Method for purifying lead electrolyte by using columnar activated carbon

A lead electrolyte and activated carbon technology, applied in chemical instruments and methods, electrolytic components, separation methods, etc., can solve the problems of precipitation and formation of electrolytic lead, and achieve the effects of low cost, simple operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

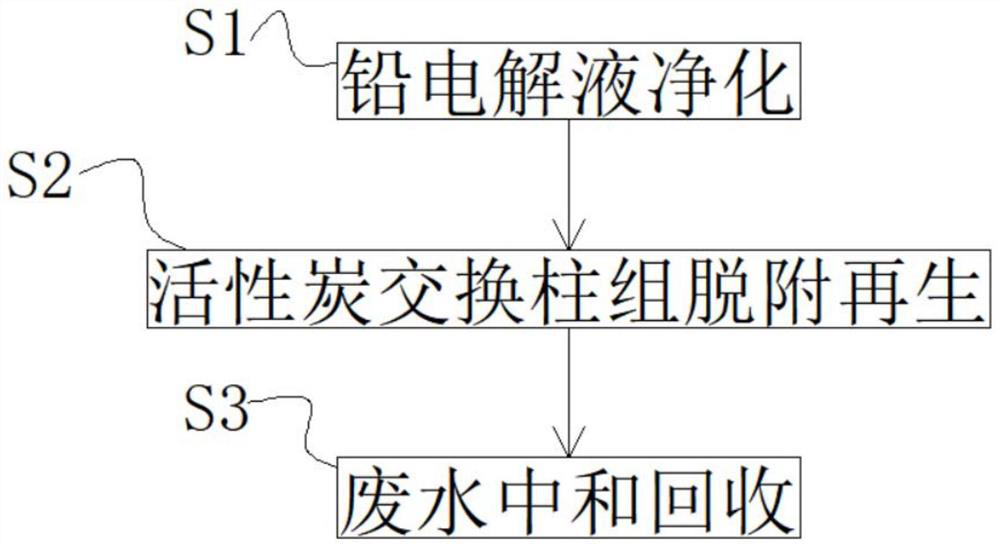

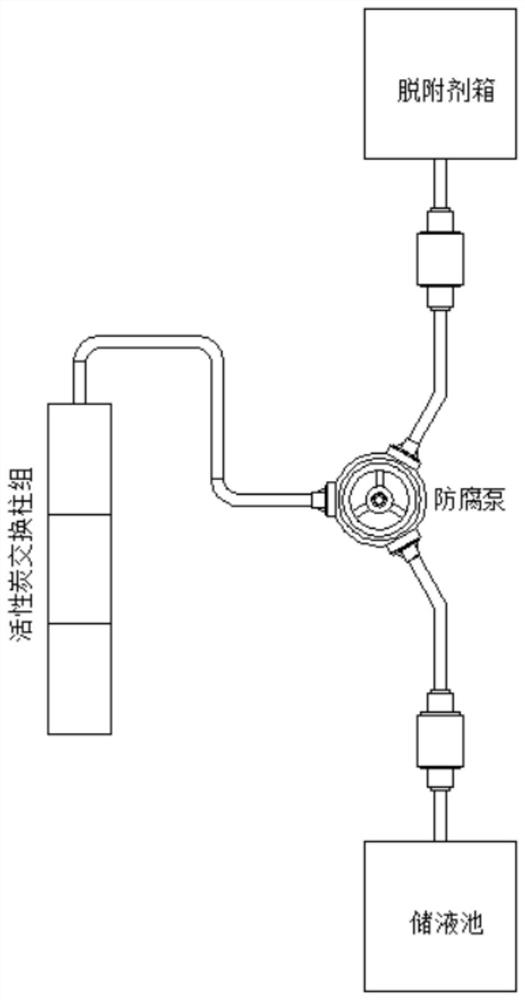

[0023] see Figure 1 to Figure 2 , the invention provides a kind of technical scheme: the method for purifying lead electrolyte with columnar activated carbon comprises the following steps:

[0024] S1. Purification of lead electrolyte: open the valve of the liquid storage tank of the lead electrolyte to be purified, open the anti-corrosion pump and related valves, control the flow rate to 50L / min, enter the lead electrolyte to be purified into the activated carbon exchange column group, and wait for purification After the lead electrolyte completely passes through the activated carbon exchange column group, take samples to analyze harmful impurities such as bismuth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com