Ageing method of liquid electrolyte battery

A liquid electrolyte and battery technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve problems affecting battery performance, self-discharge bad batteries, etc., to improve battery quality, reduce defective product rate, and improve cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

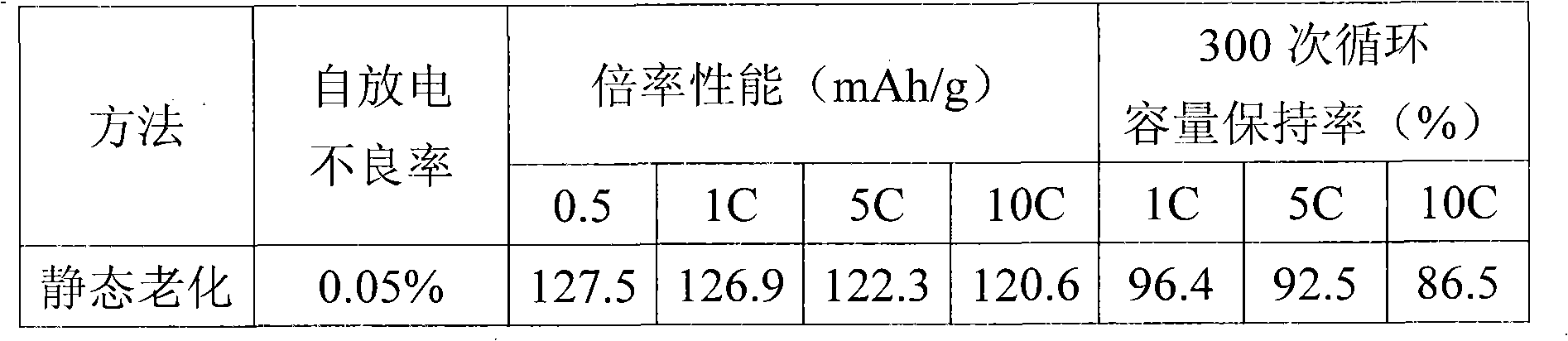

[0023] For a liquid electrolyte battery of model 18650C4 with a capacity of 2200mAh, during the aging process, the aging temperature is set at 35°C and the aging time is 7 days. Two methods are used for aging comparison. The first method is the existing static aging method; the second method is In the dynamic aging method, the rotation speed of the battery is 10 revolutions per minute. The self-discharge defect rate and cycle test results are shown in Table 1:

[0024] method

[0025] Table 1

Embodiment 1a

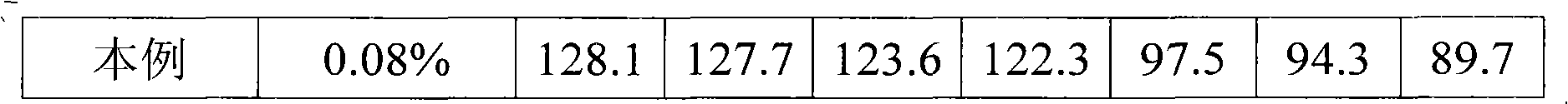

[0027] In Example 1, the rotation speed of the battery during aging was changed to 25 rpm, and other parameters were the same, and its self-discharge failure rate and cycle test results are shown in Table 2:

[0028] method

[0029] static aging

[0030] Table 2

Embodiment 1b

[0032] In Example 1, the aging temperature was adjusted to 45°C, and other parameters were the same, and the self-discharge defect rate and cycle test results are shown in Table 3:

[0033] method

[0034] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com