Method for curing fishes through negative pressure and ozone cold sterilization

A technology of ozone and fish, applied in the direction of meat/fish preservation, food preservation, food science, etc., can solve the problems of lack of hygienic quality control, food safety hazards, low labor efficiency, etc., and achieve easy corruption, short life cycle, growth quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

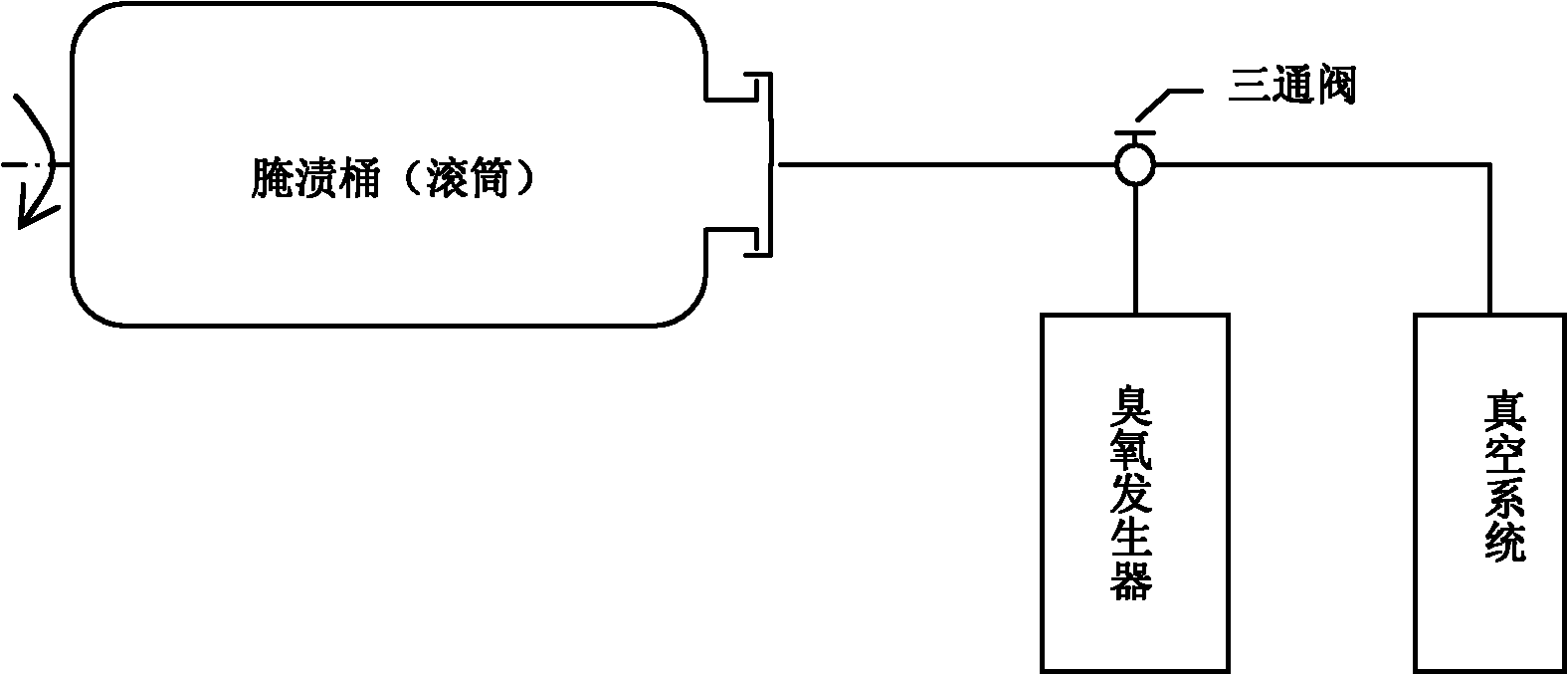

[0015] Negative pressure marinating: select the fresh mackerel, remove the head and viscera, wash and drain. Add 300kg of drained mackerel meat and 12kg of salt in the negative pressure pickling barrel, pump it to a vacuum degree (0.065Mpa), roll and knead for 5 minutes, and the rotation speed of the barrel is 20r / min; Ozone (concentration 2ppm in the barrel), after continuing to roll at a speed of 20r / min for 30 minutes, continue to turn on the vacuum pump to maintain a certain negative pressure (0.095Mpa) in the pickling barrel, then pickle for 4 hours.

