Preparation method of aluminum oxide porous foam ceramic sound absorption material

An alumina ceramic and porous foam technology, applied in the field of foam ceramic materials, can solve the problems of limited industrialization promotion, difficult control, monomer toxicity, etc., and achieve the effects of simple and easy-to-obtain raw materials, convenient operation, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

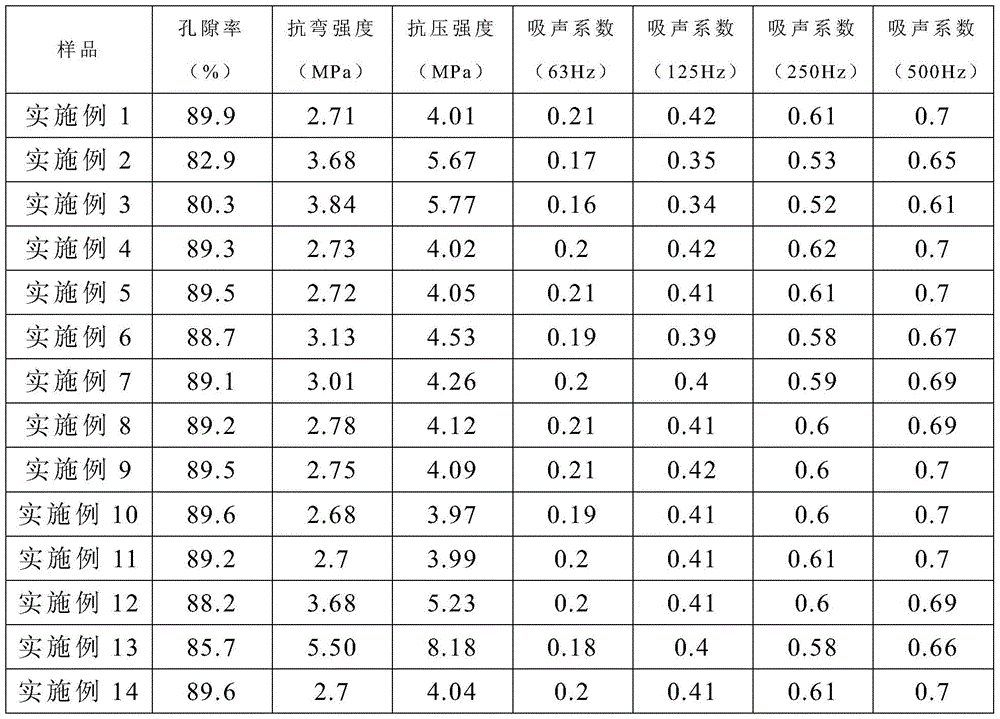

Examples

Embodiment 1

[0030] A preparation method of aluminum oxide porous foam ceramic sound-absorbing material, it comprises the steps:

[0031] Step 1: Dosing, mixing 1g of agarose with 24g of deionized water to prepare agarose solution with a concentration of 4wt.%, and then placing the prepared agarose solution in a container with a pressure of 140kpa at a temperature of 121°C Heated for 11 minutes under the same conditions, and then kept warm at 65°C for later use;

[0032] Step 2: Slurry, add 82.9g of alumina ceramic powder (particle size: 0.1-5μm) into 17.1g of ammonium polyacrylate aqueous solution (concentration: 0.5wt.%) to disperse, mix and ball mill for 6 hours after mechanical stirring, and obtain uniform dispersion Aluminum oxide ceramic slurry (solid content is 55vol.%), get 10.4g to add in the aluminum oxide ceramic slurry from the spare agarose solution of step 1, add 11.3g deionized water, obtain ceramic slurry after mixing uniformly , insulated at a temperature of 65°C for stan...

Embodiment 2

[0036] A preparation method of aluminum oxide porous foam ceramic sound-absorbing material, it comprises the steps:

[0037] Step 1: Dosing, mix 1g of agarose with 19g of deionized water to prepare agarose solution with a concentration of 5wt.%, and then place the prepared agarose solution in a container with a pressure of 140kpa at a temperature of 121°C Heated for 11 minutes under the same conditions, and then kept warm at 65°C for later use;

[0038] Step 2: Slurry, add 82.9g of alumina ceramic powder (particle size: 0.1-5μm) into 17.1g of ammonium polyacrylate aqueous solution (concentration: 0.5wt.%) to disperse, mix and ball mill for 6 hours after mechanical stirring, and obtain uniform dispersion Aluminum oxide ceramic slurry (solid content is 55vol.%), get 10.4g to add in the aluminum oxide ceramic slurry from the spare agarose solution of step 1, add 11.3g deionized water, obtain ceramic slurry after mixing uniformly , insulated at a temperature of 65°C for standby u...

Embodiment 3

[0042] A preparation method of aluminum oxide porous foam ceramic sound-absorbing material, it comprises the steps:

[0043] Step 1: Dosing, mix 1g of agarose with 15.67g of deionized water to prepare an agarose solution with a concentration of 6wt.%. Heated for 11 minutes under the same conditions, and then kept at a temperature of 65°C for later use;

[0044]Step 2: Slurry, add 82.9g of alumina ceramic powder (particle size: 0.1-5μm) into 17.1g of ammonium polyacrylate aqueous solution (concentration: 0.5wt.%) to disperse, mix and ball mill for 6 hours after mechanical stirring, and obtain uniform dispersion Aluminum oxide ceramic slurry (solid content is 55vol.%), get 10.4g to add in the aluminum oxide ceramic slurry from the spare agarose solution of step 1, add 11.3g deionized water, obtain ceramic slurry after mixing uniformly , insulated at a temperature of 65°C for standby use;

[0045] Step 3: Molding, add 0.24g of foaming agent to the ceramic slurry obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com