Silicon material cleaning device

A cleaning device and silicon material technology, applied in the direction of smoke removal, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of workers' physical hazards, large exhaust air volume, and environmental protection effects, and achieve improved pickling Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

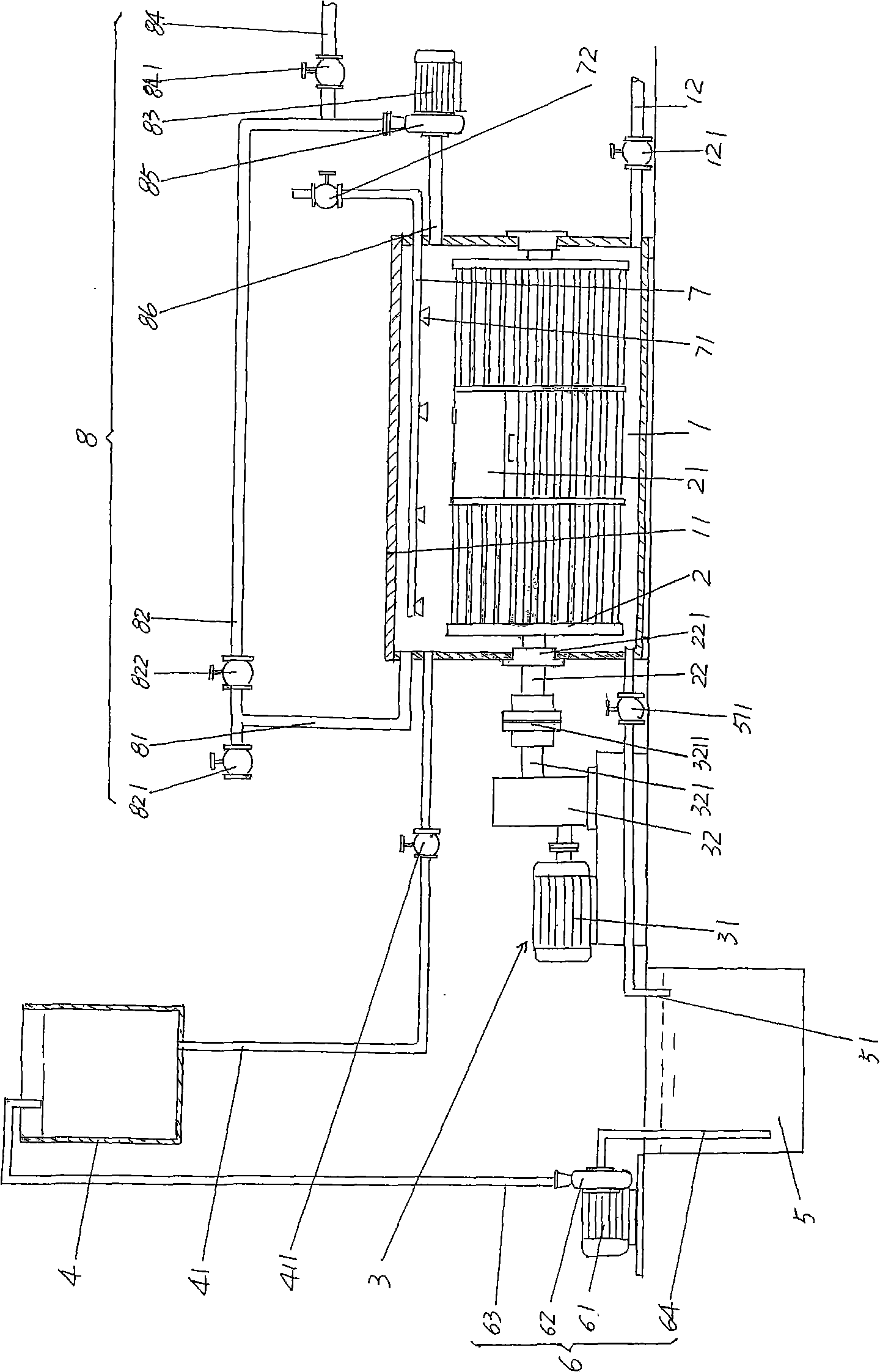

[0017] In order to enable your examiners, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the specific implementation of the present invention is described in detail below in conjunction with the accompanying drawings and examples, but all descriptions of the examples do not constitute a review of the present invention. Restriction of the invention scheme, any form but not substantive changes shall be deemed to belong to the scope disclosed in the present invention and limited by the protection of rights.

[0018] Please refer to accompanying drawing, have provided the pickling tank 1 of the preferred but not limited to cuboid of shape, the open position on the top of this pickling tank 1 is equipped with a movable cover 11, and movable cover 11 both can adopt hinge connection mode and pickling tank 1. Wash tank 11 cooperates, also can adopt the plug-and-pull mode similar to drawer to cooperate with pickli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com