Preparation method for natural vegetable gum-modified urea-formaldehyde resin

A technology of natural vegetable glue and vegetable glue resin, which is applied in the field of wood-based panel adhesives, can solve the problems of high formaldehyde release and poor water resistance, achieve good water solubility, sufficient resin polycondensation reaction, and improve water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

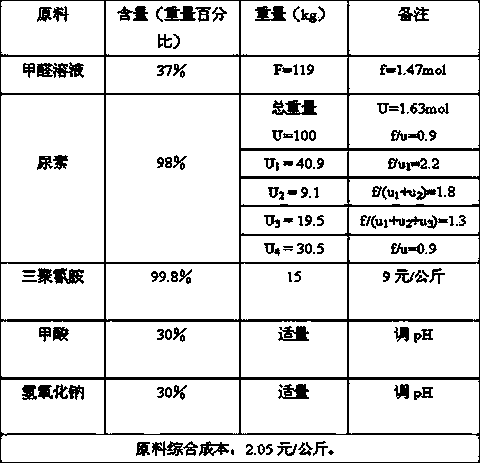

[0040] The raw material formula of table 1 embodiment one

[0041]

[0042] Note: F and U represent the weights of formaldehyde solution and urea added respectively, U 1 -U 3 respectively represent the weight of urea added in the first to third batches, f and u represent the moles of formaldehyde and urea respectively, u 1 -u 3 respectively represent the moles of urea added in the first to the third batch, and f / u represents the ratio of the moles of formaldehyde to the moles of urea.

[0043] Concrete reaction steps are as follows:

[0044] 1) Synthesis of vegetable gum resin:

[0045]A. Add the measured water, start stirring, then slowly add the measured guar gum, and rinse the coil and the wall of the kettle with water;

[0046] B. After complete dissolution, add triethanolamine, measure pH=8.5-9.0, start to heat up, heat up to 60°C and keep warm, test once every 10 minutes until the viscosity reaches 1000-1200mPa·s;

[0047] C. After reaching the viscosity, adju...

Embodiment 2

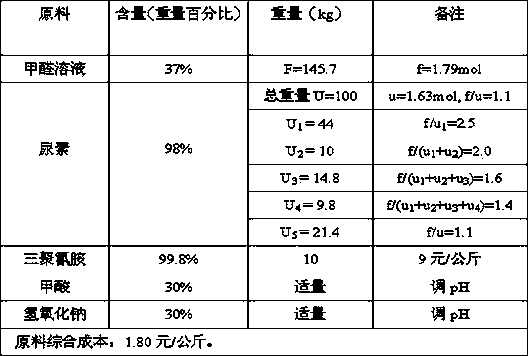

[0067] The raw material formula of table 2 embodiment two:

[0068]

[0069] Note: F and U represent the weights of formaldehyde solution and urea added respectively, U 1 -U 3 respectively represent the weight of urea added in the first to third batches, f and u represent the moles of formaldehyde and urea respectively, u 1 -u 3 respectively represent the moles of urea added in the first to the third batch, and f / u represents the ratio of the moles of formaldehyde to the moles of urea.

[0070] Concrete reaction steps are as follows:

[0071] 1) Synthesis of vegetable gum resin:

[0072] A. Add the measured water, start stirring, then slowly add the measured guar gum, and rinse the coil and the wall of the kettle with water;

[0073] B. After complete dissolution, add triethanolamine, measure pH=8.5-9.0, start to heat up, heat up to 60°C and keep warm, test once every 10min until the viscosity reaches 800-1000mPa·s;

[0074] C. After reaching the viscosity, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com