Redox flow cell stack

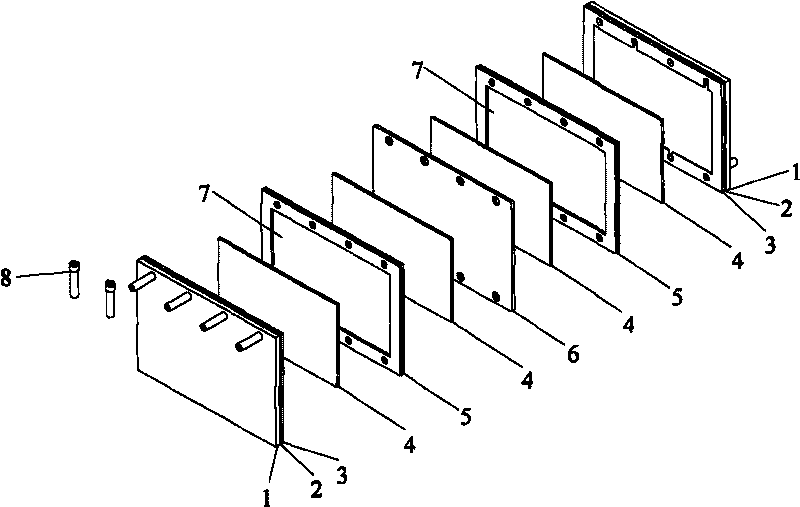

A liquid flow battery stack and liquid flow frame technology, applied in the field of battery stack structure, can solve problems such as inaccurate positioning, misalignment between components, corrosion of current collector inlet and outlet, and achieve electrolyte leakage prevention and tightness Good, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

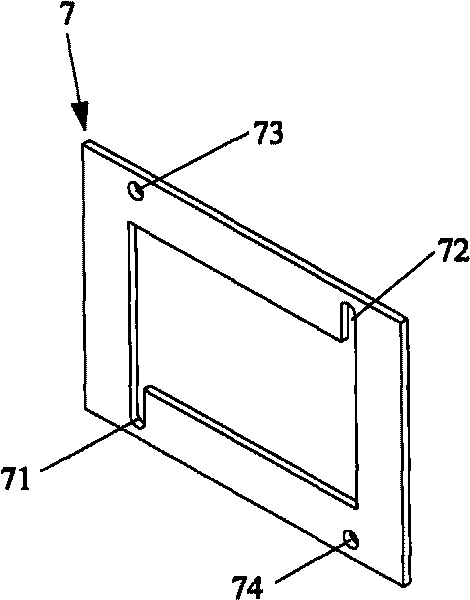

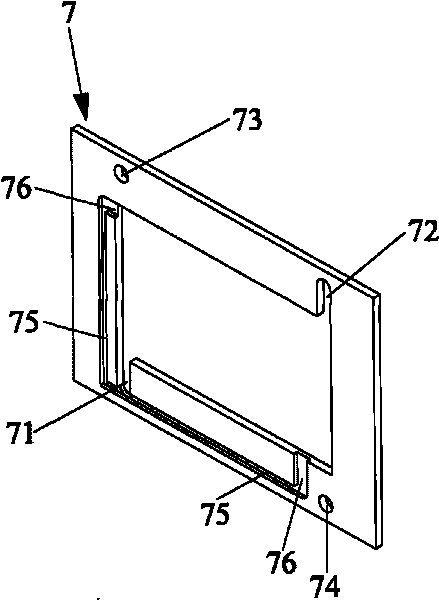

[0019] In a first embodiment of the invention, see figure 2 , The liquid flow frame 7 is a rectangular frame, and the liquid flow frame is provided with a liquid inlet hole 71 and a liquid outlet hole 72, which are respectively used to guide the electrolyte to the surface of the current collector 3 and lead it out. In addition, the liquid flow frame 7 is provided with perforations 73 and 74 as flow channels for the battery stack electrolyte to flow to other battery units.

[0020] In this embodiment, the current collector 3 is approximately equal in size to the liquid flow frame 7. When the battery stack is assembled, the current collector 3 is pressed against one side of the liquid flow frame 7, so that the liquid inlet hole 71 can guide the electrolyte To the surface of the current collector, the liquid outlet hole 72 can lead the electrolyte from the surface of the current collector.

[0021] As a preference, the liquid flow frame 7 can be set in a concave structure, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com