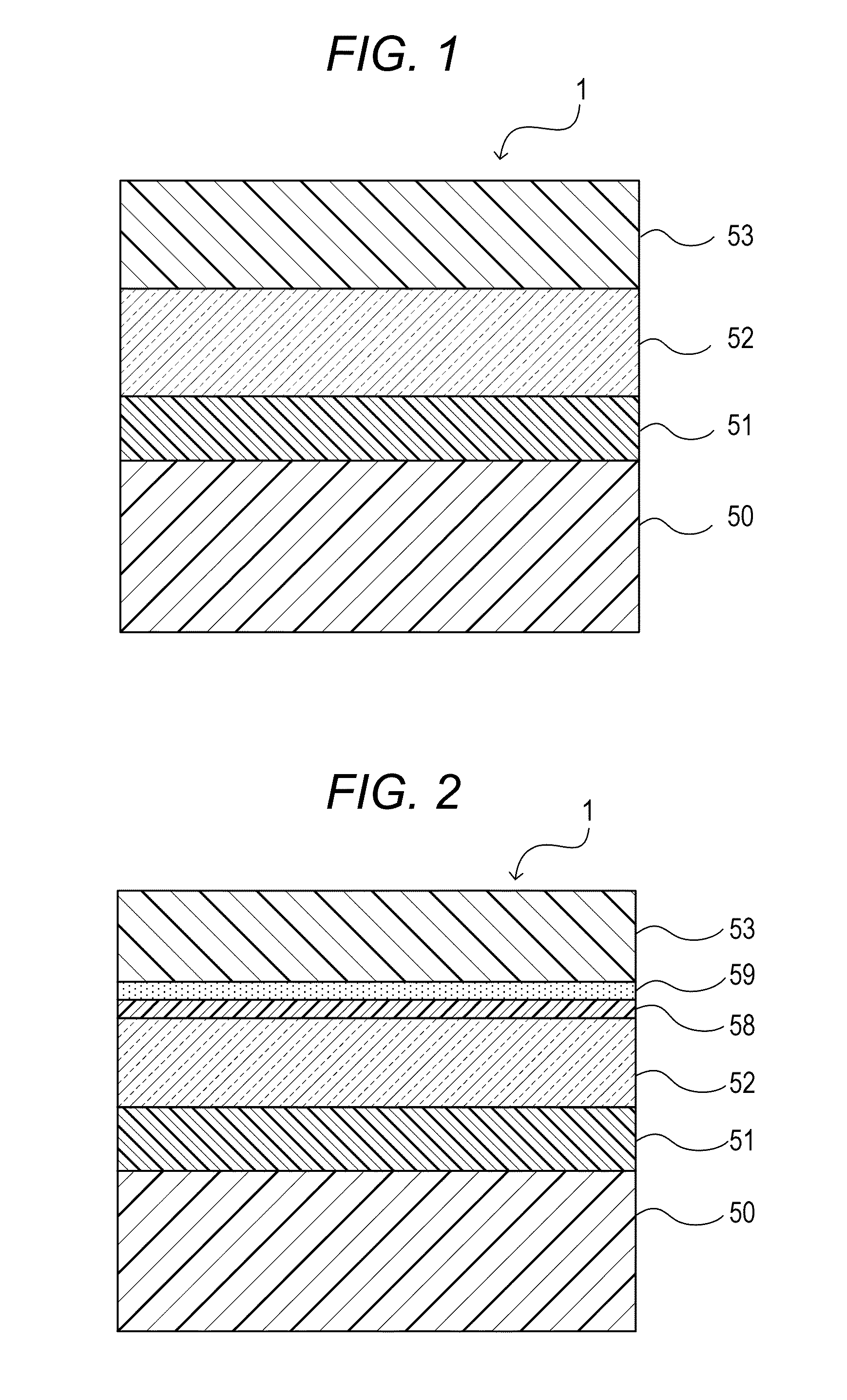

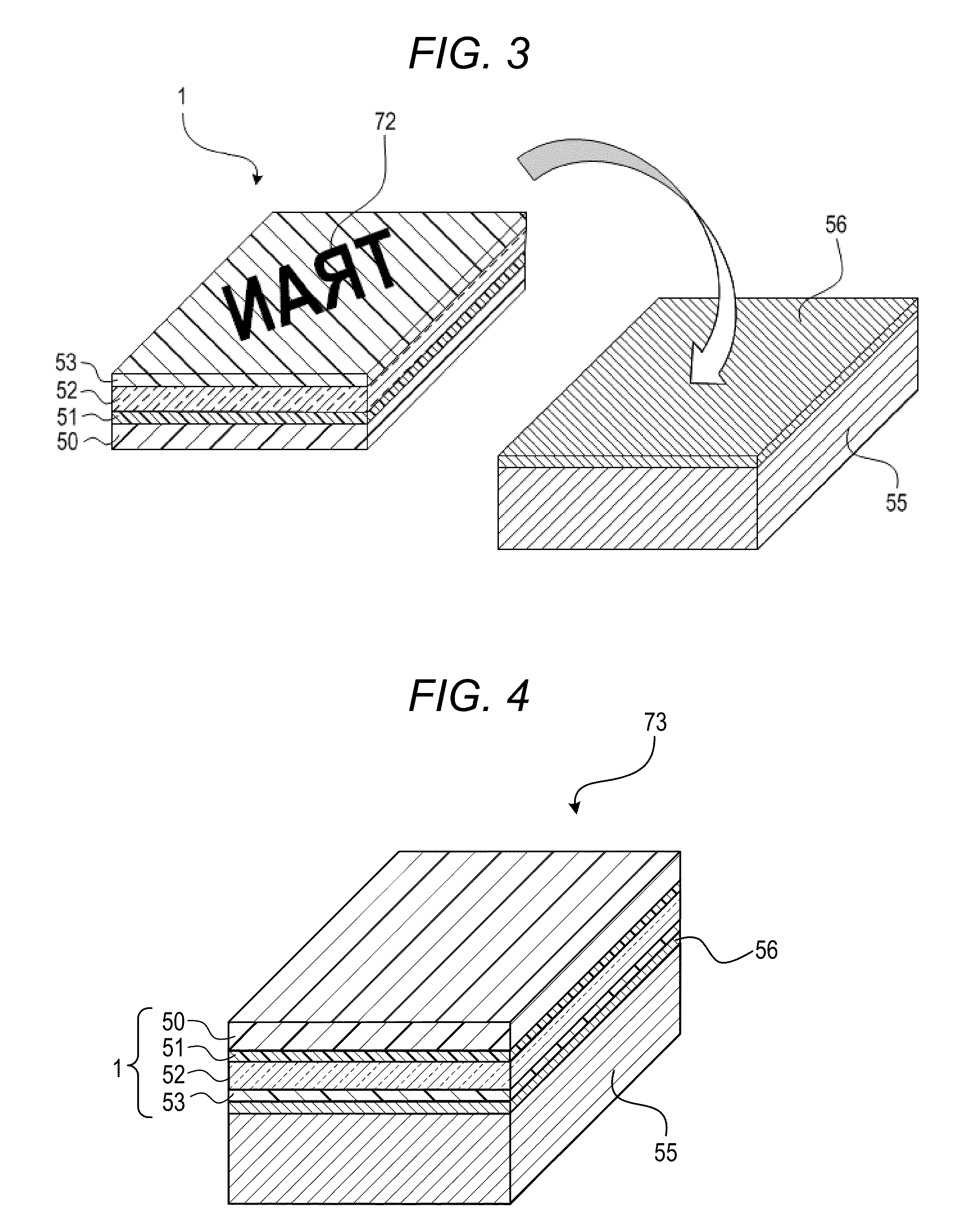

Transfer material, printed material, and manufacturing method for printed material

InactiveUS20170157910A1Improve waterproof performanceLamination ancillary operationsDecorative surface effectsMoistureWater resistance

A transfer material, a printed material, and a manufacturing apparatus and a manufacturing method for the printed material are provided in which water resistance of the printed material can be enhanced. A protective sheet allows moisture in a color material receiving layer to be discharged to the outside through passages through which the moisture can be discharged.

Owner:COPYER

Recording medium, recorded matter, and methods of manufacturing the medium and the matter

ActiveUS20150042737A1Improve productivityImprove information securityDecorative surface effectsPretreated surfacesPolyvinyl alcoholOptical transmittance

A recording medium, including: an ink-receiving layer configured to receive an ink for inkjet recording; and a transparent sheet having a total luminous transmittance of 50% or more, wherein the recoding medium has a layered structure in which the transparent sheet and the ink-receiving layer are sequentially stacked, and the ink-receiving layer includes a gap-absorption-type ink-receiving layer including a composition including at least inorganic fine particles and polyvinyl alcohol having a weight-average polymerization degree of 2,000 or more and 5,000 or less and a saponification degree of 70 mol % or more and 90 mol % or less.

