Method for measuring content of residual metal elements in OLED (Organic Light Emitting Diode) material

A technology of metal element content and metal element, applied in the field of detection, can solve the problems of poor detection results, inaccurate reproducibility, etc., and achieve the effect of high accuracy, small background blank, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

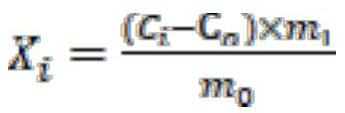

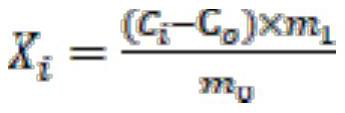

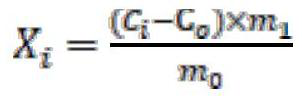

Image

Examples

Embodiment 1

[0046] Step 1: Preparation of standard solution:

[0047] Draw 1ml from Ge,In,Re,Rh,Sc,Y multi-element standard solution 3 into a 50ml PFA volumetric flask, use 10% nitric acid to dilute to get 2μg / ml Ge,In,Re,Rh,Sc,Y Element standard solution mother solution, as internal standard solution;

[0048] Draw 0.5ml from multi-element standard solution 1 and multi-element standard solution 2 into 50ml PFA volumetric flasks respectively, and use 10% nitric acid to obtain a mixed multi-element standard solution of 10μg / ml. Pipette 0.5ml, 2.5ml, 5ml, 25ml into four different 50ml PFA volumetric flasks, and dilute with 10% nitric acid to obtain 0.1μg / ml, 0.5μg / ml, 1μg / ml, 5μg / ml mixed multi-element Standard solution mother solution, draw 0.5ml from the mixed multi-element standard solution mother solution of 1μg / ml and 5μg / ml respectively to two different 50ml PFA volumetric flasks, dilute to the volume with 10% nitric acid to obtain 0.01μg / ml, 0.05μg / ml ml of mixed multi-element stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com