Highly-efficiently degreasing and rust-removal surface treating agent for metal

A high-efficiency technology for metal surface treatment, applied in the field of metal surface treatment agents, can solve problems such as easy pollution and adverse environmental impact, and achieve the effects of convenient operation, shortened cleaning time, and enhanced penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

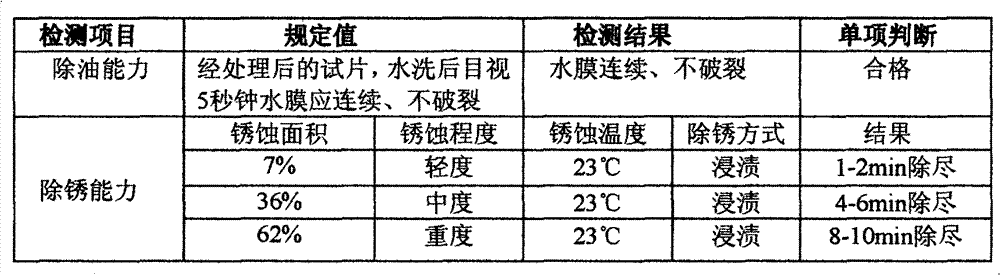

Image

Examples

Embodiment 1

[0017] Embodiment 1, preferred:

[0018] A high-efficiency degreasing and rust-removing metal surface treatment agent, composed of the following raw materials in weight percentage: 30% phosphoric acid, 1% glucose, 1% 2,3-dihydroxysuccinic acid, 0.5% thiourea, fatty alcohol polyoxyethylene ether 1.5%, the balance is water.

[0019] Production method: first dilute phosphoric acid with water, then add other raw materials into the phosphoric acid solution according to the ratio, and finally add the remaining water and stir evenly to obtain the product of the present invention.

[0020] When using, immerse the workpiece in the metal surface treatment agent, soak for about 10 minutes at room temperature, and then take out the workpiece.

[0021] The treated workpiece can be rinsed directly with clean water, or treated by spraying or brushing the workpiece with a metal surface treatment agent.

Embodiment 2

[0023] High-efficiency degreasing and rust-removing metal surface treatment agent, the composition of raw materials in weight percent: phosphoric acid 20%, glucose 0.1%, 2,3-dihydroxysuccinic acid 0.1%, thiourea 0.1%, fatty alcohol polyoxyethylene ether 0.5%, surplus The amount is water.

[0024] Production method and usage method are identical with example 1.

Embodiment 3

[0026] High-efficiency degreasing and rust-removing metal surface treatment agent, the composition of raw materials in weight percent: phosphoric acid 40%, glucose 2%, 2,3-dihydroxysuccinic acid 1.5%, thiourea 1%, fatty alcohol polyoxyethylene ether 3%, the rest The amount is water.

[0027] Production method and usage method are identical with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com