Owner:COPYER

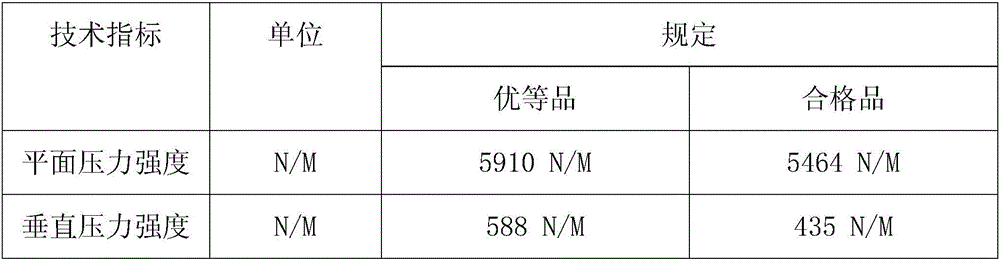

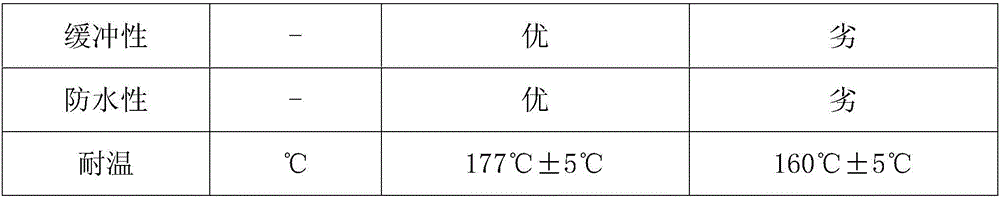

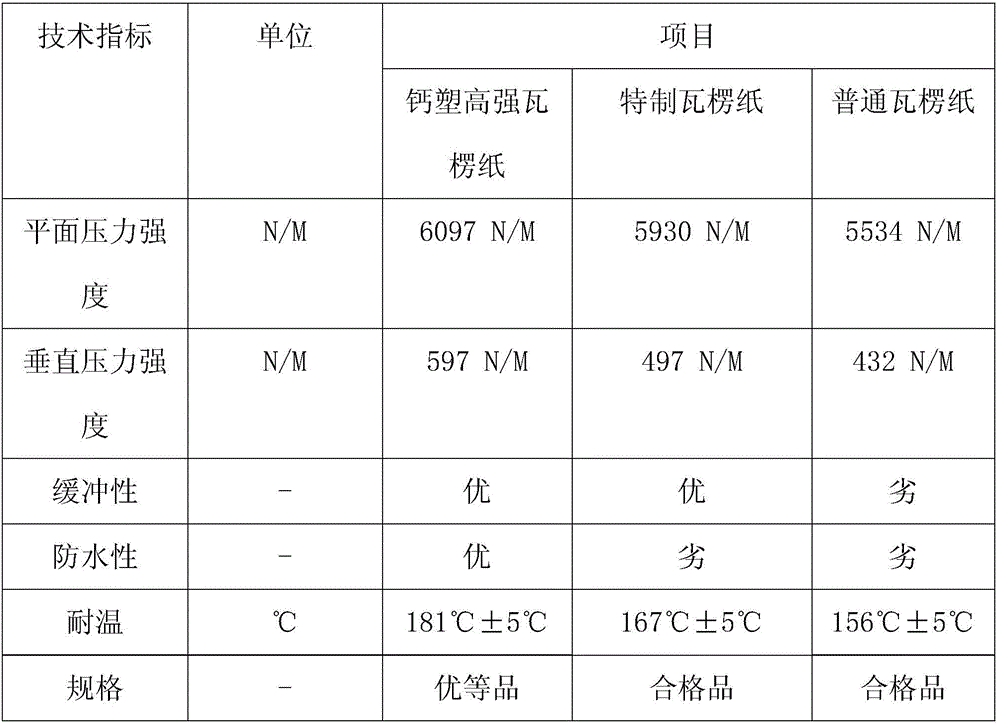

Calcium-plastic high-intensity corrugated paper and preparation method thereof

InactiveCN106480786AUniform thicknessImprove buffering effectSpecial paperSynthetic resin layered productsSodium BentoniteAluminium hydroxide

The invention discloses calcium-plastic high-intensity corrugated paper which consists of a corrugated layer and a plastic layer, and is prepared from the following raw materials in parts by weight: 200 to 400 parts of waste newspaper, 80 to 110 parts of wheat straws, 80 to 120 parts of paper mulberry barks, 100 to 160 parts of modified corn starch, 50 to 70 parts of graphene, 60 to 80 parts of borax powder, 40 to 56 parts of sodium bentonite, 30 to 36 parts of potassium permanganate, 21 to 35 parts of aluminum hydroxide, 20 to 30 parts of sodium carbonate, 11 to 27 parts of ammonium persulfate and 20 to 30 parts of calcium carbonate; and the plastic layer is prepared from the following raw materials in parts by weight: 40 to 60 parts of polyvinyl chloride, 21 to 27 parts of phenolic resin, 11 to 17 parts of industrial alcohol, 3 to 7 parts of methylbenzene, 13 to 19 parts of titanium dioxide and 14 to 22 parts of N,N-dimethyl benzylamine. The calcium-plastic high-intensity corrugated paper is uniform in thickness, high in water resistance, high in buffer property and convenient to recycle.

Owner:广州市极合技术咨询有限公司

Decorative pattern and production method therefor

InactiveUS20060194024A1Improve the decorative effectPrevent forgeryDecorative surface effectsOrnamental structuresGeneral purposeMetallurgy

When it is intended that a hologram foil is adhered to a metal pattern, a general-purpose hot-melt adhesive is inferior in an adhesion property to a metal surface and, accordingly, fixing of the hologram foil itself is difficult and, even when such fixing is achieved, a problem of peeling-off, dropping-off or the like of the hologram foil is generated. These problems are solved by forming a primer layer on a surface of the metal pattern and, thereafter, a metal foil having a design such as a hologram foil is fixed through a hot-melt adhesive.

Owner:TEFCO AOMORI

Fine abrasive paper backing material and method of making thereof

In one embodiment is provided a method of making an abrasive backing having a smooth surface comprising the steps of providing a paper having a first paper surface and a second paper surface; applying a first synthetic polymeric layer comprising a first synthetic polymeric composition to the first paper surface; and applying a second synthetic polymeric layer comprising a second synthetic polymeric composition to the first synthetic polymeric layer. The method is used to prepare fine abrasive backings having a smooth exterior surface for preparation of fine abrasive papers.