[0016] Atmospheric pressure marinating: select the fresh mackerel, remove the head and viscera, wash and drain. Add 300kg of drained mackerel meat and 12kg of salt into the normal-pressure pickling barrel, roll and knead at 20r / min for 5 minutes, then let it stand for 4 hours to pickle.

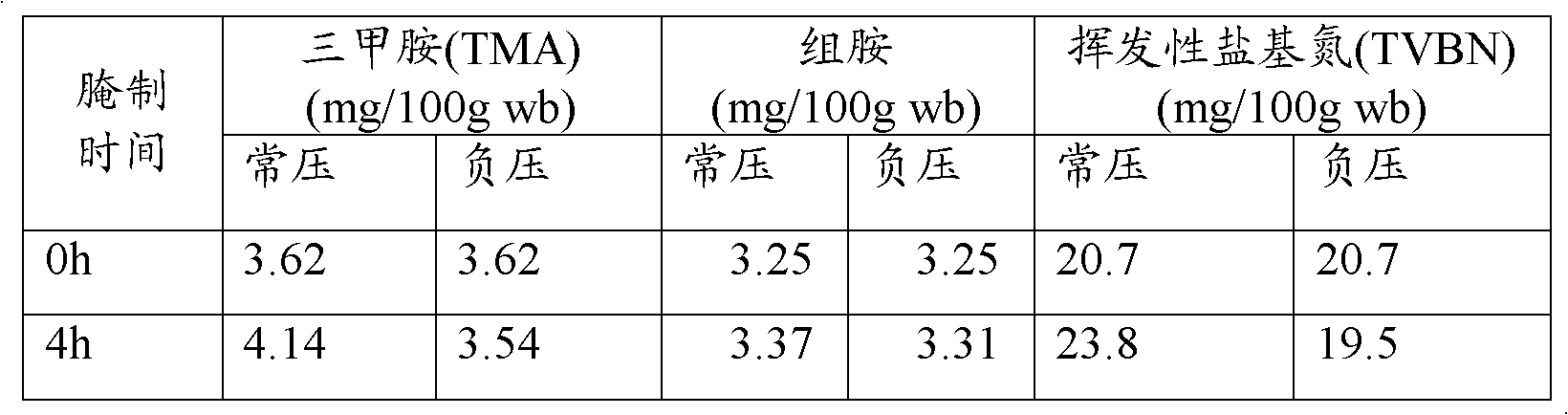

[0017] The comparison of the results of mackerel biogenic amines under normal pressure and negative pressure at 15°C is as follows:

[...

Embodiment 2

[0020] Negative pressure marinating: select the fresh mackerel, remove the head and viscera, wash, drain, and cut into 8cm sections. Add 400kg of drained mackerel meat and 4kg of salt in the negative pressure pickling bucket, pump it to a vacuum (0.03Mpa), roll and knead for 10 minutes, and the rotation speed of the bucket is 20r / min; inhale the ozone generated by the ozone generator through the three-way valve Ozone (concentration 50ppm in the bucket), after continuing to tumble with the speed of 20r / min for 5min, continue to open the vacuum pump, after making certain negative pressure (0.095Mpa) be maintained in the pickling bucket, pickle for 8 hours and get final product.

[0021] Atmospheric pressure marinating: select the fresh mackerel, remove the head and viscera, wash, drain, and cut into sections of about 8cm. Add 400kg of drained mackerel meat and 4kg of salt into the normal-pressure pickling barrel, roll and knead at 20r / min for 10 minutes, then let it stand for 8 ...

Embodiment 3

[0026] Negative pressure pickling: Thaw the frozen mackerel and select, remove the head and viscera, wash and drain. Add 250kg of drained mackerel meat and 37.5kg of salt into the negative pressure pickling barrel, pump to a vacuum (0.01Mpa), tumble for 60 minutes, and the rotation speed of the barrel is 20r / min; through the three-way valve, the ozone generator generates Ozone (concentration 25ppm in the barrel), after continuing to roll at a speed of 20r / min for 60 minutes, continue to turn on the vacuum pump to maintain a certain negative pressure (0.035Mpa) in the pickling barrel, and pickle for 12 hours.

[0027] Atmospheric pressure curing: thaw the frozen mackerel and select, remove the head and viscera, wash and drain. Add 250kg of drained mackerel meat and 37.5kg of salt into the normal-pressure pickling barrel, roll and knead at 20r / min for 60 minutes, then let it stand for 12 hours to pickle.

[0028] The comparison of the results of mackerel biogenic amines under n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com