Environment-friendly flame-retarding full-plastic type plastic runway and construction method thereof

A plastic runway, all-plastic technology, used in roads, roads, buildings, etc., can solve the problems of increasing the danger of runways, easy fading, bubbling, aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below through specific embodiments.

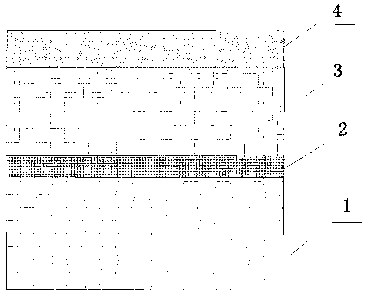

[0026] An environmentally friendly flame-retardant all-plastic plastic runway, including a base layer, and a sealing layer, a shock-absorbing layer, and an overlay protective layer sequentially laid on the base layer. The material of the base layer is poured with C30 commercial concrete, and the thickness is 150mm; The bottom sealing layer is paved with non-toxic and environmentally friendly one-component epoxy glue, black rubber particles, and quartz sand materials. 1 part of quartz sand, sprayed by a spraying machine, the thickness of the sealing layer is 1.5mm; the shock-absorbing layer is mainly laid with EPDM, SBR, CR, NR mixed rubber particles, and environmental protection single-component epoxy glue materials. The weight of the material consists of: 3 parts of environmentally friendly one-component epoxy glue, 12 parts of EPDM, SBR, CR, NR mixed rubber particles, the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com