Owner:NEENAH PAPER INC

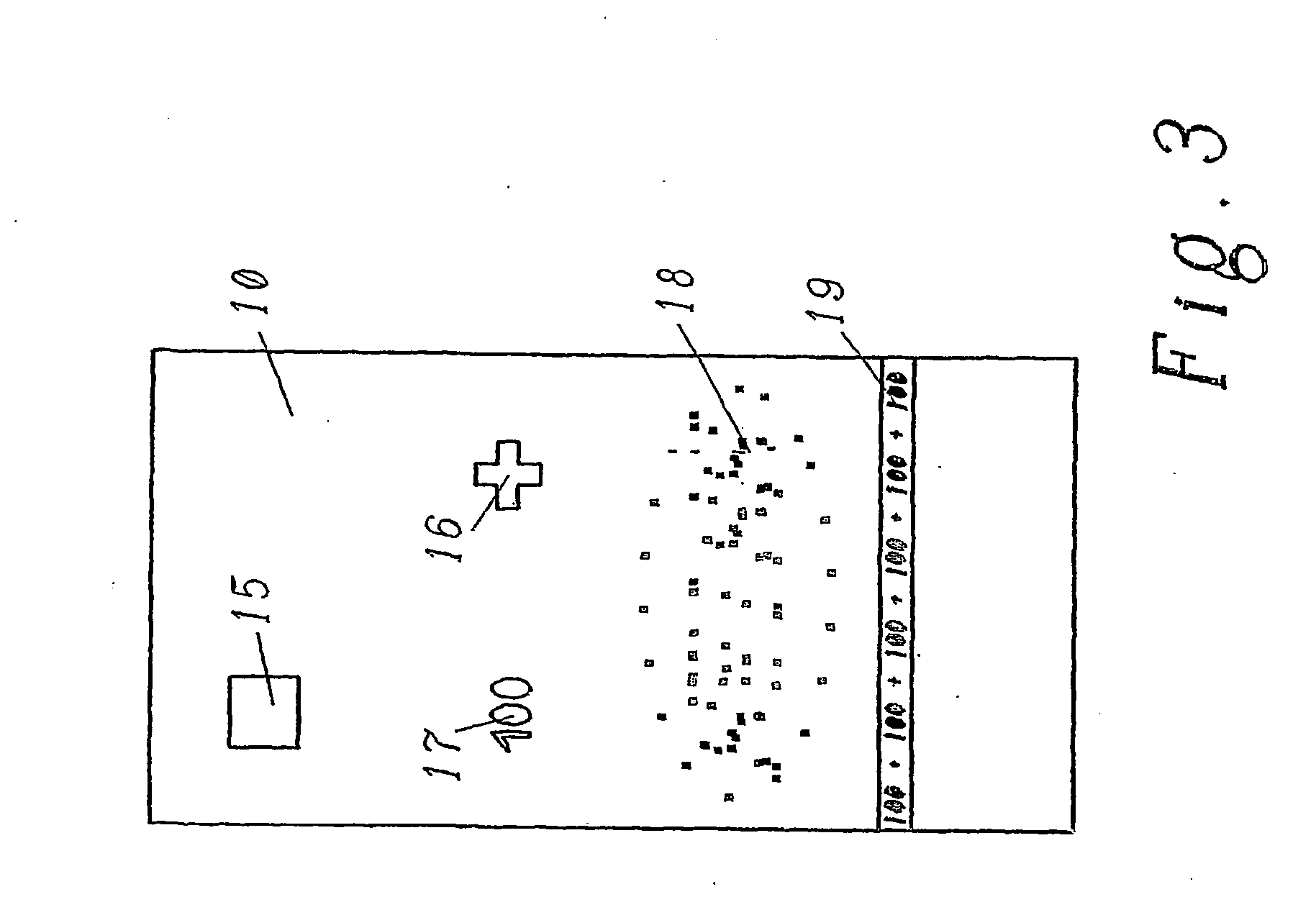

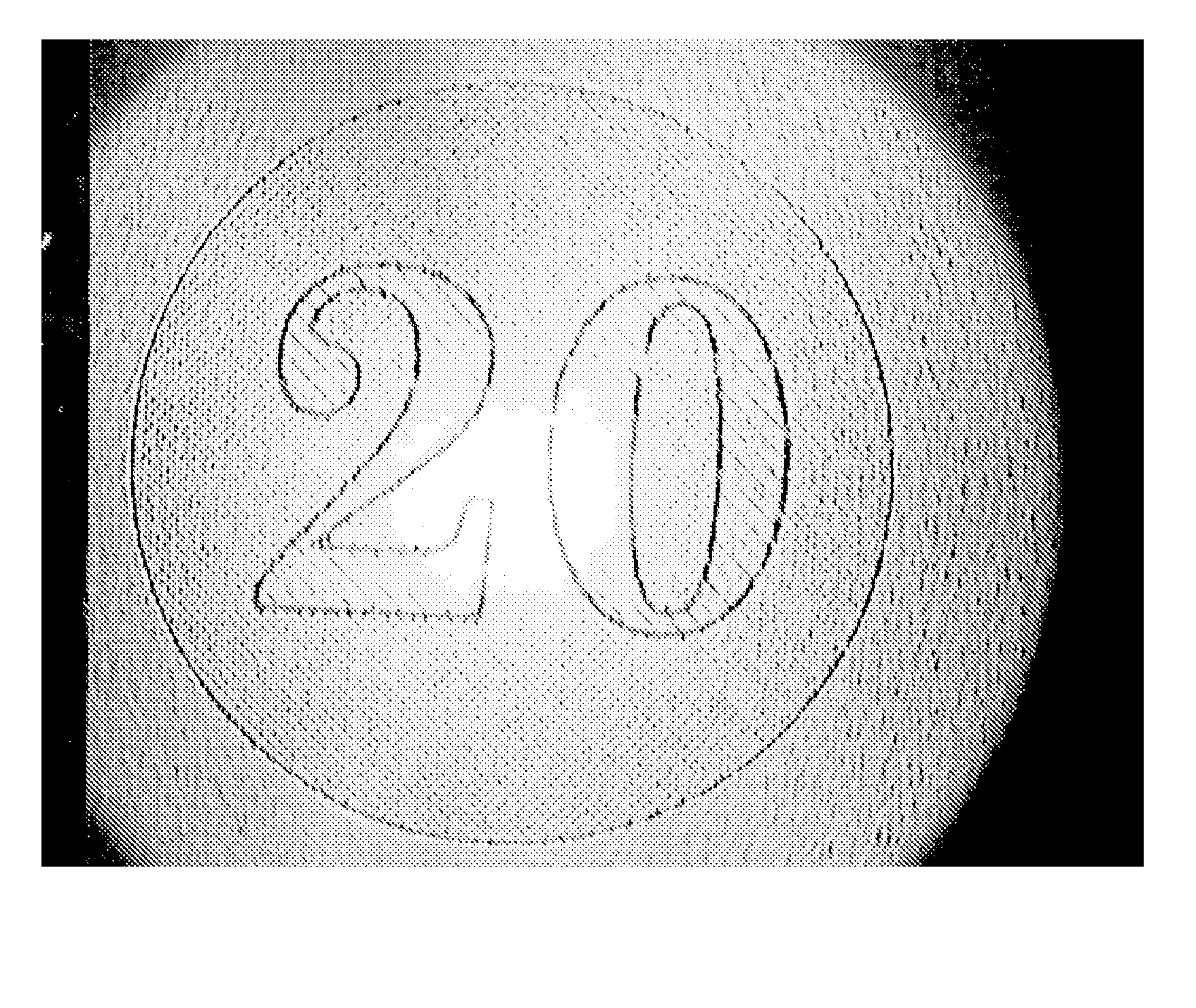

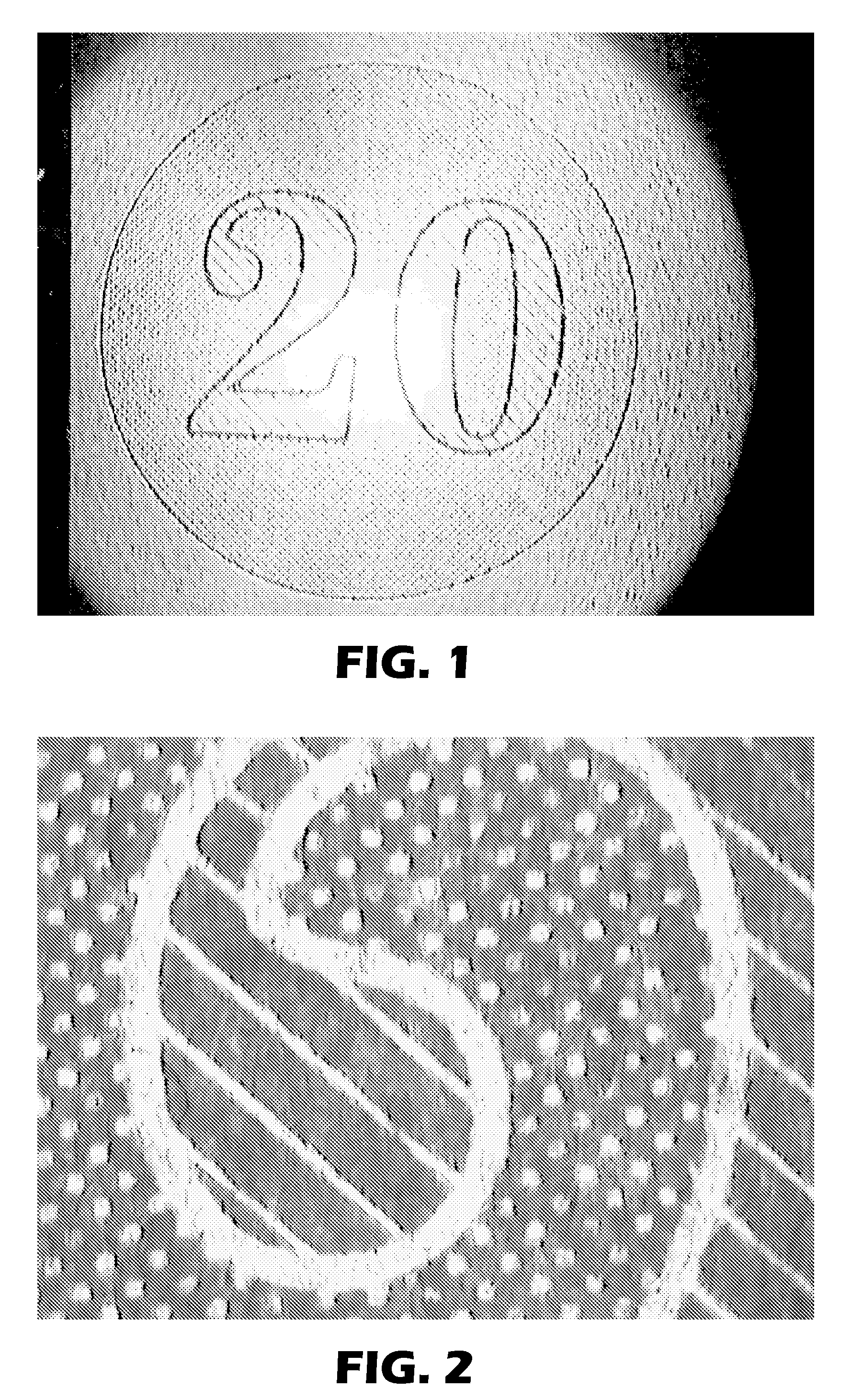

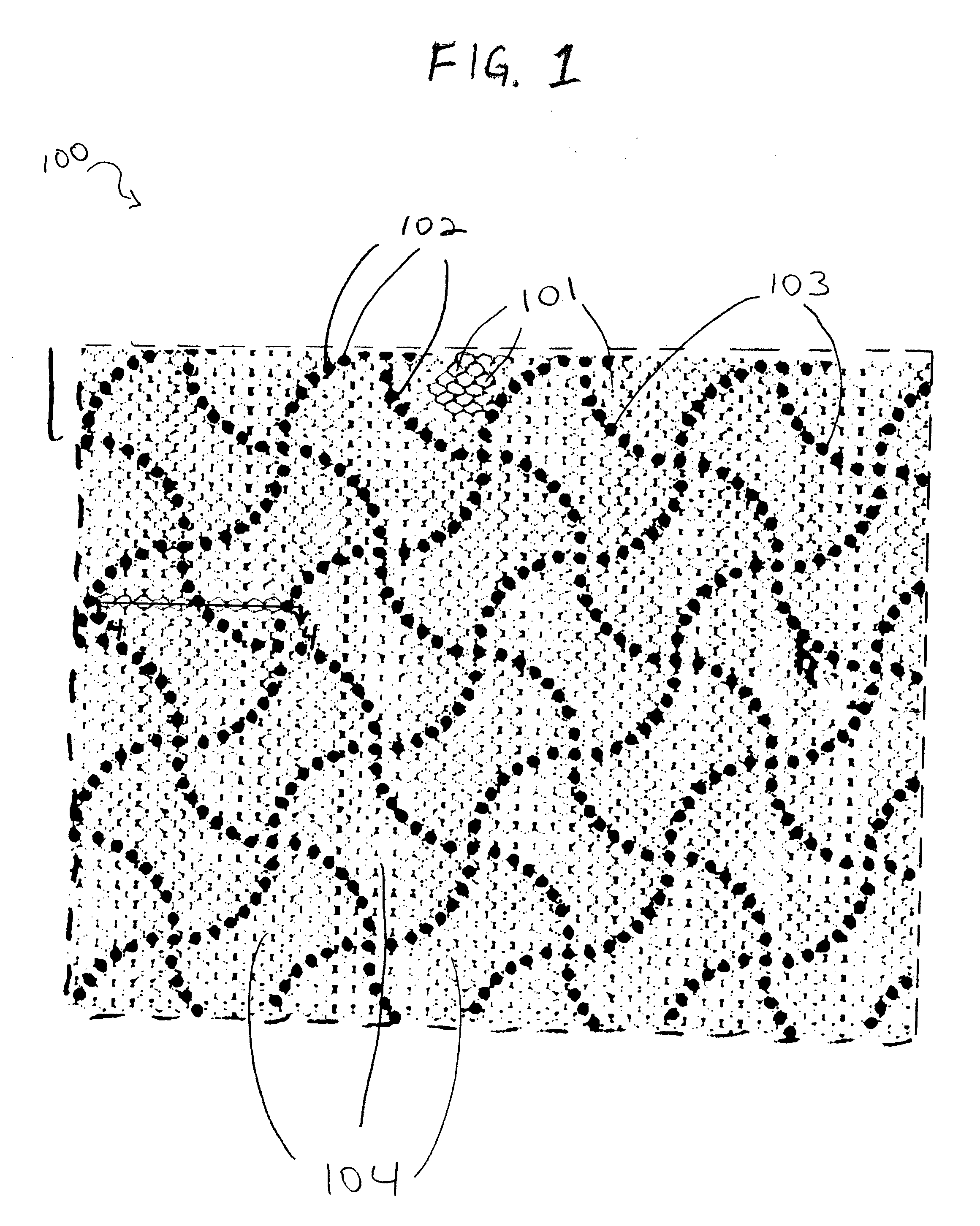

Microporous material containing a security feature

Provided is a microporous material, e.g., a microporous sheet material, having a matrix of polyolefin, finely-divided, substantially water insoluble particulate filler, a network of interconnecting pores communicating throughout the microporous material, and at least one retrospectively identifiable taggant material embedded within the matrix, optionally the at least one taggant being unique to an end user for the microporous material, wherein the polyolefin is present in the microporous material in an amount of 20 to 35 weight percent, based on the weight of the microporous material. The taggant material provides a marker, signature or code that is capable of retrospective identification by machine, instrument or by the naked eye. Articles including the microporous material and processes for preparing the microporous material also are provided.

Owner:PPG IND OHIO INC

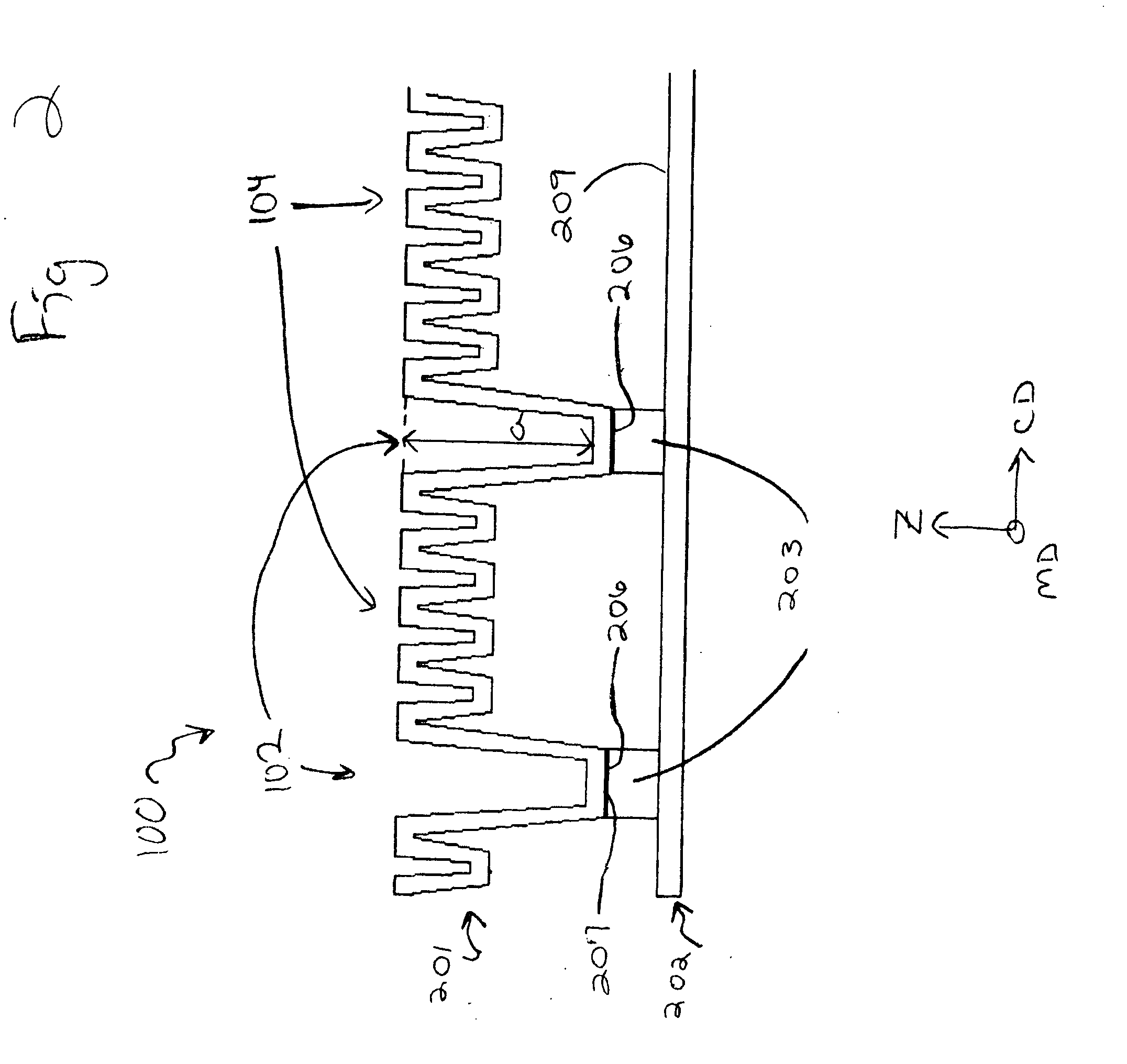

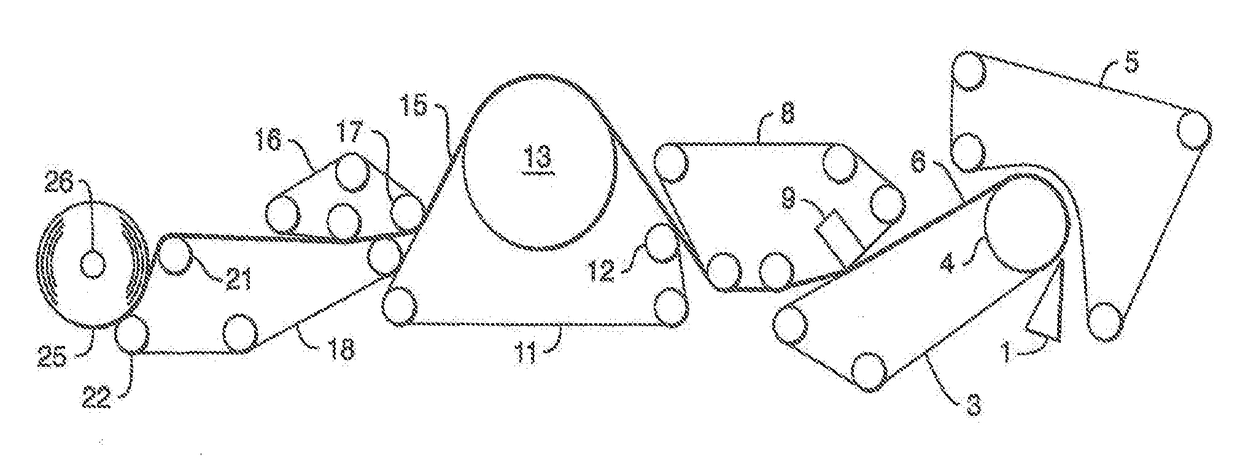

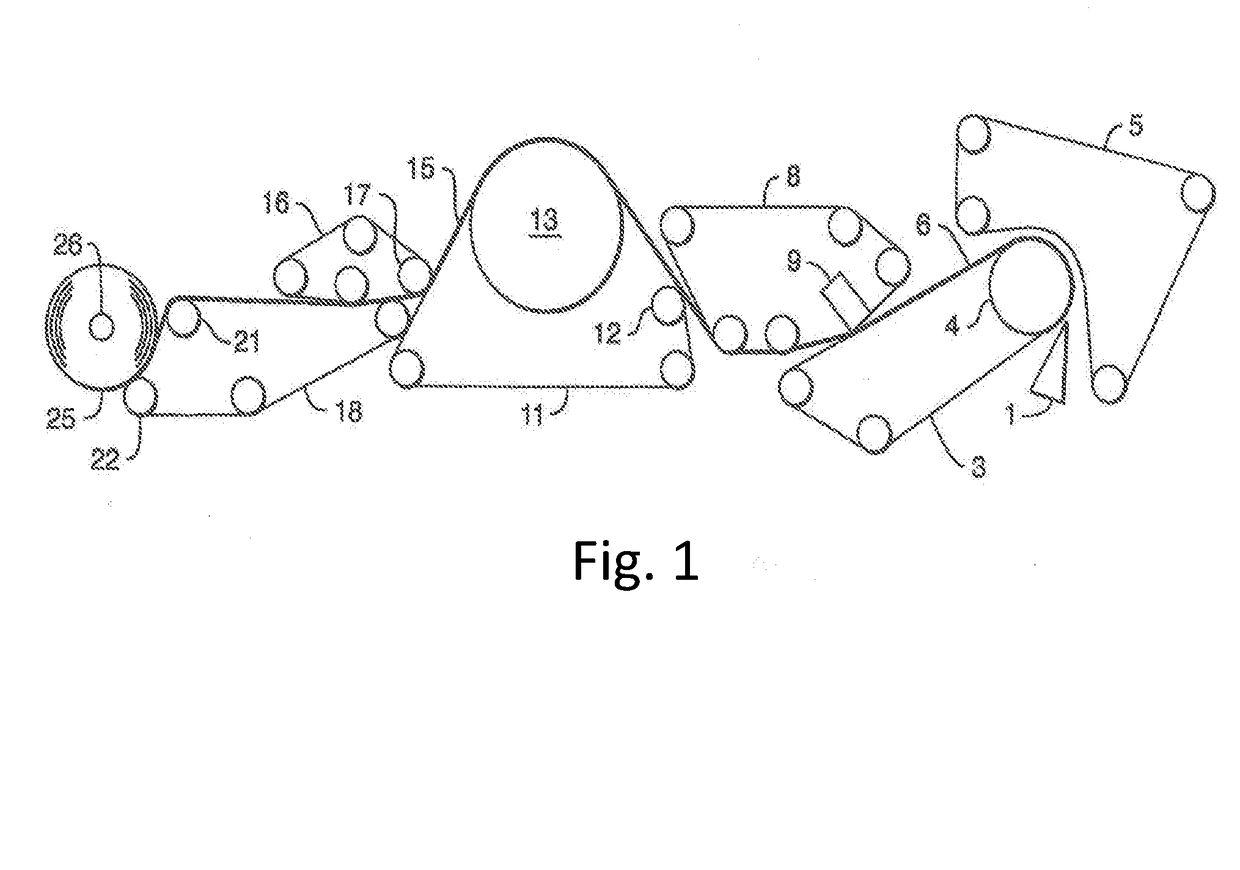

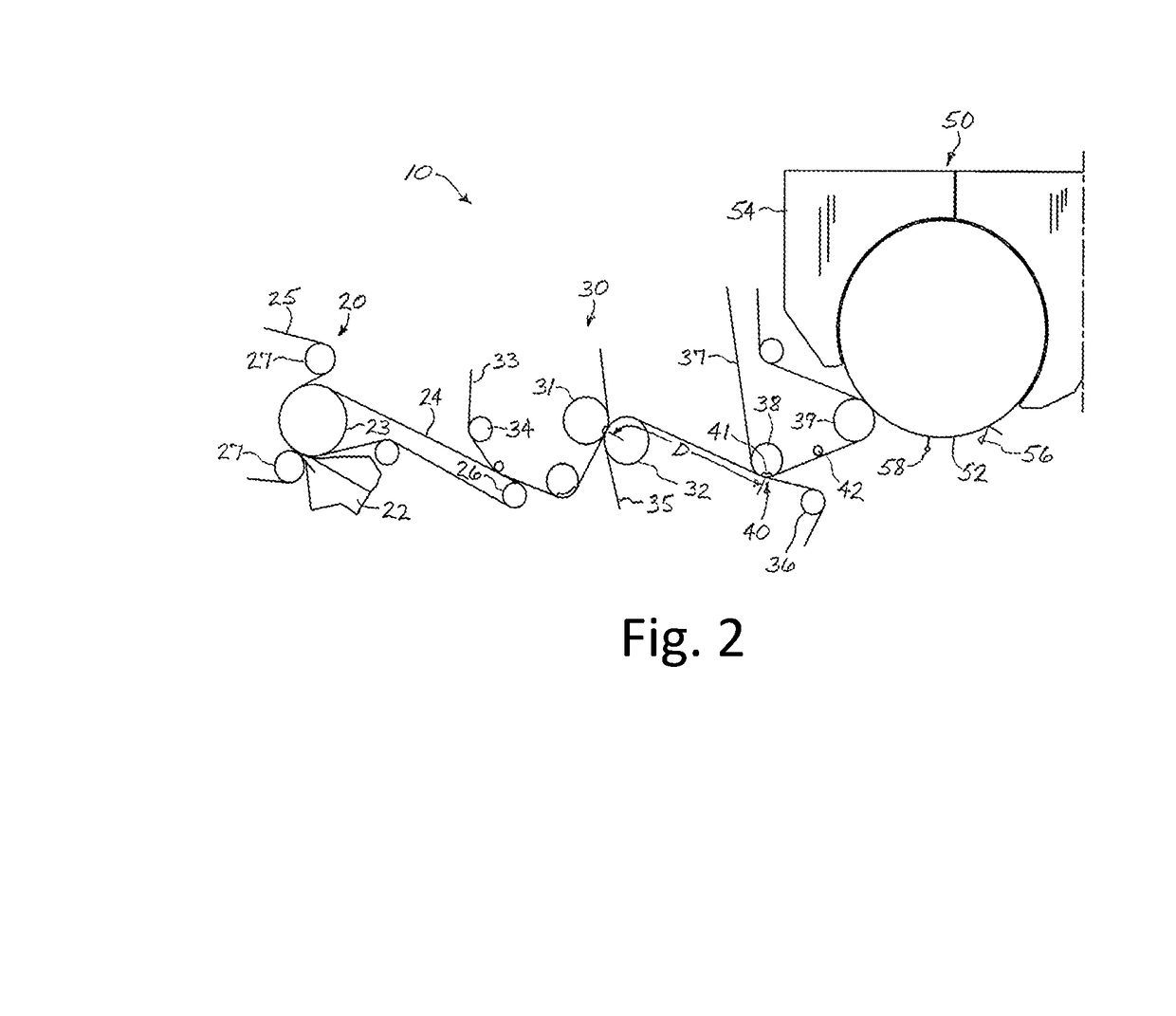

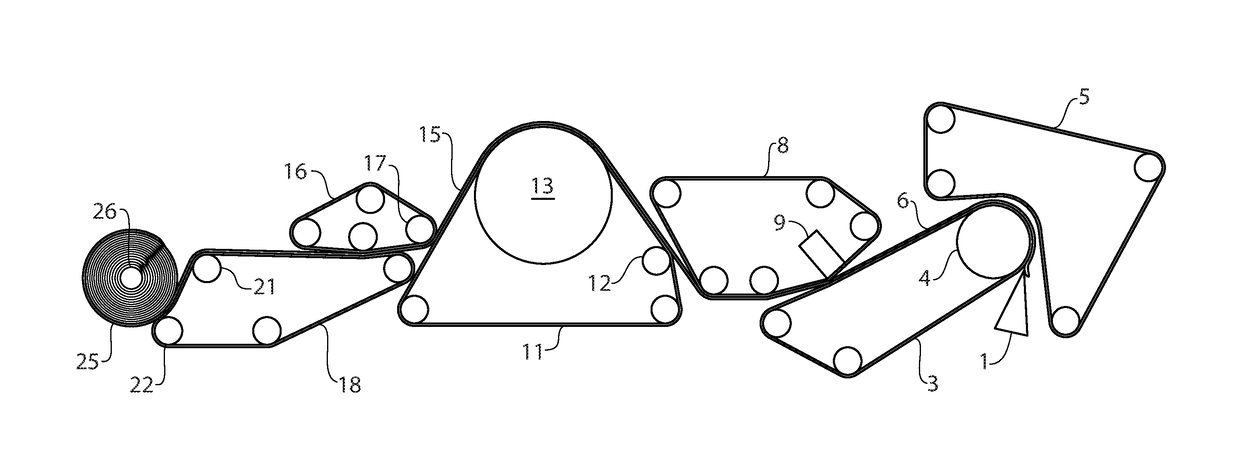

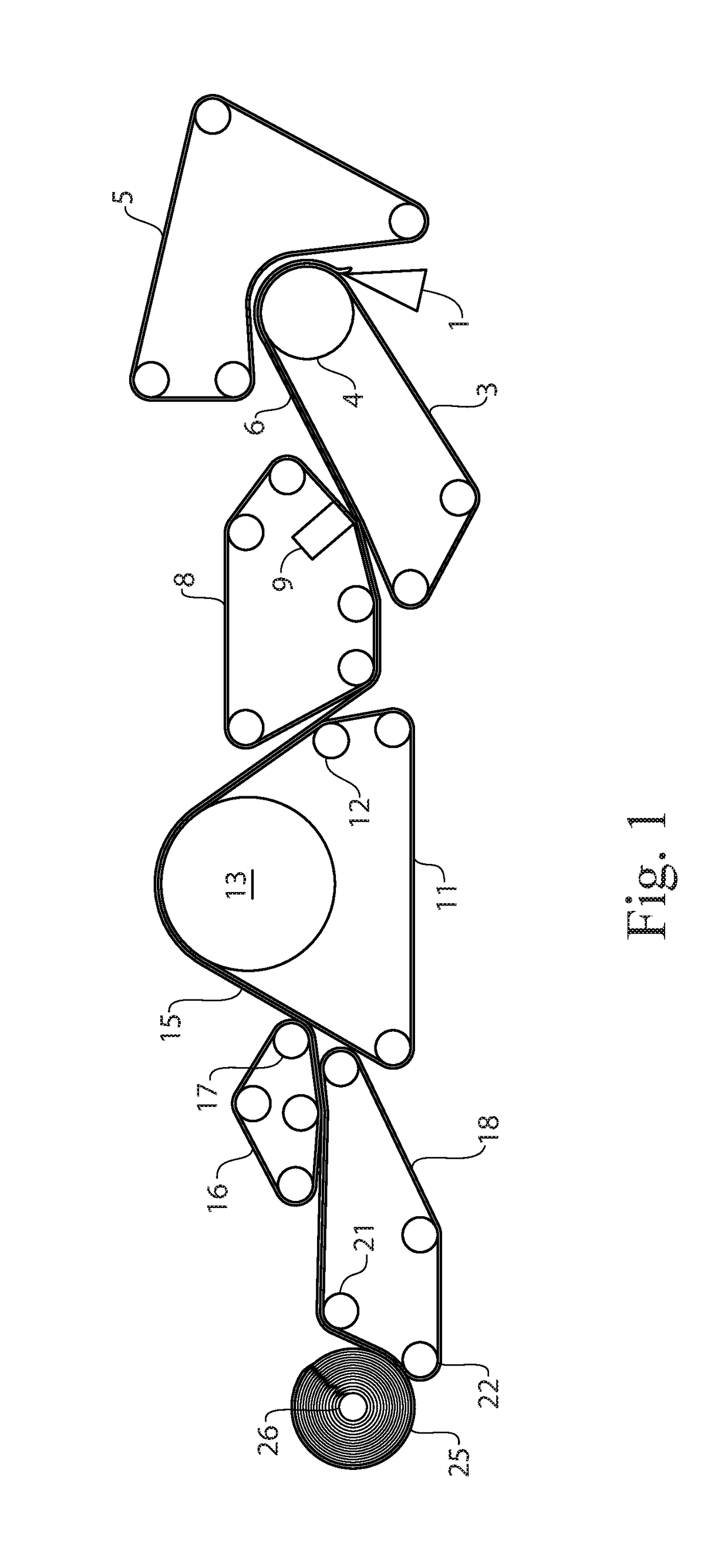

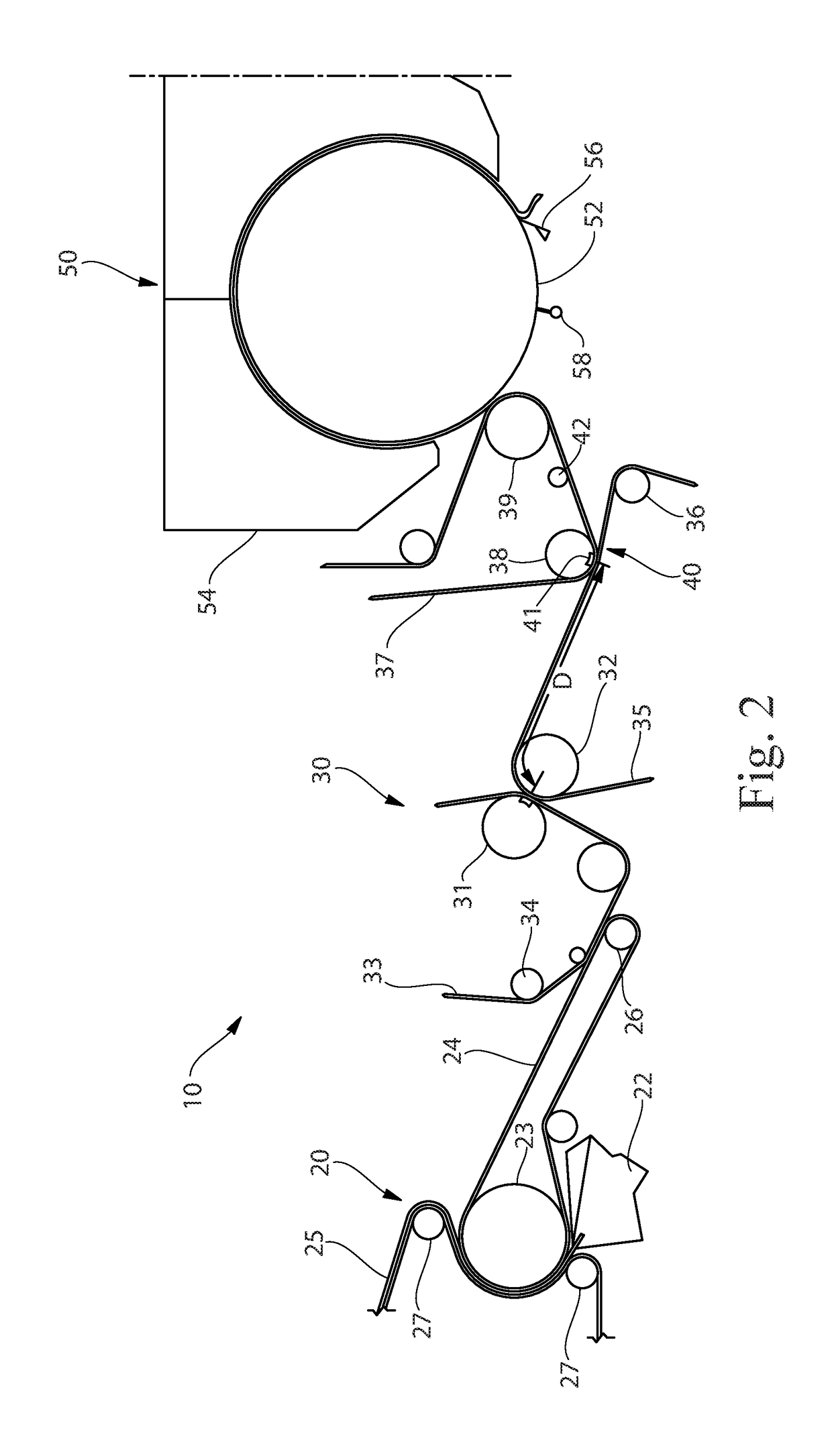

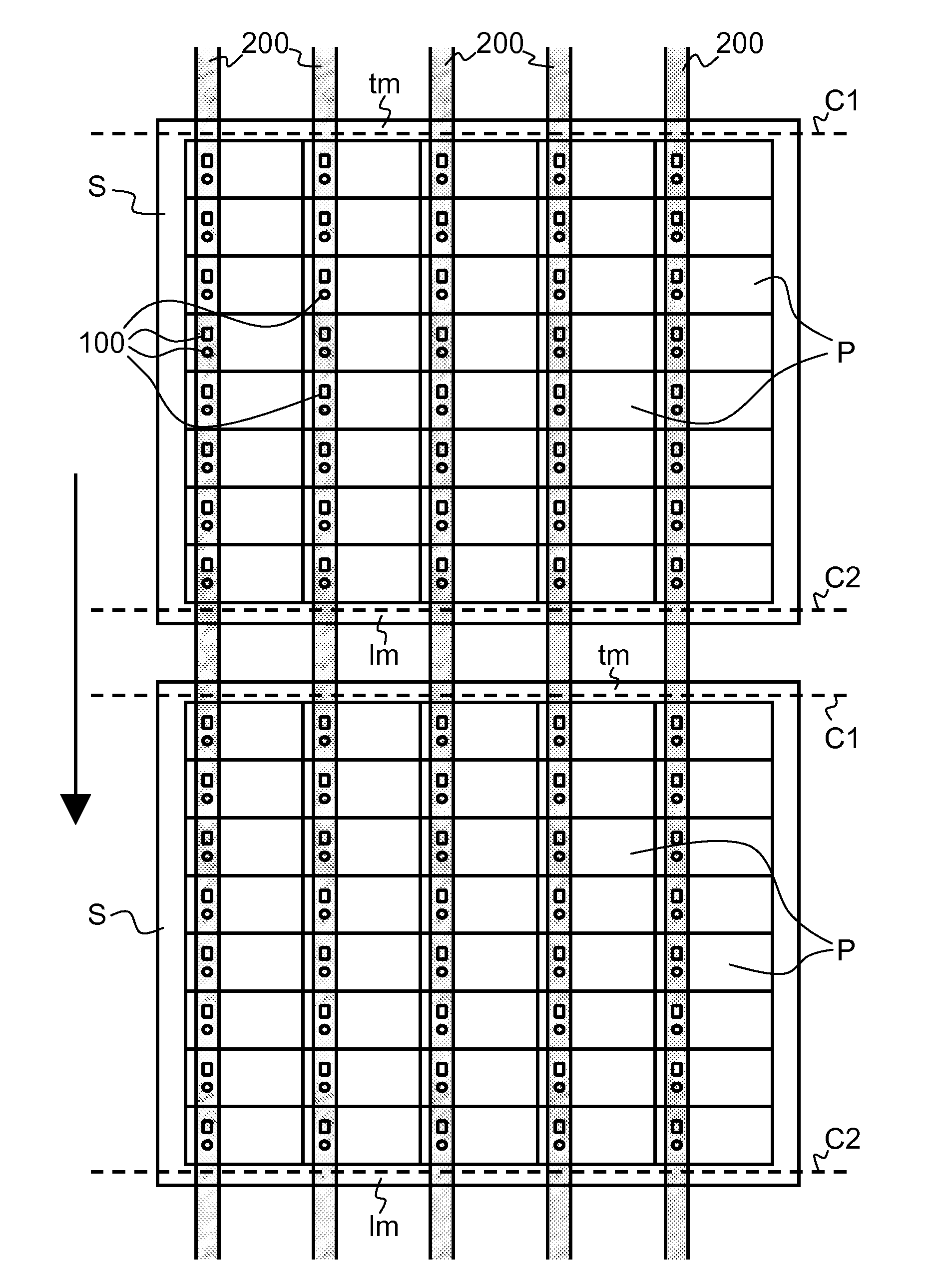

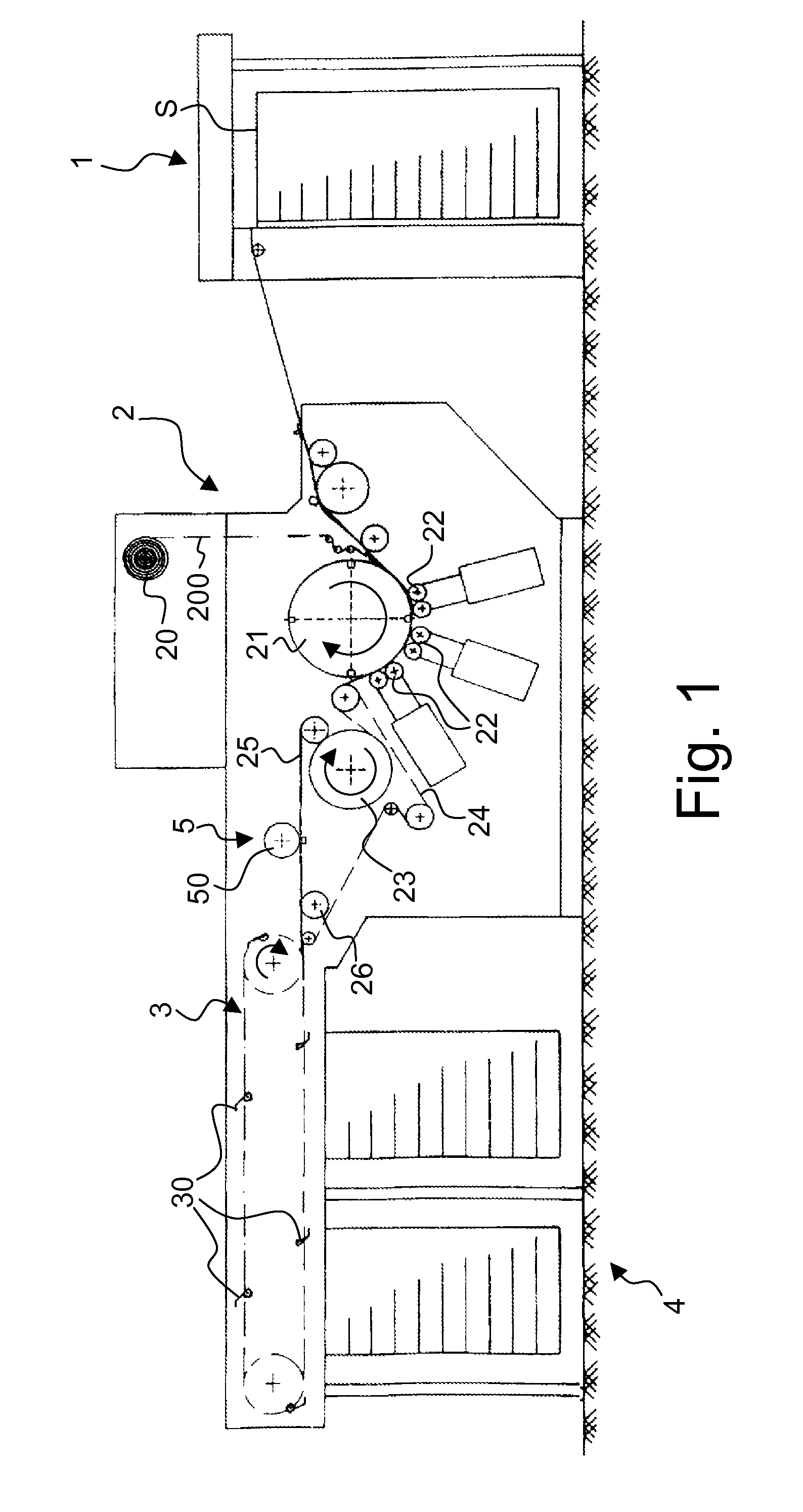

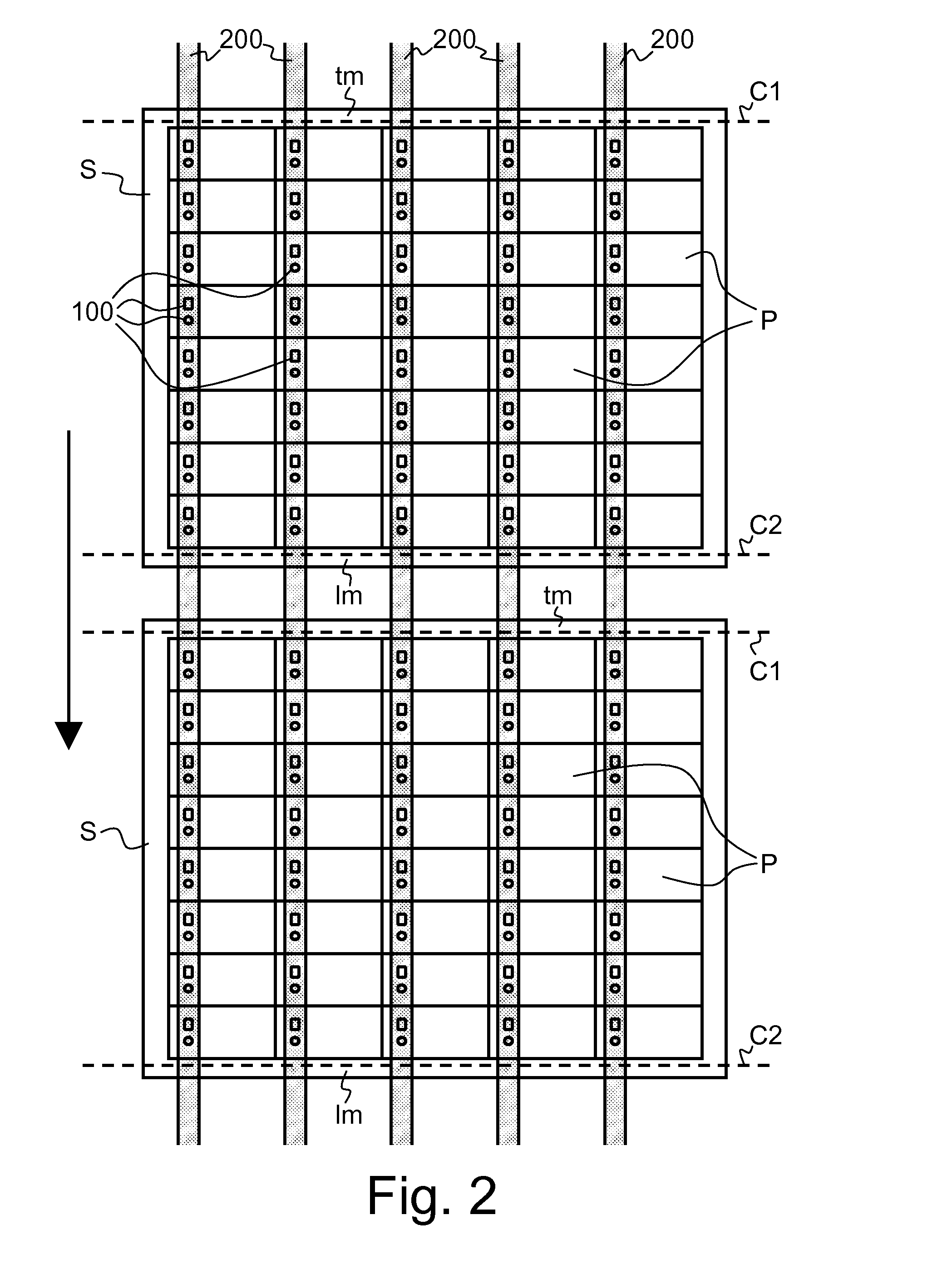

Method and installation for applying foil material onto successive sheets

InactiveUS7922858B2Precise applicationPrecise cuttingLamination ancillary operationsLayered product treatmentLeading edgeEngineering

There is described a method for applying foil material (200) onto successive sheets (S), especially sheets of securities. In a first step, individual sheets (S) are transported in succession along a sheet transport path. In a second step, at least one continuous band of foil material (200) is applied onto the individual sheets (S) along a direction substantially parallel to a direction of displacement of the individual sheets, thereby forming a continuous flow of sheets linked to one another by the said at least one continuous band of foil material (200). In a third step, the said at least one continuous band of foil material (200) is cut such that the continuous flow of sheets is again separated into individual sheets (S) with portions of foil material (200*) remaining on the sheet. The cutting is performed at positions located on the sheets (S) such that said portions of foil material (200*) remaining on the sheets do not extend beyond leading and trailing edges of the sheets (S). There is also described an installation for carrying out the above method.

Owner:KBA NOTASYS SA

Anti-counterfeiting fiber and manufacturing method thereof as well as safety paper using anti-counterfeiting fiber and safety article

ActiveCN103850144AImprove anti-counterfeiting capabilitiesPrevent copyingNon-fibrous pulp additionPaper/cardboard layered productsFiberEngineering

The invention discloses an anti-counterfeiting fiber and a manufacturing method thereof as well as safety paper using the anti-counterfeiting fiber and a safety article. The anti-counterfeiting fiber has a multilayered structure in the length direction, wherein any two adjacent layers of the multilayered structure are fixedly combined and at least one layer has chemical components which are different from those of the adjacent layer; at least one layer contains additives with anti-counterfeiting information. The manufacturing method comprises the following steps: firstly, manufacturing a sheet material with the multilayered structure in the thickness direction; machining the sheet material into the anti-counterfeiting fiber with the multilayered structure in the length direction through a cutting manner. The safety paper and the safety article using the anti-counterfeiting fiber and the safety article manufactured by the safety paper adopt counterfeiting methods including printing and the like and the anti-counterfeiting characteristics of the anti-counterfeiting fiber do not occur, so that the anti-counterfeiting capability is improved.

Owner:KUNSHAN BANKNOTE PAPER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com